AT24C256 EEPROM: Functions, Working Principle, Applications, and 24LC256 Comparison

In today's unified world, understanding the initial components of digital storage is beneficial for both professionals and enthusiasts alike. This article digs into the depths of two prominent memory solutions, PROM and AT24C256 EEPROM, offering a comprehensive overview of their roles in modern electronics. By exploring how each technology supports dangerous data retention and system integrity, we uncover the outstanding considerations that drive their selection in various applications. From the permanence of PROM to the adaptability of EEPROM, this discussion sheds light on how these memory types enable everything from gaming consoles to automotive systems to operate reliably in diverse environments. As we navigate these technologies, readers are invited to reflect on the balance between stability and flexibility that defines our increasingly digital landscape.Catalog

Exploring the Depths of Programmable Read-Only Memory

Programmable Read-Only Memory (PROM) is the first storage medium frequently used in computing. Information is inscribed onto the chip via a device known as a PROM programmer. Once data is encoded, its permanence ensures a steadfast solution for enduring data retention. PROM's unwavering nature finds its application in environments where data consistency over time resonates with a need for trustworthiness. You’ll encounter it in video game consoles and electronic dictionaries, among other devices, where steady performance weaves into the fabric of user expectations.

The immutable trait of PROM positions it as a fitting choice for scenarios where updates are deemed pointless or when safeguarding against data alteration cannot be compromised. This is principally advantageous for firmware protection, deterring unauthorized modifications that might otherwise jeopardize system fidelity. Implementing PROM involves a thoughtful evaluation process. Engineers often contemplate the virtue of data permanence alongside the trade-off posed by its rigidity. This memory type thrives in contexts where the expense of reprogramming or updating hardware outweighs perceived advantages.

AT24C256 EEPROM In-Depth Analysis

The AT24C256 , a 256kbit serial EEPROM from ATMEL, excels in storing extensive data quantities without necessitating power reliance or complex circuitry. This characteristic makes it highly suitable for diverse data storage requirements. It allows parallel connectivity of up to four chips on a two-wire bus, optimizing both space and efficiency. With a robust 256kbit capacity and a transmission speed of 400kHz, it effectively manages various data types, including binary and ASCII formats. Its sleek 8-pin inline package provides a compact yet ample solution, adaptable for applications ranging from consumer electronics to industrial systems.

Under practical conditions, the compact design and efficiency of the AT24C256 facilitate seamless integration into existing architectures, sparing the need for major redesigns. This flexibility becomes substantial in rapidly evolving technological landscapes, where the demand for consistent and reliable data storage remains unwavering.

Alternative Solutions and Comparable Devices

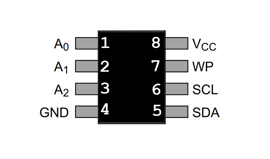

AT24C256 EEPROM Pin Configuration

The AT24C256 EEPROM, celebrated for its user-friendly design and performance, features eight pins that shape its operational framework. These pins enable communication, handle power distribution, and manage write protection, empowering the EEPROM to adapt across diverse electronic applications.

Address Inputs (Pins 1-3)

Pins 1 to 3 serve as address inputs (A0, A1, A2). They enable the unique identification of a device when several EEPROMs share the same I2C bus. This capability is major in preventing conflicts and ensuring accurate data access and storage. By skillfully managing these address pins, devices can achieve remarkable scalability and adaptability.

Ground Connection (Pin 4)

Pin 4 links to ground (GND), offering a universal reference voltage for the EEPROM. A reliable ground connection plays a role in reducing noise and promoting dependable operation, mostly in intricate systems where numerous components work together.

Serial Data (Pin 5 - SDA) and Serial Clock (Pin 6 - SCL)

Forming the core of the I2C communication interface, the serial data (SDA) and serial clock (SCL) pins are active. Pin 5 (SDA) facilitates data transfer to and from the EEPROM, while Pin 6 (SCL) aligns data transfer with the clock signal. Proficiency in the I2C protocol is instrumental in optimizing data flow and reducing delays in use cases.

Write Protection (Pin 7 - WP)

The function of pin 7 as write protect (WP) is designed to preserve data integrity by halting write operations when required. This safeguard is of great significance in protecting against unintended data erasure or corruption, mainly where data security is used, and potential loss could have severe consequences.

Power Supply (Pin 8 - VCC)

Located at pin 8 is the power supply pin (VCC), which energizes the EEPROM. Delivering consistent voltage to VCC is central to ensuring stable device performance, as voltage irregularities could result in erratic behavior or data loss. Robust power management practices in circuit design are basic to mitigating such risks.

Distinct Characteristics of AT24C256 EEPROM

The AT24C256 is celebrated for its compact 8-pin design that maximizes space efficiency across diverse electronic applications. It showcases low power usage during read and write tasks, aligning with the push towards energy efficiency in modern electronics. This becomes especially meaningful in portable devices where battery longevity can affect user satisfaction.

Storage Capabilities

Sporting a 256Kb storage capacity, the AT24C256 handles substantial data volumes with a minimal physical profile. This is well-suited for cases necessitating frequent data logging or retention of configuration settings. In automotive scenarios, these EEPROMs are commonly employed to store calibration data, thus aiding precise monitoring of vehicle performance.

Multi-Rewriting Support

Supporting multiple rewrites, the AT24C256 offers both longevity and adaptability in ever-changing environments. This quality holds particular worth in industrial control systems where operational parameters may need regular adjustments. Its ability to maintain data integrity across many rewrites highlights the device's dependability, an aspect that resonates deeply when precision is a top priority.

Functional Capabilities of the AT24C256 EEPROM

Streamlined Read and Write Operations

The AT24C256 EEPROM performs read and write tasks with exceptional swiftness, which is noteworthy for its users. By employing distinct transitions on the SCL and SDA lines, it marks the start and finish of each operation. This precision offers a stable performance, especially in settings demanding swift data exchanges.

Byte-Level Precision and Sustained Data Reliability

For byte-level data interactions, the EEPROM enhances its precision pointedly. It preserves data reliability using consistent acknowledgment signals, which systematically shape data and commands. This approach shines in scenarios demanding meticulous data management, eliminating errors that arise from device communication lapses.

AT24C256 EEPROM Operational Insights

Data Communication Protocols

In a typical setup, the Serial Data line (SDA) remains externally pulled high, creating a stable foundation for transmitting data. Data transitions on the SDA occur when the Serial Clock line (SCL) is low, orchestrating a symphony of minimal interference and ensuring seamless communication.

Start and Stop Conditions

When a high-to-low shift on the SDA line happens while the SCL line is high, it signals a start condition. Conversely, transitioning from low to high on the SDA with SCL high indicates a stop condition. These transitions frame the data exchange, enabling devices to perceive the beginning and end of communication paths, preserving orderly data flow.

Acknowledgment Mechanism

Following each byte, an acknowledgment bit is required. The receiver, upon accepting a byte, lowers the SDA line during the ninth clock pulse. This act of acknowledgment ensures that data has been correctly interpreted, fostering consistent data transfer. In high-noise environments this mechanism's effectiveness, highlights underlining the EEPROM's resilient design, which quietly endures external disturbances.

8-bit Data Sequence

Data in the EEPROM is processed in 8-bit sequences, a structure mirroring standard microcontroller architecture. This alignment eases integration and streamlines system design. Each transaction is wrapped with a start and stop condition, followed by an acknowledgment, securing reliability. It is acknowledge that this structured approach simplifies troubleshooting and enhances performance during debugging, becoming a trusted ally in achieving optimal results.

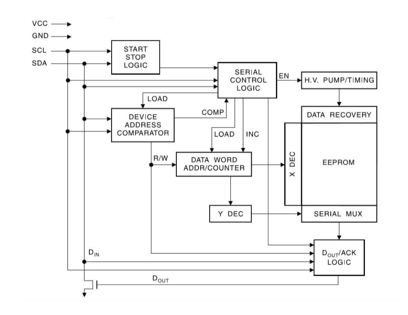

AT24C256 EEPROM Block Diagram

Applications of AT24C256 EEPROM

Storage for Configuration Settings

The non-volatile nature of the AT24C256 EEPROM supports storing active configuration settings. It ensures the preservation of data, even during power interruptions, which is mainly advantageous in industrial machinery. Maintaining precision in settings contributes to consistent product quality and helps reduce downtime, subtly impacting operational efficiency. Systems often depend on this solid data storage to transition smoothly between operational states.

Automotive Data Management

In the automotive sector, the AT24C256 handles wanted data like engine parameters and diagnostics. It endures environmental stressors such as temperature changes and vibrations, enhancing its use in onboard systems. By safeguarding such substantial data, this memory chip boosts vehicle performance and aids in pioneering predictive maintenance. It is frequently incorporate this EEPROM to refine fuel efficiency and emission controls, steering towards environmentally friendly vehicle advancements.

Program State Preservation

Another notable application is preserving program states in electronic systems. The AT24C256 maintains system states in devices, from consumer electronics to specialized instruments. This enhances you experience by allowing quick recovery from power failures, where continuity greatly improves convenience. It is utilize EEPROM’s steady performance in iterative design processes to integrate resilience into their products, leading to your-focused designs that anticipate and address challenges.

Role in Medical and IoT Equipment

In medical and IoT devices, the AT24C256 is used for data consistency and retention. In medical equipment, it stores patient data and calibration settings, ensuring operational reliability. For IoT devices, supports remote monitoring by maintaining data integrity, and dynamic for accurate performance tracking. These uses highlight the role of dependable memory solutions in advancing healthcare and smart technology, marking the intersection of data integrity and technological evolution.

Exploring Variations in AT24C256 and 24LC256

Both the AT24C256 and 24LC256 EEPROM chips cater to data storage needs, sharing similar capacities. Yet, beneath these surface similarities lie distinct differences shaping their performance in diverse scenarios.

Speed Dynamics

A main divergence is found in their operational speeds. The AT24C256 runs at up to 400KHz, meeting the demands of many routines. Conversely, the 24LC256 supports speeds reaching 1MHz, allowing swifter data processing and access. This can be advantageous in time-sensitive environments. For example, in situations requiring prompt data retrieval, like industrial automation systems, the quick pace of the 24LC256 can suggestively enhance system performance and fluidity.

Uses

When deciding between the AT24C256 and 24LC256, attention should be paid to project-specific demands. Higher speeds provide increased responsiveness for applications that necessitate rapid data exchanges, such as real-time sensor data management. Meanwhile, in contexts where speed isn't as dominant—like straightforward logging tasks—the AT24C256 remains a dependable and economical option. Insights from practice suggest that choosing the appropriate chip involves weighing considerations like speed, energy use, and budgetary factors.

Frequently Asked Questions [FAQ]

1. What is the function of EEPROM?

EEPROM allows byte-by-byte data erasure and reprogramming, ideal for storing small amounts of data in electronic devices. Its adaptability supports efficient updates in scenarios where data needs to be modified incrementally, such as in configuration settings or calibration data. By enabling targeted data changes, it enhances memory utility, especially in systems with constrained resources, akin to a sculptor skillfully crafting changes without altering the whole.

2. What is the capacity of the AT24C256?

With a 256Kbit capacity equating to 32K bytes, the AT24C256 connects seamlessly to systems like Arduino via the I2C protocol. This makes it well-suited for various uses ranging from simple data logging to complex control systems. This memory size comfortably supports medium-scale applications that demand dependable data retention without constant power, echoing the reassurance one finds in a trusted companion.

3. How is the write cycle defined?

The write cycle has a duration of 5ms for AT24C128/256 devices and is indicated by package markings. This short cycle time permits quick data changes, empowering devices that frequently modify data. The brisk write cycle boosts system responsiveness, supporting situations where real-time data handling is not just preferred but expected, like a responsive partner ready to adapt at a moment's notice.

4. What is the page-byte size of the AT24C256?

Each page holds 64 bytes, enabling effective data transfers within single I2C transactions. This page setup is useful for maximizing data throughput and minimizing communication load. Managing data in organized pages streamlines operations suggestively, mostly in limited-resource settings where reducing communication delays is akin to finding harmony in a chaotic cadence.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

CR2032 and CR2450 Button Batteries

on September 26th

AT89C51 Microcontroller: Features, Functions and Applications

on September 26th

Popular Posts

-

What is GND in the circuit?

on January 1th 3255

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2805

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 20th 2610

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2250

-

Comparison Between DB9 and RS232

on January 1th 1868

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1836

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1791

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1780

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1777

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 20th 1763