A Deep Dive into Oscilloscopes Simplifying Testing of CAN Bus Networks

In the realm of modern automotive electronics, the spotlight shines on in-vehicle network technology, with the controller area network (CAN bus) being its pulsating core. More than a mere communication tool, the CAN bus is a revolutionary force. It reshapes interactions among microcontrollers, engine control units (ECUs), sensors, actuators, and other onboard devices. Birthed over three decades ago, the CAN bus has cemented its reputation for reliability and stability. It's a technology in perpetual evolution, mirroring the automotive industry's relentless quest for innovation. This article promises a deep dive into the twists and turns of CAN bus technology. We'll explore its physical properties, network dependability, and security concerns, and delve into the nuances of using oscilloscopes in CAN testing. Our aim? To offer a panoramic view to our readers.

Catalog

In-vehicle network technology, particularly the Controller Area Network (CAN bus), stands as a foundational pillar in the realm of modern automotive electronics. This technology isn't merely facilitating; it's revolutionizing the way microcontrollers, engine control units (ECUs), sensors, actuators, and other onboard equipment communicate. Over its three-decade journey, the CAN bus has not just been embraced for its robust reliability and stability. Its continuous evolution echoes the burgeoning demands of an industry in relentless pursuit of innovation.

Consider Classic CAN (CAN 2.0) — it delineated standard (11-bit) and extended (29-bit) message identifiers while supporting data rates up to 1Mbps. As technology surged forward, CAN FD (Flexible Data Rate) emerged, a testament to adaptability, allowing data rates to soar up to 5Mbps or more during transmission, all the while ensuring backward compatibility with Classic CAN.

But the march of progress didn't halt there. Enter CAN XL, an even more sophisticated variant, boasting payloads of grander scale and data rates that peak at 10Mbps. These leaps aren't just incremental improvements; they're transformative, furnishing the network with broader bandwidth and enhanced flexibility to tackle more intricate application demands.

At the physical layer, CAN networks typically employ a solitary twisted pair for data conveyance. To mitigate signal reflection and amplify signal integrity, 120-ohm terminal resistors are integrated at both network ends. The length and quality of this network critically influence the maximum sustainable data rate — a vital consideration in the architecture of long-distance communications.

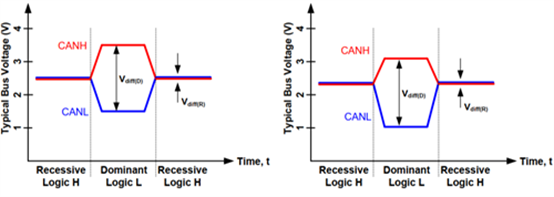

Differential signaling, a hallmark of CAN networks, utilizes two wires (CANH and CANL) to foster data transmission. This mechanism doesn't just bolster resistance against electromagnetic interference; it ensures consistent and reliable signal conveyance amid the vehicular tumult. The differential design, with its dominant and recessive levels, further escalates the network's immunity to interference and secures data's effective transit.

The network's architecture ingeniously orchestrates message conflict resolution, prioritizing messages based on urgency — a crucial attribute for applications in vehicles where time is of the essence. To bolster network security, contemporary iterations of the CAN bus have integrated an array of security and encryption measures. Enhanced error detection, coupled with sophisticated fault isolation mechanisms, fortify data integrity and network reliability amidst the rigors of high-speed transmission.

Through this granular analysis, the integral role of stability, reliability, adaptability, and the ever-evolving data transmission capabilities of the in-vehicle network and CAN bus becomes evident. As technology relentlessly advances, the CAN bus is anticipated to continuously morph, meeting the ever-complex and data-heavy demands of future vehicular systems.

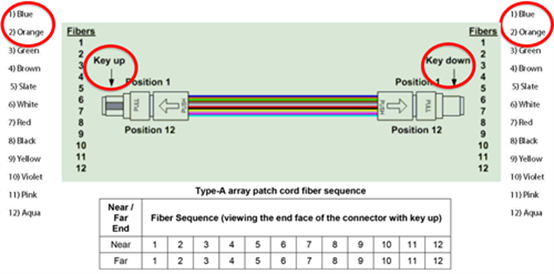

Figure 1: CAN Network Uses Terminated Twisted Pair Cabling and Nodes Are Tap-Connected

The role of oscilloscopes in CAN bus testing transcends mere stability assurance; it's about guaranteeing data's correctness and reliability. Engineers leverage these tools to execute comprehensive network diagnostics and debugging by capturing and dissecting CAN signals. The Teledyne LeCroy HDO4024A oscilloscope, for instance, with its 200MHz bandwidth, caters to the stringent demands of high-speed networks like CAN XL. Bandwidth isn't just a number — it signifies the pinnacle frequency an oscilloscope can handle, ensuring signals remain undistorted and potent.

Probe selection emerges as a pivotal decision in accurately capturing CAN signals. High-impedance probes minimize circuit disruption, while differential probes, measuring potential differences, shine in high-noise areas. Modern oscilloscopes bring to the table advanced decoding capabilities, transforming raw signals into intuitive waveform diagrams peppered with detailed decoding information. This includes not only fundamental temporal and voltage data but also specifics inherent to CAN protocols, such as identifiers and control fields.

To achieve test precision and uphold signal integrity, oscilloscopes must possess high temporal and vertical resolution. This is primarily useful for detecting transient anomalies and ensuring a precise assessment of signal quality. The exemplified oscilloscope model is merely one among a spectrum tailored for CAN testing. Engineers must weigh additional features like automatic test scripts, waveform recording capabilities, and the convenience of hot-swappable probes against the backdrop of their specific testing scenarios and environmental conditions.

Considering the widespread adoption of CAN buses in automotive and industrial environments, it mainly affects the adaptability of oscilloscopes to environmental stressors. Factors like temperature, humidity, and vibration are not mere nuisances but critical variables that determine the reliability of testing under diverse conditions. Through these intricate technical analyses and supplementary details, it's clear: that oscilloscopes are indispensable in CAN bus testing. Their performance and functionalities are vital cogs ensuring the network's reliability, stability, and efficiency. Engineers must judiciously select the right oscilloscope model and configuration, aligning with specific testing exigencies and environmental challenges, to realize efficient and accurate testing outcomes.

Through these detailed analyses and technical enhancements, the role of oscilloscope software in CAN bus testing transcends mere signal capture, extending to protocol decoding, error analysis, automated testing, and report generation. These advanced functionalities and tools elevate the oscilloscope to a formidable testing and analysis platform, significantly enriching the depth and efficiency of engineers' analysis in CAN bus testing. In practical scenarios, engineers must judiciously select software configurations and functionalities that align with specific test requirements and conditions to ensure more effective and precise test outcomes.

Figure 2: Shown Is The Differential Signal Definition of The CAN Bus CANH and CANL Wires

When actually connecting and testing the oscilloscope and CAN bus, the selection of probes, connection methods, and measurement strategies mainly play a role in ensuring test accuracy and efficiency. What follows is a detailed revision and enhancement of the initial discourse, featuring a range of technical specifics and actionable advice.

Advantages of using differential probes, specifically Teledyne LeCroy's ZD200; it captures the differential signal of the CAN bus with heightened precision. This type of probe is instrumental in negating common mode noise, thereby enhancing the signal-to-noise ratio. Notably, differential probes, characterized by their expansive bandwidth and diminished loading effects, are adept at detecting rapid signal alterations while minimally influencing the circuit under test.

The intricacies of probe connection cannot be overstated. Ensuring the probe ground lead remains succinct mitigates the loop area and the potential for noise intrusion. For differential signals, the probe ends must be carefully connected to CANH and CANL to prevent poor contact or signal interruption.

Oscilloscope software applications, coupled with protocol decoding capabilities, are the cornerstone to efficacious and precise CAN bus testing. These applications provide not only basic waveform capture but also intricate data analysis, decoding, and automated testing functionalities. Further expanding upon the original content, more technical nuances and practical advice follow.

Multi-protocol support is a hallmark of modern oscilloscope software, accommodating a variety of protocols including CAN 2.0, CAN FD, LIN, Flex Ray, and more. This versatility enables engineers to leverage a single device for the testing and analysis of various bus systems.

Real-time decoding and display: Advanced oscilloscope software can interpret communication data instantaneously, overlaying decoded information on the waveform as intuitive text. This feature allows engineers to immediately discern the specifics of each signal packet, including ID, data content, and frame type.

Error detection and analysis are more than rudimentary decoding; they encompass identification and detailed reporting of specific error frames, remote frames, overload frames, etc., complete with error statistics and in-depth error information.

Protocol-specific triggering enhances the efficiency of capturing and analyzing pertinent events by allowing engineers to set trigger conditions based on specific protocol occurrences.

The search and mark functionality enables quick navigation to and analysis of particular events or markers in extended data recordings.

Graphical user interface (GUI): The modern, user-friendly GUI typical of contemporary oscilloscope software facilitates intuitive setup, measurement, and analysis through features like drag-and-drop operations and multi-window views.

Customizable settings and storage: Engineers can tailor test parameters to their needs and save these configurations as templates for future use, streamlining similar test tasks and enhancing overall efficiency.

Automated testing supported by scripting languages or programming interfaces, like VISA or SCPI, allows for the execution of comprehensive or complex test sequences, thereby minimizing human error.

Test report generation is an automated process of post-testing that encapsulates test configuration, waveform screenshots, decoded data, and statistical information, all crucial for the documentation and sharing of test results.

This analysis intricately weaves through the CAN bus's technical evolution, its physical traits, network dependability, security, and the role of oscilloscopes in testing. These facets are not mere cogs in the vast machinery of automotive electronics; they are the driving force behind future vehicle systems. The CAN bus, in step with advancing technology, is anticipated to morph, addressing the increasingly complex and data-heavy demands of future vehicles. Engineers are at the helm, guiding the testing process with precision. They choose probes, connective tactics, and test strategies with care. Their use of oscilloscope software and protocol decoding ensures both accuracy and efficiency in testing. This article not only highlights the role of the CAN bus in modern automotive technology but also explains various technical details and strategies.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

→ Previous

In the intricate realm of electronic component design and application, the measurement of temperature stands as not just a fundamental requirement, but a pivotal element in the assurance of component performance's accuracy and reliability. This article delves deeply into the two primary temperature ...

In the expansive realm of electrical engineering, a pivotal component lies in the grasp and utilization of signals. These signals, fundamental in everything from rudimentary electronics education to the intricacies of circuit architecture, are the bedrock of understanding and application. This artic...

→ Next

Simple Formula to Convert Celsius to Fahrenheit

on January 6th

What Are Analog and Digital Signals

on January 5th

Popular Posts

-

What is GND in the circuit?

on January 1th 3036

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2606

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2161

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 13th 2064

-

Comparison Between DB9 and RS232

on January 1th 1788

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1754

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1704

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1640

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1618

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 13th 1561