Understanding the TMC2209 Motor Driver

In this article, we explore the TMC2209 motor driver, a standout in motion control for its quiet, efficient operation and powerful capabilities for two-phase stepper motors. We'll dig into its features, from easy integration with popular microcontrollers to advanced functions like dynamic current control and StealthChop technology, which reduces noise for applications requiring silence and precision. Whether you’re developing robotics, 3D printing, or energy-efficient HVAC systems, the TMC2209 offers versatile benefits in performance, reliability, and eco-friendly operation, making it a prime choice across diverse industries. Join us as we examine its pin configuration, CAD design, application insights, and comparisons with similar drivers, uncovering why the TMC2209 is a preferred solution for seamless and quiet motor control.Catalog

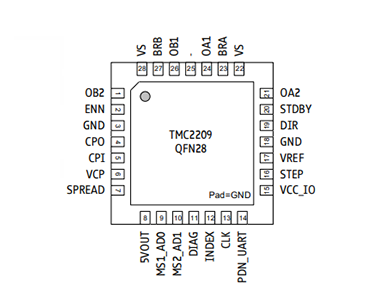

Pin Configuration

|

Pin Name |

Description |

|

VDD & GND |

Connected to 5V and GND of Controller |

|

VM & GND |

Used to power the motor |

|

M1A, M1B, M2A, M2B |

Output Pins, Connected to the 4 Wires of motor |

|

DIR |

Motor Direction Control pin |

|

STEP |

Steps Control Pin |

|

MS1, MS2 |

Microstep Selection Pins |

|

FAULT |

Fault Detection Pin |

|

PDN_UART |

UART and Auto Power Down Control: GND=on, VIO=off |

|

CLK |

Clock Input |

|

SPRD |

Chopper mode selection: Low=StealthChop, High=SpreadCycle |

|

DIAG |

Diagnostics Output (VIO=error) |

|

INDEX |

Index Output (one pulse per each four full steps) |

|

EN |

Enable Motor Outputs (GND=on, VIO=off) |

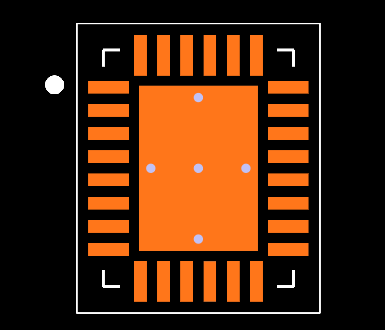

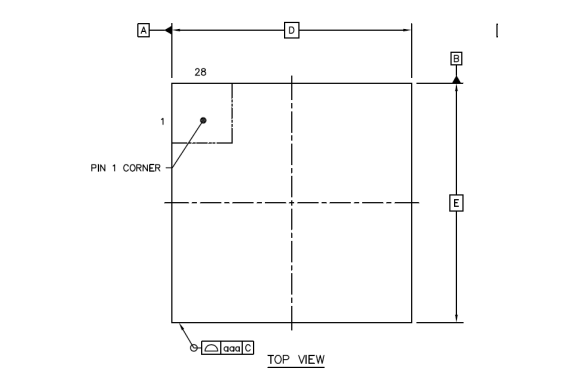

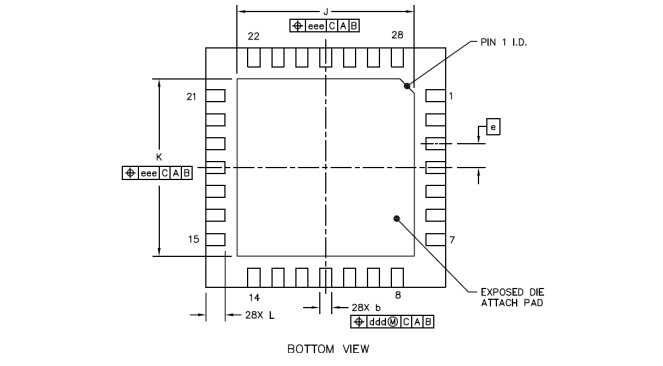

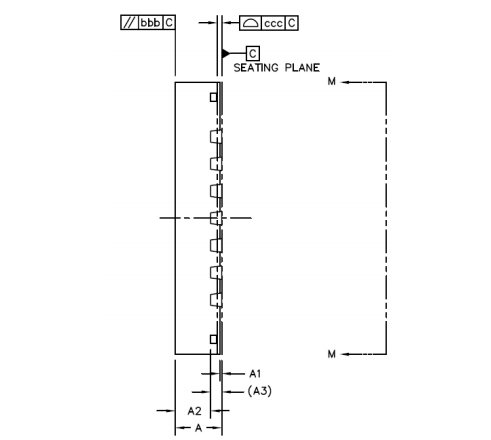

TMC2209 CAD Design

Footprint

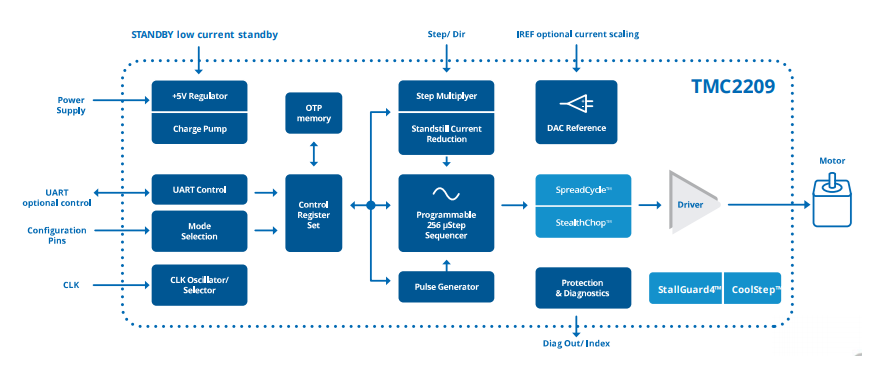

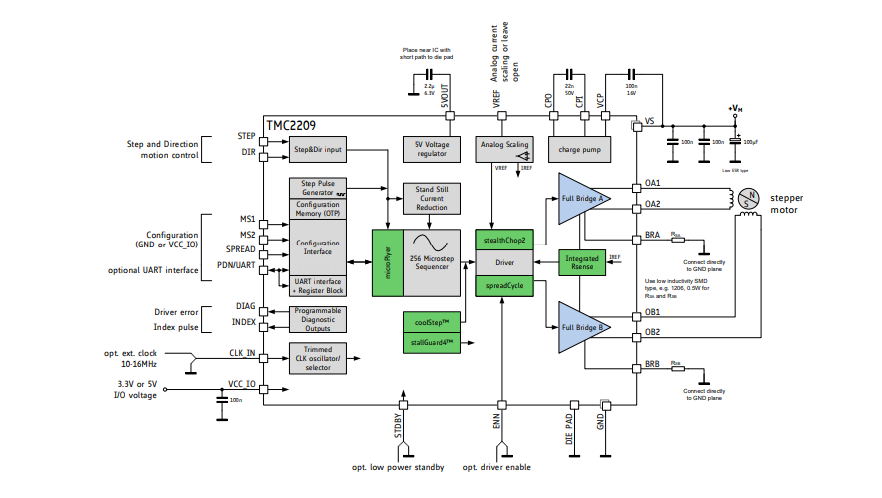

Overview of TMC2209

The TMC2209 serves as an intricate stepper motor driver, crafted to interface effortlessly with standard driver systems. It supports voltage outputs reaching up to 28 V and handles current outputs of ±2 A. A dominant component of its intricate design is the incorporation of StealthChop2 technology. This innovation facilitates nearly silent motor functioning and boosts energy efficiency, mainly beneficial for scenarios where maintaining low noise levels is of utmost concern.

StealthChop2 technology in the TMC2209 sets new standards in noise reduction and energy efficiency. Such features gain increasing significance in domains like consumer electronics, 3D printing, and robotics. Practically, this translates to motor operations that are as discreet as a whisper, elevating your experience in environments demanding minimal noise interference. Reflecting a caliber of engineering familiar with high-performance applications, this technology supports up to 1/256 micro stepping, ensuring precise control and seamless motor activity.

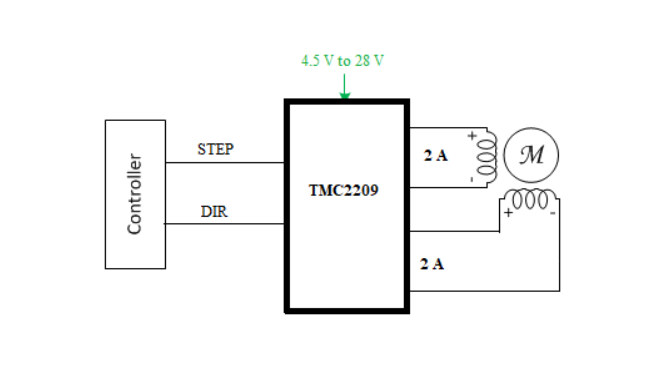

Block Diagram

Technical Specifications

Here is the table containing the specifications for the Trinamic Motion Control GmbH TMC2209-LA-T.

|

Type |

Parameter |

|

Factory Lead Time |

8 Weeks |

|

Mounting Type |

Surface Mount |

|

Package / Case |

28-VFQFN Exposed Pad |

|

Operating Temperature |

-40°C~125°C TJ |

|

Packaging |

Tape & Reel (TR) |

|

Series |

stallGuard™ |

|

Part Status |

Active |

|

Moisture Sensitivity Level (MSL) |

3 (168 Hours) |

|

Applications |

Automation Control |

|

Voltage - Supply |

4.8V~5.25V |

|

Function |

Driver - Fully Integrated, Control and Power Stage |

|

Interface |

Step/Direction, UART |

|

Output Configuration |

Step/Direction |

|

Voltage - Load |

5.5V~29V |

|

Motor Type - Stepper |

Bipolar |

|

Step Resolution |

1 ~ 1/256 |

|

RoHS Status |

ROHS3 Compliant |

Characteristics of TMC2209

|

Feature |

Description |

|

Motor Compatibility |

2-phase stepper motors up to 2.8A coil current (peak), 2A

RMS |

|

Interface |

STEP/DIR Interface with 8, 16, 32, or 64 micro steps pin

setting |

|

Micro-stepping |

Smooth Running 256 micro steps by MicroPlyer™

interpolation |

|

Silent Operation |

StealthChop2™ silent motor operation |

|

Motor Control |

SpreadCycle™ highly dynamic motor control chopper |

|

Stall Detection |

StallGuard4™ load and stall detection for StealthChop |

|

Energy Saving |

CoolStep™ current control for energy savings up to 75% |

|

Low RDS(on) |

Low Heat-Up LS 170mΩ & HS 170mΩ (Typ. at 25°C) |

|

Voltage Range |

4.75… 29V DC |

|

Power Management |

Low Power Standby to fit standby energy regulations |

|

Sense Resistor |

Internal Sense Resistor option (no sense resistors

required) |

|

Braking and Power Down |

Passive Braking, Freewheeling, and automatic power down |

|

Configuration Options |

Single Wire UART & OTP for advanced configuration

options |

|

Motion Control |

Integrated Pulse Generator for standalone motion |

|

Protection and Diagnostics |

Full Protection & Diagnostics |

|

Package |

Compact QFN package with a large heat slug |

Applications

Device Design

The TMC2209 driver significantly enhances device design, finding notable applications in 3D printers. Here, the focus on improving precision and efficiency becomes apparent, as the driver allows for smoother motor movements and quieter operations. These features resonate with the industry that seeks reliability and accuracy in both prototyping and production processes. Its role expands further into traditional and industrial printers, where it offers increased precision and reduced noise. This is especially beneficial in environments where silence is esteemed, such as offices or libraries.

Security Systems

Security systems gain substantial advantages from the TMC2209, mostly due to its capacity to handle intricate motor functions with minimal noise. This attribute proves active for operations requiring discretion. Enhancing the performance of surveillance cameras and automated locks strengthens the efficiency of security measures. You can understand that the smooth operation of these systems hinges on dependable components like the TMC2209, which ensure continuous and secure functionality.

HVAC System Efficiency

In the world of HVAC systems, the TMC2209 plays a key role in enhancing energy management and performance. Fine-tuning motor operations, support reduced energy consumption, an appealing factor for environmentally conscious consumers and businesses aiming to cut down on operational costs and environmental impact. The energy efficiency offered by the TMC2209 mirrors the surging demand for sustainable solutions in modern infrastructure, signaling a wider movement towards environmentally responsible innovations.

Textile Machinery and Office Equipment

The TMC2209's flexibility is also demonstrated in textile machinery, where precise motion control is ultimate for crafting high-quality fabrics. It aids in the weaving and cutting processes, boosting both productivity and the quality of end products. In office equipment, such as copiers and scanners, it facilitates quieter, more efficient performance. This aligns well with the contemporary emphasis on creating more peaceful and efficient work environments.

Battery-Powered Devices

As portable and battery-powered devices become ever more prevalent, the TMC2209 proves beneficial by optimizing battery usage and extending device longevity. This feature is mostly serious in mobile robotics and handheld devices, where enhanced long-term usability without frequent recharges is valued. You can persist in exploring how efficient components such as the TMC2209 can be utilized to improve energy management, driving future advancements in the field.

Application Circuit

Integrating TMC2209 into Motor Control Systems

Combining the TMC2209 driver with a microcontroller brings a notable enhancement in the precision of motor control. Using the DIR (Direction) and STEP pins, one can adeptly orchestrate motor direction and stepping, dimensions laden with human ingenuity and emotional engagement. This setup is sought after by you aiming for heightened precision in domains like 3D printing, CNC machinery, or robotics.

A distinctive characteristic of the TMC2209 lies in its capacity to adjust the micro-step resolution, modulating between 1 and 256 steps, facilitated by the MS1 and MS2 pins. This feature caters to various precision demands, making it adaptable to diverse project requirements. For example, opting for a finer micro-step resolution in pursuing high-resolution printing excellence can lead to smoother motion and more intricate outputs, reflecting the meticulous attention often seen in human pursuits for perfection.

Comparing TMC2209 and TMC2208

|

Specification |

TMC2208 |

TMC2209 |

|

Max Current Output |

Up to 1.5A (2.0A Peak) |

Up to 2.0A (2.8A Peak) |

|

Application Context |

Suitable for most consumer machines (Creality, etc.) |

Higher current capacity for advanced setups |

|

Consumer Use Case |

Typically operates below 1.0A for stock motors |

Typically operates below 1.0A for stock motors |

Alternatives to the TMC2209

• TMC2208

• A4988

• A498

• L6474

• L6207

• L6208

Dimensions

Manufacturer

TRINAMIC Motion Control GmbH develops the TMC2209 integrated circuit (IC), a key component in diverse industrial sectors, encompassing biotechnology, factory automation, and advanced motion control systems. This IC is a byproduct of technological advancement, emphasizing the intensifying quest for precision and efficiency in mechanical systems.

With the continuous evolution of technology, the appetite for efficient and dependable motion control solutions, exemplified by the TMC2209, has intensified. This component seamlessly blends innovation with the meticulous pursuit of accuracy in mechanical operations, highlighting the growing desire for refined performance.

The TMC2209 boasts a spectrum of characteristics aligned with the stringent demands of contemporary industries like silent stepper motor driver capabilities you can value its ability to dramatically lower energy consumption while refining motion control applications and dynamic current control this feature, paired with noise reduction, not only addresses operational complexities but facilitates effortless system integration.

Datasheet PDF

TMC2209-LA-T Datasheets:

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

Frequently Asked Questions [FAQ]

1. What is TMC2209?

The TMC2209 is a motor driver crafted for managing two-phase stepper motors, delivering notably silent operation. Its sophisticated structure includes a UART interface, enabling meticulous tuning for improved precision. This driver is favored in various industrial settings and appreciated for reducing noise while elevating motor performance and operational control.

2. Does TMC2209 need active cooling?

The necessity for cooling in the TMC2209 hinges on the current level. For handling currents of up to 1A, a compact heatsink effectively dissipates heat, aiding in stable function. Beyond this threshold, integrating active cooling solutions is advisable. Implementing tools like fans and heat sinks, along with thermal paste, helps maintain temperatures, thus extending device longevity and bolstering reliability.

3. What is the difference between TMC2208 and TMC2209?

A remarkable variation between TMC2209 and TMC2208 drivers is their current capacity. TMC2209 supports motor currents of up to 2.8A, offering a more robust option than the TMC2208. For applications demanding greater power, TMC2209 provides steady performance and remains acoustically subtle. When choosing between these drivers, consider the specific power needs and environmental factors of your application to optimize performance.

4. What is TMC2209 standalone?

In standalone mode, a key characteristic of the TMC2209 is its ability to autonomously manage motion tasks. Equipped with an integrated pulse generator, it ensures seamless operation across numerous applications. The driver boasts extensive safety measures and diagnostics, preventing failures and achieving optimal functioning. Its compact design enhances its adaptability, making it an attractive choice for you needing dependable and intelligent motion control solutions.

Complete Overview of 2SC945 NPN Transistor

on November 12th

KSZ9031RNXCA: Comparison, Alternatives, and Datasheet

on November 11th

Popular Posts

-

What is GND in the circuit?

on January 1th 3157

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2712

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 16th 2313

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2197

-

Comparison Between DB9 and RS232

on January 1th 1816

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1789

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1741

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1710

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1701

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 16th 1668