TL3845P PWM Controller: Pinout, Key Features, and Layout Tips

In modern electronics, efficient power management is useful for both energy conservation and system performance. Pulse Width Modulation (PWM) controllers play a main role in delivering precise power to various components. This article digs into the details of PWM controllers, starting with the basics of Pulse Width Modulation and its integration into microcontrollers, followed by an in-depth exploration of the TL3845P—a PWM controller known for its robust design and versatile applications. Through this comprehensive guide, you’ll uncover how these controllers enhance system efficiency, noise resistance, and adaptability in power management scenarios.Catalog

Understanding PWM Controllers

Pulse Width Modulation (PWM) employs digital outputs from microprocessors to govern analog circuits, offering a method to vary analog signal levels digitally. This technique is extensively utilized in measurement, communication, and power management, allowing for enhanced system efficiency and lowered power consumption.

Modern microcontrollers often include built-in PWM controllers, facilitating direct digital signaling without the need for digital-to-analog conversion. Digital control reduces noise interference as it only affects digital signals that change binary state, offering an edge over analog systems. Digitally controlling analog circuits offers several benefits including LED dimming through PWM, and eliminating the need for costly dimmer switches. Digital signals within PWM systems resist noise-induced errors, making them valuable in environments with high electromagnetic interference. Improved efficiency results in more streamlined and cost-effective designs.

PWM also has substantial applications in communication systems. Analog signals converted to PWM can be sent over longer distances with reduced noise and then filtered back to analog at the receiver end. This method ensures the integrity of communications, making it requisite in environments prone to electromagnetic interference. PWM controllers play a dangerous role in precise power delivery it is used to regulate voltage in computer power supplies, ensuring both stability and energy efficiency. This precision allows sensitive components to receive steady and reliable power, preventing potential damage and improving overall system longevity.

Aspects of the TL3845P PWM Controller

The TL3845P is a Pulse Width Modulation (PWM) controller meticulously crafted for switching power supplies. Responsive to input voltage fluctuations at the COMP terminal, this device finely adjusts the switching signal's frequency to uphold a stable output voltage. The sophisticated internal circuitry boasts a low-voltage lockout (UVLO) that delicately sips under 1 mA of current, alongside a precision reference voltage to sharpen the accuracy of the error amplifier. The ensemble includes a PWM comparator equipped with current limit control, logic for latching operations, and a versatile totem-pole output capable of delivering 200 mA. With an efficient 500 kHz operation frequency and a maximum voltage threshold of 30 V, the TL3845P performs reliably within a temperature spectrum of 0°C to 70°C.

Low Voltage Lockout (UVLO)

Cherished for its ability to protect the system during under-voltage conditions, UVLO averts malfunction by ensuring the controller remains properly biased. This feature proves invaluable in everyday scenarios where power interruptions are frequent, adding an extra layer of assurance and durability to the system.

Precision Reference Voltage

A consistent and precise reference voltage is the cornerstone of the error amplifier's accuracy, having a direct hand in output regulation. This meticulous attention to detail keeps the output steadfast against variations, a trait especially prized in high-performance electronic devices.

PWM Comparator with Current Limit Control

The pulse-width modulation comparator, integrated with current limit control, is instrumental in sustaining system stability and efficiency. By manipulating the current, the comparator alleviates the perils of overheating and undue component stress, thus fortifying the longevity of the power supply.

Latching Logic Mechanism

The latching logic mechanism, ingrained in the TL3845P, orchestrates predictable and controlled switching sequences. This regulation aspect is active in intricate systems where synchronized operations are dominant.

Totem-Pole Output

Boasting a versatile totem pole output capable of 200 mA, the TL3845P demonstrates strength in versatility and efficiency. Operating smoothly at frequencies up to 500 kHz, the output stage ensures adept handling of various power demands.

Equivalent Models

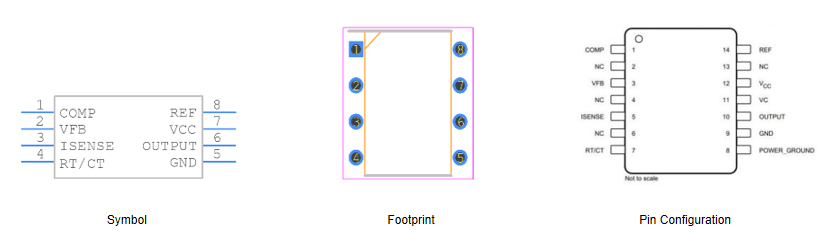

TL3845P Pinout, Symbol, and PCB Footprint

Below is the symbol, Footprint, and pin configuration representation of the TL3845P.

Features and Specifications of the TL3845P PWM Controller

The TL3845P PWM controller is meticulously designed with a range of advanced features aimed at optimizing performance in various power conversion applications. The low output resistance error amplifier ensures precise error correction, an ultimate aspect of maintaining voltage stability. Moreover, a hysteretic Undervoltage lockout (UVLO) mechanism offers robust protection by avoiding erroneous operations due to low voltage situations, keeping the system safe until normal conditions are restored.

Enhanced Protection Mechanisms

The architecture includes double pulse suppression, required for averting erroneous pulses resulting from noise or transient conditions. This feature suggestively boosts system reliability by ensuring only valid pulses influence the switching events.

Efficient Power Consumption

A standout characteristic is its low startup current requirement, less than 1mA. This efficiency is highly beneficial in energy-sensitive applications, such as battery-operated devices, where reducing power consumption during startup can substantially extend operational life.

Automatic Performance Optimization

Automatic feed-forward compensation is a noteworthy feature. It dynamically adjusts control parameters to offset variations in input voltage, enhancing converter performance across a broad spectrum of operating conditions. This adaptability echoes applications where such variations are common.

Output Power Management

The high current totem pole output structure is engineered to provide substantial output drive capability. This enables efficient control over power transistors. Pulse-by-pulse current limiting further protects against overcurrent conditions, a major aspect in industrial contexts where high currents could inflict damage.

Load Handling and Response

Enhanced load response characteristics allow the controller to swiftly adjust to changes in load demand, ensuring stability and performance. This capability is mostly active in dynamic environments where load conditions can change rapidly, such as in telecommunications or computing systems.

Analyzing the Technical Parameters of TL3845P

|

Product Attribute |

Attribute Value |

|

Manufacturer |

Texas Instruments |

|

Package / Case |

PDIP-8 |

|

Packaging |

Tube |

|

Length |

9.81 mm |

|

Width |

6.35 mm |

|

Height |

4.57 mm |

|

Switching Frequency |

500 kHz |

|

Rise Time |

50 ns |

|

Fall Time |

50 ns |

|

Operating Supply Current |

11 mA |

|

Operating Supply Voltage |

7.6V~30V |

|

Operating Temperature |

0°C ~ 70°C |

|

Part Status |

Active |

|

Pin Count |

8 |

|

Number of Outputs |

1 Output |

|

Mounting Style |

Through Hole |

|

Product Type |

Switching Controllers |

Operating Principle of TL3845P PWM Controller

Initial Activation and Error Amplification

When power is supplied to the VCC pin of the TL3845P, the chip initiates its function by energizing the internal circuits. The process unfolds as the feedback voltage enters the error amplifier. This amplifier continuously compares the feedback voltage with a stable reference voltage. The difference between these voltages produces an error signal, which serves as the foundation for subsequent processing. This process embodies the vigilance and precision desired to maintain the accuracy required for optimal performance.

PWM Signal Generation

The error signal, once generated, is handed off to the PWM comparator. The comparator, central to the PWM control mechanism, crafts a precise PWM signal from the error input. The duty cycle of this PWM signal is closely dependent on the input voltage. A higher input voltage results in a proportionally longer duty cycle. Conversely, a lower input voltage leads to a shorter duty cycle.

This modulation fine-tunes the switch tube’s on and off intervals, stabilizing the output voltage. Practically, this ensures consistent output even amidst fluctuating input conditions, empowering the system with the reliability and adaptability it needs to thrive.

Current Limiting and Overload Protection

Integrated within the TL3845P is a function dedicated to current limiting. This feature is vigilant in monitoring and controlling the output current, shielding the switch tube from potential overload situations. By curtailing current flow when it crosses safe thresholds, the controller upholds the integrity and longevity of the system components. In practical scenarios, this protection mechanism stands as a sentinel, preempting hardware damage and ensuring sustained performance under varying load conditions. This embodies a layer of defense requisite in maintaining the resilience and durability of the system.

Use Cases for the TL3845P PWM Controller

Utilization in Power Supply Systems

The TL3845P plays a major role in a diverse array of power supply systems, especially within the industrial and communication equipment sectors. Its PWM control capabilities facilitate effective energy management and reliable performance, ensuring consistent operation despite fluctuating load conditions. In environments where power integrity defines operational success, the TL3845P stands as a steadfast guardian of stability.

Consumer Electronics

Employed extensively in consumer electronics, the TL3845P graces devices such as computers, mobile phones, and televisions. These applications reap the rewards of the controller's precise power regulation, bolstering device efficiency and extending battery lifespan. The TL3845P's adeptness at swiftly accommodating shifts in power demands fosters seamless operation and optimizes overall device performance.

Isolated Flyback Power Controller

One distinguished functionality of the TL3845P lies in its role as an isolated flyback power controller. This application is focal in ensuring steady voltage and current output regulation, which is beneficial for devices dependent on a stable power supply. The robust regulation mechanism remarkably enhances transient response, equipping systems to adeptly manage abrupt surges in power demand while preserving stability and performance.

Enhancement of Transient Response

In power-sensitive environments, the TL3845P's quick adaptation to load variations proves immensely valuable. The heightened transient response achieved through continuous voltage and current output regulation bolsters operational precision and reliability. This feature shines in high-precision, robust scenarios, such as communication equipment, where maintaining an uninterrupted power supply is a must.

Designing the PCB: Layout Guidelines for the TL3845P

Select the Right Inductor

When choosing an inductor, opt for one with low Electromagnetic Interference (EMI) and a ferrite core. Toroid and encased E-core inductors are excellent options. If using inductors with open cores, ensure they still exhibit low EMI characteristics. These should be strategically placed away from low-power traces and sensitive components to minimize interference.

Optimal Placement of External Components

Position external compensation components close to the Integrated Circuit (IC). Surface-mounted devices are preferable for this purpose. This setup minimizes noise and signal interference, which is dynamic for the stability and performance of the system.

Effective Design of Feedback Traces

The design of feedback traces should emphasize being as direct and thick as possible. Ensure these traces maintain a safe distance from noise sources and are located on the PCB side opposite to the inductors. Separate these traces with a ground plane, which greatly reduces the potential for noise coupling.

Strategic Capacitor Positioning

Place input and output capacitors close to the IC to minimize inductance effects. Using surface-mounted capacitors is recommended to reduce lead length and associated noise. This approach enhances voltage regulation stability.

Efficient Power Traces and Grounding

Design power traces to be short, direct, and thick. Adhere to a minimum width of 15 mils per ampere. Ground connections should be placed as close to each other as possible, with a fully dedicated ground plane on the PCB. Implementing ground planes on both sides of the PCB effectively reduces noise by minimizing ground loop errors and absorbing EMI, thereby improving overall circuit performance.

Considerations for Multi-Layer Boards

For multi-layer boards, separate power and signal planes with ground planes. Use standard vias capable of conducting the required current between layers. It is used to ensure current loops curl in the same direction in both power states to avoid magnetic field reversals, which helps in reducing EMI.

Frequently Asked Questions [FAQ]

1. What are the typical applications of the TL3845P IC?

The TL3845P IC is found to be extensively used in DC-DC converters, voltage regulators, and power supplies across various electronic systems. It plays a substantial role in power management, basic telecommunications infrastructure, industrial automation, and consumer electronics systems. For example, telecommunications stabilize power for signal processing units, ensuring continuous and reliable communication. It helps maintain smooth operations in industrial automation systems by providing regulated power. In consumer electronics, it enhances the performance and lifespan of devices by ensuring efficient power distribution.

2. What is the replacement and equivalent of TL3845P?

Several ICs can replace the TL3845P, including TL3843P. TL3844P, AND TL3845PE4. These alternatives offer similar functionalities, ensuring minimal disruption when substituting components. For instance, engineers might opt for the TL3843P in existing designs requiring tight voltage regulation, while the TL3845PE4 could provide enhanced efficiencies in newer applications.

3. What is the TL3845P IC used for?

The TL3845P functions predominantly as a PWM voltage mode controller in power supply and voltage regulation applications. This ensures stable output voltages under varying load conditions, dangerous for computer power supplies, and maintaining safe voltage limits for processors. Electric vehicles, controlling power distribution systems, and enhancing battery life and overall vehicle performance.

4. What protections or features does the TL3845P provide?

The TL3845P IC is equipped with multiple protection features including overcurrent protection, overvoltage protection, under-voltage lockout, and a soft start feature. These protections contribute to a safer operational environment by mitigating the risks of component damage. For instance, the soft start feature gradually increases the power supply during system startups, preventing sudden surges and extending the IC's and the system's lifespan, akin to gradually intensifying tasks to avoid burnout.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

S9015 PNP Transistor: Equivalent Models, Structural Insights, and C9015 Comparison

on September 27th

A Complete Guide to the CD4046BE and Its Applications

on September 27th

Popular Posts

-

What is GND in the circuit?

on January 1th 3142

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2689

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 15th 2260

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2194

-

Comparison Between DB9 and RS232

on January 1th 1806

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1781

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1735

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1690

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1688

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 15th 1650