Inclusive Guide to Resistors: Types, Applications, and Technical Insights

Resistors are abundant components in electronic circuits, tasked with controlling the flow of electrical current through their inherent resistance. Their strategic deployment within circuitry dictates the stability and efficiency of numerous devices, from common household electronics to sophisticated industrial machinery. This article digs into the intricacies of resistors, exploring their various types, functions, and materials, alongside the implications these have for different applications. By examining the physical attributes and performance characteristics of fixed and variable resistors, as well as non-linear options like thermistors and varistors, the discussion illuminates how precise selection and utilization can significantly impact the reliability and functionality of technological systems. In addition, it also discusses resistor configurations, color coding, and tolerance, highlighting their dangerous roles in circuit design and performance optimization.Catalog

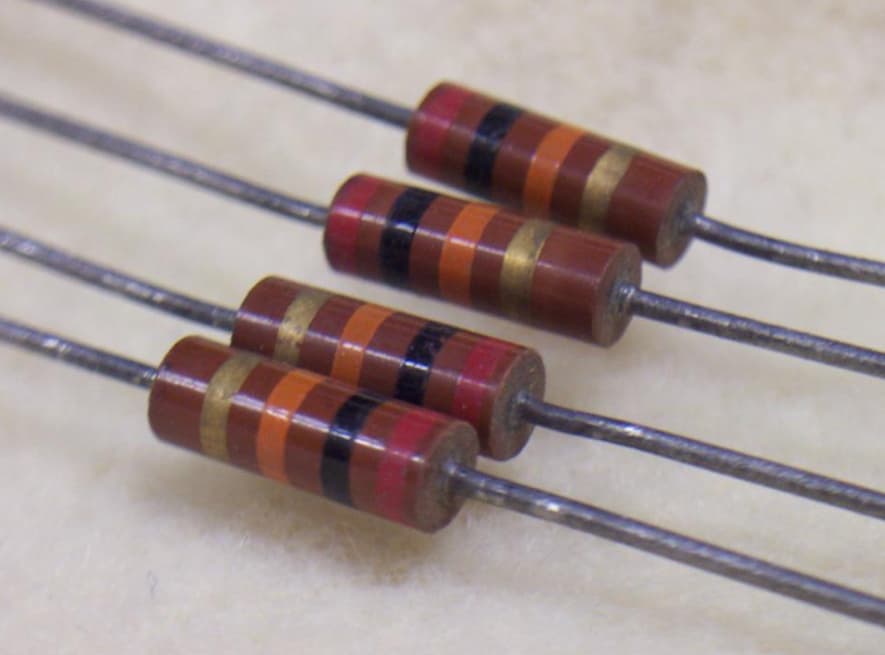

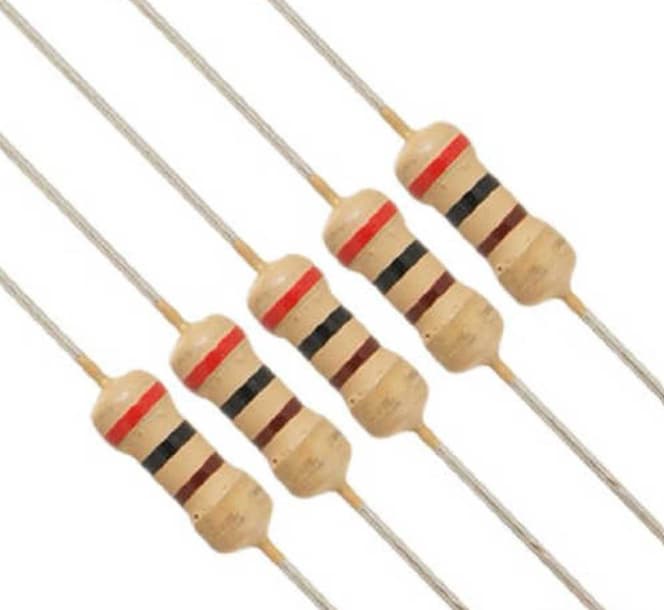

Figure 1: Resistors

Defining Resistors

Resistors are used parts of electronic and electrical circuits, playing the key role of controlling the flow of electrical current. They do this by providing a specific amount of resistance to the current, which helps maintain the stability and functionality of a wide range of devices—from everyday household gadgets to complex industrial machines.

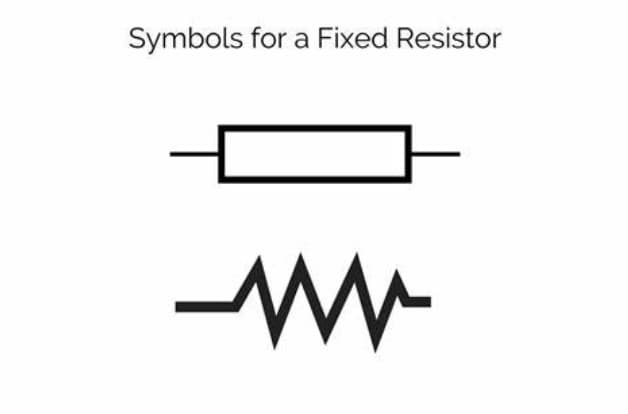

In circuit diagrams, resistors are represented by different symbols depending on the region. In North America, they are often shown as a jagged line, which resembles the physical look of wire-wound resistors commonly used in older or high-power applications. In difference, in many parts of Europe and Asia, resistors are depicted as simple rectangles—a symbol that has gained global acceptance for its clarity and ease of recognition.

The resistance of a resistor is measured in Ohms (Ω), and values can range widely. Common denominations include kilohms (kΩ) and megohms (MΩ). To keep circuit diagrams neat and easy to read, these values are usually abbreviated, such as '10k' for 10 kΩ or '2M2' for 2.2 MΩ.

Resistors come in various types, each suited for specific roles within circuits. Fixed resistors, the most common type, provide a constant resistance value, ensuring the circuit operates predictably. Variable resistors, however, allow the resistance to be adjusted, making them ideal for applications where users need to change settings or where the circuit must respond to environmental changes. There are also specialized resistors like thermistors and varistors, which offer unique functions—thermistors change resistance with temperature, while varistors respond to voltage changes, making them invaluable in more complex circuits.

Comparing Types of Resistors

Resistors fall into two main categories: fixed and variable. Each type plays a serious role in electronic circuits, contributing to how the circuit performs overall.

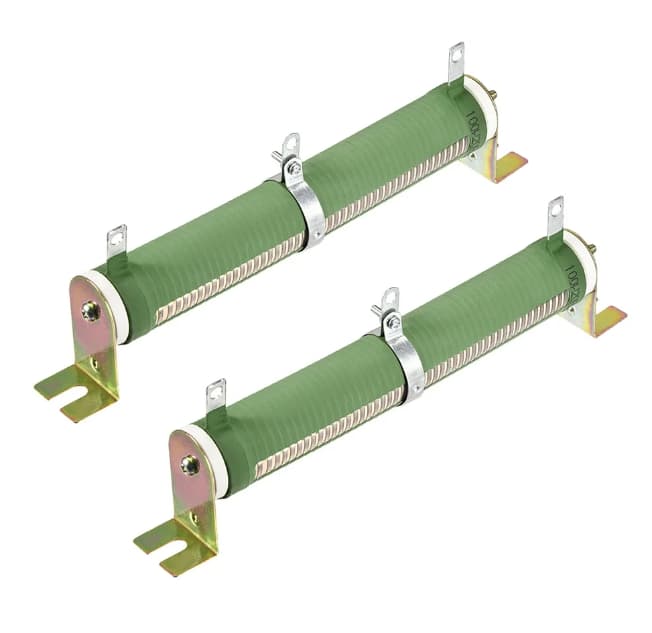

Figure 2: Fixed Resistors

Fixed resistors are commonly used in a wide range of circuits. They are designed with a specific resistance value that is set during the circuit design phase and does not change during use. These resistors come in different forms to meet various operational requirements. For example, carbon film and metal oxide resistors are often chosen for general-purpose circuits because they are reliable and affordable. In difference, circuits that need higher accuracy and stability, such as those in precision instruments, might use metal film or wire wound resistors.

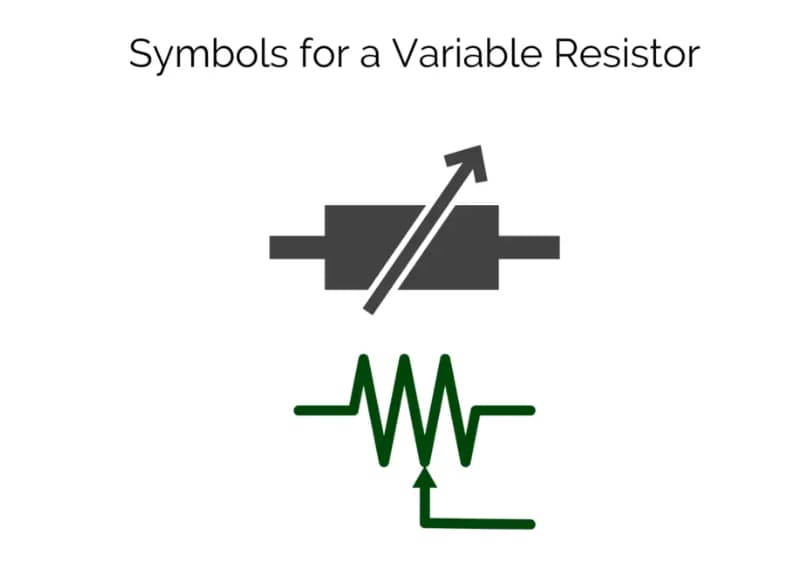

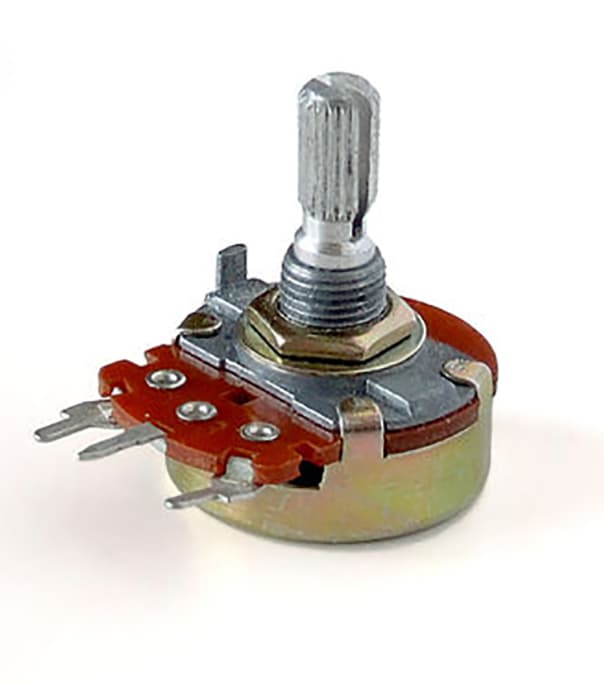

Figure 3: Variable Resistors

Variable resistors, unlike fixed resistors, allow for the resistance to be adjusted during operation. This is typically done using a mechanical component like a slider or dial that moves along a resistive element to change the resistance. This adjustability is useful in situations where precise control of current or voltage is needed. For instance, they are used to adjust the volume in audio systems or to fine-tune settings in laboratory equipment.

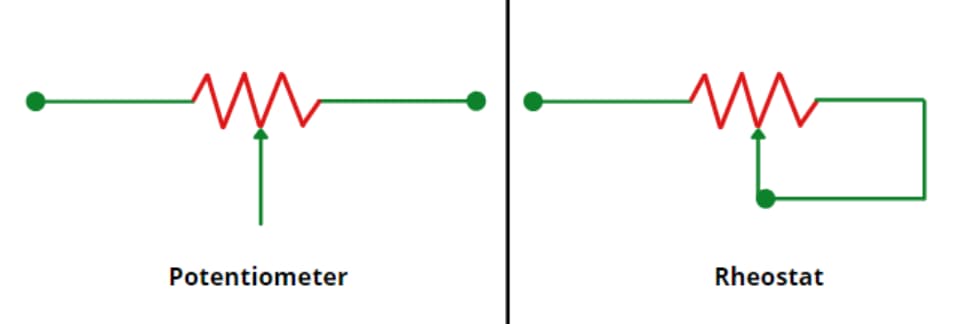

Figure 4: Potentiometers and Rheostats

There are two main types of variable resistors: potentiometers and rheostats. Potentiometers are used to divide voltage and typically involve all three of their terminals in operation. They are ideal for tasks like controlling the volume in audio devices or acting as voltage dividers in signal processing. Rheostats, however, are primarily used to adjust the flow of current in a circuit. They use two terminals and are commonly found in applications such as light dimmers or electric motor controls where the intensity of the electrical load needs to be regulated.

Classifications of Fixed Resistors

Fixed resistors come in several types, each designed to meet specific performance needs in electronic circuits. This variety ensures that circuit designs can meet a wide range of demands.

Figure 5: Carbon Composition Resistors

Once widely used, carbon composition resistors are now mostly outdated. They are made from a mix of carbon granules and a binding material. Over time, these resistors tend to degrade, especially when exposed to temperature changes. They also generate a lot of noise, making them unsuitable for modern applications where stability and precision are focal.

Figure 6: Carbon Film Resistors

Carbon film resistors are created by coating a ceramic substrate with a thin layer of carbon. They are commonly used in low-power applications due to their affordability and availability. However, they can introduce inductive properties, which can cause signal distortion in high-frequency circuits, making them less ideal for such uses.

Figure 7: Metal Oxide Film Resistors

Metal oxide film resistors offer better performance compared to carbon-based resistors. They are made by depositing a metal oxide film on a ceramic base. These resistors are valued for their stability under temperature changes and low noise generation. They are well-suited for precision applications where accuracy is key.

Figure 8: Wire-wound Resistors

Wire-wound resistors are built for high-power applications. They consist of a metal wire, often nickel-chromium, wound around a ceramic core. This construction allows them to handle higher temperatures and power levels, making them ideal for industrial settings where durability and reliability are required.

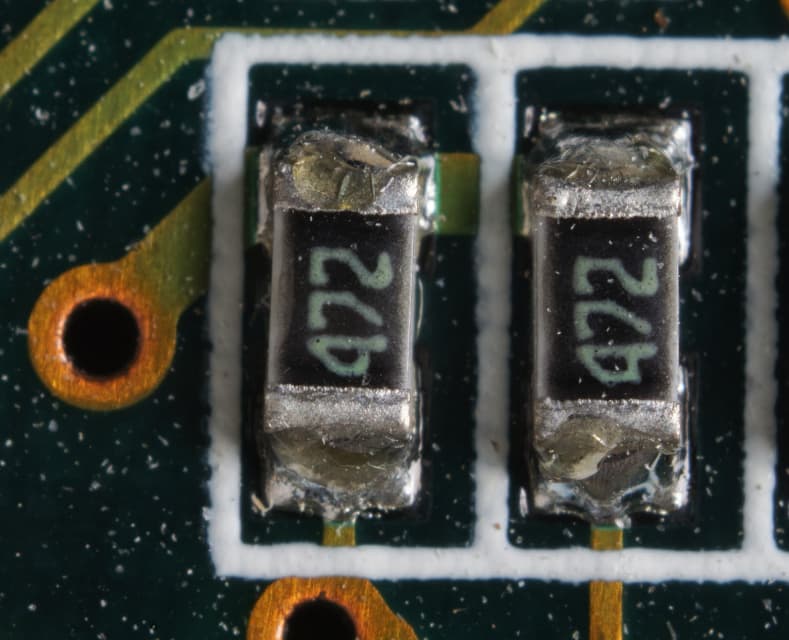

Figure 9: Surface Mount Technology (SMT) Resistors

Surface mount technology (SMT) resistors have revolutionized circuit design. These resistors are small and can be directly mounted onto the surface of circuit boards. Their compact size makes them perfect for high-density electronic devices and supports the trend toward smaller, more integrated electronics. SMT resistors are used in modern electronics, providing reliable performance in a minimal space, which is dynamic for today's increasingly miniaturized designs.

Insights into Variable Resistors

Variable resistors are useful in circuits, allowing for the adjustment of electrical properties either manually or electronically. Their ability to modify resistance enables direct user input to influence the performance of various devices.

Figure 10: Traditional Variable Resistors

The most common traditional variable resistors are potentiometers and rheostats. Potentiometers, which can be either rotary or linear, let users manually change resistance in a circuit, directly affecting voltage or current flow. This feature can be used to adjust the volume of audio equipment or control light levels using a dimmer switch. Rheostats, designed for higher power applications, adjust the resistance to regulate current within a circuit, making them significant in settings like motor speed control.

Figure 11: Digital Potentiometers

Digital potentiometers represent a significant advancement in variable resistor technology. Unlike traditional potentiometers, they use electronic methods to adjust resistance, which eliminates the risk of physical wear and mechanical failure. These devices offer high precision and repeatability, using integrated circuits controlled by digital signals. This makes them ideal for applications that demand reliability and accuracy, such as calibrating medical devices or fine-tuning automotive sensors.

Demystifying Non-Linear Resistors

Non-linear resistors are specialized components that change their resistance in response to environmental factors such as temperature, light, and voltage. This adaptive behavior sets them apart from linear resistors and makes them useful in applications requiring responsiveness to changing conditions.

Figure 12: Thermistors

Thermistors are highly sensitive to temperature fluctuations, making them key in temperature control systems.

Negative Temperature Coefficient (NTC) Thermistors: These decrease in resistance as the temperature increases. They are commonly used in automotive temperature sensors and HVAC systems where accurate temperature monitoring is needed.

Positive Temperature Coefficient (PTC) Thermistors: These increase in resistance as the temperature rises. They are often used for over-current protection, where they act as a safeguard against excessive current flow.

Figure 13: Varistors

Varistors are designed to protect circuits from voltage surges. When exposed to high voltage, they drastically reduce their resistance, diverting excess energy away from sensitive components. This protective action is dynamic in preventing damage from transient voltage spikes, commonly found in power supply lines and telecommunications equipment.

Figure 14: Photoresistors

Also known as light-dependent resistors (LDRs), photoresistors change their resistance based on the amount of light they receive. This characteristic is used in devices that need to respond to light levels, such as streetlights that automatically turn on at dusk or light meters in photography.

The Working Principles of Resistors

Resistors work by converting electrical energy into heat, following the principles of Ohm's law. In any circuit, a resistor creates a voltage drop proportional to the current passing through it. Ohm's law is represented by the equation ![]() , where

, where ![]() is the voltage across the resistor,

is the voltage across the resistor, ![]() is current, and

is current, and ![]() is the resistance.

is the resistance.

The power a resistor dissipates, which is a grave aspect of its functionality, is calculated using the formula ![]() . Alternatively, when using Ohm's law, it can be expressed as

. Alternatively, when using Ohm's law, it can be expressed as ![]() . This shows that the power increases with the square of the current, making it insistent to select a resistor that can handle the expected power load to prevent overheating. Resistors can be arranged in series or parallel to adjust the circuit's overall behavior.

. This shows that the power increases with the square of the current, making it insistent to select a resistor that can handle the expected power load to prevent overheating. Resistors can be arranged in series or parallel to adjust the circuit's overall behavior.

Series Configuration: Resistors connected end-to-end to create a total resistance equal to the sum of the individual resistances ![]() . This setup is often used to divide voltage among the resistors in proportion to their resistance values.

. This setup is often used to divide voltage among the resistors in proportion to their resistance values.

Parallel Configuration: In this arrangement, resistors are connected across the same two points, resulting in a lower total resistance that allows more current to flow than any individual resistor could handle on its own. The total resistance is calculated using the reciprocal formula ![]()

Figure 15: Resistor Color Coding

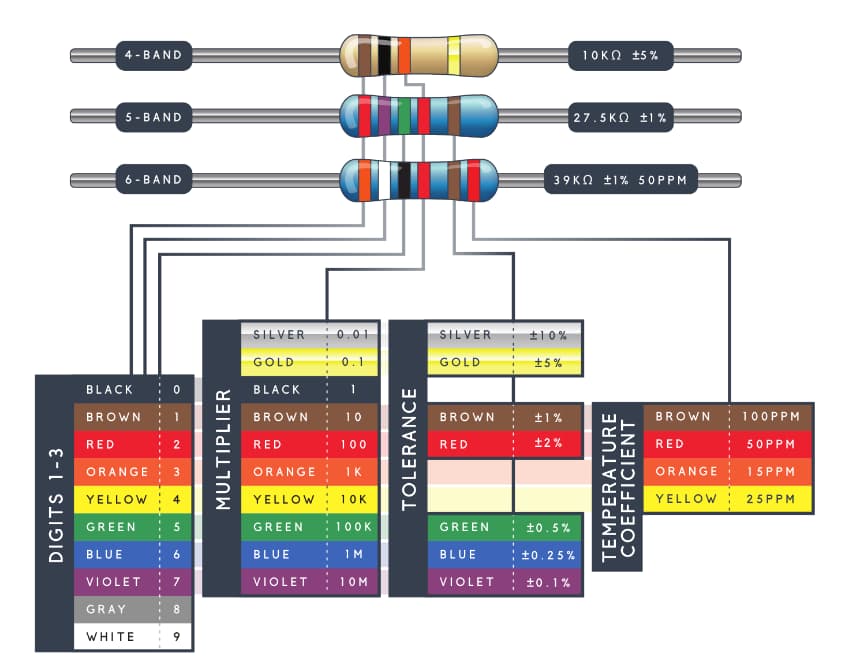

Decoding the Colour Coding System of Resistors

Resistors are marked with a color-coded band system that helps quickly identify their resistance values, multipliers, and tolerance levels. This color coding is required for technicians and engineers, enabling them to rapidly determine a resistor’s specifications and streamline their work.

The standard resistor color code can have up to six bands:

• First and Second Bands (or Third for Precision Resistors): These bands represent the first two (or three) significant digits of the resistor's value.

• Multiplier Band: This band shows the factor by which the significant digits are multiplied, determining the full resistance value.

• Tolerance Band: This band, usually after the multiplier, indicates how much the resistor's actual resistance can vary from its stated value, which is settling for ensuring the component's suitability for specific applications.

Tolerance Levels in Resistors

Resistor tolerance indicates how much the actual resistance can vary from its stated value, expressed as a percentage. Resistors come with different tolerance levels.

Standard Resistors: These typically have a tolerance of ±5% or ±10%. Such tolerances are adequate for most general-purpose applications where minor resistance variations won’t significantly affect the circuit's operation.

Precision Resistors: These resistors offer much tighter tolerances, ranging from ±1% down to as low as ±0.005%. They are used in applications requiring exact resistance values, such as in medical devices, aerospace instruments, and high-fidelity audio equipment, where accuracy and reliability are serious.

Diverse Applications of Resistors in Electronics

Resistors are beneficial in a wide range of industries, playing substantial roles in controlling voltage and current within electronic devices. They are used in everything from basic tools like multimeters to complex systems such as telecommunications networks and automotive control modules.

|

Diverse Applications of Resistors in

Electronics |

|

|

General and Precision Control |

In both everyday and industrial

electronics, resistors—whether fixed or variable—regulate voltage and current

to keep devices operating within their designed electrical limits. For

example, in power supplies, resistors stabilize the output, ensuring

consistent performance. |

|

High-Power Applications |

Wire-wound resistors are highly valued in

applications that require handling large currents and maintaining precision.

These resistors are commonly found in power generation systems, automotive

braking systems, and audio amplifiers. Their ability to manage high currents

and dissipate heat efficiently makes them requisite in these demanding

environments. |

|

Light-Sensitive Technologies |

Photoresistors are widely used in

technologies that need to respond to changes in light. Security systems often

rely on them for automatic lighting and alarms triggered by light variations.

In photography, photoresistors adjust exposure based on the surrounding

light, improving image quality. |

|

Telecommunications and Automotive

Systems |

In telecommunications, resistors play a

key role in signal modulation and impedance matching, which are required for

clear data transmission. In automotive systems, resistors are used in sensors

and to manage electrical loads, contributing to vehicle safety and

efficiency. |

|

Specialized High-Power Resistors |

Wire-wound resistors are requisite in

high-power applications where durability and precise current management are

required. They are commonly found in industrial power supplies, high-end

audio systems, and automotive braking systems. These resistors are valued for

their ability to handle large energy loads and efficiently dissipate heat. |

|

Light-Sensitive Devices |

Photoresistors are dynamic in devices

that respond to changes in light. In security systems, they control alarms or

lights based on ambient lighting conditions. In photography, photoresistors

automatically adjust exposure settings to optimize photo quality according to

light intensity. |

Resistor vs. Resistance: The Differences

While the terms "resistor" and "resistance" are closely related in electrical engineering, they refer to different concepts.

A resistor is a physical component specifically designed to provide a certain amount of resistance in an electrical circuit. It is a tangible device used to control current flow, manage voltage distribution, and maintain signal integrity. Resistors are made from various materials and come in different configurations to fulfill specific roles, such as limiting current or matching impedance in high-frequency circuits.

Resistance, on the other hand, is an inherent electrical property of all materials. It measures how much a material opposes the flow of electrical current. Unlike resistors, which are manufactured components, resistance is a characteristic found in all conductive materials, as well as insulators and semiconductors.

Materials Used in Resistors

The choice of materials in resistor manufacturing is serious, as each material offers unique properties that affect the resistor's performance in different applications.

Wire-wound Resistors: Wire-wound resistors are made by coiling high-resistance wires, typically from nickel-chromium alloys, around a ceramic core. These resistors are highly valued for their precision and stability, making them ideal for applications like measuring instruments and precision calibration systems. Their design allows for excellent tolerance and low-temperature coefficients, making them reliable in situations where minimal deviation is a must.

Metal Film Resistors: Metal film resistors consist of a thin metal layer deposited on a ceramic base. These resistors are particularly effective in high-frequency applications due to their material composition, which usually includes a blend of metals that offer good temperature stability and noise reduction. This makes them well-suited for use in telecommunication devices and high-speed digital circuits.

Metal Oxide Film Resistors: Made by depositing a thin layer of metal oxide onto a ceramic substrate, metal oxide film resistors are built to withstand high temperatures, providing reliable performance under thermal stress. They are especially useful in power supplies, automotive systems, and other applications that operate in challenging conditions.

Carbon Film Resistors: Carbon film resistors are created by applying a layer of carbon on a ceramic carrier. They are a cost-effective option, offering decent performance for general-purpose use. Although they lack the precision and thermal stability of more advanced materials, their affordability makes them suitable for consumer electronics and basic circuit applications.

Advantages of Using Resistors in Electronic Circuits

Resistors are basic components in electronic circuits, offering several advantages that make them invaluable across various applications. These benefits include their compact size, cost-effectiveness, energy efficiency, and versatility, all of which contribute to their widespread use in circuit design.

|

Advantages of Using Resistors in

Electronic Circuits |

|

|

Compactness |

Resistors are small, which makes them

ideal for use in space-constrained designs. Their compact size allows for

easy integration into intricate circuits, enabling the development of

increasingly miniaturized and portable electronic devices. |

|

Cost-Effectiveness |

Resistors are highly affordable, which is

a significant advantage, especially in mass-produced consumer electronics.

Their low cost makes it economical to use them in large quantities, and it

also ensures that replacing them during maintenance or repairs is

cost-effective. |

|

Energy Efficiency |

Resistors do not require additional power

to function; they operate solely on the energy within the circuit. This

characteristic enhances the overall energy efficiency of the devices they are

part of, as they do not draw extra power. |

|

Versatility in Application |

Resistors are incredibly versatile. For

example, carbon film resistors offer a wide range of resistance values,

allowing them to be precisely matched to specific circuit needs. Their

ability to function under various conditions makes them suitable for both

low-power consumer electronics and more demanding applications like RF

communication systems. Despite their sensitivity to noise and temperature

changes, carbon resistors remain a popular choice due to their balance of

cost and functionality. |

|

Performance in RF Applications |

In RF circuits, carbon resistors are

especially valued for their ability to maintain signal integrity at a low

cost. This makes them ideal for use in both amateur radio setups and

professional communication equipment. |

Disadvantages of Resistors

While resistors are used in electronic circuits, they do have certain limitations that can affect their performance and suitability in various applications. Key disadvantages include energy loss, challenges in thermal management, and variability in resistance, each of which can impact the overall effectiveness and reliability of electronic systems.

|

Disadvantages of Resistors |

|

|

Energy Loss and Heat Dissipation

|

One major drawback of resistors is their inherent tendency to convert electrical energy into heat. This energy loss becomes particularly significant in applications with high currents, where the heat generated can reduce system efficiency. Managing this heat is serious because excessive thermal energy can increase operational costs and potentially harm the environment. Circuit designers often need to add components like heat sinks or cooling systems to manage these thermal effects, which can complicate the design and raise costs.

|

|

Precision and Durability Issues in Carbon Resistors

|

Carbon resistors, in particular, struggle with precision and durability. They often have higher tolerance levels, meaning their actual resistance can vary more widely from the specified value. This variability can be problematic in applications that require precise resistance values for proper operation. Carbon resistors are prone to heat damage, especially during soldering. Exposure to high temperatures can cause physical degradation or even complete failure, raising concerns about their reliability in circuits that demand stable and durable components.

|

Conclusion

Throughout this detailed exploration of resistors, it becomes evident that these components are not merely passive players but ultimately in shaping the performance and reliability of electronic systems. From the basic wire wound and carbon film types to advanced digital potentiometers and surface mount technologies, resistors cater to a spectrum of needs across diverse industries. The discussion underscores the importance of understanding resistor functionality, from power dissipation and configurations to the nuances of resistor materials that influence their behavior under various conditions. The choice of the correct resistor, influenced by factors like tolerance, material, and intended application, is used in ensuring the efficacy and longevity of electronic circuits.

As technology continues to evolve towards greater complexity and miniaturization, the role of resistors as ultimate yet serious elements of electronic design remains as significant as ever. This article not only broadens the technical knowledge of resistors but also enhances appreciation for their role in advancing modern electronics, demonstrating their requisite nature in the continuous innovation and refinement of electronic devices.

Frequently Asked Questions [FAQ]

1. What is the most significant use function of a resistor?

The most significant function of a resistor is to control the amount of current flowing through a circuit. It does this by providing a precise amount of electrical resistance.

2. What is the most common resistor used for applications?

The most commonly used resistor in various applications is the fixed resistor. It's favored for its stability and predictability, making it ideal for setting up and maintaining specific currents in electronic circuits.

3. What are the types of resistors and their uses?

Fixed Resistors: Used in electronics to set a consistent resistance value.

Variable Resistors (e.g., potentiometers): These allow for adjustment of resistance and are often used in devices like volume controls.

Thermistors: Sensitive to temperature changes; used in temperature sensing devices.

Photoresistors: Change resistance based on light levels; used in light-sensitive devices.

4. What are some examples of resistors in everyday life?

In Electronics: Televisions, radios, and computers use resistors to manage currents within circuits.

Light Dimmers: Use variable resistors to adjust the brightness of lights.

Car Batteries: Use resistors to control the flow of electrical current.

5. How to choose resistors for circuits?

Determine Resistance Value: Calculate the needed resistance using Ohm's Law (V = IR), where V is voltage, I is current, and R is resistance, based on your circuit design specifications.

Select Resistor Tolerance: Choose a tolerance (±1%,±5%,±10%) that aligns with the precision required by your application. This reflects how much the resistor's actual resistance can deviate from its specified value.

Choose Resistor Type: Pick from fixed, variable, or specialized resistors (like power resistors) depending on the application's needs. Fixed resistors are typically used for general purposes.

Consider Power Rating: Ensure the resistor’s power rating exceeds the power it will dissipate (P = VI = I²R = V²/R) to avoid overheating and potential damage.

Check Environmental Factors: Account for conditions such as temperature stability, noise, and physical size that might affect performance. Metal film resistors, for example, are ideal for precision applications due to their low noise and high accuracy.

Availability and Cost: Factor in the availability and cost of the resistors, particularly for large-scale production. Determine Resistance Value: Identify the required resistance value for your circuit. This can be derived from the circuit design specifications, using Ohm's Law (V = IR), where V is voltage, I is current, and R is resistance.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

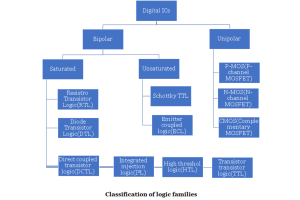

Comprehensive Overview of Logic IC Families and Technologies

on August 30th

ATMEGA16A-AU Microcontroller Comprehensive Overview: Features, Specifications and Applications

on August 30th

Popular Posts

-

What is GND in the circuit?

on January 1th 3255

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2805

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 20th 2613

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2252

-

Comparison Between DB9 and RS232

on January 1th 1868

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1836

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1791

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1781

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1777

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 20th 1765