Insights into Pressure Sensors: Functionality, Types, and Uses

In the expansive field of industrial automation and monitoring, pressure sensors emerge as key components that provide significant data for managing processes and ensuring system integrity across diverse applications. From automotive engineering to environmental science, the ability to accurately measure and monitor pressure is requisite. These sensors not only offer the flexibility to handle various gases and liquids but also adapt to different environmental conditions, making them integral in maintaining operational efficiency and safety.

This article digs into the intricate world of pressure sensors, exploring their operational principles, diverse applications, and the technological nuances that distinguish them from related devices like transducers and transmitters. By dissecting the numerous types of pressure measurements and the technologies that enable these functions, it gains a comprehensive understanding of how these sensors play a serious role in contemporary technological and industrial landscapes.

Catalog

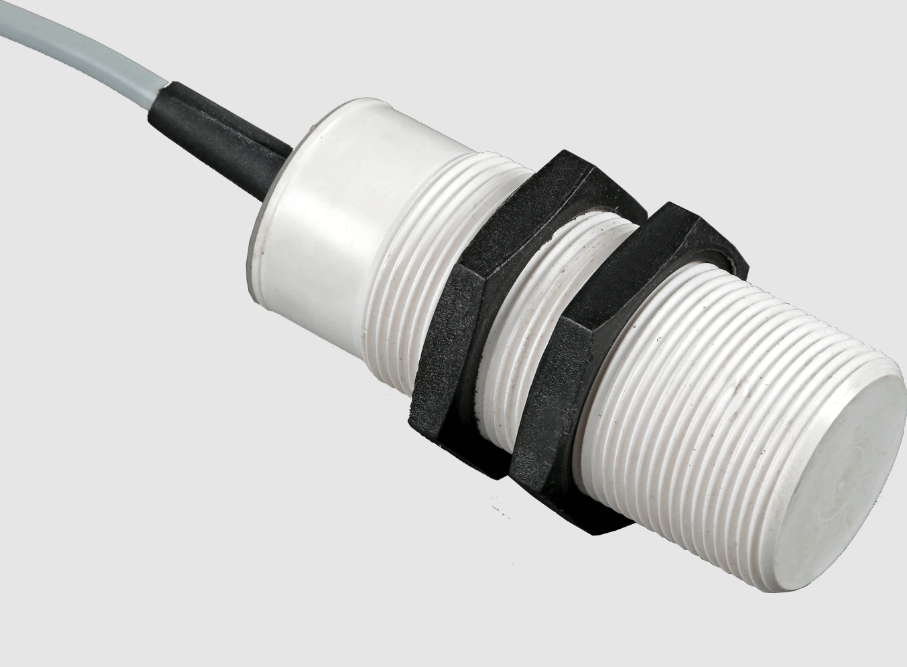

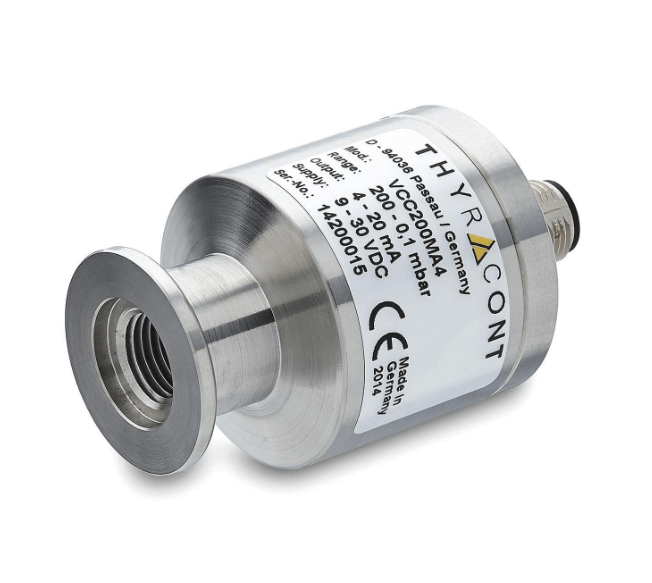

Figure 1: Pressure Sensor

Basics of Pressure Sensors

A Pressure Sensors is an advanced electronic device that detects and measures the pressure of gases or liquids. It then converts this pressure into an electrical signal. Different technologies are used in these sensors, each suited for specific situations, which we will explore further. Pressure sensors can handle a wide range of fluids and gases, regardless of their thickness. For tough environments involving materials like paper pulp, asphalt, crude oil, and some viscous foods, specially designed sensors ensure precise and reliable readings. This adaptability makes pressure sensors dynamic in many industries, offering customized solutions for accurate pressure monitoring in various applications.

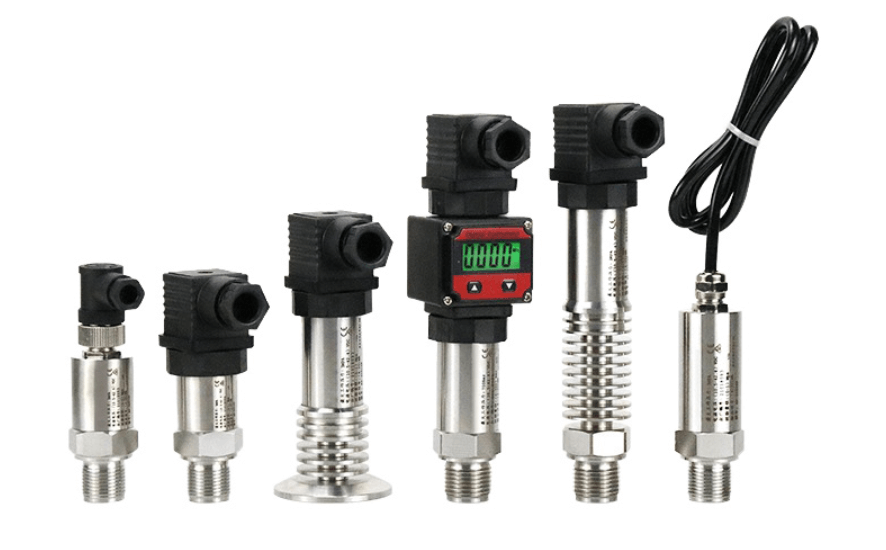

Figure 2: Types of Pressure Measurement

Exploring Different Types of Pressure Measurement Techniques

• Gauge pressure: is widely used in industrial settings. It measures pressure relative to the surrounding atmospheric pressure. A reading of zero on a gauge pressure device indicates that the measured pressure is equal to the atmospheric pressure, not a vacuum. This type of measurement is noteworthy for applications such as tire pressure, blood pressure monitoring, and HVAC systems, where the focus is on pressure values higher than atmospheric pressure.

• Absolute pressure: measures the total pressure exerted, including the atmospheric pressure. This type of measurement is taken relative to a perfect vacuum, which serves as the zero reference point. Absolute pressure sensors are influential in areas where atmospheric pressure changes can impact the process being monitored, such as meteorology, aviation, and space applications.

• Differential pressure: measures the pressure difference between two points within a system. This measurement helps determine how much pressure is lost or gained between two locations. It is unsafe in fluid dynamics for calculating flow rates, assessing filtering performance, and balancing pressure in systems.

• Vacuum pressure: measures pressures lower than the ambient atmospheric pressure. It is often expressed as a negative value or as a value less than atmospheric pressure. This type of measurement is useful in applications like vacuum packaging, where maintaining a specific vacuum level is required to preserve the quality and longevity of packaged goods.

• Compound pressure gauges: measure both vacuum and positive pressure. They provide readings that can fall below and above atmospheric pressure, effectively combining gauge and vacuum pressure measurements. This type of measurement is particularly useful in systems like refrigeration and applications involving suction, where pressures can vary above and below atmospheric levels.

Technologies Behind Pressure Measurement

The field of pressure measurement utilizes various sophisticated technologies, each designed for specific needs and environments.

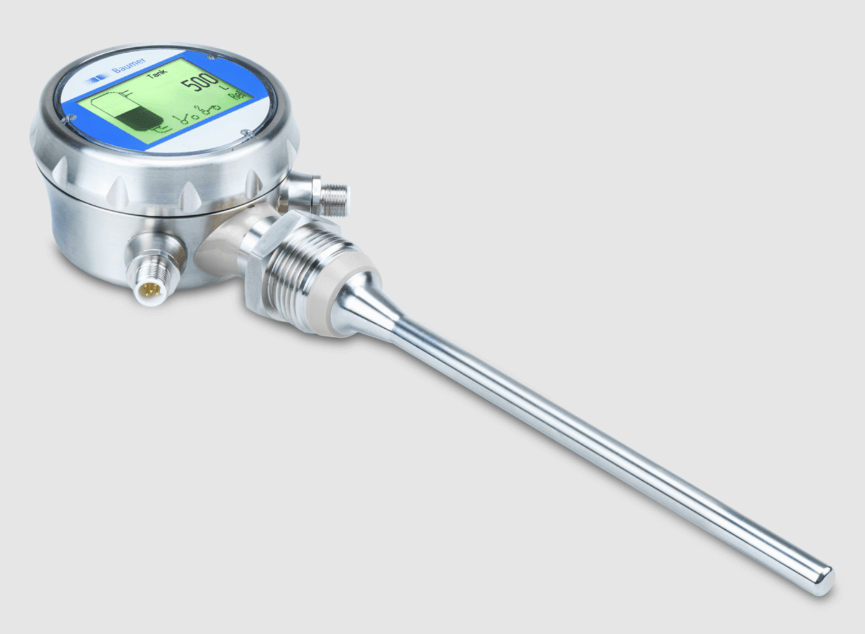

Figure 3: Potentiometric Sensors

Potentiometric pressure sensors operate by moving a wiper across a resistive element as pressure changes. This movement modifies the electrical resistance, which is measured and converted into a pressure reading. Known for their simplicity and cost-effectiveness, these sensors are used in applications such as automotive and industrial processes where high resolution is not insistent.

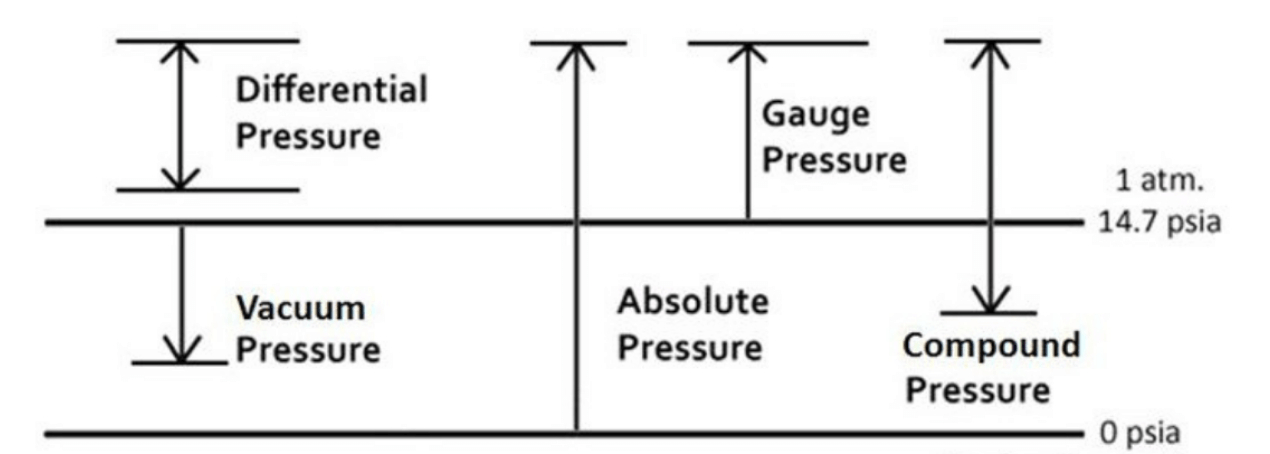

Figure 4: Strain Gauge Sensors

Strain gauge sensors detect pressure by measuring the deformation of a conductive material. When the material deforms under pressure, its electrical resistance changes. These changes are calibrated to specific pressure values. Strain gauges are highly accurate and reliable, making them popular in mechanical engineering, aerospace, and biomedical fields.

Figure 5: Capacitive Sensors

Capacitive sensors measure pressure by detecting changes in capacitance caused by the variation in the spacing between two plates. These sensors are highly sensitive and suitable for applications where small pressure changes must be detected, such as in HVAC systems and environmental monitoring.

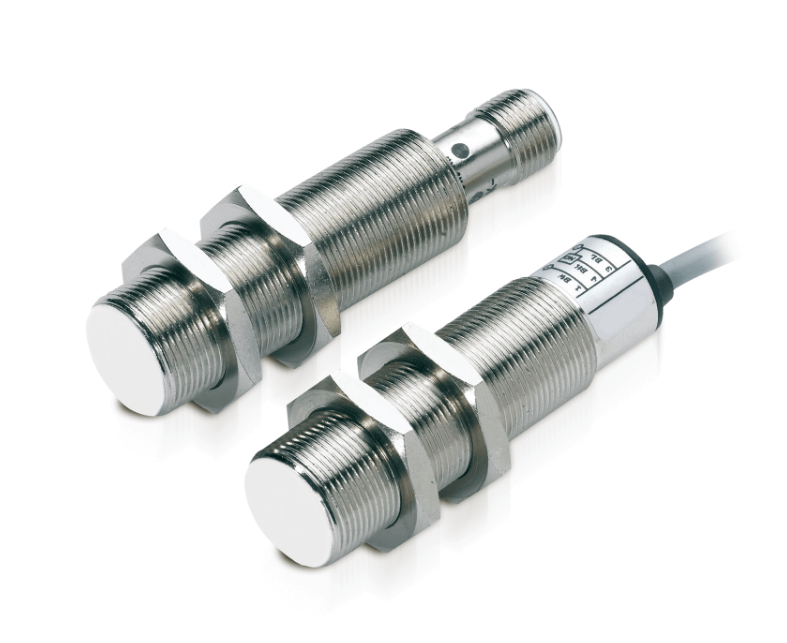

Figure 6: Inductive Sensors

Inductive pressure sensors work by detecting changes in inductance when a core moves within a coil under pressure. These sensors are robust against environmental factors like dust and moisture, making them ideal for harsh environments such as the oil and gas industry.

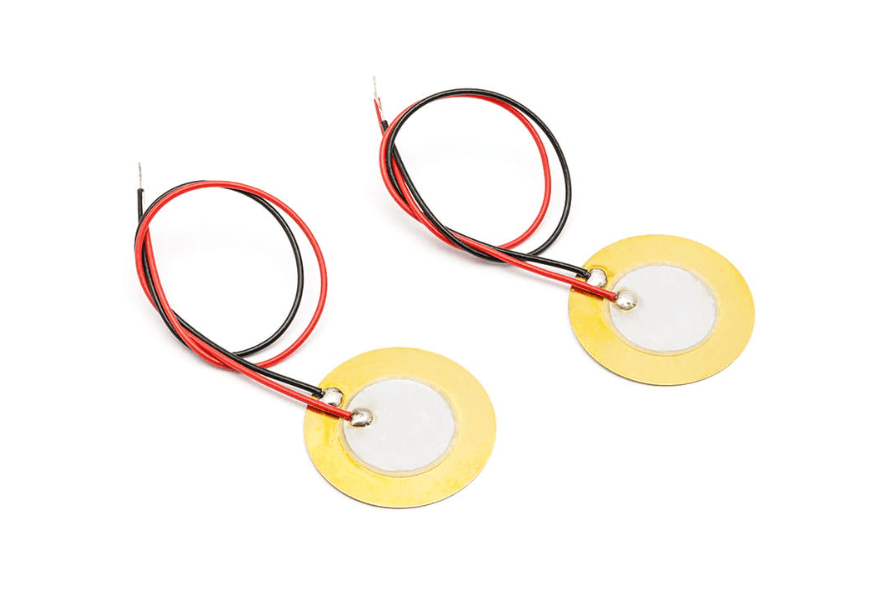

Figure 7: Piezoelectric Sensors

Piezoelectric sensors convert mechanical stress caused by pressure into an electrical charge. They are exceptionally useful in dynamic applications where rapid pressure changes occur, such as in combustion engines and shock wave measurements. These sensors are known for their high-speed response and excellent linearity over a wide range of pressures.

Figure 8: Piezoresistive Sensors

In piezoresistive sensors, pressure-induced stress changes the electrical resistance in a semiconductor material. These sensors are commonly used in consumer electronics, automotive systems, and medical devices due to their precision and small size.

Figure 9: Resonant Sensors

Resonant sensors measure pressure by detecting variations in the resonance frequency of a structure under pressure. These sensors are extremely accurate and used in applications where precision is somber, such as satellite and aerospace instrumentation.

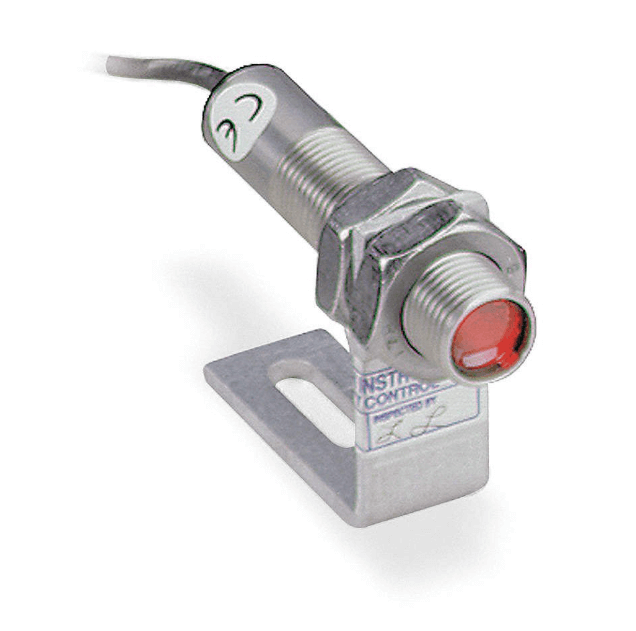

Figure 10: Optical Sensors

Optical pressure sensors use light modulation techniques to measure changes in optical properties due to pressure. This technology is advantageous in environments where electromagnetic interference or high temperatures might affect other types of sensors. Applications include undersea exploration, high-voltage equipment, and biomedical sensors where non-invasive measurement is settling.

Various Types of Pressure Sensors

Pressure sensors play a key role in many technological and industrial applications, providing useful data for monitoring and control systems.

Figure 11: Vacuum Sensors

Designed to measure pressures below atmospheric levels, vacuum sensors are dynamic in industries like semiconductor manufacturing, vacuum packaging, and scientific research. They ensure process stability and product quality by maintaining precise vacuum conditions.

Figure 12: Sealed Sensors

Sealed pressure sensors use a fixed reference pressure, typically sea-level atmospheric pressure, sealed within the sensor. They are ideal for applications requiring stable reference pressure for accurate measurements, such as laboratory environments or specialized industrial processes.

Figure 13: Vented Sensors

Also known as gauge sensors, vented sensors measure pressure relative to ambient atmospheric conditions. Common in meteorology, automotive systems, and aviation, these sensors adapt to fluctuations in barometric pressure, making them suitable for environments with changing conditions.

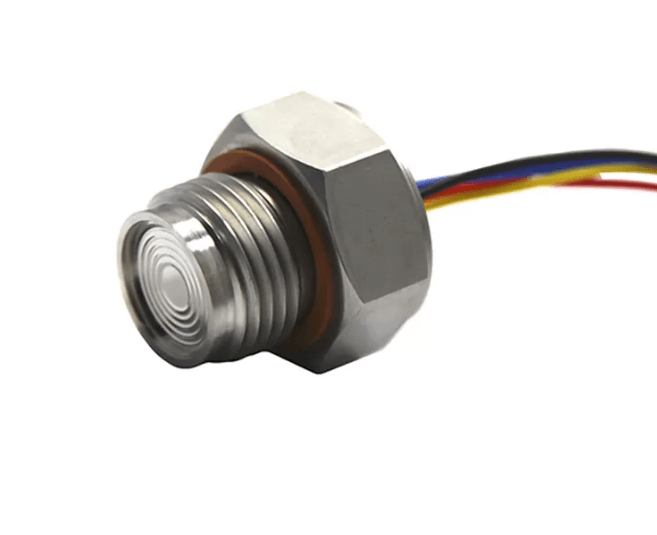

Figure 14: Diaphragm Sensors

Using a metal or polymer diaphragm that deforms under pressure, these sensors measure the degree of deformation to determine pressure. Diaphragm sensors are versatile, capable of measuring both liquids and gases, and are widely used in process industries, hydraulics, and medical devices.

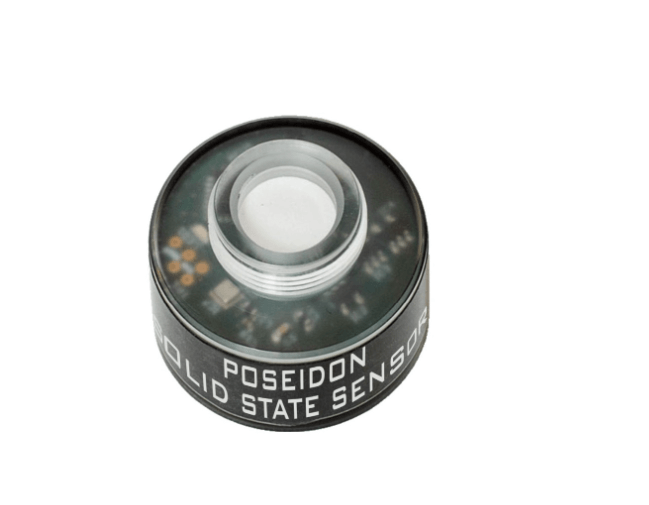

Figure 15: Solid State Sensors

Using microelectromechanical systems (MEMS) technology, solid-state sensors incorporate semiconductor materials to measure pressure. They offer robustness, high accuracy, and stability, making them suitable for electronic devices, medical equipment, and harsh environments like oil and gas exploration.

Figure 16: Thin Film Sensors

Featuring a thin film of resistive material that changes resistance under pressure, thin film sensors are highly accurate. They are used in applications where space is limited but precise pressure measurement is required, such as in automotive oil pressure sensors, industrial machinery, and aerospace components.

Design Aspects for Optimal Pressure Sensors

When designing a pressure sensor system, it's momentous to thoroughly evaluate various factors to make sure the sensor works reliably under expected conditions and meets the application's specific requirements.

|

Design Aspects for Optimal Pressure

Sensors |

|

|

Selecting the Right Type of Sensor |

Choosing the type of sensor is dominant

as it defines the technology and method used to measure pressure. This choice

influences how sensitive and accurate the sensor is, how quickly it responds,

and whether it's suitable for the medium it will monitor, like liquids,

gases, or corrosive substances. For example, piezoelectric sensors are often

used for quickly changing pressures, whereas capacitive sensors are preferred

for stable pressure conditions. |

|

Operating Pressure Range |

It's required that the sensor can

accurately measure the range of pressures it will likely encounter. Using a

sensor within its optimal range improves reliability and extends its

lifespan. |

|

Temperature Range |

Operating temperature is serious because

extreme temperatures can degrade the sensor's materials and electronics,

leading to inaccurate readings or even failures. Depending on the

environment, the sensor might need additional features for calibration or

temperature compensation. |

|

Maximum Pressure Tolerance |

The sensor should be able to handle

occasional spikes in pressure beyond its typical range without damage. This

capability is especially significant in systems like hydraulics where sudden

pressure increases are common. |

|

Output Signal Type and Level |

Ensuring that the sensor’s output signal

is compatible with other system components is dynamic for integration. The

nature of the output—whether analog or digital—determines how the sensor

connects with and communicates to control systems. Some setups may require

extra signal processing. |

|

Accuracy and Resolution |

Accuracy and resolution are particularly

significant in applications requiring precise measurements, such as in

medical or aerospace technology. Accuracy measures how closely the sensor's

readings match the true pressure levels, while resolution indicates the

smallest pressure change the sensor can detect. |

|

Supply Voltage |

The sensor's power requirements should

align with what's available in the application to avoid the need for extra

components to regulate power. This alignment is used in devices that are

portable or powered by batteries. |

|

Environmental Conditions |

Environmental factors—like humidity,

corrosive chemicals, dust, and physical impacts—can affect the sensor's

function. In tough environments, choosing sensors with high protection

ratings against water and dust, durable materials, and protective features

against shocks is required. |

Applications of Pressure Sensors in Today’s Industries

Pressure sensors are basic across many industries, enhancing safety, efficiency, and regulatory compliance.

Pipeline and Hydraulic Systems: Monitoring pressure to prevent failures and maintain system integrity.

Industrial and Scientific Processes: Using vacuum technology to support operations that require precise atmospheric control.

Environmental Monitoring: Utilized in weather stations for forecasting and in energy systems to optimize resource use.

High-Tech Manufacturing: Enables advanced production techniques where precise pressure measurement ensures quality and consistency.

Precision Engineering: Dynamic in fields that require meticulous control over environmental conditions and process parameters.

Pressure Sensor, Transducer, or Transmitter: The Difference

Analyzing the differences between pressure sensors, transducers, and transmitters is settling for choosing the right component for specific applications and ensuring seamless integration into electronic systems.

• Pressure Sensor: A pressure sensor is the primary component in a pressure measurement system. It detects physical pressure from gases or liquids and converts this force into an initial electrical signal. This low-level output directly correlates with the applied pressure. Pressure sensors are active in various applications, from automotive tire pressure monitoring to biomedical devices that measure blood pressure.

• Pressure Transducer: A pressure transducer takes the basic signal from the pressure sensor and converts it into a more usable form, typically a standardized electrical signal like voltage or current that varies proportionally with the pressure. This conversion makes it easier to integrate with electronic systems and data processing units. Transducers are often used in laboratory instruments, manufacturing processes, and other settings requiring precise electronic control and monitoring.

• Pressure Transmitter: A pressure transmitter processes the output from a pressure transducer, amplifying it to produce a stronger signal that can be transmitted over long distances without losing integrity or being affected by noise. This capability is especially valuable in industrial applications, such as petrochemical plants or water treatment facilities, where the monitoring equipment is far from the pressure measurement point. Pressure transmitters enable remote monitoring and control, making them useful, for large-scale and safety-perilous operations.

Conclusion

As explored in this detailed overview, pressure sensors are more than just components in a larger system; they are the keystones of modern industrial and scientific processes, ensuring precision, efficiency, and safety. The sophistication of these sensors, from potentiometric to optical types, allows them to operate across a spectrum of environments and applications—ranging from the vacuum of space to the depths of the ocean. Their adaptability is further exemplified by their use in various types of measurements like gauge, absolute, and differential pressures.

In addition, the distinction between pressure sensors, transducers, and transmitters highlights the tailored functionality that these devices offer to fit specific application needs. To sum up, the ongoing advancements in sensor technology and the broadening scope of their applications not only enhance their relevance but also underscore their requisite role in advancing industrial capabilities and scientific exploration.

Frequently Asked Questions [FAQ]

1. Why are pressure sensors significant?

Pressure sensors are influential because they enable the monitoring and control of pressure in various systems, which are used for safety, efficiency, and functionality. For example, in industrial processes, these sensors help maintain the correct pressure to ensure optimal performance and prevent equipment failure.

2. What is the function of a pressure sensor?

The primary function of a pressure sensor is to measure the pressure within an environment or system and convert it into an electrical signal that can be read by an instrument or controller. This allows for real-time monitoring and control of pressure levels, basic for various applications ranging from automotive to healthcare.

3. What is the importance of sensors in our daily life?

Sensors play a dynamic role in enhancing convenience, safety, and efficiency in everyday life. They are used in home security systems to detect intrusions, in smartphones for functionalities like screen orientation, and in healthcare devices to monitor vibrant signs.

4. What type of sensor is used to measure pressure?

There are several types of pressure sensors, each suited to different applications based on sensitivity, range, and environmental compatibility. Common types include piezoelectric pressure sensors, which are highly sensitive and used for dynamic changes, and strain-gauge sensors, which are robust and suited for static pressure measurements.

5. What are the advantages and benefits of using sensors?

Sensors offer numerous benefits including automation, precision, and efficiency. They reduce the need for human intervention, thereby minimizing errors and increasing safety. Sensors also enable the collection of precise data which can be used to optimize processes and predict maintenance needs, leading to cost savings and enhanced system longevity.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

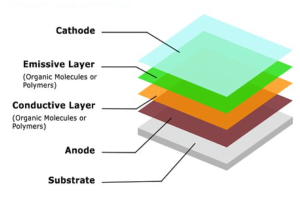

An In-Depth Exploration of Organic Light-Emitting Diode Technology

on August 8th

Learn to Solder: An In-Depth Guide

on August 7th

Popular Posts

-

What is GND in the circuit?

on January 1th 3086

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2660

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 14th 2179

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2175

-

Comparison Between DB9 and RS232

on January 1th 1799

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1772

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1725

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1667

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1664

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 14th 1615