The DRV8825 Stepper Motor Driver: Features, Functions, and Applications

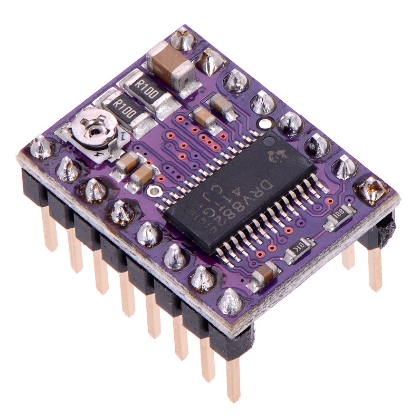

The DRV8825 stepper motor driver is a versatile and powerful solution for controlling bipolar stepper motors in various applications, from 3D printers and CNC machines to robotics and industrial automation. This driver stands out because it delivers precise motion control, offers up to 1/32 micro stepping resolution, and robust protection features. With a wide operating voltage range of 8.2V to 45V and a current output capability of up to 2.5A per coil, the DRV8825 ensures smooth motor performance and adaptability in demanding environments. This article digs into the core components and features that make the DRV8825 a popular choice in precision motion systems.

Catalog

DRV8825 Stepper Motor Driver Overview

The DRV8825 is designed to control stepper motors, which are basic to devices such as printers, scanners, and automated systems. Core components include a micro-stepping indexer and dual H-bridge drivers. The driver supports precise control and smooth motion of bipolar stepper motors. It can deliver an output current of 2.5 A per coil, making it suitable for demanding environments. Supports a broad voltage range from 8.2 V to 45 V, enabling integration into various electronic systems.

The micro-stepping indexer is a substantial feature of the DRV8825, enhancing the precision and smoothness of motor operation. By modulating current in the motor coils, micro-stepping enables smaller steps than the inherent step size. Serious for high-precision movements and reduced mechanical vibrations in CNC machines and 3D printers. Adjusting micro-stepping can optimize the balance between speed, torque, and accuracy, providing better control over motor performance.

Dual H-bridge drivers are used for controlling bipolar stepper motors. They independently regulate the current through each motor coil. Ensure effective bidirectional control and manage various motor currents. In scenarios like robotic arms and automated assembly lines, they offer dynamic response and reliable torque management. Implementing robust control mechanisms improves operational efficiency and motor lifespan, an insight noted in industrial automation practices.

Features of the DRV8825 Stepper Motor Driver

The DRV8825 is a PWM-controlled micro-stepping motor driver, celebrated for its precision and attention to detail, enabled by an integrated indexer. It supports micro stepping up to a resolution of 1/32, allowing for exact control over stepper motor movements. You can select between mixed, slow, and fast decay modes, offering extensive power management flexibility and response customization.

Versatile Power Supply and Current Handling

This driver operates across a broad voltage spectrum of 8.2V to 45V, catering to diverse application needs that vary in power supply requirements. Handling up to 2.5A drive current at 24V (ambient temperature 25°C), it shows substantial capability in driving powerful motors with considerable torque. Industries such as robotics, CNC machines, and 3D printers benefit from these specifications, where motor performance is a constant source of fascination.

Simple and Efficient Interface

The driver features a STEP/DIR interface, which greatly simplifies the integration process with microcontrollers and other control systems. This straightforward interface appeals to ensure sophisticated motor control implementations are readily achievable. The design helps reduce latency, thereby increasing motion control efficiency.

Power Conservation Features

The DRV8825 is committed to energy efficiency, demonstrated through its low-current sleep mode. This feature is mainly advantageous in power-conscious settings, such as battery-operated systems. It extends operational life and mitigates overheating, promoting stable performance over extended periods.

Integrated Reference Output

With a built-in 3.3V reference output, the driver eliminates the need for an external voltage reference, thus simplifying circuit design. This integration reduces component count, leading to more compact and reliable configurations. A streamlined design translates to easier maintenance and fewer potential component failures.

Compact Design and Robust Protection Features

The DRV8825 suits space-restricted applications, thanks to its compact form factor. It includes several protection features, enhancing reliability.

•Overcurrent Protection (OCP): Guards the driver and motor against excessive current, automatically reducing or shutting off current to prevent overheating.

•Thermal Shutdown (TSD): Activates when driver temperature surpasses safe limits, effectively preventing thermal damage.

•Undervoltage Lockout (UVLO): Ensures the driver functions within safe voltage levels, bolstering system stability and safety.

•Fault Indicator (nFAULT): Provides a visual or signal-based alert for fault conditions, facilitating quick diagnostics and troubleshooting.

DRV8825 Stepper Motor Driver Technical Specifications

|

Parameter |

Specification |

|

Operating

Voltage (VMOT) |

8V

to 45V |

|

Logic

Voltage (VDD) |

3.3V

to 5.5V |

|

Step

Modes |

Full-step,

Half-step, 1/4-step, 1/8-step, 1/16-step, 1/32-step |

|

Operating

Temperature Range |

-20°C

to 85°C |

|

Dimensions |

9.7mm

x 16.2mm |

|

Package

Type |

Surface

Mount (TSSOP-28) |

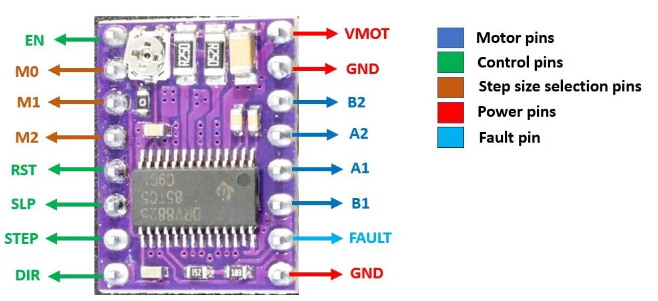

Pin Configuration of the DRV8825 Stepper Motor Driver

|

Pin Name |

Description |

|

VDD & GND |

Connected to 5V and GND of Controller |

|

VMOT & GND MOT |

Used to power the motor |

|

B1, B2 & A1, A2 |

Output Pins, Connected to the 4 Wires of motor |

|

DIRECTION |

Motor Direction Control pin |

|

STEP |

Steps Control Pin |

|

M0, M1, M2 |

Microstep Selection Pins |

|

FAULT |

Fault Detection Pin |

|

SLEEP |

Pins For Controlling Power States |

DRV8825 Stepper Motor Driver Applications

The DRV8825 stepper motor driver showcases its adaptability and dependability across a variety of high-precision and automation-focused domains.

Printers and Scanners

Incorporating the DRV8825 into printers and scanners allows for meticulous movement control, which significantly enhances the quality of prints and scans. Mostly in commercial and industrial environments, where reliability and performance consistency cannot be compromised, the DRV8825 proves invaluable in meeting these stringent requirements.

Robotics

The deployment of the DRV8825 within robotics facilitates the intricate control of robotic arms and mobile platforms. By offering multiple micro-stepping modes, this driver promotes smoother and more precise motions, which is active for the efficacy of robotic tasks where precision and repeatability are dominant.

Game Consoles

Game consoles benefit from the DRV8825 in the operation of their optical disc drives. The accurate control provided by the stepper motors is used for the precise reading and writing of data, thus ensuring a seamless gaming experience, that meets your expectations.

ATMs and Currency Processors

Precision in handling and sorting currency is enhanced through the use of the DRV8825 stepper motor driver in Automated Teller Machines (ATMs) and currency processors. The careful control of bill movement and alignment is used for minimizing errors and reducing machine downtime, thereby ensuring operational reliability.

Video Security Cameras

For video security cameras that necessitate pan-tilt-zoom functionality, the DRV8825 facilitates smooth and precise adjustments. This is requisite in security-sensitive environments where consistent and reliable surveillance operations must be maintained to ensure the safety and integrity of the area being monitored.

Office Automation Equipment

In office automation equipment, such as photocopiers and fax machines, the DRV8825 driver assures precise and dependable movement of components. Improved operational efficiency and extended equipment lifespan are the direct benefits of this precise control.

Factory Automation Systems

The DRV8825 plays a serious role in factory automation by meticulously managing the movements of various machinery and conveyor systems. Effective motor control aids in accurate positioning and the synchronization of operations, thereby fostering efficiency and productivity within the production environment.

Operations of the DRV8825 Stepper Motor Driver

The DRV8825 stepper motor driver stands out in managing stepper motor control via used pins, ensuring harmony with the A4988 driver module due to its similar pin configuration. This thoughtful design promotes effortless integration within numerous systems. Central to its function, the DRV8825 deciphers signals from a microcontroller to facilitate meticulous motor control.

Micro stepping for Enhanced Motion

A defining characteristic of the DRV8825 is its provision for micro-stepping. By subdividing each full step into finer increments, micro-stepping markedly improves the motor's fluidity and positional precision. Applications that rely on detailed motion, such as 3D printing or CNC machining, benefit immensely from this feature. Practical exposure in these fields emphasizes how each micro-step contributes to the fineness of designs and the exactitude of cuts, playing a serious role in realizing complex outputs with high quality.

Current Regulation and System Efficiency

Employing an integrated H-bridge configuration, the driver carefully regulates current through the motor coils. This strategy prevents overheating and supports ideal performance by aligning with common industry methods. The DRV8825 dynamically adjusts current, thereby prolonging motor lifespan and boosting performance. This adjustment is mostly advantageous in long-term or continuous operation environments.

Precision via Pulse Width Modulation

The operation of the DRV8825 hinges on Pulse Width Modulation (PWM) signals received from the microcontroller. PWM signals determine torque and speed using duty cycle adjustments, offering refined control over the motor's behavior. For instance, in robotics, mastering speed control via precise PWM modulation enables smooth movements and accurate navigation, which can often be the tipping point between operational success and failure.

Directional Control and Step Pulses

Direction and positioning are orchestrated through step pulses, granting meticulous motion management. Through careful timing of these pulses, movements become precise and repeatable. In automated machinery, such exact motion control is focal, ensuring equipment operates consistently and reliably. Feedback reveals the dangerous need for precise step pulse control to meet desired operational outcomes effectively.

DRV8825 Drivers Case Studies

Enhancing 3D Printing Performance

Driven by the desire for flawless 3D printing results, you can decide to enhance your 3D printer. They replaced the stock stepper drivers with DRV8825 modules, aiming for smoother and quieter operations along with improved resolution. This upgrade allowed for smoother and quieter operation, enhanced resolution, and finer calibration due to advanced micro-stepping capability. This decision significantly improved overall print quality. The enhanced micro-stepping capability of the DRV8825 facilitated more precise calibration, showcasing how focal the right component selection is in achieving the best machine performance.

Upgrading CNC Routers in Woodworking

A woodworking shop sought to boost the performance of their CNC router and opted for a retrofit using DRV8825 drivers. The upgraded drivers delivered superior motion control and reduced cutting vibrations, required for precise woodworking. Built-in overcurrent protection to prevent motor damage during tool jams. These features ensured consistent and reliable operation. This upgrade vividly illustrates the essence of integrating advanced technology into traditional craftsmanship, effectively enhancing efficiency and output quality.

Achieving Precision in Robotics

A robotics team at a university integrated DRV8825 drivers into their robot to secure precise movement and positioning capabilities. They benefited from compact design and compatibility with various microcontrollers for seamless system integration. The result was optimized navigation and manipulation tasks, demonstrating how the right driver can elevate the performance and accuracy of robotics applications. This accomplishment underlines the importance of component compatibility and design efficiency in complex projects.

Conclusion

The DRV8825 stepper motor driver is a versatile and powerful solution for controlling bipolar stepper motors in various applications, from 3D printers and CNC machines to robotics and industrial automation. This driver stands out due to its ability to deliver precise motion control, offering up to 1/32 micro stepping resolution, and robust protection features. With a wide operating voltage range of 8.2V to 45V and a current output capability of up to 2.5A per coil, the DRV8825 ensures smooth motor performance and adaptability in demanding environments. This article digs into the core components and features that make the DRV8825 a popular choice in precision motion systems.

Frequently Asked Questions [FAQ]

1. What is DRV8825?

The DRV8825 is often hailed as a top-tier stepper motor driver module, widely employed in precision machinery like 3D printers and CNC machines. These systems depend on the precise and reliable control of stepper motors to render accurate and repeatable movements.

2. How does DRV8825 work?

The DRV8825 operates by carefully managing the current flow to the motor coils, using a technique known as micro-stepping. This allows for finer increments of movement and results in smoother motion and higher precision than conventional full-step methods. This reduced vibrational noise and enhanced motion quality can significantly improve the performance of mechanical systems.

3. What are the key features of DRV8825?

The DRV8825's features make it mostly adaptable and useful for a range of applications with adjustable current control for optimal current setting, preventing motor overheating. Built-in thermal shutdown protection and overcurrent protection to safeguard the device. Support for micro-stepping up to 1/32 steps. Compatibility with a variety of control platforms, making it easy to integrate into diverse projects.

4. What is the maximum current rating of DRV8825?

The DRV8825 can typically handle up to 2.5A per coil with adequate heatsinking. Adhering to the datasheet specifications ensures optimal performance and longevity. Proper thermal management, useful to prevent overheating, can be facilitated by consulting detailed resources and datasheets.

5. What are the typical applications of DRV8825?

The DRV8825 finds use in scenarios that require meticulous stepper motor control, such as 3D printers, CNC machines, camera sliders, and linear actuators. These applications benefit from the high precision and reliability that the DRV8825 offers. Its capabilities can enhance both the operational efficiency and accuracy of automated systems.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

IP2721 Overview and Applications in Power Management

on October 10th

Why Choose the Adesto RM25C64DS-LTAI-B Memory Chip for Your Project?

on October 10th

Popular Posts

-

What is GND in the circuit?

on January 1th 2832

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2403

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2011

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 5th 1761

-

Comparison Between DB9 and RS232

on January 1th 1724

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1677

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1615

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1495

-

CR2450 vs CR2032: Can The Battery Be Used Instead?

Lithium manganese batteries do have some similarities with other lithium batteries. High energy density and long service life are the characteristics they have in common. This kind of battery has won the trust and favor of many consumers because of its unique safety. Expensive tech gadgets? Small appliances in our homes? Look around and you'll see them everywhere. Among these many lithium-manganes...on January 1th 1469

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1443