Electronic Soldering Basics and Techniques

In our era, marked by swift technological leaps, electronic welding emerges as a key player in connecting electronic components. It's a blend of precise knowledge—of both materials and processes—and skillful operation, underpinned by an intimate understanding of material traits. Soldering, a fine art within this realm, joins metal parts with precision. It uses alloys with a low melting point to create connections: strong, and safe. The complexity, at first glance, may overwhelm. But, delve into the basics, and practice, and soon, anyone with an interest in electronics manufacturing unravels this technology's mysteries.

This article delves deeply into electronic soldering. It explores its uses, necessary tools, fundamental principles, and varied technological applications. It's a comprehensive beginner's guide. Electronic welding, precise and nuanced, melds separate metal parts with specific alloys. This necessitates not only skill but also a deep understanding: of melting points, alloy composition, and compatibility with the work metal. Done right, it guarantees a stable, safe electrical link. Complex? Initially, yes. However, mastery of the essentials and hands-on experience simplifies it. Further exploration of the advanced content in the official guide unveils the welding process's various standards and complexities.

Welding, more than a cornerstone in electronic manufacturing, plays a role in diverse fields. In stained glass, it secures and joins glass pieces. In jewelry, it precisely fuses metal. In construction, it connects copper pipes, ensuring sealed, safe water and gas lines. This article, however, zeroes in on electronic soldering. This is a precision technology, especially for small electronic device manufacturing.

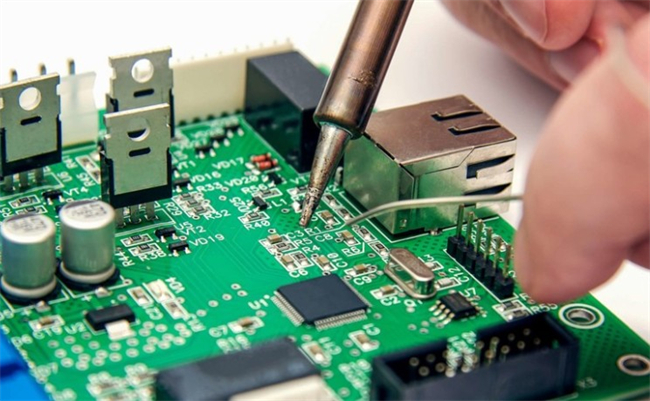

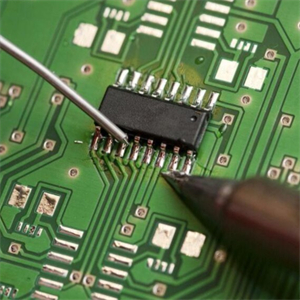

Soldering electronics, a precise art, starts with the basics: a soldering iron, solder, wire strippers, a flat cutter, pliers, and, importantly, eye protection. Then, there's the workholding fixture, often called a 'third hand,' essential for stabilizing the workpiece. A multimeter, too, becomes crucial for testing connection integrity and electrical characteristics. Heat shrink tubing and a heat gun (or a lighter) are employed for post-welding treatment and protection. Complex tasks? A solder wick or desoldering pump might be indispensable, especially for correcting soldering errors.

Soldering's core principle revolves around using heat. This causes the solder to flow between two parts, creating a connection. Proper heating makes the solder flow naturally over the heated component, resulting in a bright, strong connection, often with a concave structure between components. When dealing with components facing significant forces, wrapping the wire or component mechanically before welding enhances structural strength.

The market offers various electrical solders. Rosin core solder, whether lead or lead-free, is ideal for most electronic applications. During welding, the flux in the solder is key, creating an oxidation-resistant environment for the metal connection when boiling. Post-soldering, remember: residual flux might need cleaning. It could affect appearance and lead to moisture absorption, potentially causing corrosion of components and PCBs. Conversely, rosin-core solder and "no-clean" solder simplify the process.

Tin plating components before starting is a useful pre-processing step, especially with stranded wire. This tinning involves pre-applying a thin solder layer, aiding in maintaining the structure and stability of the stranded wire during soldering. When heated, these pre-coated solders melt again, allowing for a more even solder flow and a stronger, more reliable connection. Tin plating not only enhances the welding effect but also minimizes the risk of electrical failures due to poor welding.

For beginners, starting with a simple LED and battery circuit is an excellent learning exercise. Such projects help grasp basic electrical connections and circuit design while offering a safe practice environment. As skills progress, more complex projects await, like transferring a breadboard circuit to a prototype board. This practice hones soldering skills and deepens the understanding of electronic component layout and circuit design.

Ensuring adequate heating stands as the most critical aspect of the welding process. Often, soldering woes trace back to insufficient heat, resulting in unstable, weak solder joints. If the hot solder meets an underheated component, rapid cooling ensues. This causes an oxide layer to form, compromising the solder joint's quality. Such scenarios, leading to the dreaded "cold welding," can be remedied by reheating the joint. Proper reheating ensures uniformity and stability throughout the melting and solidification process.

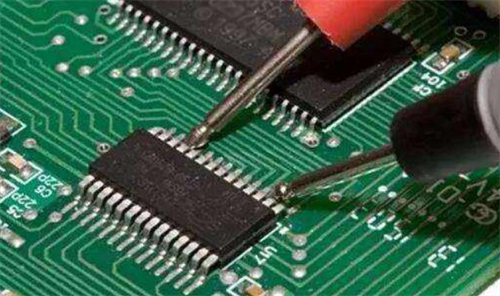

Sometimes, during soldering, connections need reworking. This involves reheating the joint and using a solder extractor to remove excess solder. Another crucial step is using a multimeter's continuity test function to verify the soldered connection's correctness. An unresponsive multimeter during testing often signals a solder joint issue, like cold soldering, insufficient solder, or other connection problems.

Heat shrink tubing is key for protecting completed solder joints, effectively preventing electrical shorts. When heated, it shrinks, enveloping the joint in a protective layer. This not only isolates the joint from other conductors but also shields it from damage due to vibrations or external pressure. For splicing multi-wire cables, employing heat shrink tubes of varying sizes is beneficial. It protects each joint individually and aids in maintaining wire organization and tidiness.

Mastering basic wire-to-wire soldering skills is just the beginning. Next, try soldering wires onto a circuit board, a surefire way to sharpen your abilities. Remember, as components shrink, the challenge of hand soldering grows. For surface mount components (SMT), the norm is automation: solder paste applied with stencils, parts placed by pick-and-place machines, and a reflow oven to finalize the process. Larger through-hole components, however, might still demand hand soldering, even when wave soldering machines are in play, to ensure connection quality and reliability.

Disassembling SMT? Use a hot air rework station. This is particularly effective with small, hard-to-reach pads. The station's precisely controlled hot air flow directly heats specific areas, melting solder joints locally. This facilitates easy removal or repositioning of SMT components. This technique, advanced and nuanced, requires a deep understanding of temperature control. It's a skill set to explore after mastering the basics.

In essence, electronic soldering spans a vast array of applications and demands meticulous skills. Its importance is undeniable, both in electronics manufacturing and in everyday life. From choosing the right tools to mastering intricate soldering techniques, from simple circuit board tasks to advanced SMT removal, each step is a dance of precision and detail. As technology evolves, so do the methods and applications of electronic soldering, opening a world of endless possibilities for those dedicated to learning this craft. Whether a professional or hobbyist, mastering electronic soldering is a key to unlocking the vast, intricate world of electronics.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

→ Previous

An operational amplifier, at its core, is a high-performance voltage amplifier, integral to a myriad of electronic systems. This device pivots on a design philosophy that leverages inductors, capacitors, and resistors. These components intertwine in a dance of sophistication, orchestrating voltage g...

As a fundamental yet crucial element in the realm of electronic components, the potentiometer stands out. Its unique working principle and expansive application spectrum render it an essential in both designing and maintaining electronic equipment. Delving into the nuances of its principle, function...

→ Next

Operational Amplifiers: Inverting Vs Non-Inverting Topologies

on January 4th

What Is A Potentiometer

on January 3th

Popular Posts

-

What is GND in the circuit?

on January 1th 3272

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2815

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 20th 2640

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2265

-

Comparison Between DB9 and RS232

on January 1th 1882

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1846

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1807

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1801

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1799

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 20th 1782