Full Analysis of Potentiometers

In a comprehensive review of potentiometers, from their construction details to their wide range of types, applications, and challenges in electronic design, this article aims to provide a comprehensive perspective to understand the role of potentiometers in modern electronics. An in-depth understanding of the performance characteristics and correct application of potentiometers is the key to efficient and accurate circuit design for electronic technology professionals.Catalog

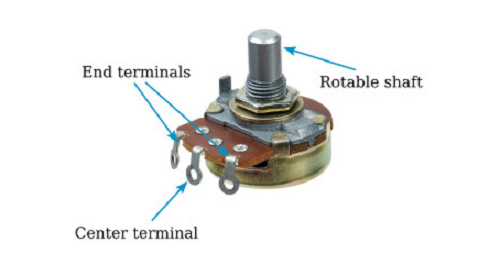

Figure 1: General Appearance of a PotentiometerGeneral Appearance of a Potentiometer

Basic Knowledge of Potentiometers

The potentiometer serves as an adjustment and control function in electronic equipment. Through its unique structure and design, it achieves precise control of the current and voltage in the circuit.

The potentiometer's design is exquisite, including a fixed resistive element, a sliding contact, and an adjustment mechanism. These building blocks work together to allow the user to precisely adjust the circuit's resistance through simple physical operations, such as turning a knob or sliding a slider. The resistance element is the core of the potentiometer. Depending on the manufacturing material, such as carbon film, metal film, or conductive plastic, the potentiometer's resistance characteristics and applicable scenarios will also be different. For example, metal film potentiometers are suitable for applications requiring high accuracy and stability due to their excellent temperature coefficient and durability.

In terms of technical applications, potentiometers are used in a wide range of applications. In audio equipment, potentiometers enable fine control of volume by adjusting the amount of current flowing through speakers or headphones. Especially the logarithmic potentiometer, because its adjustment curve is closer to the way the human ear perceives sound intensity, makes the volume adjustment more ergonomic and improves the user experience. In electronic circuit design, the potentiometer's role as an adjustable voltage divider allows engineers to precisely control the voltage levels at various points in the circuit, which is important for signal processing and optimization of analog circuits.

Typically, potentiometers have a relatively low power-carrying capacity and are generally not suitable for direct use in high-power circuits. However, this limitation can be overcome by using potentiometers in conjunction with power amplifiers to enable effective control of higher powers. In addition, the durability and accuracy of potentiometers are affected by materials and design. In demanding applications, choosing a more costly but better-performing metal film potentiometer can improve system reliability and stability.

Types and Characteristics of Potentiometers

Potentiometers are divided into multiple types according to their working principles and application requirements. Each type has its own unique characteristics and application scenarios.

The most common type of potentiometer is the analog potentiometer. If further broken down, it can be divided into two forms: linear and rotary.

Linear potentiometers adjust resistance values through a sliding mechanism that moves linearly. This intuitive physical movement method makes linear potentiometers particularly suitable for applications that require precise control of resistance changes, such as laboratory instruments and precision adjustment devices. The design accuracy and adjustability of linear potentiometers allow them to accurately calibrate and adjust circuit parameters.

Figure 2: Linear Potentiometer

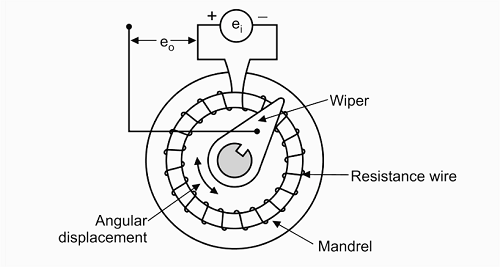

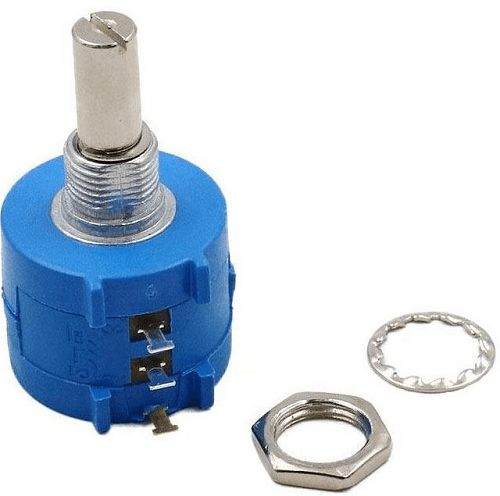

Rotary potentiometers adjust the resistance value by the angular movement of the knob and shaft. This type of potentiometer is widely used in consumer electronics for its user-friendly interface and smooth adjustment function. From volume control to tuning functions, rotary potentiometers are designed to not only optimize the user experience but also improve product operability and adjustment efficiency.

Digital potentiometers utilize digital signals to control resistance values, allowing precise resistance adjustments to be made through software. Fine control of resistance values is achieved by receiving digital signals from communication protocols such as SPI or I²C, revolutionizing automated test equipment, precision electronic adjustments, and advanced audio applications. The programmability and high-precision adjustment capabilities of digital potentiometers give them an unrivaled advantage where complex resistance adjustment solutions are required.

Multi-turn potentiometers, which enable more detailed adjustability by providing multiple turns of rotation, are important primarily in industrial control systems where small changes in resistance can have a significant impact on system performance.

The dual potentiometer controls two independent adjustment parts through a shared operating mechanism, which is particularly suitable for stereo audio systems to ensure balanced and precise volume control of the two channels.

Figure 3: Rotary Potentiometer

Potentiometer vs Rheostat and Encoder

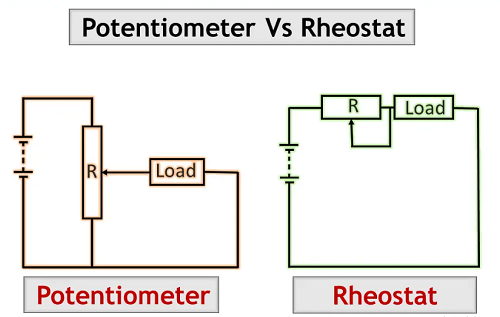

As a three-terminal device, the potentiometer is designed to include a fixed terminal, a sliding terminal, and a ground terminal. This device structure allows the potentiometer to be used both as a varistor (using only its two terminals) and as a voltage divider, providing any intermediate value from zero to the maximum resistance value. By changing the resistance value, the voltage through the load is indirectly adjusted, thus controlling the volume.

Typically having only two terminals and a simpler structural design than a potentiometer, the role of a varistor is focused on controlling the current by changing the resistance of the current path. Varistors are therefore more suitable for applications that require precise control of current, such as regulating motor speed or dimming LED brightness. It should be noted that varistors are suitable for directly controlling the load through which the current flows, rather than dividing the voltage.

Figure 4: Potentiometer vs. Rheostat

The working mechanism of a rotary encoder is significantly different from that of a potentiometer. Encoders use optical or magnetic sensors to identify shaft rotation and then convert the angle of rotation into a digital signal output. This design makes rotary encoders particularly suitable for applications that require precise angle measurements, such as stepper motor control or precise positioning of robot joints. Because encoders provide digital signal outputs, they are particularly important in applications that require high accuracy and complex control systems.

In terms of technical applications and component selection, potentiometers are often used in user interface control and adjustment of analog signals due to their ability to provide continuous analog output and ease of operation. In those high-power applications that require direct current control, varistors show better applicability. Rotary encoders are the first choice in modern automation and precision control systems because they can provide high-precision position information and digital feedback.

Through these analyses, we can see the unique positions and application values of potentiometers, rheostats, and encoders in electronic circuits and control systems. Proper understanding and selection of these components are key to optimizing the design and achieving precise control.

Potentiometer taper

The taper parameter of the potentiometer elucidates the dynamic change of the resistance value during the calibration process and is an important indicator of the change of the resistance value during the adjustment process. Therefore, understanding the different types of potentiometer tapers and their application scenarios can help designers make more reasonable choices.

Linear taper potentiometers are very common in technical fields that require continuous and even adjustment of resistance, as the resistance change is proportional to the adjustment position. This intuitive method of adjustment ensures that the user can predict and control changes in resistance values, maintaining consistency and accuracy in process control.

Logarithmic taper potentiometers utilize their non-linear resistance change characteristics to better accommodate human auditory response characteristics, especially in volume control. The design principle is to provide a faster change in resistance at the beginning of the adjustment and then gradually slow down at a later stage. This pattern of change makes the volume adjustment process appear smoother and more natural. For this reason, logarithmic taper potentiometers are preferred in audio and broadcast systems, as they help to achieve a balanced transition from mute to maximum volume, thus improving the overall listening experience of the audio system.

The antilog taper potentiometer design concept is the exact opposite of the logarithmic taper, providing a slower change in resistance during the initial stages of adjustment and a rapid increase in resistance as the maximum position is approached. This potentiometer is suitable for applications that require a rapid increase in output at the adjustment end. For example, in certain audio processors and effects, antilog taper potentiometers provide finer control, especially when adjusting high dynamic range signals.

Figure 5: Volume Control Potentiomete

When selecting the potentiometer taper, in addition to considering the specific technical requirements of the application, you also need to consider the user's operating habits and expected control effects. For most audio applications, logarithmic or antilogarithmic taper potentiometers are more suitable because of their matching to the hearing characteristics of the human ear, while linear taper potentiometers show advantages where uniform and continuous control is required. Comprehensive consideration of application requirements, user experience, and cost factors can guide designers to make the most appropriate choice among many options to ensure the best match between the performance of the potentiometer and the application scenario.

Other key parameters of the potentiometer

The performance and adaptability of a potentiometer are deeply affected by its key parameters, which together determine the performance and reliability of the potentiometer in different situations. Understanding these parameters and their impact on potentiometer performance is extremely important to selecting the appropriate potentiometer and ensuring that it performs well for a given application.

Resistance value and resistance range are the primary considerations when designing a potentiometer. They directly define the maximum resistance between the two ends of the potentiometer and determine the resistance adjustment range that the potentiometer can achieve in the circuit. High-resistance potentiometers are often used in fine signal conditioning applications, such as volume controls in audio equipment because they provide a large resistance adjustment range, suitable for fine-tuning signal strength. Low-resistance potentiometers are more commonly used in current control scenarios, such as motor speed adjustment because they can provide higher current passing capabilities within a smaller resistance range.

Figure 6: Multi-turn Potentiometer

The potency index signifies the utmost power capacity that the potentiometer can sustain persistently without succumbing to overheating. This metric assumes paramount significance in upholding the stable functionality of the potentiometer while concurrently prolonging its operational lifespan. In applications necessitating high power, such as fine-tuning resistors for power amplifiers, the judicious selection of a potentiometer boasting a sufficiently elevated power rating becomes imperative to avert overheating and potential consequential damage.

Resolution delineates the minimum discernible alteration in resistance that a potentiometer can accurately perceive. Its pertinence becomes particularly pronounced in scenarios mandating meticulous adjustment of resistance. Take, for instance, laboratory instrumentation and high-precision control systems where potentiometers endowed with heightened resolution capabilities facilitate nuanced adjustments, thereby enhancing response precision and system controllability.

Sliding noise is electrical noise produced by poor mechanical contact within a potentiometer, which can result in reduced signal quality in audio and high-precision signal processing applications. Choosing a potentiometer with a low-noise design, such as one that uses high-quality materials and precision manufacturing processes, can significantly reduce sliding noise and maintain signal clarity and purity.

Temperature coefficient is a measure of the sensitivity of a potentiometer's resistance value to changes in temperature. When using a potentiometer in an environment with large temperature fluctuations, choosing a potentiometer with a low-temperature coefficient can ensure the stability of the resistance value. This is especially critical for applications that are sensitive to temperature changes, such as precision measurement and control systems.

Finally, the mechanical durability and operating life of the potentiometer are also factors that must be considered when selecting. In applications that require frequent adjustments or operate in harsh environments (such as high temperature, high humidity, or the presence of corrosive gases), choosing a potentiometer with high durability and long life can ensure the reliability of the equipment and reduce the need for maintenance.

By considering these key parameters, designers can select the potentiometer that best suits their specific application needs, not only improving circuit performance and reliability but also optimizing the user experience.

Conclusion

Potentiometers offer a range of advantages including simple design, affordability, wide resistance range, ease of operation, and proven technology. They are reliable devices used in electronic and electrical systems for voltage control, measurement, and precise sensing of linear or rotary motion. Designers need to select the most suitable potentiometers with due consideration of the corresponding parameters and their limitations to ensure that they perform as expected in the target application.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

What is GND in the circuit?

on February 20th

CR2025 vs CR2016 Battery: Revealing the Secrets of Button Batteries

on February 4th

Popular Posts

-

What is GND in the circuit?

on January 1th 3272

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2815

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 20th 2640

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2265

-

Comparison Between DB9 and RS232

on January 1th 1882

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1846

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1807

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1801

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1799

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 20th 1782