L293DD Channel Driver: Complete Guide to Pinout, Features, and Datasheet

Managing inductive loads efficiently is a serious challenge in modern electronics, and the L293DD four-channel push-pull driver stands out as a versatile solution. With integrated diodes for flyback protection and the ability to drive relays, solenoids, and DC or stepping motors, it’s a favored choice for applications such as industrial automation and educational robotics. This article explores the L293DD’s pinout, key features, and performance characteristics, providing the basic details for leveraging its motor control and switching systems capabilities.Catalog

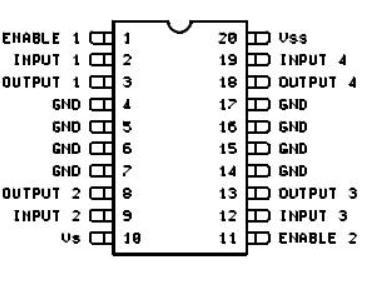

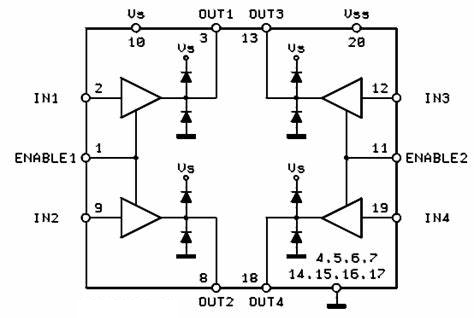

Pinout of L293DD

L293DD Overview

The L293DD is a high-voltage, high-current four-channel driver designed to accommodate standard DTL or TTL logic levels. This versatile IC excels at driving inductive loads such as relays, solenoids, DC and stepping motors, and power transistors. It's mostly effective in switching applications with frequencies up to 5 kHz. The package is a 20-pin surface mount type, featuring 8 center pins dedicated to heatsinking for efficient thermal management.

The L293DD’s ability to interface with both DTL and TTL logic levels enhances its adaptability across a wide array of applications. In industrial automation, devices frequently transition between different types of loads; the L293DD manages these changes seamlessly thanks to its high-current handling capacity. Its robustness in dealing with inductive loads without performance deterioration opens up practical uses, such as motion control in manufacturing equipment.

Managing heat effectively is paramount in high-current driver applications. The 8 center pins for heatsinking in the 20-pin configuration epitomize the L293DD’s focus on maintaining stable operating temperatures. Effective heat dissipation reduces the risk of thermal shutdown and prolongs the device’s lifespan. Practical applications often benefit from integrating heat sinks or optimizing PCB design to enhance heat transfer, further improving operational reliability. With an operational range extending to 5 kHz, the L293DD is ideal for applications requiring swift switching. This frequency range is versatile, covering low-frequency motor control and higher-frequency switching in power transistors. Actual efficiency often involves precise tuning of driver controls to match specific load characteristics, resulting in optimized performance and reduced energy losses, thereby contributing to overall system efficiency.

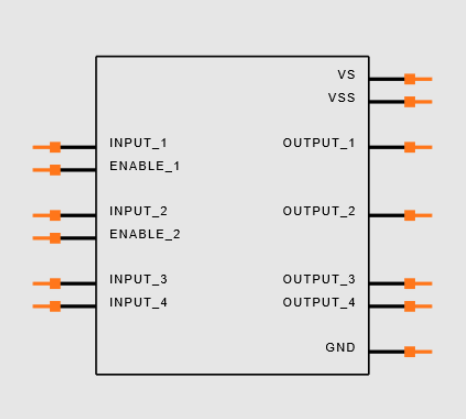

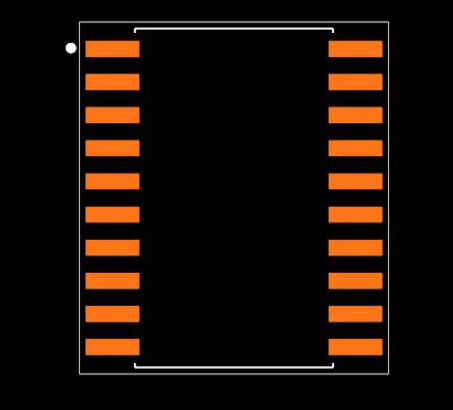

L293DD CAD Representation

Symbol

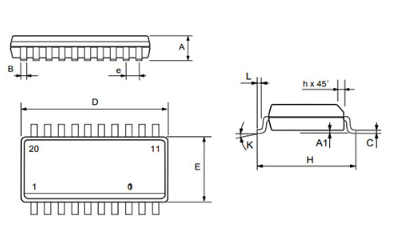

Footprint

3D Model

Key Specifications

|

Type |

Parameter |

|

Lifecycle

Status |

ACTIVE

(Last Updated: 6 months ago) |

|

Factory

Lead Time |

10

Weeks |

|

Mount |

Surface

Mount |

|

Mounting

Type |

Surface

Mount |

|

Package

/ Case |

20-SOIC

(0.295, 7.50mm Width) |

|

Number

of Pins |

20 |

|

Voltage

Rated |

50V |

|

Operating

Temperature |

-40°C

~ 150°C TJ |

|

Packaging |

Tube |

|

Tolerance |

1% |

|

JESD-609

Code |

e4 |

|

Part

Status |

Active |

|

Moisture

Sensitivity Level (MSL) |

3

(168 Hours) |

|

Number

of Terminations |

20 |

|

ECCN

Code |

EAR99 |

|

Resistance |

15kOhm |

|

Terminal

Finish |

Nickel/Palladium/Gold

(Ni/Pd/Au) |

|

Applications |

General

Purpose |

|

Power

Rating |

100mW |

|

Voltage

- Supply |

4.5V

~ 36V |

|

Terminal

Position |

DUAL |

|

Terminal

Form |

GULLWING |

|

Peak

Reflow Temperature (°C) |

250 |

|

Supply

Voltage |

5V |

|

Terminal

Pitch |

1.27mm |

|

Time

@ Peak Reflow Temperature (Max) |

30s |

|

Base

Part Number |

L293 |

|

Function |

Driver

- Fully Integrated, Control & Power Stage |

|

Case

Code (Metric) |

1608 |

|

Case

Code (Imperial) |

603 |

|

Max

Output Current |

1.2A |

|

Operating

Supply Voltage |

24V |

|

Number

of Channels |

4 |

|

Interface |

Parallel |

|

Nominal

Supply Current |

2mA |

|

Output

Configuration |

Half

Bridge (4) |

|

Output

Characteristics |

3-STATE |

|

Output

Current per Channel |

600mA |

|

Collector-Emitter

Voltage (VCEO) |

36V |

|

Max

Collector Current |

1.2A |

|

Output

Polarity |

TRUE |

|

Input

Characteristics |

STANDARD |

|

Voltage

- Load |

4.5V

~ 36V |

|

Output

Peak Current Limit-Nom |

1.2A |

|

Supply

Voltage1-Nom |

24V |

|

Built-in

Protections |

THERMAL |

|

Motor

Type |

Brushed |

|

Output

Current Flow Direction |

SOURCE

SINK |

|

Motor

Type - AC, DC |

Brushed

DC |

|

Motor

Type - Stepper |

Bipolar |

|

Height |

450μm |

|

Length |

1.6mm |

|

Width |

800μm |

|

REACH

SVHC |

Unknown |

|

Radiation

Hardening |

No |

|

RoHS

Status |

ROHS3

Compliant |

|

Lead-Free |

Lead-Free |

Core Features of L293DD

Output Current Handling

The L293DD is planned to deliver an output current of 600mA per channel, capable of reaching a peak current of up to 2A per channel in short, non-repetitive bursts. These characteristics make it suitable for driving medium-power devices, enhancing the system's robustness. Specialists find these attributes mainly valuable in applications requiring nuanced motor control, which in turn boost’s reliability.

Enable Facility

An enable facility allows for the selective activation of motor channels. This feature optimizes efficiency by tailoring energy flow to specific components. This output control mechanism is beneficial in designing circuits that require conditional actuation or staggered channel engagement, ensuring both precision and energy conservation.

Overtemperature Protection

Thermal management significantly influences the longevity and performance of electronic components. The L293DD’s overtemperature protection mechanism detects excess heat buildup and adjusts operations to prevent thermal damage. This safeguard makes the L293DD ideal for use in environments where temperature fluctuations are a common concern, thus providing a reliable solution to overheating risks.

High Noise Immunity Logical Input

Signal integrity can be compromised by environmental noise. The L293DD’s high noise immunity logical input guarantees accurate signal interpretation, minimizing errors. This feature assures consistent performance in electrically noisy surroundings, thereby enhancing overall system stability and reliability.

Internal Clamp Diodes

The internal clamp diodes of the L293DD protect transistors from voltage spikes, mainly those caused by inductive loads. This built-in protection is invaluable in scenarios involving components like motors or relays, as it mitigates potential voltage transients that could damage electronic circuits.

Circuit Diagram of L293DD

Applications of L293DD

Use in DC Motor Drivers

Frequently employed in DC motor driver circuits, the L293DD supports various robotics and automation projects. It offers bidirectional control, allowing for precise movement and speed regulation, used for tasks needing high accuracy. For instance, in automated guided vehicles (AGVs) and robotic arms used in manufacturing, precise control of motor operations is achieved through the L293DD, significantly enhancing efficiency and precision.

Role in Relay Drivers

The L293DD is also prominent in relay driver circuits. Relays require sufficient current to function, which the L293DD can effectively supply. Highly beneficial in industrial automation systems, the L293DD manages the switching of heavy loads, ensuring reliability and safety in environments such as controlling heavy machinery or regulating HVAC systems.

Application in Stepper Motor Drivers

Stepper motors operate correctly only with precise control of step sequences. The L293DD excels in this area and is widely used in stepper motor driver applications. Handling rigorous requirements of CNC machines and 3D printers ensures accurate and repeatable movements. In medical devices like automated syringe pumps and precise imaging equipment, the L293DD achieves the needed precision and reliability.

Use in Two-Phase Motor Driver Applications

The L293DD proves instrumental in two-phase motor driver applications. These motors, common in small household appliances and office equipment, benefit from the L293DD's efficient and controllable power supply. Ensuring smooth operation and prolonging device life, the L293DD plays a basic role in printers and scanners. The motor reliability directly improves your experience and equipment lifespan.

Dimensional Outline of L293DD

Manufacturer Information

STMicroelectronics, a pioneering semiconductor company, stands at the forefront of technological innovation. They possess extensive expertise in both silicon and system solutions, contributing significantly to modern technology trends. The innovative spirit and technical mastery of this company are evident in its diverse product range, such as the L293DD.

STMicroelectronics showcases leadership through its deep involvement in SoC technology. This technology integrates multiple functions onto a single chip, which enhances performance and reduces costs. The L293DD stands as a testament to their ability to produce compact and efficient electronics. Actual applications of SoC technology are prevalent in many consumer electronics, where seamless functionality and reduced power consumption draw your admiration and satisfaction.

Leveraging advanced fabrication techniques and deep design knowledge, STMicroelectronics addresses complex technological challenges. Their components drive the efficiency of modern electronic systems. These advancements have been validated through widespread industry adoption, demonstrating a blend of notional and actual mastery. Their expertise allows them to create solutions tailored to the specific demands of various high-tech applications, cementing their edge in the competitive semiconductor landscape.

Comparable Parts

|

Part Number |

Manufacturer |

Package / Case |

Number of Pins |

Interface |

Supply Voltage |

Supply Voltage1-Nom |

RoHS Status |

Part Status |

Terminal Form |

|

L293DD |

STMicroelectronics |

20-SOIC

(0.295", 7.50mm Width) |

20 |

Parallel |

5 V |

24 V |

RoHS3

Compliant |

Active |

Gull

Wing |

|

SN751177NSR

|

Texas

Instruments |

16-SOIC

(0.209", 5.30mm Width) |

16 |

- |

5 V |

5 V |

RoHS3

Compliant |

Active |

Gull

Wing |

|

TJA1048T,118 |

NXP

USA Inc. |

14-SOIC

(0.154", 3.90mm Width) |

- |

- |

5 V |

- |

RoHS3

Compliant |

Active |

Gull

Wing |

|

PCF8584T/2,518

|

NXP

USA Inc. |

14-SOIC

(0.154", 3.90mm Width) |

- |

- |

5 V |

- |

RoHS3

Compliant |

Active |

Gull

Wing |

|

TJA1043T,118

|

NXP

USA Inc. |

20-SOIC

(0.295", 7.50mm Width) |

- |

Parallel |

5 V |

- |

RoHS3

Compliant |

Active |

Gull

Wing |

Datasheet PDF

L293DD Datasheets:

SN751177NSR Datasheets:

TJA1043T,118 Datasheets:

Cylindrical Battery Holders.pdf

Frequently Asked Questions [FAQ]

1. What is L293D?

The L293D is a motor driver IC with 16 pins. It facilitates the concurrent control of two DC motors, enabling independent governance over each motor's directional movement. This IC finds favor in embedded systems and robotics applications, appreciated for its versatility and efficient performance.

2. How does the L293D operate?

The L293D leverages its 16 pins to enable multi-directional control of DC motors, accommodating both small and large varieties. The architecture supports the precise manipulation of two motors independently. This capability translates to a broad range of applications in automated systems, ensuring precise motor control.

3. How to program L293D?

Mount the L293D on a breadboard. Supply 5V voltage to the Enable 1, Vss, and Vs pins. Connect digital output pins to input 1 and input 2. This setup permits the coordination of motor directions via software, typically through a microcontroller like an Arduino. The successful motor operation often hinges on meticulous pin configuration.

4. What is the purpose of the L293D motor driver?

The L293D IC manages two DC motors, providing bidirectional drive currents up to 600mA per channel, with operational voltages spanning from 4.5V to 36V. Robotics applications and automotive applications' role in enhancing control efficiency is frequently highlighted in manufacturing practice.

5. Which is better L293D vs L298N?

The L293D and L298N motor drivers have distinct characteristics. L298N is higher current handling up to 4A with adequate heatsinking and operating voltages up to 46V. L293D is driving currents up to 600mA and operates within a voltage range of up to 36V. In production practice, the choice often depends on the specific current and voltage requirements, balancing functionality, and power efficiency.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

Exploring the SSM2164 VCA: Feature, Schematic, and Alternatives

on October 13th

Arduino Micro: Features, Benefits, and Applications

on October 13th

Popular Posts

-

What is GND in the circuit?

on January 1th 2824

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2399

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2009

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 5th 1758

-

Comparison Between DB9 and RS232

on January 1th 1723

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1674

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1613

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1492

-

CR2450 vs CR2032: Can The Battery Be Used Instead?

Lithium manganese batteries do have some similarities with other lithium batteries. High energy density and long service life are the characteristics they have in common. This kind of battery has won the trust and favor of many consumers because of its unique safety. Expensive tech gadgets? Small appliances in our homes? Look around and you'll see them everywhere. Among these many lithium-manganes...on January 1th 1469

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1438