on April 12th

799

What is SMD Packaging?

In the dynamic field of electronics manufacturing, the adoption of Surface-Mount Devices (SMD) represents a significant shift toward more efficient, compact, and high-performance technologies. SMDs, crucial elements in modern circuit design, are directly mounted onto the surface of printed circuit boards (PCBs) using Surface-Mount Technology (SMT). This introduction explores how SMD packaging, with its specialized designs tailored for various electronic components like transistors, resistors, capacitors, diodes, and integrated circuits, revolutionizes device assembly and functionality. By eliminating the need for components to penetrate the PCB, SMDs allow for a denser configuration of parts, fostering the development of smaller electronic devices that maintain or enhance functional capabilities. This packaging technology is characterized by a systematic assembly process where precision is paramount—from the application of solder paste to the exact placement of components by automated machinery, culminating in reflow soldering that solidifies connections, ensuring high-quality, error-minimized electronic assemblies. As we delve deeper into the specifics of different SMD packaging types and their applications, it becomes clear that the evolution of this technology is a cornerstone for the miniaturization and performance enhancement in today's electronics. This passage will give you a detailed introduction to SMD packaging types, packaging methods, characteristics, etc.

Catalog

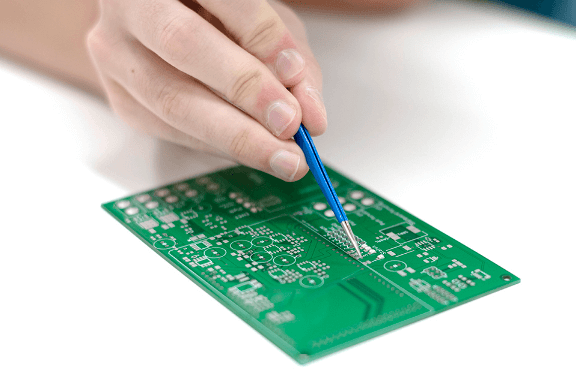

Figure 1: SMD Package

Surface-Mount Devices (SMD) are essential components in modern electronic manufacturing. These components mount directly to the surface of a printed circuit board (PCB) without having to be mounted through the board. The packaging of these devices, known as SMD packaging, is designed to facilitate this mounting process using Surface-Mount Technology (SMT).

SMD packaging involves a specific physical design and layout that accommodates various component types, such as transistors, resistors, capacitors, diodes, and integrated circuits. Each type of component has a unique physical size, pin count, and thermal performance, tailored to meet different application requirements. This method of packaging enhances assembly efficiency, optimizing both the performance and cost-effectiveness of products.

In practical terms, the process of mounting SMDs on a PCB is highly systematic. Initially, the PCB is prepared with solder paste applied at precise locations. Components are then picked up and placed accurately by automated machines, based on their design specifications. The board passes through a reflow soldering oven where the solder melts and solidifies, securing the components in place. This process is not only fast but also minimizes error, ensuring high-quality electronic assemblies.

This approach to electronic component packaging allows for a greater density of parts on the circuit board, leading to smaller and more compact electronic devices without compromising their functionality. As a result, SMD packaging plays a pivotal role in the advancement of electronic technology, accommodating the ongoing trend towards miniaturization and improved performance.

|

SMD

Package Size

|

Length

(mm)

|

Width

(mm)

|

Height

(mm)

|

|

0201

|

0.6

|

0.3

|

0.3

|

|

0402

|

1.0

|

0.5

|

0.35

|

|

0603

|

1.6

|

0.8

|

0.35

|

|

0805

|

2.0

|

1.25

|

0.45

|

|

1206

|

3.2

|

1.6

|

0.45

|

|

1210

|

3.2

|

2.5

|

0.45

|

|

1812

|

4.5

|

3.2

|

0.45

|

|

2010

|

5.0

|

2.5

|

0.45

|

|

2512

|

6.4

|

3.2

|

0.45

|

|

5050

|

5.0

|

5.0

|

0.8

|

|

5060

|

5.0

|

6.0

|

0.8

|

|

5630

|

5.6

|

3.0

|

0.8

|

|

5730

|

5.7

|

3.0

|

0.8

|

|

7030

|

7.0

|

3.0

|

0.8

|

|

7070

|

7.0

|

7.0

|

0.8

|

|

8050

|

8.0

|

5.0

|

0.8

|

|

8060

|

8.0

|

6.0

|

0.8

|

|

8850

|

8.0

|

5.0

|

0.8

|

|

3528

|

8.9

|

6.4

|

0.5

|

Chart 1: Common SMD Package Sizes

Surface-mount device (SMD) packaging comes in several common types, each designed for efficiency and compactness, contrasting sharply with the older through-hole technology. Here’s a breakdown of the primary SMD packaging types and their specific roles in electronic manufacturing:

Figure 2: Types of SMD Packaging

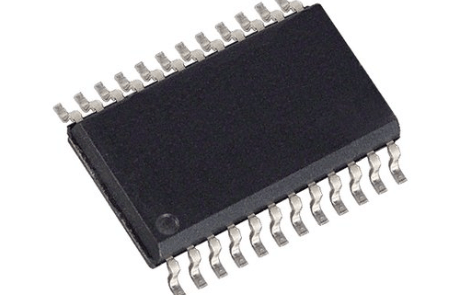

SOIC (Small Outline Integrated Circuit): This type of packaging is particularly used for integrated circuits. SOIC packages are characterized by their narrow body and straight leads, which make them suitable for applications where space is a premium but not extremely limited.

Figure 3: SOIC

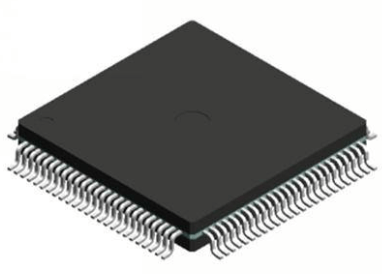

QFP (Quad Flat Package): Featuring leads on all four sides, QFP packages are utilized for integrated circuits that require more connections than what SOIC can offer. This package type supports a higher pin count, facilitating more complex functionalities.

Figure 4: QFP

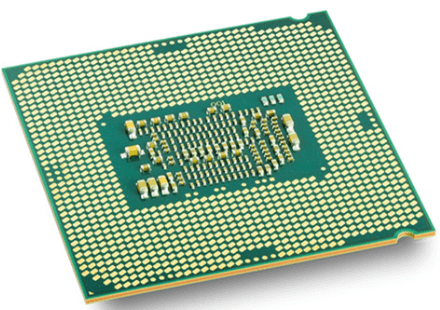

BGA (Ball Grid Array): BGA packages use tiny solder balls as connectors instead of traditional pins, allowing for a much higher density of connections. This makes BGAs ideal for advanced integrated circuits in compact devices, enhancing assembly density and overall device performance dramatically.

Figure 5: BGA

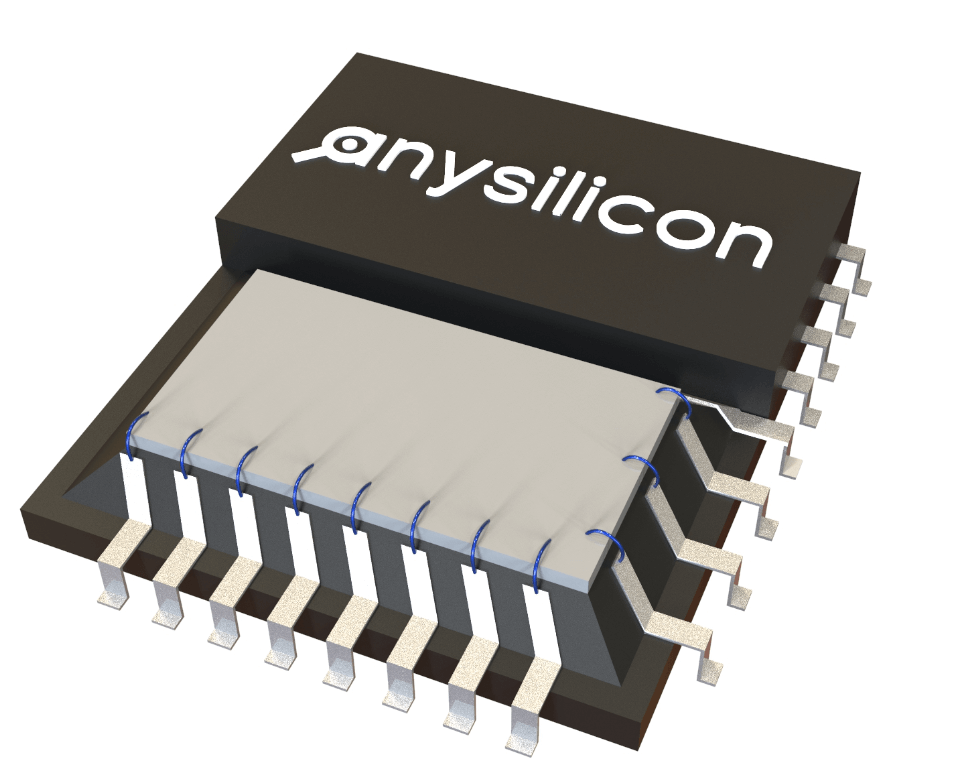

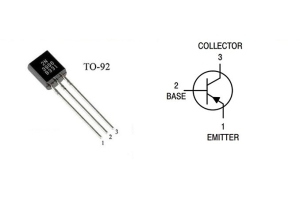

SOT (Small Outline Transistor): Designed for transistors and similar small components, SOT packages are tiny and efficient, providing reliable connections in tight spaces without taking up much room on the PCB.

Figure 6: SOT

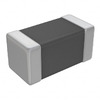

Standard Size Components: Common sizes such as 0603, 0402, and 0201 are used for resistors and capacitors. These dimensions indicate increasingly smaller components, with 0201 being one of the smallest standard sizes available, ideal for extremely compact PCB layouts.

In practical applications, the choice of SMD packages is a headache, because there are many types to choose from and it is difficult but also important to choose the right one. For instance, when assembling a consumer electronic device that requires both high functionality and compact size, a combination of QFP for complex circuitry and BGA for high-density IC packaging might be employed. SOT packages could be used for power management components like transistors, while standard-size components like 0603 resistors and capacitors help in maintaining a balance between size and functionality.

Each type of SMD packaging enhances the final product by allowing more efficient use of space and enabling the development of smaller, more powerful electronic devices. This miniaturization trend is supported by the meticulous design of each package type to meet specific technological needs.

|

Chip

package type

|

Dimensions

in mm

|

Dimensions

in inches

|

|

01005

|

0.4x0.2

|

0.016x0.008

|

|

015015

|

0.38

x 0.38

|

0.014x0.014

|

|

0201

|

0.6x03

|

0.02x

0.01

|

|

0202

|

0.5x0.5

|

0.019

x0.019

|

|

02404

|

0.6

x1.0

|

0.02

x0.03

|

|

0303

|

0.8x0.8

|

0.03x0.03

|

|

0402

|

1.0x0.5

|

0.04x0.02

|

|

0603

|

1.5

x 0.8

|

0.06

x 0.03

|

|

0805

|

2.0x1.3

|

0.08x0.05

|

|

1008

|

2.5x2.0

|

0.10x0.08

|

|

1777

|

2.8x2.8

|

0.11

x 0.11

|

|

1206

|

3.0

x1.5

|

0.12

x0.06

|

|

1210

|

3.2x2.5

|

0.125

x0.10

|

|

1806

|

4.5x1.6

|

0.18x0.06

|

|

1808

|

4.5x2.0

|

0.18

x0.07

|

|

1812

|

4.6x3.0

|

0.18

x 0.125

|

|

1825

|

4.5x6.4

|

0.18

x0.25

|

|

2010

|

5.0x2.5

|

0.20x0.10

|

|

2512

|

6.3x3.2

|

0.25

x0.125

|

|

2725

|

6.9

x 6.3

|

0.27

x0.25

|

|

2920

|

7.4x5.1

|

0.29

x0.20

|

Chart 2: Diode SMD Package Size Table

Next, we will take the SMD integrated circuit packaging type as an example to explain in detail. Integrated circuits (ICs) are housed in a variety of SMD packaging types, each tailored to meet different technical requirements and applications. The choice of packaging significantly impacts the IC's performance, particularly in terms of thermal characteristics, pin density, and size. Here’s a detailed look at the major types:

SOIC (Small Outline Integrated Circuit): SOIC packaging is generally chosen for integrated circuits that have moderate complexity. The pin count for SOIC packages usually ranges from 8 to 24. The physical design is straightforward, featuring a slim, rectangular body with pins extending laterally, making it easy to handle and solder on standard PCB layouts.

QFP (Quad Flat Package) and TQFP (Thin Quad Flat Package): These packages are ideal for applications requiring a large number of pins, typically ranging from 32 to 144 pins or more. The QFP and TQFP variants have leads on all four sides of a square or rectangular package, which allows for a high level of integration in complex circuit designs while maintaining a relatively compact footprint.

BGA (Ball Grid Array): BGA packages distinguish themselves by using solder balls instead of traditional pins to connect the IC to the PCB. This design supports a substantial increase in pin count within a small area, which is crucial for advanced, high-performance applications. BGAs are particularly favored in dense electronic assemblies because they provide efficient heat dissipation and reliable electrical connections even under mechanical stress.

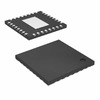

QFN (Quad Flat No-leads) and DFN (Dual Flat No-leads): These packages utilize pads located at the bottom of the IC rather than external pins. The QFN and DFN are used for ICs with a medium to high number of connections but require a smaller footprint than QFP. These packages are excellent for their thermal performance and electrical conductivity, making them suitable for power management and signal processing circuits.

Figure 7: QFN

In actual assembly processes, each type of packaging requires specific handling and soldering techniques. For example, BGAs need careful placement and precise temperature control during reflow soldering to ensure that the solder balls melt uniformly and connect securely without bridging. Meanwhile, QFNs and DFNs demand accurate pad alignment and good solder paste application to achieve effective thermal contact and electrical connections.

These packaging types are chosen based on their ability to meet the demands of specific applications, such as digital processing or power management while accommodating the spatial and thermal constraints of modern electronic devices. Each package contributes uniquely to maximizing IC performance and enhancing device reliability and longevity.

|

Package type

|

Properties

|

Application

|

|

SOIC

|

1. Small

outline integrated circuit

2. Surface-mount

equivalent of the classic through-hole DiP (Dual-inline Package)

|

1.

Standard package for logic lC

|

|

TSSOP

|

1. Thin

shrink small outline package

2. Rectangular

surface mount

3. Plastic

integrated circuit (lC) package

4. Gull-wing

leads

|

1. Analog

amplifiers,

2.

Controllers and Drivers

3.

Logic devices

4. Memory

devices

5. RF/wireless

6.

Disk drives

|

|

QFP

|

1. Quad

flat package.

2. Easiest

option for high pin-count components

3. Easy

to inspect by AOl

4. Assembled

with standard reflow soldering

|

1.

Microcontrollers

2. Multi-channel

codecs

|

|

QFN

|

1. Quad

flat no-lead

2. Electrical

contacts do not come out of the component

3. Smaller

than QFP

4. Require

extra attention in PCB assembly

|

1.

Microcontrollers.

2. Multi-channel

codecs

|

|

PLCC

|

1.

Ball grid array

2.

Most complex

3. High-pin

count component

4. Electrical

components are below silicon lC

5. Requires

reflow soldering for PCB assembly

|

1.

Prototype PCB assembly

|

|

BCA

|

1.

Plastic leaded chip carrier

2. Allow

components to be directly mounted on the PCB

|

1. High-speed

microprocessor

2.

Field programming gate array(FPGA)

|

|

POP

|

1. Package-on

package technology

2. Stacked

on the top of others

|

1. Used

for memory devices and microprocessors

2. High-speed

design, HDL design

|

Chart 3: Integrated Circuit SMD Package

SMD packages of resistors are also very common. Surface-mount device (SMD) resistors come in various sizes to meet different application needs, particularly where space and power handling are concerned. Each size is designed to optimize the circuit’s performance and reliability, given its specific electrical characteristics and space constraints. Here’s an overview of commonly used SMD resistor sizes and their typical applications:

0201: This is one of the smallest available sizes for SMD resistors, measuring approximately 0.6 mm by 0.3 mm. Its tiny footprint makes it ideal for high-density applications where space is extremely limited. Operators must handle these resistors with precision equipment due to their minute size, which can be challenging to place and solder without specialized tools.

0402 and 0603: These sizes are more common in devices where space is a constraint but slightly less so than in the most compact electronics. The 0402 measures about 1.0 mm by 0.5 mm, and the 0603 is slightly larger at 1.6 mm by 0.8 mm. Both are frequently used in mobile devices and other portable electronics where efficient use of PCB space is very important. Technicians prefer these sizes for their balance between manageability and space-saving features.

0805 and 1206: These larger resistors measure approximately 2.0 mm by 1.25 mm for the 0805 and 3.2 mm by 1.6 mm for the 1206. They are selected for applications requiring higher power handling and greater durability. The increased size allows for easier handling and soldering, making them suitable for less dense parts of a circuit or in power applications where heat dissipation is a concern.

Choosing the correct SMD resistor size helps ensure that the circuit operates as expected and does not take up unnecessary space or risk failure due to power overload. Operators must consider both the electrical requirements and the physical layout of the PCB when selecting resistors. This decision impacts everything from the ease of assembly to the ultimate performance and reliability of the electronic device. Each size category serves a distinct role, influencing how designers and technicians approach the assembly and repair of modern electronics.

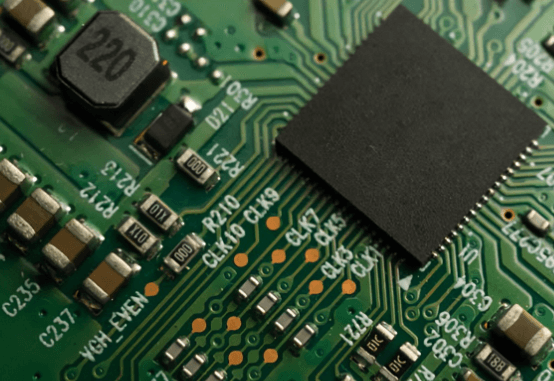

Figure 8: Install The Circuit Board

Surface-mount devices (SMD) are favored in modern electronics manufacturing due to several significant advantages that they offer over traditional through-hole components.

Compact Size: SMD components are markedly smaller than their through-hole counterparts. This size reduction allows for more compact electronic devices, enabling manufacturers to produce sleeker and more portable products. Technicians benefit from the ability to fit more components onto a single printed circuit board (PCB), which is critical for advanced technology like smartphones and wearable devices.

Cost-Effectiveness: The smaller dimensions of SMDs reduce material usage, which can significantly lower the cost per component. The high level of automation in SMD assembly processes reduces labor costs. Automated pick-and-place machines handle these tiny components with speed and precision, which not only cuts down manufacturing time but also minimizes the risk of human error and inconsistencies.

Enhanced Performance: The reduced size of SMDs minimizes lead inductance, making them better suited for high-speed or high-frequency applications. This is helpful for industries such as the telecommunications and computing industries that pursue higher speed and efficiency. Technicians observe improved signal integrity and quicker response times in circuits utilizing SMDs.

Double-Sided Mounting Capability: SMDs can be mounted on both sides of the PCB, which doubles the real estate available for components on each board. This capability enhances the density and complexity of the PCB, allowing for more advanced functionalities within the same or reduced space.

Versatility: SMD technology accommodates a wide range of electronic components, making it applicable to virtually any type of electronic assembly. This versatility is particularly advantageous in multifunctional devices that require diverse components to perform various tasks.

Increased Production Efficiency: The automation of SMD assembly boosts production rates and ensures consistent quality across batches. Machines precisely place each component, reducing the likelihood of placement errors and defective units, which in turn decreases waste and increases overall manufacturing efficiency.

Despite these benefits, SMD technology does come with certain limitations that need consideration in the design and manufacturing stages. Manual soldering of SMDs, for instance, is challenging due to their small size, requiring specialized skills and equipment. Additionally, SMDs are susceptible to damage from electrostatic discharge (ESD), necessitating careful handling and specific protective measures during both assembly and transport.

Understanding these characteristics helps manufacturers optimize their production processes and develop products that meet the increasing demands for smaller, more powerful electronic devices.

|

Packages

|

Dimensions(mm)

|

Applications

|

Component

type

|

Number

of pins

|

|

SMA

|

3.56

x2.92

|

RF

and microwave devices

|

Diode

|

2

|

|

D0-214

|

5.30x6.10

|

Power

rectification diodes

|

Diode

|

2

|

|

DO-213AA

|

4.57

x3.94

|

Small

signal transistors and diodes

|

Diode

|

2

|

|

SMC

|

5.94x5.41

|

Integrated

circuits, resistors, and capacitors Power MOSFETs and voltage regulators

|

Diode

|

2

|

|

TO-277

|

3.85

x3.85

|

Power

MOSFETs and voltage regulators

|

MOSFET

|

3

|

|

MBS

|

2.60

x1.90

|

Switching

diodes and high-density integrated circuits

|

Diode

|

2

|

|

S0D-123

|

2.60

x1.90

|

Small

signal diodes and transistors

|

Diode

|

2

|

|

0603

|

1.6x0.8

|

Consumer,

automotive, and industrial equipment

|

Resistors,

capacitors, and inductors

|

2

|

|

0805

|

2.0

x1.25

|

Consumer,

automotive, and industrial equipment

|

Resistors,

capacitors, and inductors

|

2

|

|

1206

|

3.2

x1.6

|

Consumer,

automotive, and industrial equipment

|

Resistors,

capacitors, and inductors

|

2

|

Chart 4: Comparison of Commonly Used SMD Originals

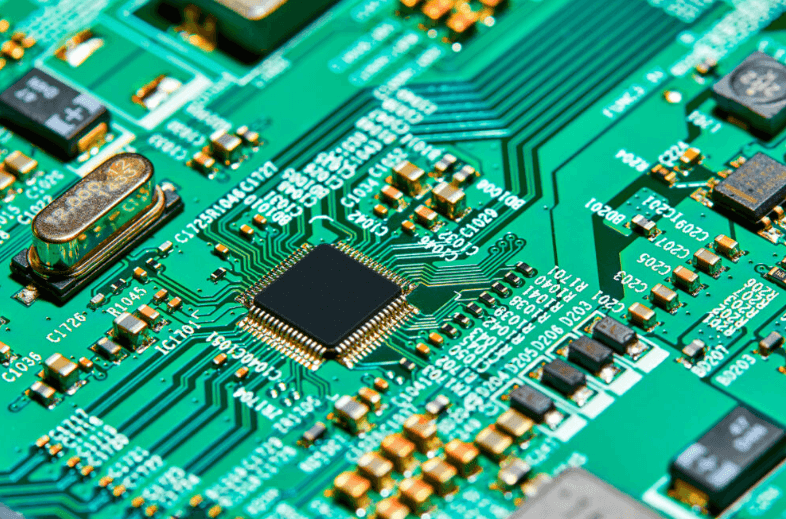

In the realm of electronic manufacturing, Surface-Mount Devices (SMDs) and Surface-Mount Technology (SMT) are closely intertwined concepts, each playing a critical role in the production of modern electronics.

SMD - The Components: SMDs refer to the actual electronic components such as capacitors, resistors, and integrated circuits. These devices are characterized by their small size and ability to be mounted directly on the surface of a printed circuit board (PCB). Unlike traditional components that require leads to go through the PCB, SMDs sit on top of the surface, which allows for a more compact design.

Figure 9: SMD Package Install

SMT - The Assembly Process: SMT is the method by which these SMDs are applied and soldered onto the PCB.

This process involves several precise and coordinated steps:

PCB Preparation: The PCB is first prepared with a pattern of solder paste applied only where components will be placed. This paste is typically applied using a stencil that ensures precision and uniformity.

Component Placement: Specialized automated machines then pick up and place SMDs onto the prepared areas of the PCB. These machines are highly accurate and can place hundreds of components per minute, aligning them perfectly with the solder paste.

3Reflow Soldering: After placement, the entire assembly passes through a reflow oven. The heat within this oven melts the solder paste, thereby creating a solid solder joint between the SMDs and the PCB. The controlled heating and cooling cycles are crucial to avoid defects like cold solder joints or overheating, which could damage the components.

Inspection and Testing: The final stage involves inspecting and testing the assembled board to ensure that all connections are secure and the board functions correctly. This might involve visual inspections, automated optical inspections (AOI), and functional testing.

The integration of SMD and SMT has drastically enhanced the capability to design more compact, performance-oriented electronic devices. By allowing more components to be mounted in a smaller space, these technologies not only optimize the performance and complexity of devices but also contribute to cost and space efficiency. The advancement of SMT has propelled the trend towards miniaturization and higher efficiency in electronic devices, fitting more functionality into smaller packages and supporting the evolution of digital technology.

This close relationship between components (SMD) and their application methods (SMT) has an unparalleled role in pushing the boundaries of what is possible in electronics design and manufacturing, driving the industry towards innovative solutions that fit increasingly complex systems into compact Space.

The exploration of Surface-Mount Device (SMD) packaging types throughout this passage underscores their integral role in pushing the boundaries of modern electronic design and manufacturing. Each packaging variant, from SOIC and QFP to BGA and beyond, is meticulously engineered to meet distinct performance criteria, addressing the thermal, spatial, and functional demands of sophisticated electronic assemblies. These technologies facilitate the integration of high-density, high-efficiency components into increasingly compact devices, driving advancements in various sectors, including consumer electronics, telecommunications, and medical devices. As we consider the meticulous process of applying these components using Surface-Mount Technology (SMT)—from the precise application of solder paste to the strategic placement and soldering of components—it is evident that SMD and SMT are not just about component attachment. They represent a comprehensive design and manufacturing philosophy that enhances device reliability, scalability, and manufacturability. Acknowledging challenges like manual soldering and susceptibility to electrostatic discharge, the industry continues to innovate in developing more robust handling and protective measures to safeguard these components. Ultimately, the ongoing evolution of SMD and SMT highlights a relentless pursuit of technological excellence, ensuring that electronic devices are not only smaller and more powerful but also more accessible and cost-effective, heralding a new era of electronic innovation.

Frequently Asked Questions [FAQ]

1. What is an SMD package?

An SMD (Surface-Mount Device) package refers to the physical enclosure and configuration of electronic components designed to be mounted directly onto the surface of printed circuit boards (PCBs).

2. Why is SMD used?

SMDs are used primarily due to their significant advantages in size, performance, and manufacturing efficiencies: Size Reduction, High Performance, Manufacturing Efficiency, Double-sided Mounting

3. What is the difference between SMD and SMT?

SMD refers to the actual components (Surface-Mount Devices) that are applied to PCBs, while SMT (Surface-Mount Technology) refers to the methodology and processes involved in placing and soldering these components onto the PCB.

4. What are the types of SMD IC packages?

SOIC (Small Outline Integrated Circuit), QFP (Quad Flat Package), BGA (Ball Grid Array), QFN (Quad Flat No-leads) and DFN (Dual Flat No-leads).

5. Are SMD components cheaper?

Yes, SMD components are generally cheaper than their through-hole counterparts when considering large-scale production.

Share: