on May 9th

675

Car Battery Output - DC or AC?

Electricity is the invisible force that powers our modern world, coursing through the veins of our infrastructure in two distinct forms: Direct Current (DC) and Alternating Current (AC). DC, characterized by its steady and unidirectional flow of electricity, powers everything from the smallest handheld devices to the largest electric vehicles, offering precision and energy efficiency. In contrast, AC's ability to change direction and voltage easily makes it ideal for the widespread distribution required by national power grids, facilitating the transmission of electricity over long distances with minimal loss. The distinctions between DC and AC, their applications, advantages, and the technology that supports them paint a vivid picture of their integral roles in both historical and contemporary contexts.

Catalog

Figure 1: Car Battery

Direct Current (DC) and Alternating Current (AC) are two fundamental forms of electricity, each with its distinct characteristics and applications. Direct current features a constant flow and voltage, primarily sourced from batteries, solar panels, or converted from AC through rectifiers. It is ideal for devices requiring steady, consistent power, such as electronic control units and microprocessors. In smaller electronic devices, like transistor controls, DC effectively manages the on/off states, ensuring precision and stability in device operations.

DC

DC's low energy loss during transmission makes it widely used in portable electronics and electric vehicles. Electric vehicles utilize battery packs that directly provide DC, allowing motors to use the power efficiently without conversion losses. What's more, DC is easy to store and release through batteries or other storage systems, important for independent power systems and emergency power backups.

In terms of environmental and energy efficiency, DC demonstrates significant advantages. Devices powered by DC typically have higher energy efficiency, directly powering end devices and minimizing conversion losses. This reduction in energy waste significantly lowers carbon emissions and environmental impact. Moreover, DC simplifies power management and distribution, reducing system complexity and maintenance costs.

AC

Alternating current, on the other hand, periodically changes direction and magnitude. This characteristic enables AC to be easily transformed across different voltage levels, facilitating efficient power transmission and distribution on a large scale. AC's ease of transformation makes it the preferred choice for modern electrical systems for long-distance transmission and widespread distribution. In residential, commercial, and industrial settings, AC is easily distributed through power grids to various consumption points.

Another advantage of AC is its adaptability and control, meeting diverse electrical load demands. Power companies dynamically adjust power generation and grid voltage based on consumer demand, optimizing resource allocation and enhancing system efficiency and reliability.

Comparing DC and AC, DC is better suited for applications needing stable voltage and high energy efficiency, like data center power supply, electric vehicle drivetrains, and mobile device power. AC, with its transmission and distribution capabilities, is more applicable for building power networks and large-scale power applications like factory power supply and residential electricity. Each type of current has its benefits, but they are often used complementarily in practice, creating an efficient and reliable power supply system.

|

|

DC Battery

|

AC Battery

|

|

Power Type

|

Direct Current (DC)

|

Alternating Current (AC)

|

|

Power Storage

|

Stores DC power

|

Does not exist in the traditional sense

|

|

Power Output

|

Provides DC power

|

Requires an inverter to convert DC to AC

|

|

Common Applications

|

Portable electronic devices, vehicles,

off-grid systems

|

Not commonly used

|

|

Power Generation

|

Not involved in power generation

|

Not involved in power generation

|

|

Common Battery Types

|

Lithium-ion, lead-acid, nickel-cadmium

|

Not applicable

|

|

Grid Compatibility

|

Can be used with DC devices and some AC

devices with the help of inverters

|

Not applicable without conversion

|

|

Energy Conversion

|

No conversion is needed, power is readily

available as DC

|

Requires conversion from DC to AC using

an inverter

|

Chart

1: DC Battery vs AC Battery

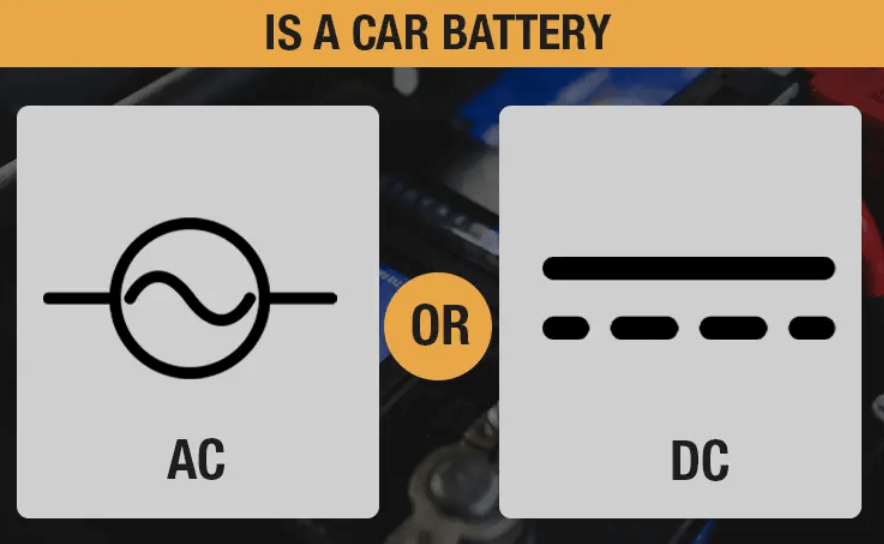

Figure 2: Is a Car Battery AC or DC?

In the realm of modern automotive technology, the design and functionality of car battery chargers are important, especially for electric and hybrid vehicles. A primary function of these chargers is to convert the alternating current (AC) from the electrical grid into direct current (DC), which can be stored in the vehicle's battery. This conversion process must be efficient and executed in a manner that promotes the health and longevity of the battery.

At the heart of the battery charger is the rectifier, a component tasked with transforming AC into DC. During this process, the rectifier employs power electronic devices such as diodes or transistors to control the direction of the current and prevent any backward flow, ensuring a one-way stream of electricity. Once converted, the direct current must then be finely adjusted by a device known as a DC-DC converter to meet the specific charging standards of the battery, which typically involves modifying the voltage and current to precise levels.

The application of smart charging technology marks a significant advancement in modern automotive chargers. These systems continuously monitor the battery's condition, tracking variables like voltage, current, temperature, and charge cycles. Utilizing this data, smart chargers dynamically adjust the charging parameters to optimize battery life and enhance energy efficiency. For instance, as the battery nears full capacity, the charger reduces the charging current to minimize thermal stress and physical wear on the battery.

Many contemporary charging systems are integrated with communication capabilities that allow the charger to share information with the vehicle's central control system. This integration enables the charger to automatically start or stop charging as needed and provides warnings and diagnostic support if battery performance issues are detected, ensuring driver safety. Modern chargers also consider the balance of the electrical grid, particularly in cities with a high penetration of electric vehicles. Smart chargers can increase charging power during off-peak hours when grid demand is low and decrease it during peak times.

Modern cars are increasingly reliant on batteries that can handle complex functions and meet high energy efficiency standards. Different types of batteries have unique advantages and are selected based on the specific needs of the vehicle under various operating conditions.

Lead-acid Battery

Lead-acid batteries remain prevalent in traditional gasoline vehicles due to their cost-effectiveness and well-established technology. These batteries are primarily used for starting, lighting, and ignition—commonly referred to as SLI applications. Their main advantages include low cost and a well-developed recycling process. However, their heavy weight and lower energy efficiency limit their use in newer electric vehicles.

Figure 3: Lead-acid Battery

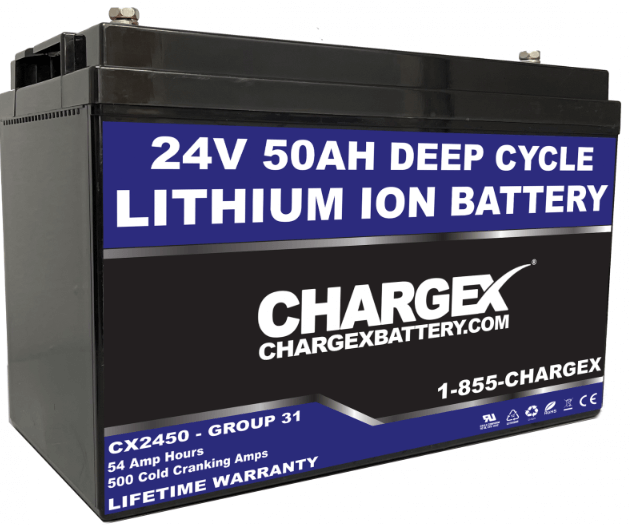

Lithium-ion Battery

In contrast, lithium-ion batteries are favored in electric and hybrid vehicles because of their high energy density and longevity. Lithium-ion batteries offer three to four times the energy density of lead-acid batteries, allowing them to store more energy in a smaller, lighter package. This is crucial for extending the driving range and enhancing overall vehicle performance. Additionally, lithium batteries support rapid charging and efficient deep discharge cycles, making them ideal for the high energy demands and frequent usage patterns of modern electric vehicles.

Figure 4: Lithium-ion Battery

AGM Battery and Gel Battery

For high-end models and vehicles equipped with start-stop technology, Absorbent Glass Mat (AGM) batteries and gel batteries represent advanced lead-acid battery technologies. These batteries are designed to withstand the high load and frequent charge cycles associated with frequent starts and stops. AGM batteries use glass mat separators and compressed battery plates, which not only provide better resistance to vibrations but also maintain stable performance across a broader temperature range. Gel batteries incorporate silicone gel in the electrolyte, enhancing their vibration resistance and temperature tolerance, making them better suited for extreme conditions.

Figure 5: AGM Battery

Figure 6: Gel Battery

The choice and application of these battery types reflect automakers' efforts to meet increasingly stringent performance and environmental standards while balancing cost-effectiveness and technological feasibility. By considering these factors, automakers can equip different types of vehicles with the most appropriate battery solutions, thereby optimizing performance, cost, and environmental impact.

The operation of a car battery involves complex chemical and electrical processes that enable it to store and release energy, powering various automotive electrical demands. Lead-acid batteries are the most common type found in cars, operating on a chemical reaction between lead and sulfuric acid to generate electricity.

Inside the battery, there are several cells, each made up of a positive plate coated in lead dioxide and a negative plate of spongy lead. These plates are immersed in a sulfuric acid solution, which serves as the electrolyte. During discharge, the lead and lead dioxide react with the sulfuric acid to form lead sulfate and water, releasing electrons that flow through the external circuit to produce electricity. Each cell generates about 2 volts, and when six cells are connected in series, they provide a total of 12 volts, which meets the standard requirement for most vehicles.

To meet the substantial current demands of a car, especially during engine startup, the battery is designed to release a large amount of current quickly. Its materials and structure are specifically chosen to withstand rapid charge and discharge cycles. Vehicles of different models and specifications may be equipped with batteries of varying capacities to suit their specific energy needs and electrical system characteristics.

Advancements in modern automotive technology have also led to improvements in battery maintenance and charging mechanisms. Most modern cars are equipped with an alternator, which converts mechanical energy into electrical energy while the vehicle is running. The AC generated by the alternator is converted to DC by a rectifier, which then charges the battery and powers the vehicle’s electrical system. This charging system not only ensures the battery is continuously recharged while driving but also helps extend its life and maintain performance. The rectifier plays a crucial role in this process, ensuring that the electricity generated by the alternator is efficiently converted into safe DC power for the battery and the vehicle's electrical systems.

Figure 7: Battery Damage

To effectively assess the health and functionality of a car battery, recognizing certain symptoms can indicate its deterioration, pointing to the possible need for professional examination, repair, or replacement. Gaining a detailed understanding of these symptoms can prevent major failures and ensure the battery receives timely maintenance.

When the engine cranks slowly, it's often one of the first and most noticeable signs that the battery might be failing. This manifests when you turn the ignition key and encounter an unusually slow startup, accompanied by a labored "whirring" noise. This sound is a telltale sign that the battery is struggling to provide the necessary current required to power the starter motor effectively.

Another common indicator of battery issues is the illumination of the 'check engine' light on your dashboard. Although this warning light can signal various engine-related issues, its activation without accompanying engine troubles often points to a battery not maintaining its charge efficiently. In certain cases, other warning lights, such as the coolant light, might also light up, indirectly hinting at battery-related problems like overheating that compromise the battery’s performance.

A significant drop in battery fluid level can also indicate issues. Most

car batteries are equipped with a translucent part of the casing that allows you to visually check the fluid level. If you notice the fluid level is below the tops of the lead plates, which conduct energy, it could be due to excessive charging or high temperatures adversely affecting the battery. Modern vehicles often have sealed battery casings that don't allow manual topping off, making it necessary to seek a professional battery health assessment if the fluid level is critically low.

Physical changes to the battery case, such as swelling or bulging, clearly signify battery failure. This swelling typically results from internal overheating, which causes the casing to expand. This not only mars the battery's appearance but also drastically reduces its efficiency and lifespan by potentially leading to internal short circuits and further degrading the battery's capacity.

If you detect an unpleasant sulfur smell—reminiscent of rotten eggs—around the battery, it could indicate that the battery is leaking acid. Such leaks often result from overcharging or breakdown of internal components, releasing hydrogen sulfide gas, which is not only noxious but also corrosive and potentially dangerous.

Paying more attention to the replacement and maintenance of car batteries can keep the vehicle running smoothly for a long time. It is generally recommended to replace the battery every three to five years, but the actual timing can vary based on several factors such as the vehicle's usage, battery performance, and external environmental conditions. A decline in battery performance can be detected through several clear signs. For instance, the illumination of the battery warning light on the dashboard is often the first indicator of potential undercharging or deteriorating battery performance.

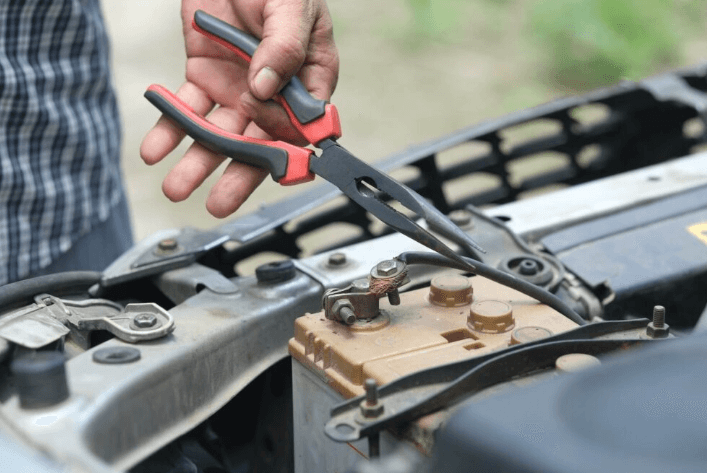

Battery performance is particularly vulnerable in cold environments, where low temperatures significantly reduce the battery's ability to start the engine. Difficulty in starting the vehicle in cold conditions typically signals that the battery may no longer maintain a proper charge. Physical signs like corrosion or leakage around the battery are urgent issues that need immediate attention. Corrosion at the battery terminals can lead to poor connections, affecting the stability of the vehicle’s electrical system. Leakage not only damages the battery itself but can also corrode other parts of the vehicle.

To extend the life of the battery and maintain optimal performance, we need to check the battery regularly. These inspections should include checking that the battery is securely mounted to prevent any movement; examining the battery terminals for signs of corrosion and cleaning them with a specialized brush if necessary; and verifying the fluid level in maintainable lead-acid batteries to ensure it adequately covers the plates and topping it up with distilled water as needed. Moreover, using a professional battery tester to regularly check the battery’s charging state and overall health can inform owners whether a replacement is necessary.

Figure 8: Repair Car Battery

The role of a car battery extends far beyond its basic function. It is not only the primary power source for starting the engine but also continues to support the entire electrical system of the vehicle after the engine is turned off. This support is crucial because modern cars increasingly rely on electrical power for both essential and enhanced features such as lighting, sound systems, navigation, and various sensors.

The battery's ability to store energy is also a point of concern. It stores the surplus electrical energy generated by the alternator while the engine is running. This mechanism ensures that devices within the vehicle, such as interior lighting, security systems, and entertainment devices, can continue to operate even when the engine is off. This functionality is indispensable for the modern car's operation and passenger comfort. For example, when using the onboard entertainment system or navigation devices while parked, the battery provides the necessary power allowing these systems to function seamlessly without draining the engine's resources or affecting the vehicle's ability to start.

The car battery plays a supporting role in the vehicle’s safety systems. In emergencies, critical safety components such as the airbag system and electronic brake systems must operate independently of engine power. Thus, the reliability of the battery directly impacts driving safety.

The function and importance of a car battery go well beyond simple energy supply; it is a core component that ensures the performance, safety, and comfort of modern vehicles. As automotive technology evolves, the role and demands on batteries are increasing, especially in the context of electric and hybrid vehicles. Advances and optimizations in battery technology are becoming increasingly critical. Therefore, maintaining high performance and longevity of the battery, along with timely maintenance and replacement, are crucial aspects of modern vehicle management.

The dichotomy between Direct Current (DC) and Alternating Current (AC) underpins much of modern electrical engineering and energy distribution, reflecting a complex interplay of efficiency, convenience, and technological advancement. From powering delicate electronic circuits with DC to lighting up cities with AC, the uses of each form of current are tailored to their unique properties. As we delve deeper into the age of technology, the importance of understanding and optimizing these currents continues to grow, particularly with the rise of renewable energy sources and electric vehicles. The ongoing developments in battery technology and power conversion ensure that both DC and AC continue to evolve, enhancing the functionality and environmental sustainability of future power systems. This journey through the realms of DC and AC not only highlights the sophistication and potential of modern electrical systems but also underscores the critical need for continued innovation in a world increasingly dependent on reliable, efficient power solutions.

Frequently Asked Questions [FAQ]

1. Are car batteries DC or AC?

Car batteries are DC (Direct Current). They provide a steady, unidirectional flow of electricity, suitable for the consistent energy supply needed by automotive systems.

2. Are AC car batteries more environmentally friendly?

AC car batteries do not exist in the conventional sense, as vehicles use DC batteries. The environmental impact of a battery generally depends on the type (e.g., lead-acid vs. lithium-ion) and how the electricity to charge the battery is generated, rather than whether it is AC or DC.

3. Is 12V AC the same as 12V DC?

No, 12V AC is not the same as 12V DC. Although both have the same voltage level, AC voltage varies with time, passing through zero to a positive peak, back through zero to a negative peak, and back to zero. DC voltage remains constant, providing a steady voltage. This difference affects the behavior and applications of the two currents.

4. Are spark plugs AC or DC?

Spark plugs in vehicles use DC. The car's battery provides DC power, which is used to create the spark necessary for ignition in the engine's cylinders.

5. Is it possible to convert my car’s electrical system from DC to AC?

Converting a car’s electrical system from DC to AC is not practical. Cars are designed to use DC power for their electrical systems, including starting the engine and powering the internal electronics. The conversion would require extensive modifications to the electrical architecture and components, making it impractical and costly with no clear advantage.

Share: