Comparing Carbon Film Resistors and Metal Film Resistors - Advantages and Disadvantages, Performance, Structure

In electronic circuit design, resistors are indispensable basic components, among which metal film resistors and carbon film resistors are two common resistor types. They differ in structure, manufacturing process, performance, and application scenarios. Metal film resistors, usually represented by the symbol RJ, use special metals or alloys as resistance materials, and form a resistance film layer on a ceramic or glass substrate through vacuum evaporation or sputtering. This manufacturing process results in metal film resistors with superior electrical properties, including better heat resistance, low noise potential, and stable temperature and voltage coefficients. In contrast, carbon film resistors are formed by coating a suspension containing organic binders, carbon ink, graphite, and fillers on an insulating substrate, and then forming a carbon film through a pyrolysis reaction in a high-temperature and vacuum environment. Although carbon film resistors are cheaper to manufacture and easier to mass produces, their electrical performance and stability are not as good as metal film resistors. This article will compare in detail the advantages and disadvantages, manufacturing processes, and applicability of these two resistors in different applications, providing readers with comprehensive technical analysis and practical guidance.Catalog

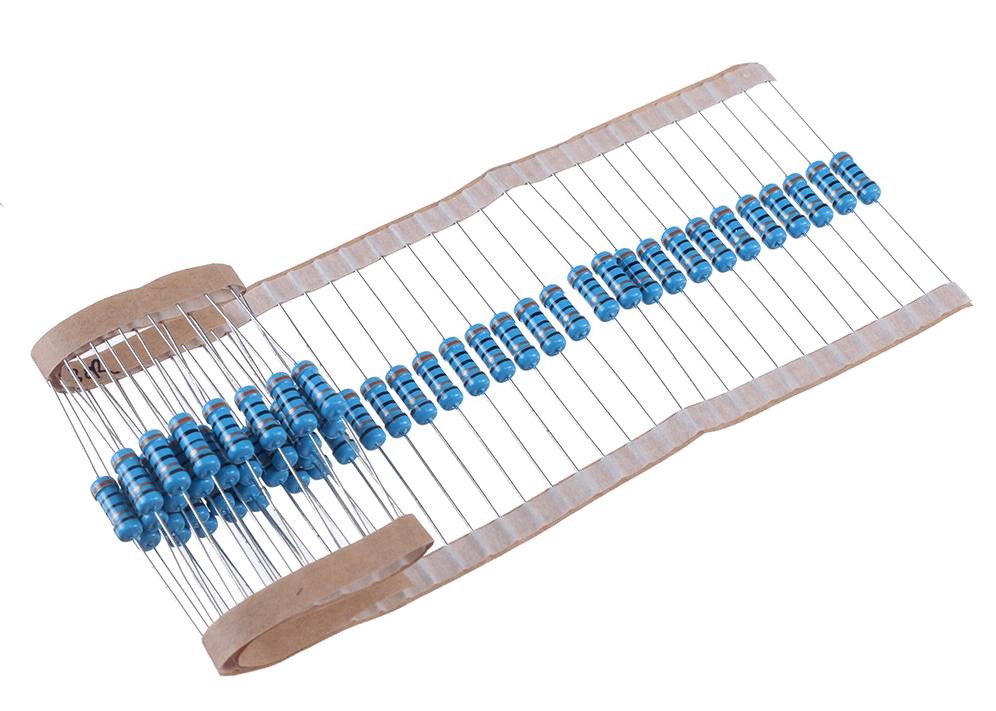

1. What is a metal film resistor?

Metal film resistors, usually represented by the symbol RJ, are resistors that use special metals or alloys as resistance materials and form a resistance film layer on ceramics or glass through vacuum evaporation or sputtering. During the manufacturing process, the alloy is heated in a vacuum, causing it to evaporate and form a conductive metal film on the surface of the porcelain rod. By grooving and changing the thickness of the metal film, the resistance value can be precisely controlled. The electrical performance of this resistor is better than that of carbon film resistors, with better heat resistance, low noise potential, stable temperature coefficient, and voltage coefficient. The manufacturing process of metal film resistors is very flexible. The resistance value can be adjusted by adjusting the material composition, film thickness, and grooves, thereby producing resistors with excellent performance and a wide resistance range.

The main advantages of metal film resistors include:

The cost is relatively low: the production process is mature and material costs are controllable.

Less noise: Low electrical noise, suitable for high-precision applications.

High stability: Excellent performance in various environments, suitable for long-term use.

Small size: easy to integrate into small electronic devices.

High precision: The resistance value is accurate and can be used in circuit design that requires high precision.

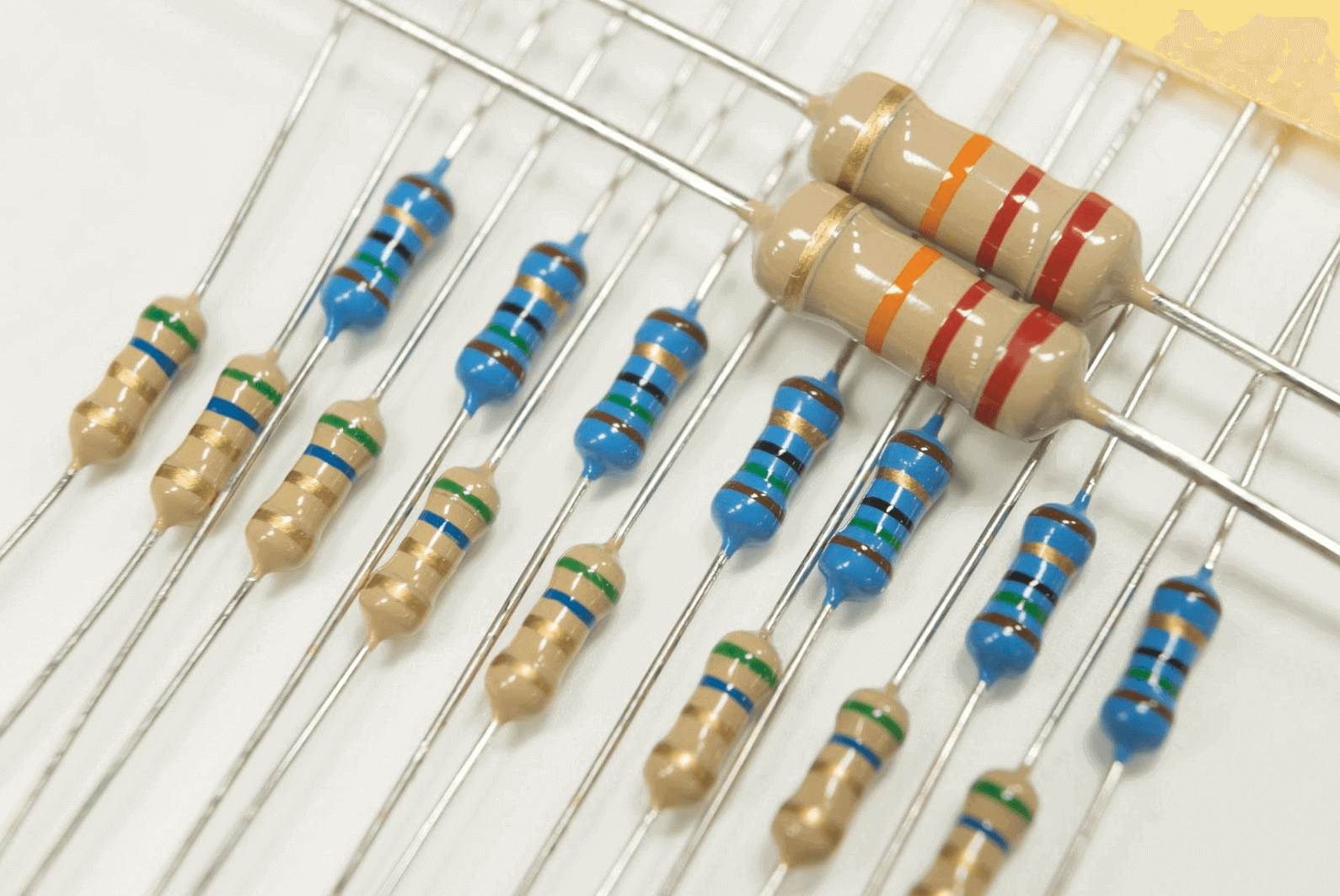

2. What is a carbon film resistor?

Carbon film resistors are made by coating a suspension containing organic binders, carbon ink, graphite, and fillers on an insulating substrate and then polymerizing it through heating. During its manufacturing process, gaseous hydrocarbons are decomposed under high temperatures and vacuum, and carbon is deposited on the porcelain rod or tube to form a crystalline carbon film. By changing the thickness of the carbon film and the length of the groove, different resistance values can be obtained. Carbon film resistors have lower cost, but their electrical properties and stability are poor, so they are generally not used as general-purpose resistors. However, due to the ease of making high-resistance films, carbon film resistors are mainly used for high-resistance, high-voltage resistors, and their applications are similar to high-voltage resistors.

Advantages and Disadvantages of Carbon Film Resistors

advantage

Low cost: The manufacturing process is simple and the material cost is low.

High resistance: Easy to make high resistance films, suitable for high resistance and high voltage applications.

Easy to mass produce: suitable for large-scale, low-cost production needs.

shortcoming

Poor electrical performance: Not as stable and accurate as metal film resistors.

High noise: The electrical noise generated when the current passes through is large and is not suitable for high-precision applications.

High-temperature coefficient: The resistance value changes greatly with temperature, which affects the stability in high-temperature environments.

3. Carbon Film Resistors vs. Metal Film Resistors: Side-by-Side Comparison

Understanding the differences between metal film resistors and carbon film resistors helps in choosing the right component for specific applications. This comparison focuses on key performance metrics such as the temperature coefficient of resistance (TCR), voltage coefficient of resistance (VCR), and overall stability.

Temperature Coefficient of Resistance (TCR)

The TCR indicates how the resistance value changes with temperature fluctuations. Typically, the resistance increases when the temperature rises and decreases when it drops. Metal film resistors exhibit a TCR ranging from ±20 to ±200 parts per million per Kelvin (ppm/K), suggesting minor changes in resistance with temperature variations. In contrast, carbon film resistors have a TCR of -200 to -1000 ppm/K, indicating a more significant resistance fluctuation under temperature changes. This makes metal film resistors more dependable for applications involving extreme temperatures. Moreover, they generate less thermal noise, enhancing their suitability for sensitive electronic devices like radios and radar systems.

Voltage Coefficient of Resistance (VCR)

The VCR measures how resistance changes with voltage application. When voltage is applied to a resistor, typically, the resistance slightly decreases. Metal film resistors have a low VCR, nearly 1 ppm/V, showing minimal change in resistance when subjected to voltage. Carbon film resistors, however, have a higher VCR of -10 ppm/V, indicating a more noticeable resistance change with voltage application. This property makes metal film resistors more stable and reliable under high-voltage conditions.

Stability

Stability is crucial for resistors operating in diverse environments. Metal film resistors excel in stability, performing robustly against external factors like radiation, heat, and cold. This makes them particularly well-suited for high-demand environments. Although carbon film resistors also offer decent stability, they do not perform as well as metal film resistors under similar conditions.

4. Carbon film resistors and metal film resistors: structural comparison

There are significant differences in the construction and manufacturing processes of carbon film and metal film resistors, with each resistor being customized for specific applications based on its structural properties and performance characteristics.

Manufacturing Carbon Film Resistors

The process begins with a ceramic substrate that is coated with a mixture of carbon ink, graphite, and a binder suspension. The component is then exposed to high temperatures, triggering a cleavage reaction. As the temperature increases, the carbon compound decomposes, leaving behind a layer of pure graphite that crystallizes and forms a durable carbon film on the ceramic base. This graphite layer is responsible for the resistor's ability to conduct electricity. To protect the fragile carbon film from thermal damage and environmental factors, the resistors are encased in a protective plastic housing. Copper leads are attached to both ends of the ceramic base to provide electrical connection points.

Manufacturing Metal Film Resistors

Metal film resistors are produced through a more complex process. These resistors typically use metals such as nickel-chromium (NiCr), but other materials such as tantalum nitride, gold, platinum or tin and antimony can be used depending on the required specifications. The metal of choice is vapor deposited onto a substrate to form a thin layer. This metal layer is then artificially aged at low temperatures for an extended period of time to enhance its electrical properties. Fine-tuning the resistor value by etching spiral grooves into the metal film allows for precise control of the electrical path and therefore the total resistance provided by the resistor.

Performance comparison

Carbon film resistors are generally cheaper to produce and simpler to design but have lower electrical performance and stability. They are most effective in high resistance and high voltage settings, but because they are susceptible to temperature changes and aging, they are not ideal for applications requiring high accuracy.

In contrast, metal film resistors, although more expensive and complex to manufacture, provide superior electrical performance and stability. Careful control of film thickness and etching processes enables these resistors to operate reliably in applications requiring high precision and stability, such as sensitive measurement instruments and critical electronic circuits.

5. Carbon Film Resistors vs. Metal Film Resistors: Availability

Both carbon film and metal film resistors are essential components in various electronic applications, each with unique specifications that suit different needs.

Carbon Film Resistors

Carbon film resistors are available in resistance values ranging from 1 ohm to 25 megohms, with power ratings from one-quarter watts up to five watts. Their widespread use can be attributed to the low cost of production and their adaptability across a broad spectrum of applications. The resistance value of carbon film resistors is determined by several factors. The resistance decreases as the cross-sectional area of the carbon-coated rod increases. Conversely, the length of the rod enhances the resistance—the longer the rod, the higher the resistance. Additionally, the resistance lowers as the concentration of carbon in the coating increases, allowing for a versatile range of resistances by adjusting these dimensions during manufacturing.

Metal Film Resistors

Metal film resistors, known for their precision and stability, are offered in a range of tolerances including 2%, 1%, 0.5%, 0.25%, and 0.1%. They have temperature coefficients (TCR) that vary from 10 to 100 ppm/ K, making them ideal for use in sophisticated electronic devices where accuracy is crucial. The factors influencing the resistance of metal film resistors are closely tied to their manufacturing process. The resistance decreases as the width of the cut spiral grooves on the metal film increases— wider cuts result in lower resistance. Furthermore, increasing the number of layers of the metal film also results in decreased resistance. This allows manufacturers to achieve precise control over the resistor's properties by adjusting the depth and the number of spiral cuts.

6. Carbon film resistors VS metal film resistors: Disadvantages

Although metal film resistors perform best in terms of frequency response, carbon film resistors still have their unique advantages due to their low cost and high resistance. However, both also have their drawbacks.

Disadvantages of Carbon Film Resistors

Temperature Sensitivity: Carbon film resistors have a significant temperature coefficient of resistance (TCR), typically ranging from -200 to -1000 ppm/K. This high TCR means that their resistance changes significantly with temperature, which can be problematic in temperature-sensitive applications.

Stability Issues: The resistance value of carbon film resistors can change significantly over time or under extreme environmental conditions. This instability can lead to unpredictable performance, especially in precision electronic circuits where consistent resistance values are critical.

Physical Size: Generally, carbon film resistors are larger compared to other types of resistors. For compact electronic devices where space is limited and miniaturization is a priority, the larger size can be a disadvantage.

Disadvantages of Metal Film Resistors

Cost Factor: Compared to carbon film resistors, the production of metal film resistors involves more complex processes and higher quality materials, resulting in higher manufacturing costs. As a result, they are more expensive, which can be a significant disadvantage for projects on a tight budget.

Power Dissipation: Metal film resistors may dissipate more power in applications where high current flows through the resistor. This increased power consumption may cause efficiency issues in power-sensitive circuits, which may result in higher operating costs and heat generation.

7. Summary

Through a detailed comparison of the structure, manufacturing process, electrical performance, and application of metal film resistors and carbon film resistors, their respective advantages and disadvantages can be seen. Metal film resistors have become the first choice for demanding electronic equipment due to their high precision, high stability, and low noise. Although their manufacturing costs are higher, they are undoubtedly the best choice for applications that require long-term reliability and precise control. Carbon film resistors are widely used in high-resistance and high-voltage circuits that do not require high electrical performance due to their low cost, high resistance, and ease of mass production. In actual operation, engineers should carefully weigh the characteristics of these two resistors and select the most appropriate resistor type based on specific application requirements to ensure the reliability and performance stability of the circuit design. Both metal film resistors and carbon film resistors play an important role in modern electronic technology, and their continuous development and improvement will continue to promote the progress and innovation of electronic technology.

Frequently Asked Questions [FAQ]

1. What is the difference between metal film resistors and carbon film resistors?

Metal oxide film resistors operate in a wide range of resistors and can withstand a higher temperature than the resistors of the carbon film. Noise Design In contrast to carbon film resistors, metal oxide film resistors have a low noise design. They keep the minimum current. Therefore, it ensures less noise.

2. Can metal film resistors be used instead of carbon film resistors?

Replacing them is your choice. Both carbon film and metal film will work the same. Some like the super accuracy of metal films (1%, 2%, etc.). Some like carbon films because they're similar to the originals elsewhere in the receiver.

3. Why are carbon resistors no longer the most common?

Carbon resistors usually are not designed to carry large currents. If too much current passes through this type of resistor, it will heat to the point that permanent damage results. Even currents that are slightly too large may cause changes in the resistivity of the carbon material.

4. How to tell whether a resistor is a metal film resistor?

Carbon film resistors have a layer of black protective paint on the surface. We can distinguish by looking at the color of the protective paint. Metal film resistors usually use a bright white protective film.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

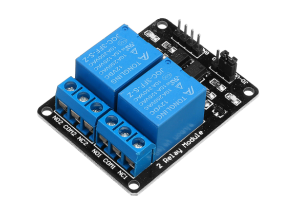

Mastering Relay Technology: Construction, Types, Working Principles, and Testing Methods

on May 16th

Lumens vs. Watts: The New Metric for Choosing Light Bulbs

on May 14th

Popular Posts

-

What is GND in the circuit?

on January 1th 2946

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2502

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2091

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 9th 1898

-

Comparison Between DB9 and RS232

on January 1th 1765

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1714

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1662

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1567

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1550

-

CR2450 vs CR2032: Can The Battery Be Used Instead?

Lithium manganese batteries do have some similarities with other lithium batteries. High energy density and long service life are the characteristics they have in common. This kind of battery has won the trust and favor of many consumers because of its unique safety. Expensive tech gadgets? Small appliances in our homes? Look around and you'll see them everywhere. Among these many lithium-manganes...on January 1th 1519