Solid State Relays vs. MOSFETs Guide – Definitions, Comparisons, How to Choose

Solid state relays (SSR) and metal oxide semiconductor field effect transistors (MOSFET) are two extremely critical components in modern electronic technology, each with its own characteristics. This article aims to deeply explore the functional characteristics, application scenarios, and application scenarios of these two devices. Performance in actual operations, thereby providing engineers and technicians with a reference for making correct choices in different applications.

Catalog

1. What is a solid-state relay?

A Solid State Relays, or SSR, is a type of electrical switch. Unlike traditional switches that physically move to open or close a circuit, SSRs operate without any moving components. This absence of mechanical parts means there's nothing to wear out or fail over time, enhancing their durability and reliability. SSRs are also notably quieter since there are no moving parts to produce noise.

These switches function by using an electrical signal to control the flow of electricity. This method allows for a faster response when turning an appliance on or off, which is particularly advantageous in applications that demand quick or frequent switching. For instance, in environments where high currents are managed, the ability to rapidly switch without physical contact points reduces the risk of malfunction and promotes a smoother operation.

By controlling current flow electronically, SSRs outperform traditional electromagnetic relays, which depend on mechanical contacts to function. The electronic management of the switching process not only speeds up the operation but also enhances the overall efficiency and reliability of the electrical system where the SSR is used.

2. Application fields of solid-state relays

Solid-state relays (SSRs) are versatile tools used in many fields because of their ability to electronically control electrical currents. This approach provides precise, immediate response without the physical movement required by traditional relays, resulting in consistent and reliable performance.

In manufacturing, solid-state relays are important for automating production lines. For example, in a facility where robotic arms operate, SSR manages the electric motors that power those robotic arms. This management includes frequent and precise starting and stopping of motors, which is essential for continuous production. The instantaneous switching provided by SSR not only increases efficiency but also minimizes mechanical wear, thereby extending the life of the equipment.

SSR also plays an important role in industries that require strict temperature control, such as materials manufacturing and food processing. These setups typically use SSR in heating systems to ensure precise temperature regulation. The SSR's ability to turn on and off every few seconds allows for quick response to temperature control commands, ensuring optimal power output from the heating element. This precise regulation maintains consistent product quality and reduces energy consumption by avoiding overheating or underheating.

In addition, the compact size and low power consumption requirements of SSRs make them an optimal choice for office automation and consumer electronics. In an office environment, SSR helps equipment such as printers and copiers run quieter and more energy-efficiently. They effectively control power and mechanical functions, creating a more comfortable workplace. In consumer electronics, SSR's small footprint and high efficiency facilitate the design of sleeker, more energy-efficient devices such as laptops and smart home systems.

3. Advantages of solid-state relays

Solid-state relays (SSRs) offer several key advantages that make them superior to traditional electromechanical relays. These advantages include fast switching capability, voltage-free switching, longevity, and electrical isolation between control and power circuits.

Quick switching capability

One of the most significant advantages of SSRs is their ability to turn on and off very quickly. This speed is achieved due to the lack of mechanical components, instead relying on electronic control. As in robotic automation systems, for example, the fast motion of the SSR ensures seamless operation of the robotic arm. Likewise, in high-speed data processing equipment, fast switching improves the efficiency of data flow and processing tasks.

No voltage switch

SSRs have voltage-free switching capabilities, which means they can switch circuits without creating any arcing. In traditional relays, arcing often occurs during the switching process, causing the contacts to wear out and eventually fail. The absence of arcing in SSRs not only extends the life of the relay itself but also reduces safety hazards, making SSRs ideal for use in potentially explosive environments such as chemical processing plants or oil and gas facilities.

Longevity

The SSR also stands out for its durability. Since there are no mechanical parts to wear out, SSRs can operate for hundreds of millions of hours under normal conditions, significantly exceeding the service life of mechanical relays. This longevity means less frequent replacement and lower maintenance costs, providing considerable economic benefits over the life of the relay.

Electrical isolation

Another important advantage of SSRs is that they provide electrical isolation between control signals and power circuits. This separation is critical to protecting the control system from high voltage or current surges, enhancing the overall stability of the system, and ensuring operator safety. This feature is especially important in safety-critical environments where protecting sensitive electronic equipment and personnel is critical.

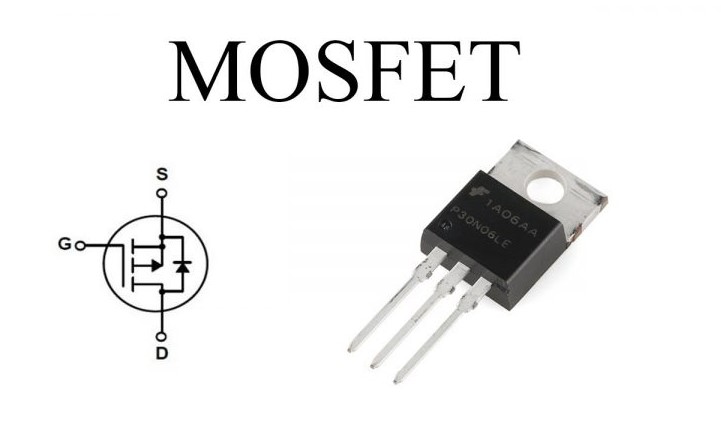

4. Definition and types of MOSFET

MOSFET Definition and Types

Metal-oxide-semiconductor field-effect transistors (MOSFETs) are components in modern electronics that excel in their role in amplifying and switching electronic signals. These devices allow precise control of current flow, which is directed through the gate voltage between the source and drain terminals.

MOSFET functions

MOSFETs have a very simple but very efficient structure, requiring only a small input voltage at the gate to manage large currents. This simplicity facilitates efficient operation, especially where high efficiency and fast response to electronic commands are required.

Applications in smart devices

MOSFETs demonstrate their versatility and efficiency particularly well in smart devices. For example, in smart home systems, MOSFETs control various functions such as lighting and temperature regulation. Homeowners or operators can easily adjust these settings through a simple interface such as a touch screen or smartphone app. When a command is input, the MOSFET responds quickly by adjusting the current flow, thereby changing the operating status of the connected device. This results in an immediate and seamless response to user commands, enhancing the functionality and user experience of your smart home system.

5. Main types and characteristics of MOSFET

There are two main types of MOSFETs, or Metal Oxide Semiconductor Field Effect Transistors: depletion mode and enhancement mode. Each type has specific properties that make it suitable for different applications in electronics.

Depletion mode MOSFET

Depletion-mode MOSFETs are equipped with an inherent conductive channel created during the manufacturing process. This design allows the MOSFET to conduct electricity even when no gate voltage is applied, classifying it as a "normally-on" switch. This feature is particularly useful in applications requiring constant current. For example, in power supply circuits, depletion-mode MOSFETs ensure that power continues to flow, which is important for equipment that cannot withstand interruptions, such as emergency medical equipment or critical industrial machinery.

Enhancement mode MOSFET

In contrast, enhancement-mode MOSFETs operate as "normally-off" switches. These devices require a voltage at the gate to form a conductive channel and start conducting electricity. This feature means that the enhancement MOSFET turns off when no power is applied, increasing safety by preventing accidental activation. They are particularly valuable in applications where controlled start-up and precise current modulation are critical. Common uses include signal amplification in communications equipment, where precise control of the signal output is required, or in motor drives for precise speed regulation in robotics and automation systems.

6. Comparative analysis of solid-state relays and MOSFETs

Similarities Between SSR and MOSFET

Circuit Control: Both SSRs and MOSFETs are used to turn circuits on and off, effectively controlling where and how current flows in those circuits.

Electrical Isolation: They provide the necessary electrical isolation that helps protect sensitive parts of a circuit from high voltages or currents, thereby enhancing safety and system integrity.

Signal Control: Both devices are controlled by electrical signals such as current or voltage, allowing their operation to be precisely managed.

Application Versatility: SSR and MOSFETs are used in a variety of fields, including consumer electronics, industrial controls, telecommunications, and automotive systems.

Difference Between SSR and MOSFET

Component type: SSR is a passive component, mainly used to control power, and does not have any amplification function. In contrast, MOSFETs are active components that switch and amplify electrical signals.

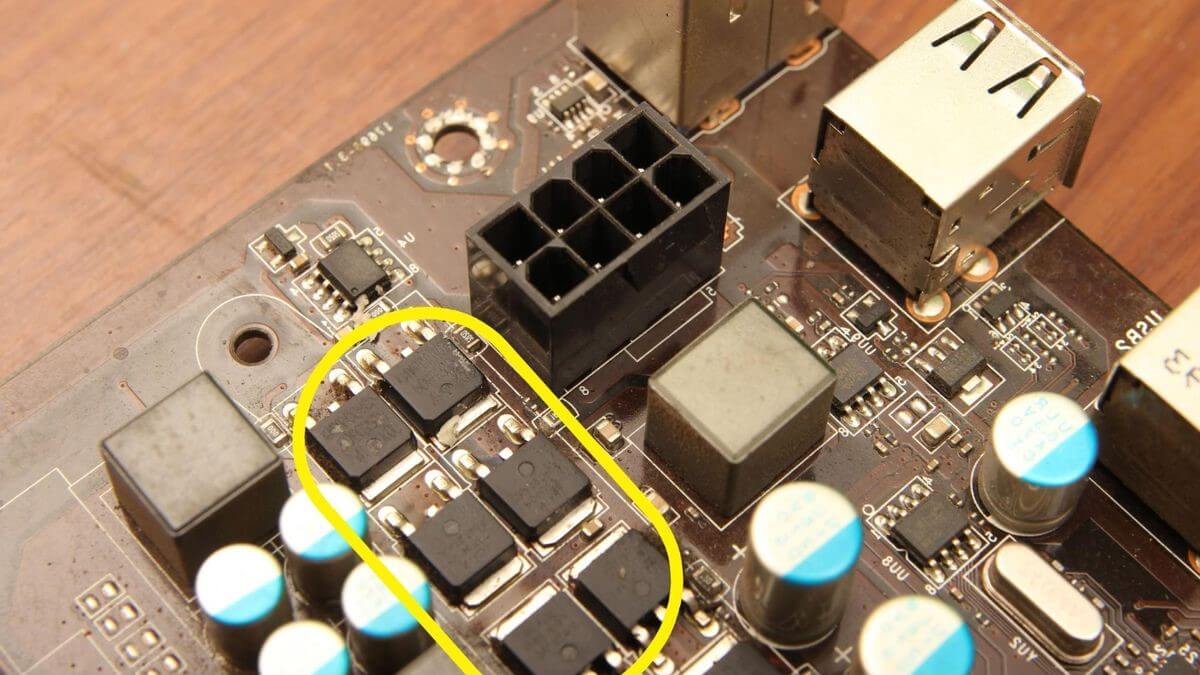

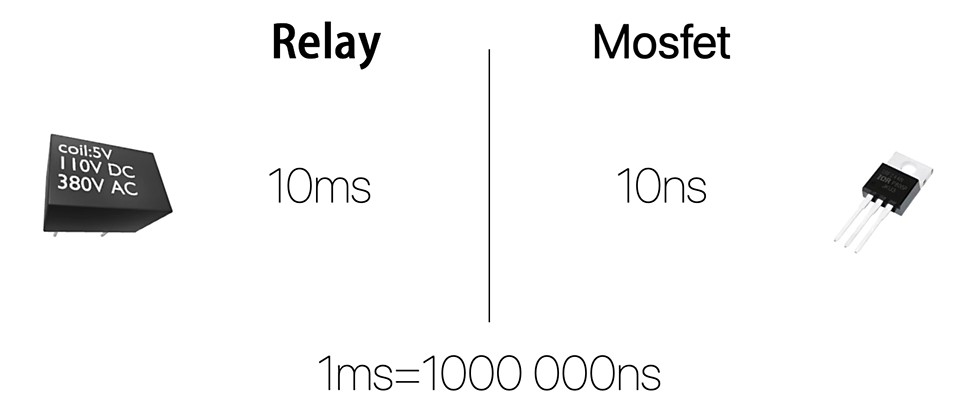

Switching Speed: MOSFETs typically switch at much higher speeds compared to SSRs. This fast switching makes MOSFETs particularly useful in applications that require fast response times, such as in high-speed processing equipment.

Cost and Performance: In terms of cost-effectiveness, SSRs are generally cheaper than MOSFETs. However, MOSFETs, due to their voltage control characteristics, often provide higher performance in applications requiring precise voltage control.

Physical size: MOSFETs are smaller than SSRs. This compact size makes MOSFETs ideal for applications where space is limited, such as portable electronics or tightly packed circuit boards.

7. How to choose solid state relays and MOSFETs according to application requirements

Selecting the correct solid-state relays (SSRs) and metal-oxide-semiconductor field-effect transistors (MOSFETs) requires careful consideration of multiple factors to ensure they meet the performance and cost requirements of a specific application.

Switching speed and application frequency

MOSFET: These devices are known for their extremely fast response times (usually in the nanosecond range). This makes MOSFETs ideal for applications that require fast switching, such as high-frequency electronic switching or precision control systems for timing.

SSR: Although not as fast as a MOSFET, the response time of an SSR is typically measured in milliseconds. This speed is sufficient for many industrial uses. SSRs are particularly valuable in applications that handle high currents and require high reliability, such as motor control and large heating systems.

Power requirements and electrical isolation

SSR: These relays excel at providing excellent electrical isolation, which is critical for protecting sensitive control systems from high voltage spikes. Operators using SSRs in high-power settings will notice effective isolation between the input and output terminals, protecting the control system from voltage fluctuations.

MOSFETs: They offer greater flexibility in managing power from very low currents to tens of amps. This makes them suitable for a variety of applications, from power management in compact devices to handling higher power requirements.

Cooling requirements

MOSFETs: In high-power applications, MOSFETs often require additional cooling strategies, such as heat sinks or cooling fans. These devices tend to concentrate heat, so effective heat dissipation can help maintain stability and extend their service life.

SSR: Generally speaking, SSR has better inherent heat dissipation capabilities and is suitable for long-term use in industrial environments. However, it is still important to pay attention to thermal management in system design, even though its requirements are generally lower than for MOSFETs.

Cost-effectiveness

MOSFETs: They may have advantages in terms of initial cost and are particularly attractive in applications requiring lower power or smaller quantities. Their flexibility and efficiency in power management make them cost-effective for specific technical uses.

SSR: The durability and low maintenance requirements of SSRs often translate into greater cost-effectiveness in the long term, especially in high-current environments where reliability is important.

8. Summary

In conclusion, whether it is the high reliability and powerful current handling capabilities of solid-state relays or the fast response and high-performance operation of MOSFETs, they are both important components in electronic design and automation systems. I hope that you have found this article helpful, but if you need to discuss more technical knowledge about primary MOSFET relays, you can contact us.

Frequently Asked Questions [FAQ]

1. What is the difference between solid-state relays and Mosfet relays?

Solid-state relays often use optical coupling technology (LEDs and photosensitive elements) to isolate inputs and outputs, which can handle larger currents and voltages and provide higher electrical isolation. MOSFET relays use one or more MOSFETs as switching elements. MOSFET relays can provide very fast response times and are suitable for high-frequency switching applications.

2. What is the difference between a transistor and a MOSFET?

A transistor (such as a bipolar transistor, BJT) controls the current flow between the collector and emitter by current flowing through the base. Transistors are highly sensitive to input signals and usually require continuous current to control their switching state. MOSFETs control the current flow between the source and drain by the voltage on the gate. This type of device is called a field-effect transistor, and it has a high input impedance, which means that little gate current is required during normal operation.

3. Why use MOSFETs instead of transistors?

The choice to use MOSFETs instead of transistors is usually based on the following points:

Higher efficiency: Due to their high input impedance, MOSFETs can control high-frequency circuits more efficiently and consume less power.

Fast switching speed: MOSFET can achieve faster switching speed, suitable for applications requiring fast response.

Good thermal performance: In high-current applications, MOSFETs often manage heat more efficiently than transistors.

4. Do MOSFETs control voltage or current?

MOSFETs essentially regulate current by controlling voltage. A change in voltage on the gate changes the conductive path between the source and drain, thereby controlling the flow of current. Therefore, although the direct function of a MOSFET is to regulate current, this regulation is accomplished through voltage. This makes MOSFETs particularly suitable for applications that require precise control of current by regulating voltage.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

→ Previous

In the realm of digital electronics and computer engineering, adders represent one of the most essential building blocks, pivotal in the construction and functionality of more intricate arithmetic circuits. As integral components of the Arithmetic Logic Unit (ALU), adders facilitate numerous computi...

Electricity is the invisible force that powers our modern world, coursing through the veins of our infrastructure in two distinct forms: Direct Current (DC) and Alternating Current (AC). DC, characterized by its steady and unidirectional flow of electricity, powers everything from the smallest handh...

→ Next

Detailed Guide to Full Adder

on May 10th

Car Battery Output - DC or AC?

on May 9th

Popular Posts

-

What is GND in the circuit?

on January 1th 3272

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2815

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 20th 2640

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2265

-

Comparison Between DB9 and RS232

on January 1th 1882

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1846

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1807

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1801

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1799

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 20th 1782