What Happens If You Disconnect Throttle Position Sensor

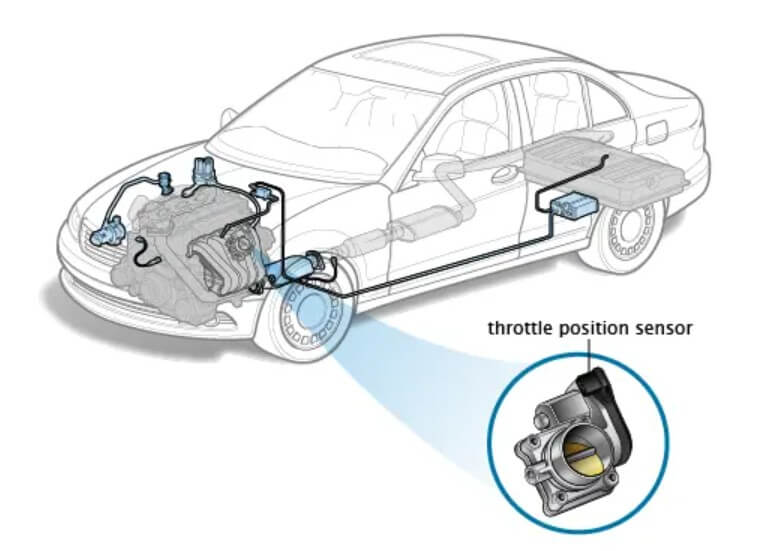

The throttle position sensor (TPS) is a crucial component of the engine management system that monitors throttle opening and directly impacts the intake air volume. This data enables the engine control module (ECM) or engine control unit (ECU) to precisely adjust the air-fuel mixture, ignition timing, and idle speed. A malfunctioning TPS leads to various performance issues and can cause severe engine damage. Here's a detailed breakdown.

Catalog

Figure 1: What Happens If You Disconnect Throttle Position Sensor

Engine Performance Issues

With a disconnected or faulty TPS, the ECM can't accurately read throttle position data, causing mismatched fuel delivery and ignition timing. This mismatch may lead to stalling during deceleration, idle, or acceleration.

Drivers may notice a significant delay in acceleration when pressing the gas pedal because the TPS can't accurately relay throttle position to the ECM. This results in either insufficient or excessive fuel delivery.

The engine may idle erratically, with RPMs fluctuating or even stalling outright. The ECM can't stabilize the idle due to missing TPS data, significantly impacting driving experience.

The engine may surge violently during idle or acceleration, often accompanied by increased engine noise.

Unstable Power and Safety Mode Activation

If the ECM detects unstable or lost TPS data, it may activate "limp mode" to protect the engine. This mode restricts throttle and engine RPM, drastically limiting acceleration and reducing power.

A malfunctioning TPS prevents the ECM from accurately adjusting fuel delivery, leading to sharp declines in fuel efficiency and significantly higher fuel consumption.

Engine Shutdown and Starting Issues

A disconnected TPS fails to provide accurate throttle position data, leading to the ECM miscalculating the air-fuel mixture. This can cause the engine to suddenly stall during acceleration or deceleration. As drivers accelerate or slow down, they might feel a sudden loss of power, disrupting the driving experience and posing a hazard, particularly in heavy traffic.

Figure 2: Engine Shutdown and Starting Issues

A malfunctioning TPS disrupts fuel supply to the engine, creating an unstable air-fuel mixture. This makes the engine hard to start, often requiring multiple attempts or even making it impossible to start at all. This issue is more pronounced when the engine is cold. Drivers might hear the starter motor but can't engage the engine.

Check Engine Light (CEL) Activation

When the TPS is faulty, the ECM stores error codes like P0120, P0121, P0122, and P0123. These codes trigger the CEL to alert drivers of potential problems. An OBD-II scanner can read these codes and confirm the issue.

Figure 3: Car Trouble Light

Inspect the wiring, connectors, and the sensor itself for corrosion or loose connections. Use an electrical contact cleaner to clean the contact surfaces. If the sensor's voltage output remains inconsistent, consider replacing it.

Follow the vehicle manual to find a TPS replacement that matches the original. Disconnect the battery's negative cable to prevent short circuits, remove the old sensor, and carefully install the new one. Ensure the electrical connection is secure. Reconnect the battery and start the engine, confirming that the CEL is off and that idle and acceleration are stable. Some vehicles may require throttle recalibration by gradually pressing the accelerator pedal.

These steps help drivers accurately diagnose and resolve TPS issues, ensuring smooth engine operation and reducing safety risks.

Diagnosing Diagnostic Trouble Codes (DTCs)

When the throttle position sensor (TPS) circuit malfunctions, the ECM or ECU generates specific diagnostic trouble codes (DTCs). Common codes include P0120 through P0123, indicating various types of electrical issues within the TPS.

Figure 4: Car Trouble Light

Use an OBD-II scanner to retrieve the codes. Turn the ignition to the "ON" position, connect the scanner, and read the trouble codes. For instance, P0120 may indicate a "TPS circuit malfunction," while P0121 and P0122 signal "TPS voltage issues," and P0123 points to "TPS voltage too high." This information provides crucial diagnostic insights for technicians.

To confirm the issue, use a multimeter to check the voltage range of the TPS output. While slowly pressing down the gas pedal, the voltage should smoothly increase from low to high, typically ranging between 0.2V and 4.8V. If the voltage jumps, remains static, or is absent altogether, the sensor likely needs replacement or recalibration.

Acceleration Issues

A disconnected TPS prevents the ECM or ECU from accurately reading throttle position, resulting in incorrect fuel supply. Drivers will notice poor acceleration, with the vehicle struggling to gain speed or failing to achieve normal acceleration levels when pressing the gas pedal.

Figure 5: Acceleration Issues

When the gas pedal is pressed, the ECM may restrict fuel supply to avoid flooding the engine, resulting in slow acceleration and a clear lack of power. This can produce a noticeable "lag" sensation.

In severe cases, a faulty TPS triggers "limp mode," drastically limiting the vehicle's acceleration ability. Drivers might find it impossible to exceed a certain speed.

Checking and Fixing the Above Six Issues

Diagnosis: Start by reading the diagnostic codes using an OBD-II scanner. Look for codes like P0120, P0122, and P0123.

Check Connections: Make sure the engine is off and the keys are removed. Examine the TPS connector for corrosion, looseness, or broken wires. Use a contact cleaner if necessary.

Test the Sensor: Use a multimeter to measure the TPS output voltage. Turn the key to the "ON" position without starting the engine. Slowly press the gas pedal, watching for steady voltage increase. It should range from 0.2V to 4.8V. If voltage jumps, cuts out, or is out of range, the TPS likely needs replacement.

Figure 6: Test the Sensor

Install Replacement: Ensure the new sensor matches the original. Carefully install it using the right torque. Position it correctly and reconnect the plug, then reconnect the battery.

Calibrate: Some vehicles require TPS calibration after installation so the ECM can read the data accurately. Gradually press and release the gas pedal to adjust the throttle fully open and closed.

Attention to Detail: Accurate execution ensures maximum safety and performance. For complicated situations, consult a mechanic to prevent further damage.

Dirt Build-Up Under the Hood

A faulty TPS can affect the intake system's precise control. This may cause an improper air-fuel mix near the throttle body, resulting in carbon and dirt accumulating under the hood.

Solution

Check for Carbon Build-Up: Open the hood and inspect the area around the throttle body for signs of carbon, dirt, or oil.

Cleaning Steps: Use throttle body cleaner and a soft brush to remove carbon deposits. Disconnect the negative battery cable first to prevent damage to electrical components.

Restore Condition: After cleaning, reinstall the TPS and related parts, ensuring all connections are secure. Start the engine, gradually press the gas pedal, and verify smooth throttle response.

Poor Fuel Efficiency

When the TPS fails, the PCM (powertrain control module) can't accurately monitor throttle position and relies on default values to calculate fuel supply. This can lead to excess fuel entering the engine, disrupting the air-fuel ratio, causing rich combustion, increased carbon buildup, and higher fuel consumption.

Symptoms in Practice

Increased Fuel Consumption: Owners may notice that the vehicle consumes more fuel than usual, requiring refueling more frequently.

Discolored Exhaust: Excess unburned fuel may result in black smoke from the exhaust pipe.

Engine Carbon Build-Up: A rich air-fuel mixture leads to carbon deposits inside the engine, which further reduces performance.

Solutions

Sensor Reset: Start by disconnecting the negative battery terminal to reset the ECU and clear TPS-related error codes. After reconnecting, monitor for improvements.

Inspect Wiring: Ensure the wiring between the TPS and PCM is intact.

Sensor Replacement: If the issue persists, replace the TPS with a new one and clear any error codes after installation to ensure proper system function.

Lean Engine Running

When the powertrain control module (PCM) supplies insufficient fuel due to a faulty throttle position sensor (TPS), the air-fuel mixture becomes too lean, resulting in lean engine running.

Practical Symptoms

Reduced Power: Drivers may notice that the vehicle struggles to accelerate or loses power when climbing hills.

Difficult Starting: The vehicle may require several ignition attempts to start up.

Stalling Risk: The car may stall easily, especially when driving at low speeds.

Inspection and Solutions

Check the TPS: Use a multimeter or an OBD-II scanner to check for TPS error codes and verify if it's accurately relaying throttle position.

Inspect Fuel System: Check the fuel pump, filter, and injectors to ensure they supply adequate fuel and maintain stable pressure.

Adjust Mixture: If the sensor is faulty, reset or replace it. If the ECU is miscalibrated, restore its default settings or update the firmware to ensure accurate readings.

Rich Engine Running

If too much fuel is supplied, resulting in an overly rich air-fuel mixture, the engine will run rich, leading to excessive emissions, reduced performance, and carbon buildup.

Practical Symptoms

Abnormal Emissions: The exhaust pipe may release black smoke or a strong fuel odor.

Carbon-Fouled Spark Plugs: Spark plugs may become carbon-fouled, reducing ignition efficiency.

Unstable Idle: The vehicle might exhibit irregular shaking or surging while idling.

Inspection and Solutions

Check Sensors: Ensure that the TPS and other sensors are accurately relaying data. Use a multimeter to verify that the TPS voltage signal falls within the standard range.

Examine Spark Plugs: Inspect the spark plugs. Replace them if carbon-fouled, and adjust the ignition timing if necessary.

ECU Adjustment: Calibrate the ECU using diagnostic tools, update its software, and clear error codes to ensure precise fuel injection control.

Conclusion

A disconnected TPS can severely impact engine performance and fuel efficiency. Professional diagnosis and repair are the best ways to address TPS issues effectively.

What is a Throttle Position Sensor (TPS)?

A throttle position sensor (TPS) is an electronic component used to detect the position of the throttle. It generally uses potentiometer or Hall effect technology to accurately measure the throttle's angle and position, then sends this information to the powertrain control module (PCM). Let's delve into the principles behind its operation and practical application.

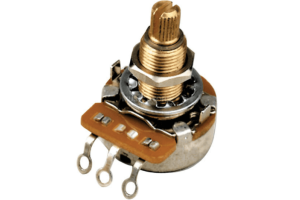

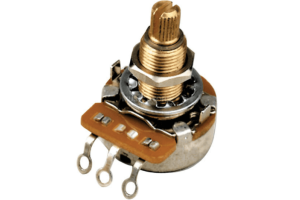

Figure 7: Throttle Position Sensor (TPS)

How It Works

Potentiometer Type

The potentiometer-style TPS is made up of a rotating shaft connected to the throttle and a resistance element. As the shaft turns, the resistance value changes proportionally to the throttle angle, producing a voltage signal that the PCM interprets to gauge throttle opening.

Hall Effect Type

The Hall effect-style TPS uses magnetic sensing principles. As the throttle rotates, the magnetic field shifts, and the sensor converts these changes into voltage signals that the PCM uses to determine throttle position.

Operational Details and Practical Application

Installation and Calibration

Alignment: When installing the sensor, ensure it aligns properly with the throttle shaft and tighten the screws securely.

Calibration Steps:

Confirm that the sensor output is zero or nearly zero when the throttle is fully closed.

Gradually open the throttle and check that the voltage signal changes proportionally.

If the readings deviate significantly, reposition and adjust the sensor accordingly.

Signal Processing and PCM Interaction

Signal Transmission: The TPS continuously monitors the throttle position, sending voltage signals to the PCM.

PCM Response: The PCM adjusts the fuel injection accordingly to maintain an optimal air-fuel ratio.

Fault Detection: If the signal is out of the expected range or unstable, the PCM logs a fault code and illuminates the engine warning light.

Common Issues and Troubleshooting

Unstable Signals: Often caused by loose sensor wiring or aging internal circuits. Inspect the wiring and ensure a solid connection.

Inaccurate Readings: Could result from improper calibration or internal wear. Recalibrate or replace the sensor if necessary.

Diagnostic Steps: Use a multimeter to measure TPS voltage. Gradually open the throttle and check if the voltage changes smoothly and aligns with manufacturer standards.

By accurately detecting the throttle position, the TPS ensures the engine operates at an optimal air-fuel ratio, achieving ideal fuel efficiency and power output. Precise installation and calibration, reliable signal interaction with the PCM, and prompt troubleshooting are key factors in maintaining its performance.

How Does a Throttle Position Sensor (TPS) Work?

The throttle position sensor (TPS) directly senses the throttle angle changes that occur with the gas pedal.

Monitoring Throttle Angle

When the driver presses the gas pedal, the throttle opens, allowing air to enter the engine.

The TPS detects the throttle's angle and generates a voltage signal proportional to the throttle's opening.

This voltage signal is sent through wires to the engine control unit (ECU), providing real-time data on the throttle position.

ECU Calculation and Adjustment

The ECU analyzes the voltage signal from the TPS to determine the exact throttle position.

By combining this data with input from other sensors, like the mass air flow (MAF) sensor and oxygen sensors, the ECU calculates the ideal air-fuel mixture.

The ECU then adjusts the fuel injector output, ignition timing, and idle speed control to optimize engine performance and fuel efficiency under varying loads.

Why Connect a Throttle Position Sensor (TPS)?

Connecting and maintaining your Throttle Position Sensor (TPS) maximizes vehicle performance, fuel efficiency, and emissions control. Here’s why.

Monitoring Throttle Opening for Accurate PCM Control

Precise Fuel Demand Monitoring: The TPS monitors throttle position in real time and relays the data to the powertrain control module (PCM). This allows accurate fuel adjustments to meet the engine's current load requirements.

Avoiding Air-Fuel Ratio Issues: By maintaining an accurate air-fuel ratio, the TPS helps prevent engine surging, knocking, or stalling.

Providing Accurate Ignition and Fuel Injection Timing

Optimized Ignition Timing: With data from the TPS, the PCM can accurately gauge engine conditions and set the ignition timing to ensure optimal performance under various loads.

Fuel Injection Timing Adjustment: TPS signals, combined with data from other sensors, assist the PCM in adjusting fuel injector operation to ensure the fuel delivery matches air intake.

Enhancing Driving Safety and Vehicle Performance

Preventing Stalling and Surging: The TPS helps regulate fuel delivery and ignition timing so the engine operates smoothly under different driving conditions, reducing the risk of stalling or power loss.

Maintaining Fuel Efficiency: Optimized fuel injection and ignition timing not only improve vehicle performance but also enhance fuel economy by minimizing waste and reducing emissions.

Figure 8: Throttle Position Sensor (TPS)

How to Repair a Throttle Position Sensor (TPS)

Repairing a throttle position sensor (TPS) requires careful handling. Follow these steps and suggestions for effective repairs.

Disconnecting the Battery and Reprogramming

Battery Disconnection:

Turn off the vehicle's power, find the battery's negative cable, and disconnect it.

Leave the cable disconnected for five minutes to clear any cached data, then reconnect it.

This step helps reset the PCM and TPS programming. Handle the cables cautiously to avoid damaging other components.

Remove the ECM Fuse:

Locate the fuse for the engine control module (ECM) and remove it.

Wait a few minutes before reinserting it to reset the ECM and TPS calibration.

Proceed with care to prevent electrical circuit issues.

Inspecting and Repairing Wiring

Check Wiring Status:

Thoroughly inspect all TPS connections to ensure each terminal is secure and free from corrosion.

Use a multimeter to measure cable continuity and identify breaks, shorts, or abnormal resistance.

Repair or Replace Cables:

Repair or replace any worn or loose cables promptly.

Treat terminals with an anti-corrosive agent to ensure reliable long-term performance.

Figure 9: Throttle Position Sensor (TPS) Position

Calibrating or Replacing the Sensor

Calibrate the Sensor:

Use a multimeter while gradually rotating the throttle shaft to confirm that voltage signals change smoothly and meet the manufacturer's standards.

If the readings are unstable or inconsistent, recalibration may be needed.

Replace the Sensor:

If the sensor is severely damaged or too worn to recalibrate, replacing it is the best way to restore vehicle performance.

Align the new sensor properly with the throttle shaft and tighten the screws securely.

Diagnostics and Testing

Fault Diagnosis:

After reconnecting the sensor, use diagnostic tools to verify if the PCM error codes have been cleared.

Road Test and Inspection:

Perform a road test in controlled conditions, monitoring acceleration, idle, and power output for stability.

If issues persist, recheck the TPS and related sensor connections and signals.

These steps will help diagnose and repair TPS issues effectively, ensuring your vehicle operates smoothly.

Can a Car Operate Without a Throttle Position Sensor (TPS)?

While a vehicle can technically run without a throttle position sensor (TPS), its performance and stability will significantly decline. Here's why.

Acceleration and Idle Issues

Without the TPS, the engine control module (ECM) can't accurately determine the throttle opening, making it unable to adjust fuel supply effectively.

This often results in delayed response and insufficient power during acceleration, leading to instability.

The ECM can't fine-tune the air-fuel mixture during idle without data from the TPS, causing rough idling or stalling.

Ignition Timing and Shifting Delays

Without a TPS signal, the ECM can't accurately adjust ignition timing, which can cause knocking or power loss.

This makes power delivery inconsistent, especially in situations that require a quick response.

Automatic transmissions rely heavily on throttle position signals for timing shifts. Without TPS data, shifting becomes erratic or delayed.

Safety and Driving Experience

Incorrect air-fuel adjustments can cause the engine to stall unexpectedly, posing a serious safety risk.

Insufficient power during acceleration or passing can endanger the driver and other road users.

Fuel supply can't be precisely controlled, leading to an overly rich or lean mixture that significantly lowers fuel efficiency.

Recommendations

Immediate Testing and Replacement:

If a TPS failure is detected, repair or replace it promptly to ensure the ECM receives accurate throttle data.

Use diagnostic tools to read error codes and check related sensors and wiring.

Avoid Long Drives:

Don't drive for long periods with a faulty TPS to prevent further engine issues.

Visit a repair shop or consult a professional technician for sensor diagnostics and repairs.

How to Disconnect a Throttle Position Sensor Plug

Disconnecting a throttle position sensor (TPS) plug requires careful handling. Follow these steps for safe and effective removal.

Figure 10: How to Disconnect a Throttle Position Sensor Plug

Preparations

Turn Off the Vehicle:

Ensure the engine is off and fully cooled down to avoid burns or damage to engine parts.

Check the Manual:

Different vehicle models have slightly different TPS locations and removal methods. Consult the manual for your vehicle's specific instructions.

Locate and Inspect the Connector

Find the TPS:

It's usually mounted on the throttle body and connected to the throttle shaft. Identify the cable harness and plug attached to it.

Inspect the Locking Mechanism:

Most TPS plugs have a locking mechanism, which might be a push, slide, or twist lock. Observe how it's locked to understand the proper unlocking technique.

Release and Disconnect the Plug

Reduce Cable Tension:

Gently pull the cable harness before unplugging to ensure no tension or pinching on the wires.

Release the Lock:

Press or slide the lock as needed to release it, then carefully pull the plug out of the TPS socket.

Inspect and Install the New Sensor

Check the Plug and Harness:

After unplugging, inspect for damage, corrosion, or looseness. Make sure the connector is clean and oil-free.

Install the New TPS:

Align the new TPS with the throttle shaft. Connect the plug securely, making sure the lock engages.

Test the Connection:

Turn the vehicle power back on and use a diagnostic tool to confirm the TPS connection and signal output are functioning properly.

Note: Before installing a new sensor, read the manual thoroughly to follow each step according to the manufacturer's specific requirements.

What Is the Cost to Replace a Throttle Position Sensor (TPS)?

The cost of replacing a throttle position sensor (TPS) depends on several factors.

Parts Pricing

Various TPS models and brands have different prices depending on quality and manufacturer. General-purpose sensors usually cost between $10 and $100, while higher-end or OEM sensors can range from $200 to $600.

Some vehicles require specific sensors that can't be replaced with generic parts, driving up costs. OEM parts for luxury or specialized vehicles tend to be pricier.

Labor Costs

If a professional mechanic replaces the TPS, expect to pay for labor. Typically, labor costs range from $50 to $200, varying by shop pricing and location.

The more complex the vehicle design, the longer it will take the mechanic to replace the sensor, increasing costs. Some models require additional disassembly steps or special tools, which can raise labor expenses.

Total Costs

Considering parts and labor, the total cost to replace a TPS can range from $60 to $800.

If you have the necessary mechanical skills to replace the TPS yourself, costs will significantly decrease, as you'll only need to cover the cost of the sensor.

Tip: Before purchasing or replacing a TPS, carefully review the vehicle manual or consult a mechanic to choose the right sensor and accurately estimate the required costs.

How to Replace a Throttle Position Sensor

Removing the Sensor

Figure 11: Throttle Position Sensor (TPS)

Find the TPS and Disconnect the Power

Locate the throttle position sensor (TPS) on your vehicle's engine. It's typically attached to the throttle body and connected to the throttle shaft.

To prevent electrical shock or error codes, disconnect the negative battery cable first.

Remove the Sensor

Identify the cable harness connected to the TPS. Find the locking mechanism, unlock it, and disconnect the plug.

Use a correctly sized screwdriver or wrench to loosen and remove the screws securing the TPS. Slide the sensor off the throttle shaft.

Select a Replacement Sensor

Make sure the new sensor matches the original in size and specs to ensure compatibility.

Opt for a reliable, high-quality brand to avoid poor-quality or cheap replacements.

Installing the New Throttle Position Sensor

Install the Sensor

Secure the Sensor: Mount the new TPS on the throttle shaft. Align the screw holes and tighten the screws securely, avoiding over-tightening to protect the threads.

Connect the Electrical System: Plug the TPS connector back in, ensuring it's firmly locked.

Reconnect the Battery and Test

Restore Power: Reconnect the negative battery cable to power the vehicle system.

Start and Test: Start the vehicle and observe idle and acceleration.

Adjust if Needed: If idle or acceleration isn't consistent, manually adjust the TPS or use a scanning tool for automatic calibration to ensure optimal performance.

Frequently Asked Questions [FAQ]

1. Will disconnecting the battery reset the throttle position sensor (TPS)?

Disconnecting the battery may not directly reset the throttle position sensor (TPS). Many vehicles require a specific calibration procedure to reset the TPS. For instance, some models require a specific sequence of turning the ignition on and off. Disconnecting the battery can reset the engine control unit (ECU), potentially affecting engine performance, but it’s not a guaranteed fix for the TPS.

2. Can the TPS cause shifting problems?

Yes, a faulty or inaccurate throttle position sensor (TPS) can lead to shifting issues. An incorrect TPS reading sends wrong information to the vehicle’s computer, which can cause automatic transmissions to shift poorly. This can result in delayed shifts, rough gear changes, or the transmission sticking in one gear.

3. Can the TPS be terminated?

No, the TPS cannot be disabled or terminated because it's essential for the engine’s fuel injection and ignition systems. If it’s malfunctioning, the sensor can be replaced. This involves unplugging the TPS’s electrical connector and removing the sensor from the throttle body.

4. Do you have to reset the computer after replacing the TPS?

Yes, resetting the computer is recommended after replacing the TPS. This step allows the engine control unit (ECU) to recognize the new sensor and recalibrate. To reset the computer, you can disconnect the battery briefly or use a diagnostic tool to clear error codes and recalibrate the system.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

→ Previous

Electricity is the invisible force that powers our modern world, coursing through the veins of our infrastructure in two distinct forms: Direct Current (DC) and Alternating Current (AC). DC, characterized by its steady and unidirectional flow of electricity, powers everything from the smallest handh...

In the intricate world of electronic components, the potentiometer stands out for its versatility and precision in controlling various parameters within a circuit. This fundamental component, integral to both amateur and professional electronic setups, allows for the adjustment of resistance, thus i...

→ Next

Car Battery Output - DC or AC?

on May 9th

What Is the Function of a Potentiometer?

on May 8th

Popular Posts

-

What is GND in the circuit?

on January 1th 3272

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2815

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 20th 2640

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2265

-

Comparison Between DB9 and RS232

on January 1th 1882

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1846

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1807

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1801

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1799

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 20th 1782