Exploring Piezoelectric Materials: Types, Properties, and Technological Impact

Over the years, advances in material science have created different piezoelectric materials such as single crystals, ceramics, and thin films. This article takes a close look at piezoelectric materials including their properties, types, how they work, and their uses. It highlights their importance in linking mechanical and electrical engineering, driving innovation in many areas.

Catalog

Figure 1: Piezoelectric Material

What Is Piezo?

The word "piezo" comes from the Greek word "piezein," means "to press" or "pressure." This fits well with its use in science for piezoelectricity. In 1880, French physicists Jacques and Pierre Curie discovered piezoelectricity. They found that when certain crystals like tourmaline, quartz, topaz, and Rochelle salt, were pressed, they produced an electrical charge. They also saw that these crystals could change shape when an electrical current was applied showing that the process could work both ways.

This discovery led to the creation of various piezoelectric devices. During World War I, piezoelectricity was mainly used in ultrasonic submarine detectors. Today, piezoelectric materials are used in many things. They are found in everyday items like electric cigarette lighters and inkjet printers, as well as in advanced technologies like medical ultrasound imaging and precision motion control in robotics.

Types of Piezoelectric Materials

Figure 2: Examples of Piezoelectric Materials

Single Crystal Piezoelectric Materials

Single crystal piezoelectric materials are characterized by their continuous and uniform crystal lattice, free from grain boundaries. This uniform structure often leads to better electromechanical coupling efficiencies compared to other piezoelectric materials. Examples of such materials include quartz and langasite. These single crystals are produced using precise growth methods like the Czochralski process or hydrothermal synthesis. Their exceptional performance makes them perfect for precise applications like advanced medical imaging systems, telecommunications resonators and filters, and vibration monitoring in aerospace.

Figure 3: Piezo Crystal Quartz Material

Ceramic Piezoelectric Materials

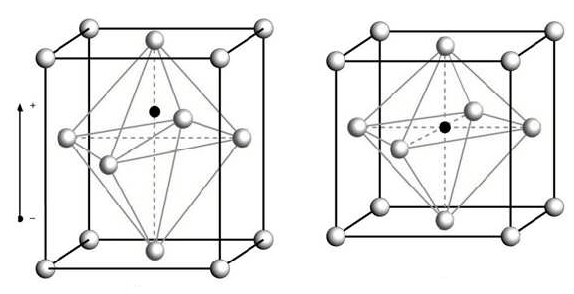

Piezoelectric ceramics are made from perovskite-structured materials like lead zirconate titanate (PZT). These materials are polycrystalline and are created by sintering powdered substances. Their piezoelectric properties are developed through a poling process and aligns the electric dipoles by applying an external electric field. These ceramics can be easily shaped into various forms and sizes. Their durability and cost-effectiveness make them popular for use in actuators, sensors, ultrasonic transducers, and consumer electronics buzzers.

Figure 4: Structure of PZT Type Piezoelectric Ceramic

Thin Film Piezoelectric Materials

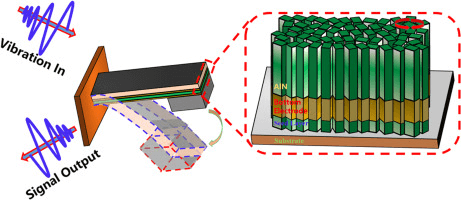

Thin film piezoelectrics are made by depositing layers that range from a few nanometers to several micrometers in thickness using advanced fabrication techniques like sputtering, chemical vapor deposition or pulsed laser deposition. Common materials used in thin films include PZT, zinc oxide (ZnO), and aluminum nitride (AlN). The thinness of these films allows them to be integrated into microelectromechanical systems (MEMS) and nanoelectromechanical systems (NEMS), enhancing their functionality in compact devices such as microphones, microswitches and advanced sensor arrays. Their compatibility with standard semiconductor processes and scalability makes them suitable for integrated circuits and flexible electronics.

Figure 5: AlN Piezoelectric Thin Films

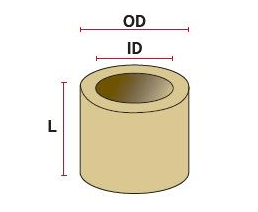

Figure 6: Bulk Piezo Elements

Choosing between thin-film and bulk piezoelectric materials depends on the application's specific needs for precision, power and durability. Thin-film piezo materials are suited in small-scale technologies. In contrast, bulk piezo materials are preferred in more demanding, larger-scale applications. The table below compares thin-film piezo materials and bulk piezo materials based on their thickness, manufacturing techniques, key features and applications.

|

Category |

Thin-Film Piezo Materials |

Bulk Piezo Materials |

|

Thickness |

A few nanometers to several micrometers |

Several millimeters to centimeters |

|

Manufacturing Techniques |

Sputtering, pulsed laser deposition,

chemical vapor deposition |

Pressing, extrusion, machining |

|

Features |

High-Frequency Response: Quick response

times |

High Power Generation: Produces power

under mechanical stress |

|

Flexibility: Applicable to flexible

surfaces |

Durability: Strong and durable, suitable

for heavy loads and harsh conditions |

|

|

Precision: Precise control on a

microscopic level |

Versatility: Easily shaped and sized for

specific needs |

|

|

Applications |

Microelectronics and MEMS:

Accelerometers, gyroscopes, inkjet printer heads |

Energy Harvesting: Converts mechanical

stress from vibrations into electrical energy |

|

Medical Devices: Ultrasonic transducers

for imaging and therapy |

Actuators and Sensors: Large actuators in

automotive and aerospace industries, high-load sensors |

|

|

Telecommunications: Filters and

resonators in mobile phones and communication devices |

Sonar and Ultrasonic Devices: Sonar

systems for naval use, industrial ultrasonic cleaners |

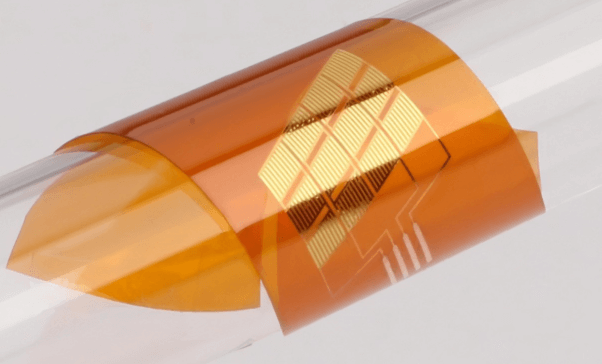

Thin-Film PZT and Deposition Methods

Thin-film lead zirconate titanate (PZT) materials are used in sensors, actuators, and microelectromechanical systems (MEMS) because of their great piezoelectric properties. The composition and effectiveness of PZT thin films depend a lot on their deposition methods that may affect their structure, orientation, and piezoelectric performance. The three main deposition techniques: sol-gel, sputtering, and Metal Organic Chemical Vapor Deposition (MOCVD).

Figure 7: Flexible Thin-Film PZT

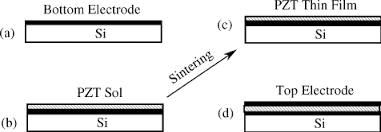

Sol-Gel Process

The sol-gel process is a cost-effective way to deposit PZT thin films and allowing control over film composition at the molecular level. This technique starts with preparing a colloidal solution (sol) that turns into a gel. Important steps include hydrolyzing and polymerizing metal alkoxides. The resulting gel is applied to a substrate using spin coating or dip-coating, followed by heat treatment to remove organic components and crystallize the PZT phase.

Figure 8: Sol-Gel Process for PZT Thin Films

Advantages

• Allows fine control over stoichiometry, improving piezoelectric properties

• Uses lower temperatures compared to other methods

Challenges

• It's hard to get consistent thickness and composition across large areas

• High shrinkage during drying and firing often causes cracks

Sputtering

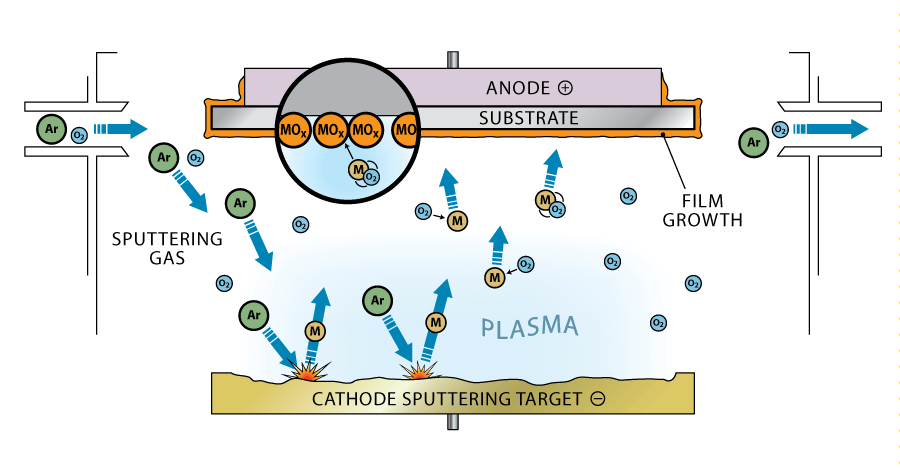

Sputtering is a physical vapor deposition (PVD) technique where high-energy particles knock material off a target then deposits onto a substrate. For PZT films, RF magnetron sputtering is used involving a plasma of argon ions hitting the PZT target.

Figure 9: Sputter Deposition Method of Thin-Film Deposition

Advantages

• Produces films with good adhesion and density

• Suitable for coating large substrates uniformly

Challenges

• Stress can build up in the films affecting their properties

• The target's composition may change during sputtering due to differential sputtering yields

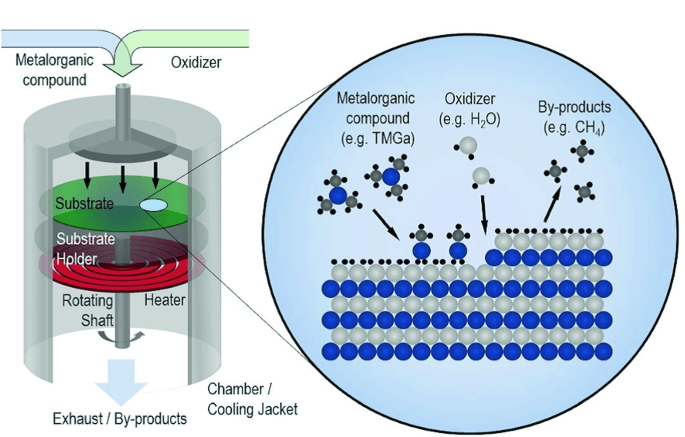

Metal Organic Chemical Vapor Deposition (MOCVD)

MOCVD involves decomposing metal-organic precursors in a vapor phase and react or decompose on a heated substrate to form a thin film. This method is preferred for producing high-purity, well-crystallized films suitable for electronic applications.

Advantages

• Provides excellent film uniformity and conformity even on complex-shaped substrates

• Good for high-volume production

Challenges

• Requires higher temperatures than other methods

• Handling and storage of metal-organic precursors can be hazardous

Figure 10: Metal Organic Chemical Vapor Deposition

How Materials Act Under Stress

Behavior Under Compression

When materials like quartz or barium titanate are squeezed, they change in ways that impact their use in various devices. These materials have special structures that create electrical charges when they are pressed. As they are compressed, they shrink and their internal structure changes.

This squeezing causes the electrical charges inside the crystal to become unevenly distributed. The pressure moves ions in the crystal's structure, creating an electric field. This happens because the positive and negative charge centers in the material shift. The amount of electrical response depends on the type of crystal, the force applied and the crystal's direction relative to the force.

For example, in sensors, the voltage produced by the crystals can measure the force applied making them perfect for detecting pressure and monitoring loads. In actuators, applying an electrical field can make the crystal change shape, allowing precise control of movements in things like ultrasonic devices and car fuel injectors.

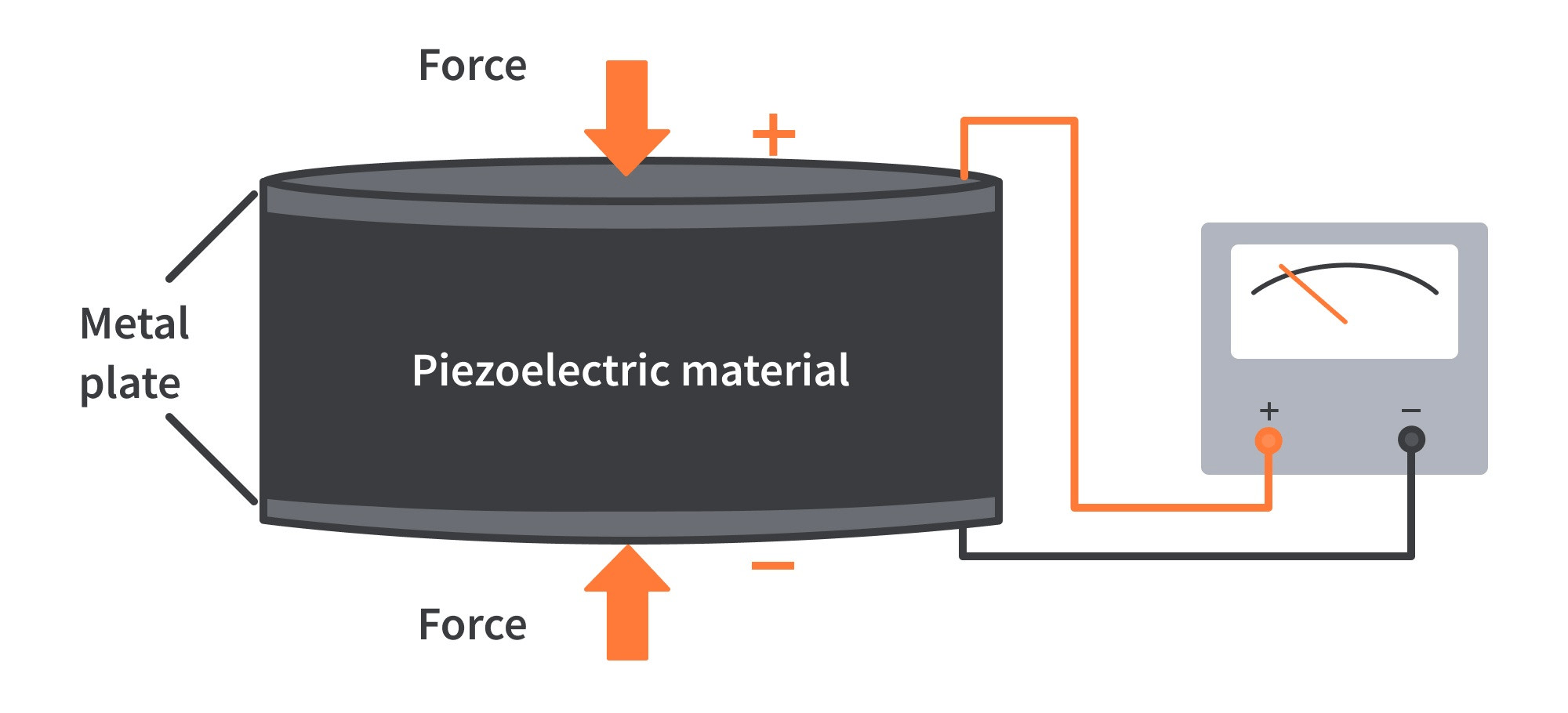

Figure 11: Piezoelectric Materials Works

Piezoelectric Response to Pressure

When piezoelectric materials face mechanical pressure, their molecules realign, affecting their electrical properties. The force changes the molecular structure, aligning regions with uniform electrical direction, increases electrical polarization.

This alignment boosts the charge separation in the material, enhancing its electrical polarization. In simple terms, the pressure makes the dipoles (molecules with two opposite charges) more uniform, creating a stronger electric field for a given force.

The ability to control this response accurately under different pressures makes piezoelectric materials very useful in many technologies. Their capability to convert mechanical pressure into electrical signals and vice versa allows them to be used effectively in tasks like generating precise electronic frequencies and monitoring vibrations in industrial settings.

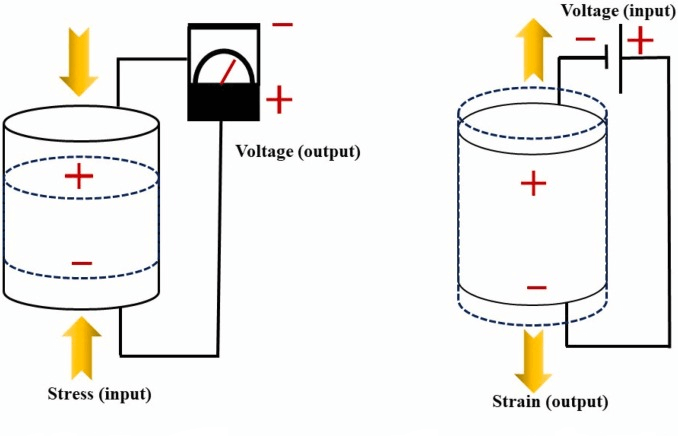

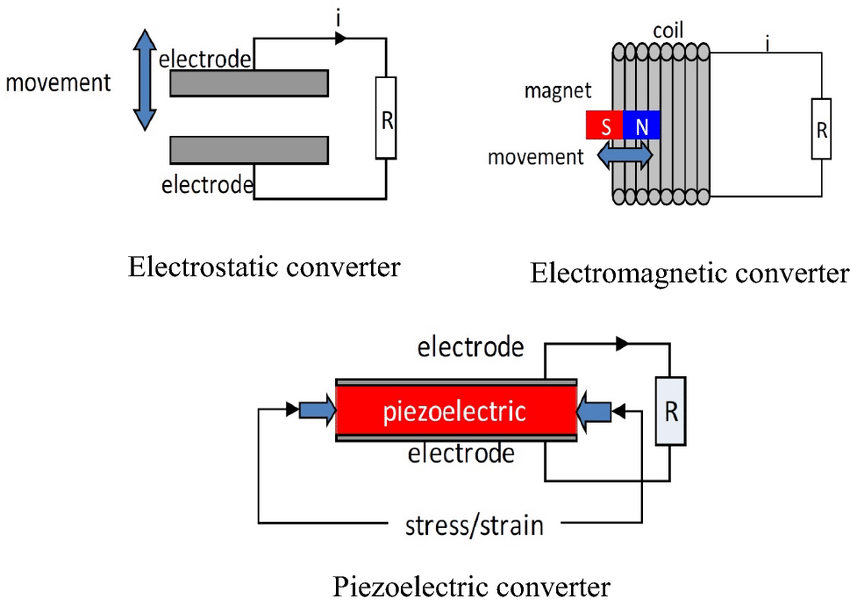

The Piezoelectric Effect

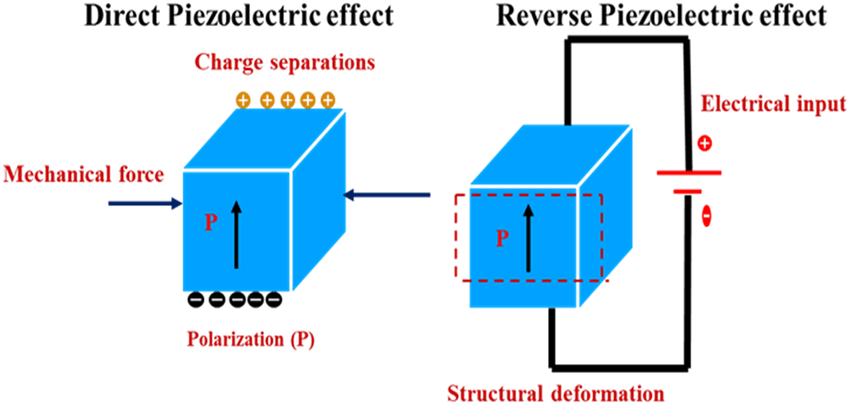

Figure 12: The Piezoelectric Effect

Turning Mechanical Energy into Electrical Energy with the Piezoelectric Effect

The piezoelectric effect changes mechanical energy into electrical energy by deforming certain crystal materials. These materials, known as piezoelectrics include natural substances like quartz and synthetic ones like advanced ceramics.

When a piezoelectric material faces mechanical stress such as being squeezed, twisted, or bent, its crystal structure, doesn't have a central symmetry and gets disturbed. This disturbance shifts the charge centers in the crystal causing polarization and creating an electrical potential at certain points in the material.

Key points of this process:

The electrical charge produced matches the amount of mechanical stress applied. This means the electrical output can be precisely controlled based on the known force applied;

When the force is removed, the material returns to its original state and the electrical charge goes away. This ensures the material's durability and reliability good for devices that need to work well repeatedly.

Turning Electrical Energy into Mechanical Energy with the Reverse Piezoelectric Effect

The reverse piezoelectric effect changes electrical energy back into mechanical energy. Applying an electrical voltage to a piezoelectric material creates an electric field that changes the crystal lattice structure, altering the material's dimensions.

This effect is used in precision actuators in optical instruments and micro-positioning systems. The reverse piezoelectric effect ensures that small electrical inputs result in precise, controlled mechanical adjustments, helping advancements in robotics, automotive technology, medical instruments, and telecommunications.

The dual ability of the piezoelectric effect to act as both a mechanical-to-electrical and electrical-to-mechanical transducer supports technological advancements. It connects the mechanical and electrical domains, expanding modern engineering and innovation.

Figure 13: Direct and Reverse Piezoelectric Effect

Comparing Non-Piezoelectric and Piezoelectric Materials

Non-piezoelectric and piezoelectric materials are different in how they handle mechanical and electrical energy. Non-piezoelectric materials like steel and aluminum can conduct electricity but don't create an electric charge when stressed. Piezoelectric materials, such as quartz and certain ceramics, can change mechanical energy into electrical energy because of their special crystal structure.

Non-piezoelectric materials have symmetrical crystal lattices, so they don't produce an electric dipole when stressed. Piezoelectric materials have asymmetrical crystal lattices, that allows them to generate an electric charge when under stress. This deformation causes internal polarization and creating electrical potential.

Non-piezoelectric materials behave like regular conductors or insulators based on their electron mobility and band structure and they don't create an electric charge when deformed. Piezoelectric materials exhibit two effects: the direct piezoelectric effect, where mechanical stress generates an electric charge, and the inverse piezoelectric effect, where an electric field causes mechanical deformation. These characteristics make piezoelectric materials suitable for use in sensors and actuators.

Due to their different properties, non-piezoelectric and piezoelectric materials are used in different applications. Non-piezoelectric materials are used in structural components, electrical wiring, and standard electronic parts where strength and conductivity are important. Piezoelectric materials are utilized in fields that require precise control and mechanical-electrical energy conversion, such as ultrasound equipment, precision positioning devices, and various sensors and actuators good for advanced technologies.

Applications of Piezoelectricity

Consumer Electronics: In smartphones and other devices, piezoelectric parts are used in speakers and microphones. They turn electrical signals into sound vibrations or sound vibrations into electrical signals for audio input.

Automotive Industry: Modern cars use piezoelectric sensors for many purposes like controlling the fuel injection in engines and monitoring tire pressure.

Environmental Monitoring: Piezoelectric sensors detect pressure changes, vibrations, and sounds. They are used for checking environmental conditions and ensuring the safety of buildings and bridges.

Energy Harvesting: Piezoelectric materials can capture energy from mechanical stress. For example, floors that convert footsteps into electrical energy can power lights and electronics in busy areas, helping create sustainable environments.

High-Voltage Piezoelectric Lighters: These lighters used for lighting gas stoves and barbecues and create a high voltage from a small mechanical click, producing a spark to light the burner. This shows the practical use of piezoelectric materials.

Medical Imaging: Piezoelectric crystals are useful in ultrasound machines. They produce sound waves that bounce off tissues and organs, creating images for diagnosis.

Precision Actuators in Scientific Instruments: Piezoelectric materials in precision actuators create tiny movements for optics and nanotechnology. These actuators adjust mirrors, lenses, and other parts with microscopic accuracy for scientific research and semiconductor manufacturing.

Conclusion

Studying piezoelectric materials shows a strong connection between physics and engineering, demonstrating how their natural properties can be used for many technological purposes. The versatility of piezoelectric materials available as both strong bulk materials and flexible thin films, makes them suitable for various applications, such as energy harvesting, environmental monitoring, and developing sustainable technologies. As innovation continues, research and development in piezoelectric materials are more important, promising improvements in efficiency, precision, and functionality for future technologies.

Frequently Asked Questions [FAQ]

1. What causes electricity to be produced from piezoelectric effect?

The piezoelectric effect occurs when certain materials produce an electric charge in response to mechanical stress. These materials, a crystals like quartz, ceramics like barium titanate and some polymers, possess a crystal lattice structure that is non-centrosymmetric, meaning it lacks a center of symmetry. When mechanical force such as pressure or vibration is applied, this structure becomes distorted. This distortion displaces the ions within the lattice, creating areas with positive and negative charges. The spatial separation of these charges results in an electric potential generating electricity. This effect is reversible and applying an electric field to these materials will also induce mechanical stress.

2. What device uses the piezoelectric effect?

Devices that utilize the piezoelectric effect are varied and include both everyday and specialized equipment. Common applications are:

Quartz watches: Using the regular vibrations of quartz under an electric field to keep time accurately.

Medical ultrasound devices: Generating sound waves that echo inside the body to create diagnostic images.

Fuel injectors in cars: Using piezoelectric actuators to control the timing and amount of fuel injected into the engine cylinders.

Piezoelectric sensors and accelerometers: Measuring changes in pressure, acceleration, strain, or force by converting them into an electrical signal.

3. How many volts is a piezo?

The voltage output of a piezoelectric element can vary widely depending on its size, material, and the amount of mechanical stress applied. A small piezo element like those found in lighters or electronic devices can produce a voltage spike ranging from a few volts to several hundred volts. However, these outputs are generally at very low currents and last only microseconds.

4. Does a piezo need a resistor?

In many applications, a resistor is used with a piezoelectric element to limit the current and protect other components in the circuit from the high voltage spike produced when the piezo is activated. The value of the resistor depends on the specific requirements of the circuit including the desired response time and sensitivity. Without a resistor, the piezo can potentially damage connected electronic components due to the high initial voltage spike.

5. How is piezoelectric related to human power?

The piezoelectric effect is directly applicable to harnessing human power in innovative ways. It can convert mechanical energy from human activities, such as walking or pressing buttons, into electrical energy. This technology is explored in various applications:

Energy-harvesting floor tiles: These tiles generate electricity from the pressure of footfalls in busy areas like subway stations or malls.

Wearable technology: Embedding piezoelectric materials in shoes or clothing to generate power for small devices through normal body movements.

Medical implants: Using body movements to power devices like pacemakers, reducing or eliminating the need for external batteries.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

Comprehensive Guide to Wrist Watch Battery Replacement

on July 26th

D Battery Vs. C Battery

on July 26th

Popular Posts

-

What is GND in the circuit?

on January 1th 3173

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2748

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 18th 2414

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2216

-

Comparison Between DB9 and RS232

on January 1th 1836

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1808

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1763

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1733

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1724

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 18th 1706