The Complete Guide to Printheads: Types, Functions, and Maintenance

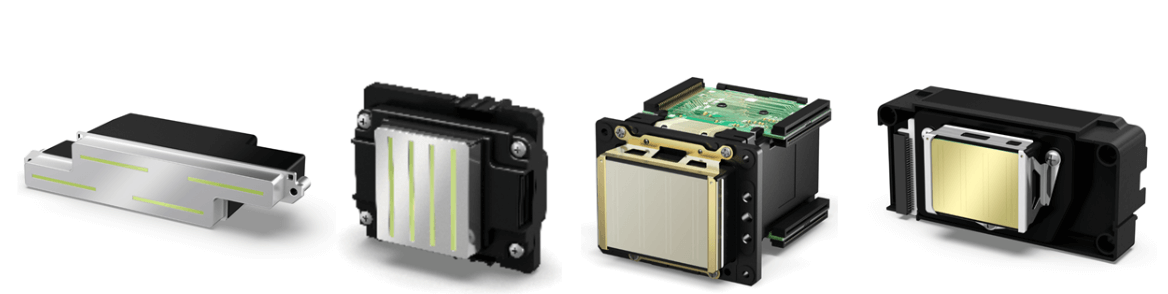

In the ever-evolving world of printing technology, printheads stand as key components that greatly influence the functionality, quality, and efficiency of printers. These sophisticated devices, which apply ink to various substrates, have undergone significant advancements to meet the increasing demands for higher resolution and color accuracy in printed outputs. This article explores the intricate roles of printheads within different printing systems, categorizes the main types of printing methods, and explores the operational characteristics and maintenance needs of various printhead technologies.

In analyzing the mechanics behind printhead operation, including the influence of nozzle design, ink flow dynamics, and component durability, users and manufacturers can optimize printer performance and extend the lifespan of these serious components.

Catalog

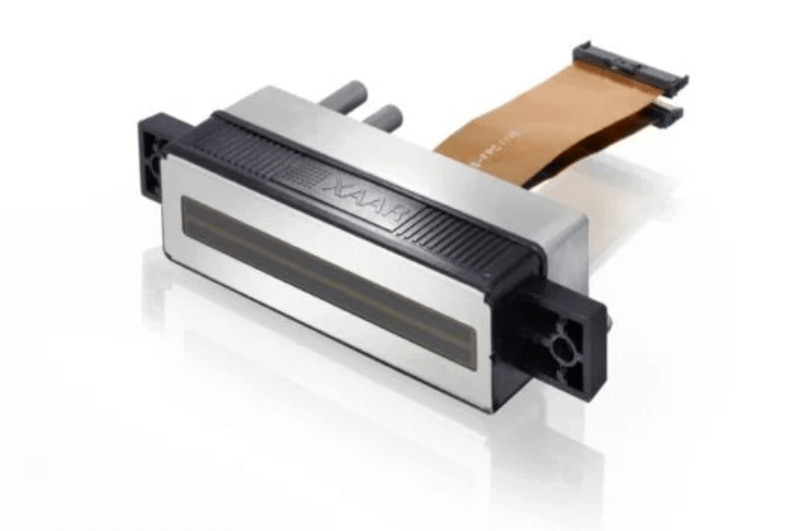

Figure 1: Printheads

Anatomy of a Printhead

A printhead is a sophisticated device engineered to deliver high-quality printing through a precisely coordinated set of components. It features nozzles, which are tiny outlets that project ink droplets onto the print medium. The size and precision of these nozzles play a key role in determining the resolution and overall print quality. The ink chambers are small reservoirs that store ink until it is ejected, with the stability and consistency of ink flow from these chambers directly affecting print sharpness and uniformity. Actuators, dynamic components within the printhead, propel ink out of the nozzles.

There are two types of actuators: thermal actuators, which use heat to vaporize the ink, creating a bubble that pushes the ink out, and piezoelectric actuators, which use electric charges to deform a crystal, effectively squeezing the ink out. Additionally, control electronics, which are integrated circuits, manage the timing and sequence of ink ejection, coordinating with the printhead’s movement over the medium to ensure accurate print patterns. In thermal printhead systems, heat sinks are influential as they absorb and dissipate the heat generated during operation, helping to preserve the integrity of the printhead and ensuring consistent performance over time.

Role of Printheads in Printing Technology

Printheads are basic components in modern printing systems. They directly apply ink to substrates like paper, creating texts and visuals. Inside the printhead, a series of finely tuned nozzles eject ink droplets at high speed. These droplets align accurately to form the desired patterns. The printhead's smooth movement over the medium is used for uniform ink distribution, which affects print quality attributes such as resolution, color accuracy, and detail richness.

Proper print head maintenance can maintain the high performance of the print head. Any blockages or dried ink buildup can degrade the print quality and shorten the printer’s lifespan. Regular maintenance, including thorough cleaning and following the manufacturer’s guidelines, is required to prevent nozzle clogs. This routine upkeep not only keeps the printhead in good condition but also ensures consistent output quality over time, thus protecting the printer's overall effectiveness and longevity.

Classification of Printing Methods

Printers are categorized based on their technology into two main types: impact and non-impact printing. Each type caters to specific needs and offers distinct advantages.

Impact Printing

Impact printers use mechanical contact to transfer ink from a ribbon to paper. There are two primary types within this category:

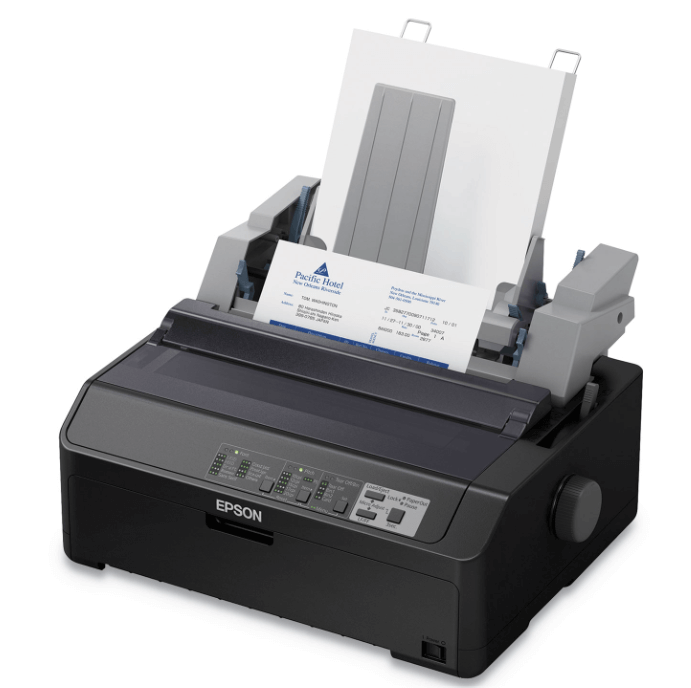

Figure 2: Dot Matrix Printers

These printers use a printhead with pins that strike an ink-coated ribbon, which then presses against the paper to create images or characters. They are ideal for applications needing continuous feed, such as ATMs and industrial data logging.

Figure 3: Typewriter-Style Printers

These printers use fixed-character plates to press text directly onto the page, similar to traditional typewriters. Although less common today, they are valued for specific forms that require pre-printed stationery.

2 Non-Impact Printing

Non-impact printers operate without direct contact between the printing mechanism and the substrate. This category includes several advanced methods:

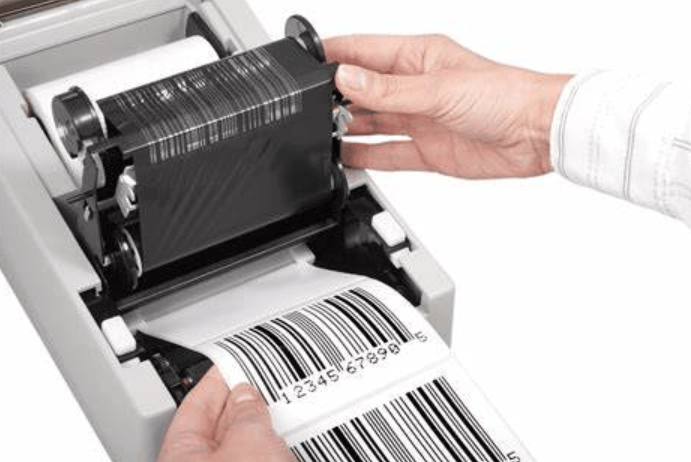

Figure 4: Thermal Transfer Printing

In this method, a printhead heats a wax or resin ink ribbon, melting the ink onto the paper to create durable images. It is often used for high-durability labels and barcode printing.

Figure 5: Inkjet Printing

Inkjet printers use microscopic nozzles to spray fine droplets of ink onto paper, producing high-resolution outputs suitable for detailed graphics and photo-quality prints.

Figure 6: Electrophotographic Printing

Common in laser printers, this method uses lasers or LEDs to create an electrostatic charge pattern on a photosensitive drum. The toner adheres to these charged areas and is then transferred to paper, making it a popular choice for office document printing.

Figure 7: Direct Thermal Printing

This technique involves a heated printhead targeting heat-sensitive paper, causing a chemical reaction that changes the paper’s color to form text and images. It is commonly used for printing receipts and tickets.

Various Types of Inkjet Printer Printheads

Inkjet printers use different types of printheads, each designed for specific durability and maintenance needs:

Disposable printheads are built into the ink cartridges. When the ink runs out, the entire cartridge, including the printhead, is replaced. This design simplifies the replacement process and requires minimal maintenance. However, replacing the printhead with each cartridge change can lead to higher overall costs.

Fixed printheads are designed to last the entire lifespan of the printer. They are cost-effective over time but require regular cleaning to prevent clogs and maintain print quality. This type is ideal for users who prioritize long-term durability and are committed to routine maintenance.

Separate printheads function independently from the printer and the ink cartridges. They can be replaced as needed without changing the ink cartridge, potentially reducing replacement costs. This design offers flexibility, allowing users to replace printheads based on wear and performance rather than ink levels.

Exploring Printhead Types and Their Applications

Printheads are designed with specific mechanisms and materials to meet various printing demands. Here’s a look at the different types and their applications:

Figure 8: Thermal Printheads

Thermal printheads use heat to vaporize ink, creating microbubbles that propel ink onto paper. This method is common in consumer desktop printers because it is simple and cost-effective.

Figure 9: Piezoelectric Printheads

Piezoelectric printheads utilize electric charges to deform piezoelectric materials like ceramics. This deformation expels ink from the nozzles with high precision and control. This technology is ideal for graphic arts and professional photo printing, where accuracy is dominant.

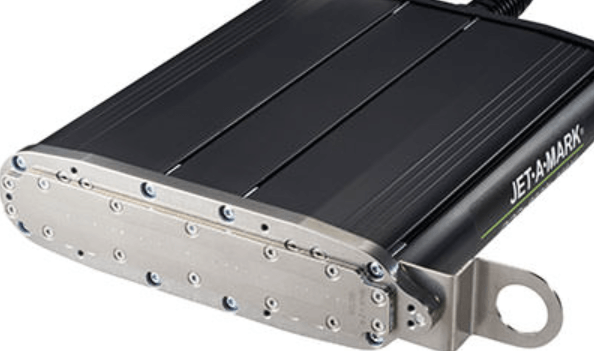

Figure 10: Continuous Inkjet Printheads

Continuous inkjet printheads eject a constant stream of ink droplets. Electric charges deflect the required droplets onto the substrate, while unused droplets are recycled. This type is perfect for high-speed, high-volume printing in industrial environments.

Figure 11: Drop-on-Demand Printheads

Drop-on-demand printheads release ink only when needed, enhancing ink efficiency and placement accuracy. These versatile printheads are used in various inkjet printers, from small office models to large commercial machines.

Printhead Replacement Timelines

The lifespan of a printhead depends significantly on its design and maintenance. Here's a breakdown:

Piezoelectric printheads: are durable and can last up to five years with typical home use. Their longevity is due to the piezoelectric materials' resilience and the precise control they offer.

Thermal printheads: which are exposed to heat during operation, typically need replacement within four years. The frequency of use and adherence to maintenance guidelines can affect this timeline.

Preventative Measures and Solutions for Printhead Issues

Proper maintenance is used to extend the lifespan and efficiency of printheads. Here are key strategies to keep your printhead in optimal condition:

|

Preventative Measures and Solutions |

|

|

Routine Cleaning Cycles |

Regularly use the printer’s automatic

cleaning cycles to prevent ink buildup and clogs. This keeps the nozzles

clear and maintains smooth ink flow. |

|

Manual Cleaning |

Periodically clean the printhead manually

with recommended cleaning solutions. This helps remove stubborn ink deposits

that automatic cleaning might miss. |

|

Conservative Use |

Use the printer only when needed to

minimize wear and tear. Judicious operation reduces the risk of clogs and

mechanical issues. |

|

Specialized Equipment |

For severe clogs, consider using tools

like the Printhead Doctor. These tools can effectively dislodge blockages and

restore printhead functionality. |

|

Power Management |

Turn off the printer when it’s not in

use. This prevents overheating and stops ink from drying in the nozzles,

reducing the chance of clogs. |

Conclusion

The comprehensive exploration of printhead technology underscores its serious role in defining the capabilities and performance of modern printers. From impact to non-impact printing methods, each technique benefits from specific printhead designs tailored to meet unique printing needs and challenges. Maintenance measures such as regular cleaning and proper handling can prevent clogging and ensure the life of the printhead, especially in high-resolution printing environments.

As the printing industry continues to innovate, the development of more efficient and durable printheads remains insistent for enhancing print quality and operational efficiency. The future of printing technology hinges on continuous improvements in printhead design and maintenance, promising even greater advancements in the quality and reliability of printed materials.

Frequently Asked Questions [FAQ]

1. How do you fix a problem with the printhead?

To address a printhead issue, start by identifying whether the problem is clogging, misalignment, or electronic. For clogs, run the printer's cleaning cycle using the software utility provided by your printer’s manufacturer. If misalignment is the issue, use the alignment function, also found in your printer’s settings. If these steps don't resolve the problem, manually cleaning the printhead might be needed. Remove the printhead (if removable), soak it in warm distilled water for about 10 minutes, dry it completely, and then reinstall it.

2. Is a printhead the same as an ink cartridge?

A printhead and an ink cartridge are not the same. The printhead is the component in a printer that applies ink onto the paper. It often contains multiple nozzles that spray ink. An ink cartridge, on the other hand, is a container that holds the ink. In some models, the printhead is built into the printer, while in others, it’s part of the replaceable ink cartridge.

3. How do I clear my printhead?

To clear a printhead, use the printer’s built-in cleaning function, which can be accessed through the printer’s software or menu on the printer itself. This function often involves pushing ink through the nozzles to flush out blockages. If the automated process fails, manually cleaning by soaking the printhead in warm distilled water or using a damp lint-free cloth to gently wipe the nozzle area can help.

Q4. How to unclog printhead Epson?

For unclogging an Epson printhead, first try the printer's cleaning cycle a few times. If the clog persists, turn off the printer and remove the cartridges and printhead (if the model allows). Soak just the nozzles in a shallow dish of warm distilled water for a few hours, avoiding getting electronic components wet. Dry thoroughly before reinstalling. Repeated cleaning cycles might be needed after reassembly.

Q5. What is a good substitute for a printhead cleaning solution?

If you need a substitute for a commercial printhead cleaning solution, a mixture of distilled water and isopropyl alcohol can be effective. Mix these in a 50/50 ratio. This homemade solution can help dissolve dried ink. Use it to soak the printhead nozzles, if removable, or apply it with a syringe or a lint-free cloth for non-removable printheads. Always ensure the printhead is completely dry before reinstalling.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

CR927 Battery Equivalents and Replacements

on July 25th

A23 Battery Specifications and Compatibility

on July 25th

Popular Posts

-

What is GND in the circuit?

on January 1th 3177

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2754

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 18th 2423

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2217

-

Comparison Between DB9 and RS232

on January 1th 1840

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1810

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1765

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1737

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1725

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 18th 1711