TLP250 Driver for MOSFET and IGBT: Manufacturer Overview, Footprint, and Application Guide

The TLP250 optical coupler, produced by Toshiba, plays a basic role in ensuring reliable electrical isolation between high-power and low-power circuits. Designed for applications like PWM control, motor drivers, and inverters, it efficiently bridges the gap between control and power systems using optical means. With its robust isolation voltage and ability to operate across a wide temperature range, the TLP250 offers suitable protection and noise suppression, making it an invaluable component in industrial, renewable energy, and consumer electronics applications. This post delves into its features, practical applications, and future developments, providing insights into its basic role in modern electronic systems.Catalog

Understanding the TLP250

The TLP250 optical coupler, manufactured by Toshiba, features a GaAlAs series LED on its input side and an integrated photodetector on the output side, providing electrical isolation that enables low-power and high-power circuits to interface without direct electrical contact through optical means. This isolation is major for reliable signal transmission. Supporting a forward current of 20mA and offering a minimum isolation voltage of 2500Vrms, it operates efficiently within a temperature range of -55°C to 125°C. With built-in high-voltage switches and low-power drivers, it suppresses noise, enhances resistance to transient impacts, and offers reverse voltage protection. These attributes make the TLP250 mostly well-suited for demanding applications such as PWM control, motor drivers, and inverters, ensuring robust performance in both industrial and consumer electronics.

Replacements and Equivalents

- FOD817

- MOC3021

- PC817

- TLP250H

TLP250 Manufacturer

Toshiba, a celebrated Japanese multinational corporation headquartered in Tokyo since 1875, is the producer of TLP250. The company has cultivated a vast array of capabilities, including power generation, industrial production, and environmental technologies. Throughout its long history, Toshiba has become Japan's top semiconductor producer and a major player in motor manufacturing. Toshiba boasts a history almost a century and a half long, importance of its resilience and adaptability in a rapidly evolving technological world. Their prowess in developing cutting-edge solutions for power generation and industrial production has solidified their standing as an industry leader. Toshiba's specialization in semiconductor technology has proven to be the backbone for advancements in power electronics and motor drive applications. In practical scenarios, the integration of Toshiba’s components frequently results in improved efficiency and dependability of industrial systems.

Toshiba’s semiconductor offerings range from large-scale integrated circuits (LSIs) to discrete devices, each plays a major role in optimizing power management and driving systems in various industrial applications. These innovations shine particularly bright in new energy vehicles (NEVs). Toshiba’s technologies are instrumental in boosting the performance and energy efficiency of these vehicles. The seamless integration of Toshiba's semiconductors in electric and hybrid vehicles highlights their dangerous role in modern automotive advancements.

Toshiba's focus on environmental sustainability is evident through its development of new technologies and products aimed at minimizing environmental impact while enhancing operational efficiency. Their dedication is reflected in the extensive use of Toshiba's semiconductors in new energy vehicles, contributing to lower emissions and greater energy efficiency. By championing environmentally friendly technologies, Toshiba supports global efforts to combat climate change and foster a sustainable future.

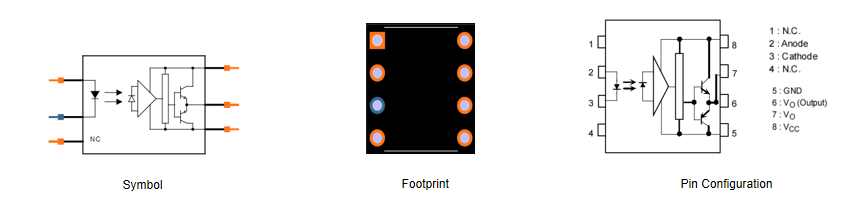

TLP250 Component Overview: Symbol, Footprint, and Pin Configuration

The TLP250, a component valued in optocoupler technology, consists of 8 pins designated for specific roles, each one contributing to the device's overall efficacy in its applications.

Pin Functions

Pin 1 (NC): No Connection

Pin 1 is not linked electrically to the internal circuitry. This pin offers flexibility in PCB layout, allowing designers to route paths without worrying about interference, thus simplifying the design process.

Pin 2 (Anode): LED Anode Terminal

The LED's anode within the TLP250 interfaces directly with control signals. Applying a consistent voltage to the anode is useful for the optocoupler's proper function, driven by microcontrollers in numerous applications.

Pin 3 (Cathode): LED Cathode Terminal

The cathode completes the LED circuit within the TLP250. Proper grounding of the cathode is requisite for efficient LED operation, which, in turn, ensures robust signal isolation.

Pin 4 (NC): No Connection

Much like Pin 1, Pin 4 has no electrical function internally. PCB designers often leverage NC pins to optimize signal path layouts, reducing potential cross-talk and noise.

Pin 5 (GND): Ground Connection

Pin 5 serves as the ground terminal. Ensuring a low-impedance connection to the ground mitigates noise and erratic behaviors, which is dominant in scenarios involving high-speed switching applications.

Pin 6 & 7 (Vo): Output Terminals

Pins 6 and 7 function as the output terminals, delivering the isolated signal to the load. These pins, often connected in designs for redundancy and current-sharing, ensure efficient signal transfer.

Pin 8 (Vcc): Positive Supply Terminal

Pin 8 is for the positive supply voltage. A stable, noise-free voltage supply is decided to maintain the LED and opto-transistor's internal operations, thereby influencing the component's reliability and performance.

Features of TLP250

Bidirectional Data Transmission and Low Current Operation

TLP250 facilitates bidirectional data transmission while operating with minimal current, a feature that enhances user experience suggestively. Low current usage directly contributes to power conservation, thereby bolstering energy efficiency and ensuring system reliability.

Wide Voltage Range Compatibility

The device functions effortlessly across a broad voltage range, which lends it flexibility and ease of integration with various electronic systems. This feature makes TLP250 highly adaptable to different circuit designs, enhancing its applicability in a broad spectrum of technological environments.

High-Speed Transmission with Minimal Delay

High-speed data transmission and negligible delay characterize this device. Such swift data transfer with minimal latency is basic for maintaining data stability. In real-time data processing applications, reducing transmission delays improves the overall performance of communication systems and other high-speed data-dependent applications.

Robust Isolation Voltage

With an impressive isolation voltage of 2500Vrms, TLP250 effectively separates distinct circuit segments. This protective feature safeguards sensitive components from electrical interference, which is particularly used in high-precision applications such as medical devices or industrial automation, where signal integrity and equipment protection are priorities.

Specifications and Technical Details of the TLP250

|

Product Attribute |

Attribute Value |

|

Manufacturer |

Toshiba |

|

Package

/ Case |

DIP-8 |

|

Packaging |

Tube |

|

Package

Length |

9.66mm |

|

Package

Width |

6.4mm |

|

Package

Height |

3.65mm |

|

Input

Voltage |

7 V

~ 40 V |

|

Output

Type |

Push-Pull |

|

Operating

Temperature |

-20°C

~ 85°C |

|

Mounting

Style |

Through

Hole |

|

Part

Status |

Obsolete |

|

Pin

Count |

8 |

|

Configuration |

Single |

Using TLP250 as an Isolated MOSFET Driver

The TLP250 exhibits notable utility in specific applications, yet its inherently low output current highlights the need for an external power amplifier circuit to sufficiently drive high-power Insulated Gate Bipolar Transistors (IGBTs). The operational dynamics of the device gain particular prominence when handling overcurrent scenarios. On detecting an overcurrent condition, the TLP250 engages directly with the system controller, receiving a shutdown signal. This interaction induces a negative voltage to be applied to the IGBT gate, effectuating an impressively rapid shutdown within 10 microseconds.

External Power Amplifier Circuit Integration

The low output current of the TLP250 suggests it struggles to directly drive high-capacity IGBTs or MOSFETs. It thus finds it typical to incorporate an external power amplifier circuit, bridging the gap between the TLP250’s output and the high current demands of these power transistors. Practical implementations frequently employ discrete transistor amplifiers or integrated power driver stages to attain the requisite power levels.

Swift Shutdown and Overcurrent Management

The TLP250's responsiveness in overcurrent conditions marks a substantial feature. On receiving a shutdown signal, its ability to promptly apply a negative voltage to the IGBT gate ensures a rapid cessation within a mere 10-microsecond interval. This swift action plays a dynamic role in safeguarding both the driver and the driven components from potential damage, emphasizing the importance of its design.

The rapid shutdown of IGBT conduction can induce considerable voltage spikes across the device, posing a risk of breakdown or failure. To combat these spikes, techniques like snubber circuits or transient voltage suppression (TVS) diodes are often utilized. Practical systems meticulously consider voltage ratings and transient response times to guarantee reliable operation, enhancing the robustness of the design.

Applications of TLP250

The TLP250, an optoisolator, finds diverse applications across various domains due to its ability to ensure secure electrical isolation and enhance signal integrity. This section delves deeper into its utility across several fields, uncovering its complex value.

Medical Equipment

Within medical equipment, the TLP250 ensures patient safety by effectively isolating control circuits. Medical devices, such as patient monitoring systems and imaging equipment, demand stringent isolation to prevent electrical shock. By integrating the TLP250, these systems achieve high reliability and safeguard patient well-being, reducing risks associated with direct electrical connections in sensitive medical environments.

Communication Equipment

In communication systems, the TLP250 thwarts interference between transmission and reception circuits, maintaining the integrity of communication signals. Network routers and signal transmission devices provided by the TLP250 preserve signal clarity, reduce crosstalk between channels and ensure uninterrupted communication, reinforcing the stability of data transmission.

Serial Communications

The TLP250 excels in isolating serial communication interfaces like RS-232 or RS-485 connections. It shields communication lines from transients or surges, thus safeguarding data integrity during transmissions. This isolation is paramount in industrial settings where harsh conditions can compromise the reliability of communication systems.

High-Voltage Measurements

In scenarios necessitating high-voltage measurements, the TLP250 separates measuring instruments from high-voltage circuits. In power distribution systems, this isolation ensures that high voltage doesn't affect sensitive measurement equipment, maintaining accuracy and safety, and allowing for precise data acquisition without compromising equipment integrity.

Industrial Automation

In the sphere of industrial automation, the TLP250 separates control signals from actuators to reduce electrical interference. Automated manufacturing lines this mitigation maintains signal integrity, thereby enhancing the overall efficiency and reliability of automation processes, ensuring consistent performance and stability.

Motor Drivers

Motor drivers often face challenges due to electrical noise from motors, which can disrupt control signals. The TLP250 isolates these control signals, preventing motor noise from interfering with the drive circuits. This results in smoother operation and more precise control of motors — used for applications where high precision and stability are required.

Frequently Asked Questions [FAQ]

1. What is the function of TLP250?

TLP250 operates as a gate driver for Insulated Gate Bipolar Transistors (IGBTs) or power Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs). It maintains electrical isolation between low-power control circuitry and high-power switching devices through a Gallium Aluminum Arsenide (GaAlAs) LED paired with an integrated photodetector. This arrangement ensures robust electrical isolation and efficient signal transmission, a necessity in applications requiring integrity between different power domains for safe and efficient operation.

2. How to use TLP250?

TLP250 serves as a non-inverting low-side driver for MOSFETs. For stable operation, it is advisable to connect a 0.47µF electrolytic capacitor to the power supply, aiding in voltage stabilization. Practical experience demonstrates that placing such capacitors reduces voltage ripple, enhancing the TLP250’s performance. Users often discover that configuring the TLP250 with suitable peripheral components suggestively boosts the reliability of power-switching circuits.

3. How does the TLP250 provide electrical isolation?

The TLP250 achieves electrical isolation through the use of an infrared LED that emits light detected by a phototransistor. This optical coupling method ensures no direct electrical connection between the emitter and detector, thus completely isolating the control and power sections of the circuitry. This approach is instrumental in preventing high voltages from feeding back into control electronics, preserving signal integrity, and safeguarding the system.

4. What are the advantages of using a TLP250 in circuit design?

The TLP250 offers multiple advantages enhanced performance and reliability in switching circuits, effective isolation between control and power sections, reduction of voltage ripple through appropriate capacitor integration, and improved safeguarding of control electronics from high voltage feed-back.

5. Can the TLP250 be used to control high-power loads?

While primarily a low-power device, the TLP250 is effectively utilized in control circuits driving high-power components like relays and power transistors. It serves as an intermediary gate driver within larger systems handling substantial power levels. Engineers frequently deploy the TLP250 in scenarios necessitating precise control over high-power switching, taking advantage of its dependable isolation and signal transmission features for optimal system performance.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

TL494CN PWM Controller: Pin Layout and How it Works?

on September 27th

STM32F103RCT6 Microcontroller: Alternatives, Pinout, and Strengths

on September 27th

Popular Posts

-

What is GND in the circuit?

on January 1th 3126

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2680

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 15th 2230

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2187

-

Comparison Between DB9 and RS232

on January 1th 1804

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1778

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1731

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1683

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1676

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 15th 1642