An In-Depth Exploration of Organic Light-Emitting Diode Technology

In the rapidly evolving world of display technology, Organic Light-Emitting Diodes (OLEDs) represent a significant advancement over traditional display systems. This article digs into the intricate architecture and operational mechanics of OLEDs, highlighting their unique features through detailed descriptions of their composition, light emission processes, and various types. It explores the significant benefits OLEDs offer, such as superior color accuracy, flexibility, and energy efficiency, while also addressing their limitations, including sensitivity to moisture and higher power consumption under certain conditions.

In addition, the discussion extends to the cutting-edge innovations and prospects of OLED technology, encapsulating its transformative impact on modern electronic displays and potential applications in various industries.

Catalog

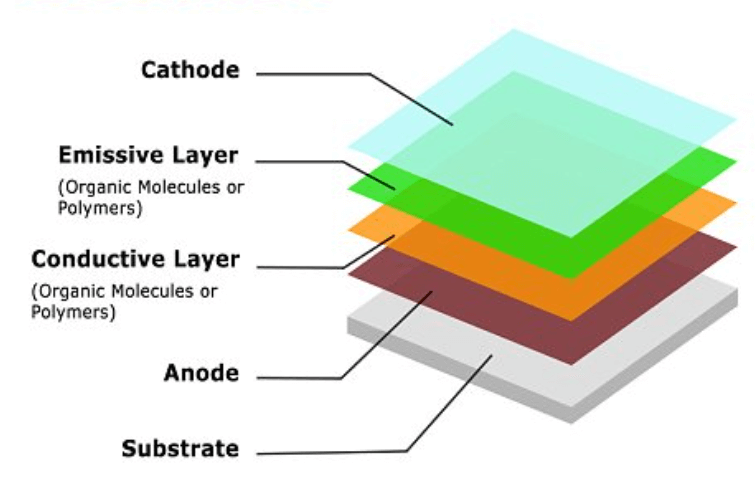

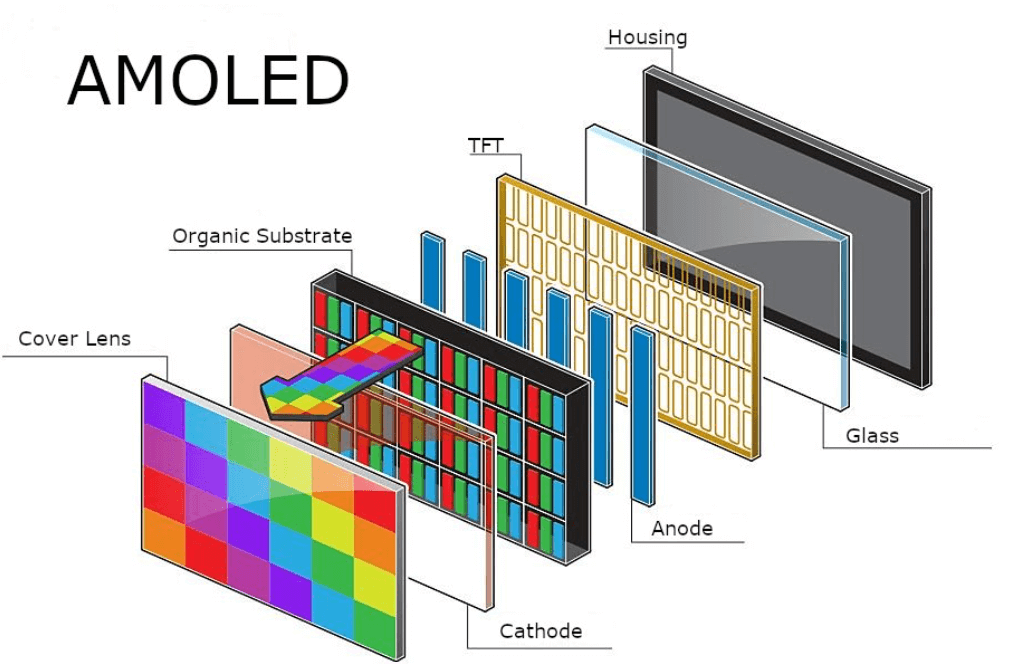

Figure 1: Composition of an OLED

Composition of an OLED

An Organic Light-Emitting Diode (OLED) is made up of multiple layers, each playing a dynamic role in its function. At the base is a glass substrate, which acts as a stable foundation. Above this is the anode, which is positively charged to attract and withdraw electrons from the next layer.

The conductive layer, located above the anode, is useful for transporting "holes" (the absence of electrons) upwards. This movement is used for the electrical flow within the device. Next is the emissive layer, made of organic molecules or polymers, which moves electrons downward from the cathode. This is where light is produced when electrons and holes recombine.

On top of the emissive layer is the cathode, which is negatively charged. The cathode injects electrons into the emissive layer, where they meet holes to create light. The design and materials of the cathode are noteworthy for the OLED’s efficiency and brightness. The entire structure is enclosed by another glass plate to protect the organic layers from moisture and oxygen, which can damage the materials and reduce the lifespan of the device. This sealing is settling for the durability and performance of the OLED.

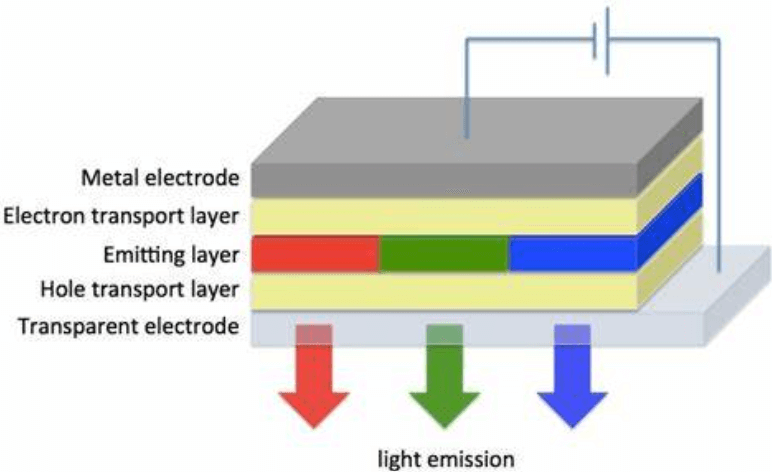

Figure 2: OLED Light Emission Process

OLED Light Emission Process

The light emission in an Organic Light-Emitting Diode (OLED) involves a precise series of steps that start when an electrical current is applied. This current activates the anode and cathode layers. At the anode, holes (positively charged spaces where electrons are missing) are injected into the conductive layer. Simultaneously, the cathode sends electrons into the emissive layer.

The heart of the light emission occurs in the emissive layer. Here, electrons meet the holes. When an electron fills a hole, it drops to a lower energy state, releasing energy as photons, which are particles of light. This efficient process, known as electroluminescence, produces bright and pure light without needing extra backlighting. OLEDs can emit light from organic materials, allowing for thinner and more flexible displays compared to traditional LEDs that need rigid backlight components. This flexibility enables innovative display designs, such as curved screens and foldable devices.

Each pixel in an OLED display lights up independently, allowing for precise image control. When a pixel needs to show black, it can be completely turned off rather than just dimmed. This capability enhances contrast and color vibrancy, making OLED screens ideal for high-definition visual applications where color accuracy and contrast are influential.

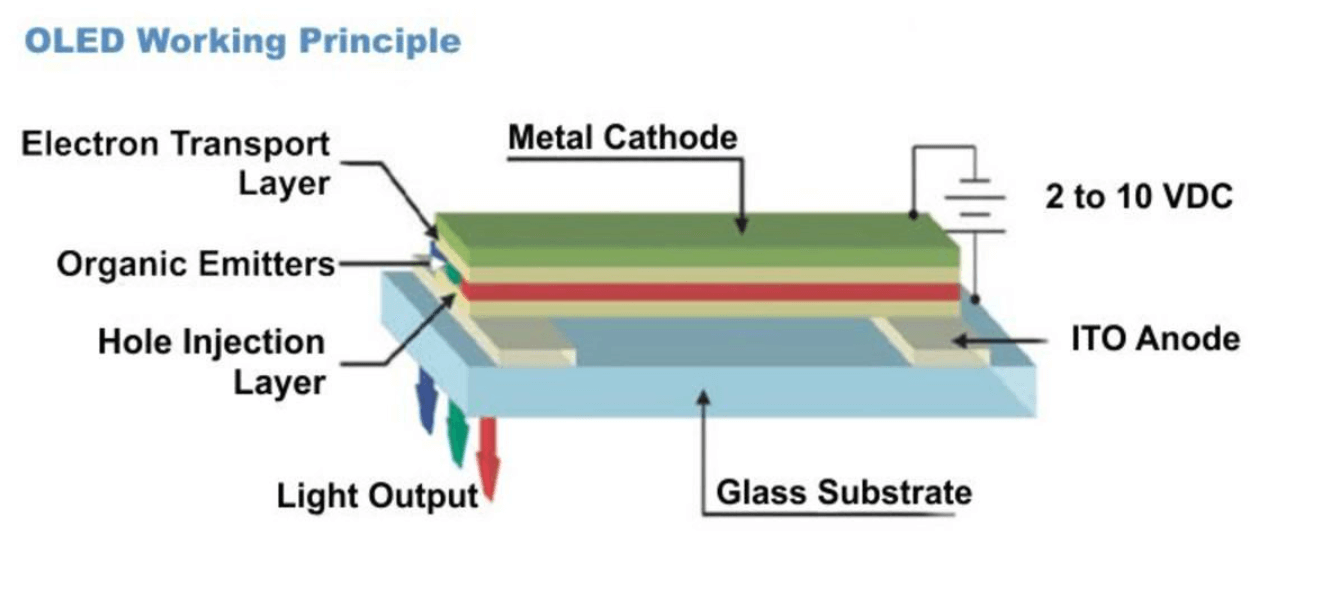

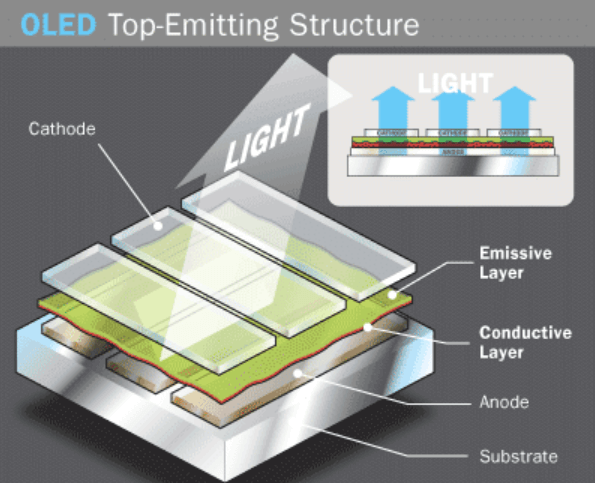

Figure 3: Operational Mechanics of an OLED

Operational Mechanics of an OLED

Organic Light-Emitting Diodes (OLEDs) are an advanced version of traditional diode technology, using organic compounds to emit light. An OLED is built from six specific layers, each playing a key role in its function. At the center of an OLED are the emissive and conductive layers, which contain organic materials. The emissive layer, next to the cathode, is where light is produced. It contains organic molecules that emit light when energized. The conductive layer, adjacent to the anode, transports holes (positively charged spaces) toward the emissive layer.

The outer layers are protective and consist of either glass or plastic. The bottom layer, or substrate, and the top layer, or seal, shield the internal components from environmental damage and physical stress, ensuring the display's durability and longevity. Surrounding the organic layers are the cathode and anode. The cathode injects electrons into the emissive layer, while the anode introduces holes into the conductive layer. When electrons and holes meet in the emissive layer, they create light through electroluminescence.

Varieties of OLEDs

OLED technology is highly adaptable, with different types designed for specific applications and needs.

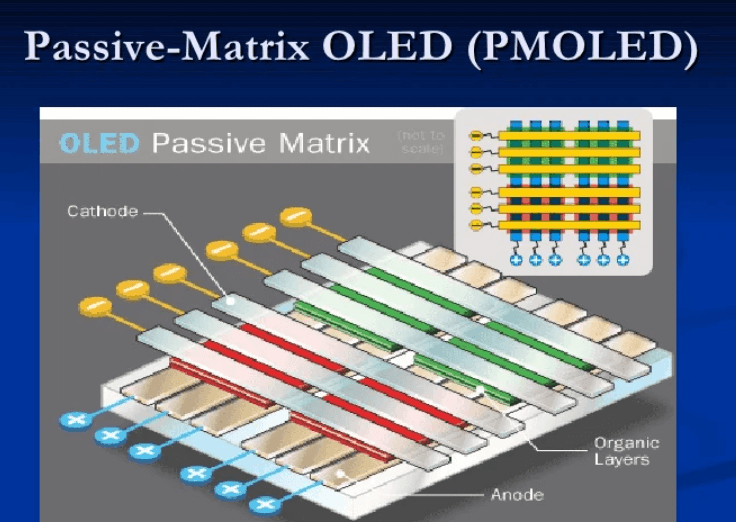

Figure 4: Passive-Matrix OLEDs (PMOLEDs)

PMOLEDs are best for smaller displays, like those in wearable devices. They operate by controlling each row or column in sequence. This simple control method is cost-effective but less power-efficient for larger screens.

Figure 5: Active-Matrix OLEDs (AMOLED)

AMOLEDs are ideal for larger, high-resolution displays, such as those in smartphones and TVs. Each pixel in an AMOLED is controlled by a thin-film transistor (TFT) array, allowing for faster response times and precise control over large screen areas. This results in rich, vibrant colors and deep blacks, enhancing the user experience in high-end electronics.

Figure 6: Transparent OLEDs

Transparent OLEDs offer visibility even when in use, making them perfect for augmented reality and heads-up displays in cars. When deactivated, they can be transparent, integrating seamlessly into windows and glass surfaces.

Figure 7: Top-Emitting OLEDs

Designed for situations where the substrate can't be transparent, top-emitting OLEDs emit light through the top layer. They're ideal for devices like smart cards, where the back of the display might be obstructed or needs to be reflective.

Figure 8: Foldable OLEDs

Using flexible organic materials, foldable OLEDs can endure repeated bending, making them perfect for modern mobile devices with foldable or curved screens. Their flexibility and durability address the weaknesses of traditional rigid displays.

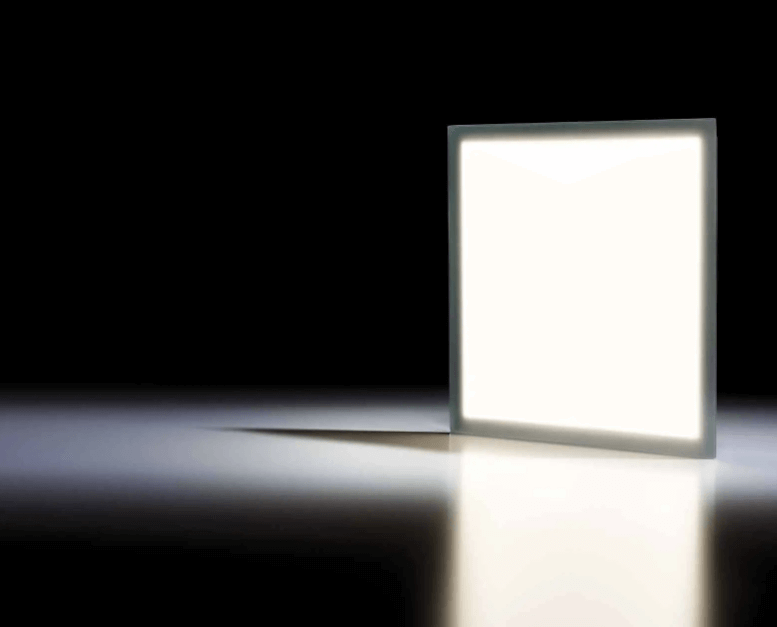

Figure 9: White OLEDs

White OLEDs emit bright white light by combining the light from multiple OLEDs or using a blue OLED with a yellow phosphor layer. This technology is becoming popular in the lighting industry as an energy-efficient alternative to traditional lighting, suitable for both home and commercial use.

Advantages and Limitations of OLED Technology

OLED technology offers impressive benefits but also faces certain limitations that affect its applications.

Advantages

OLED displays excel in color accuracy and can show true blacks. Each pixel emits its light, removing the need for a backlight. This ability to completely turn off pixels results in deep black levels and enhanced picture quality. Since each pixel emits light independently, OLED screens maintain consistent colors and brightness even from sharp angles. This makes them superior to traditional displays in terms of viewing experience. OLEDs are energy-efficient, particularly when displaying darker colors. Black pixels turn off completely, reducing power consumption. OLEDs have a quick response time, which is dynamic for the smooth rendering of fast-moving images. This makes them ideal for high-definition video playback and advanced gaming applications.

Limitations

OLEDs are vulnerable to moisture, which can significantly reduce their lifespan. This requires robust sealing and encapsulation to protect the organic materials from environmental damage. Displaying brighter colors consumes more power because it requires more electricity to maintain the brightness of each pixel. This can impact energy efficiency in certain conditions. Prolonged exposure to UV light can degrade the organic materials in OLEDs, leading to reduced brightness and color accuracy over time. This degradation affects the long-term durability of OLED displays.

Applications and Future Prospects of OLEDs

Since their introduction, OLEDs have transformed display technology, offering a compelling alternative to traditional LED and LCD screens. OLEDs are now integral to various high-end electronic devices, from large TVs and computer monitors to smartphones and wearable devices.

OLEDs are valued for their thin and lightweight design, basic for modern electronics. Their flexibility has enabled the creation of devices with foldable or curved screens, such as seamless foldable smartphones and curved TVs that enhance viewer immersion. OLED technology is increasingly used in dynamic advertising, offering vibrant displays that attract consumer attention more effectively than traditional signage. OLEDs are being integrated into electronic textiles, revolutionizing fashion with fabrics that can change color or pattern at the touch of a button.

The future of OLED technology is promising, driven by continuous advancements in materials and manufacturing. As production costs decrease, OLED displays are becoming more accessible, broadening their market reach and application scope. Future developments may include transparent displays for augmented reality systems and more durable screens for automotive use. The potential for OLEDs to revolutionize human interaction with digital displays is immense. Innovations like ultra-thin, rollable screens that can be stored when not in use and highly efficient, organically lit living spaces are within reach.

Innovations in OLED Design: Heterojunction and Graded Heterojunction OLEDs

Recent advancements in OLED technology have significantly improved efficiency and performance through heterojunction and graded heterojunction structures. These innovations enhance the quantum efficiency of OLEDs, which measures how effectively electrons are converted into photons, basically doubling the light output compared to traditional OLED designs.

Heterojunction OLEDs: Heterojunction OLEDs feature an interface between materials with different electronic properties, facilitating better charge carrier control. This structure manages the flow of electrons and holes more efficiently, directing them to the emissive zones where recombination is most effective. This precise recombination enhances overall brightness and color purity.

Graded Heterojunction OLEDs: Graded heterojunction OLEDs build on this concept by gradually varying the concentration of electron-transporting and hole-transporting materials across the emissive layer. This gradient smooths the transition of charge carriers into the emissive zone, optimizing their recombination rate and reducing energy losses. This improvement boosts light output and extends the device's lifespan by minimizing the degradation of organic materials.

Planar Heterojunction OLEDs: Advancements in planar heterojunction OLEDs focus on improving stability and longevity. New material blends optimize electron flow across junctions, enhancing light stability and brightness. These materials also ensure uniform light distribution across the display, preventing issues like burn-in and uneven aging.

The Development of Stacked OLEDs

Stacked OLEDs represent a breakthrough in display technology by layering multiple pixel structures vertically, unlike traditional displays that arrange pixels side-by-side on a single plane.

In stacked OLEDs, red, green, and blue sub-pixels are layered on top of each other. This vertical arrangement allows for improved color depth and fidelity. Each layer can be individually controlled, leading to a richer and more nuanced color palette. The vertical stacking reduces the gaps between pixels, known as the "screen door" effect, resulting in sharper and higher-resolution images. The multilayer setup saves physical space, reducing the area needed for each pixel. Aligning sub-pixels vertically also minimizes light wastage and enhances luminance, which is particularly beneficial in bright ambient light conditions.

The superior visual quality of stacked OLEDs is ideal for high-definition applications like advanced smartphones, high-end televisions, and professional monitors where color accuracy and image clarity are insistent. This technology is promising for virtual reality headsets and augmented reality devices, where high-resolution and color-rich displays enhance immersive experiences.

Conclusion

OLED technology, with its profound implications for the future of digital displays, stands at the forefront of a revolution in visual technology. The detailed examination of its structure, from the composition of its layers to the sophisticated light emission mechanism, underscores the significant strides made in enhancing display performance. Innovations such as heterojunction OLEDs and stacked OLEDs further exemplify the potential for greater efficiency and enhanced visual output.

Despite facing challenges such as environmental sensitivity and energy demands, the continuous advancements in material science and manufacturing forecast a bright future for OLEDs. This promising trajectory not only enhances the user experience across diverse applications but also paves the way for groundbreaking developments in electronics, advertising, and beyond. As OLED technology continues to evolve, it promises to redefine the paradigms of display technology, offering thinner, more flexible, and highly efficient alternatives to traditional displays.

Frequently Asked Questions [FAQ]

1. How does a light-emitting diode (LED) work?

A light-emitting diode (LED) works by passing an electrical current through a semiconductor material. When electrons in the semiconductor recombine with holes (empty spaces left by missing electrons), they release energy in the form of photons, which we see as light. The specific materials used in the semiconductor determine the color of the light emitted.

2. What is the working principle of OLED technology?

OLED, or Organic Light Emitting Diode technology, operates on a similar principle to traditional LEDs but uses organic materials (carbon-based compounds) as the semiconductor. When an electrical current is applied, these organic materials emit light. The organic layer is situated between two electrodes, at least one of which is transparent, allowing light to escape.

3. How are organic LEDs constructed?

To construct an OLED, manufacturers deposit thin layers of organic materials onto a substrate. These layers include a cathode (which injects electrons), an anode (which removes electrons), and emissive and conductive layers in between. The layers are often deposited via vacuum evaporation techniques and must be extremely thin and precisely controlled to function properly.

4. How do they make OLED screens?

OLED screens are made by placing thin films of organic materials between two conductors on a substrate and then sealing this arrangement in a protective enclosure to prevent damage from moisture or air. Each OLED pixel is created by patterning these materials to form red, green, and blue sub-pixels, which can be combined in various intensities to produce a full spectrum of colors. The manufacturing process requires precision and clean-room conditions, as the organic materials are sensitive to contaminants.

5. Why is OLED so expensive?

OLED technology is expensive due to several factors:

Material Cost: The organic materials used in OLEDs are complex and costly to synthesize.

Manufacturing Complexity: The process of depositing and patterning the organic layers requires high precision and sophisticated equipment, which are expensive to develop and operate.

Yield and Durability: The production of OLED screens has a lower yield compared to traditional LED screens; more units are defective and must be discarded. Additionally, OLEDs have a shorter lifespan and are more sensitive to water and air exposure, necessitating advanced encapsulation techniques that add to the cost.