Exploring the Innovations in Electric Vehicle Charging Technology

Electric vehicles (EVs) are becoming more popular, signaling a big move towards eco-friendly transportation. Battery Electric Vehicles (BEVs) are important because they are efficient and have a low environmental impact. This article explores the different technologies for charging BEVs, from traditional wired systems to new wireless methods and battery swapping. It looks at how these technologies make EVs easier to use and help reduce carbon emissions and promote energy independence. The article also compares mobile and stationary charging options, discussing their effectiveness in various situations. This detailed review highlights the role of charging infrastructure in making electric vehicles viable and successful, offering insights into the current and future state of BEV technology.

Catalog

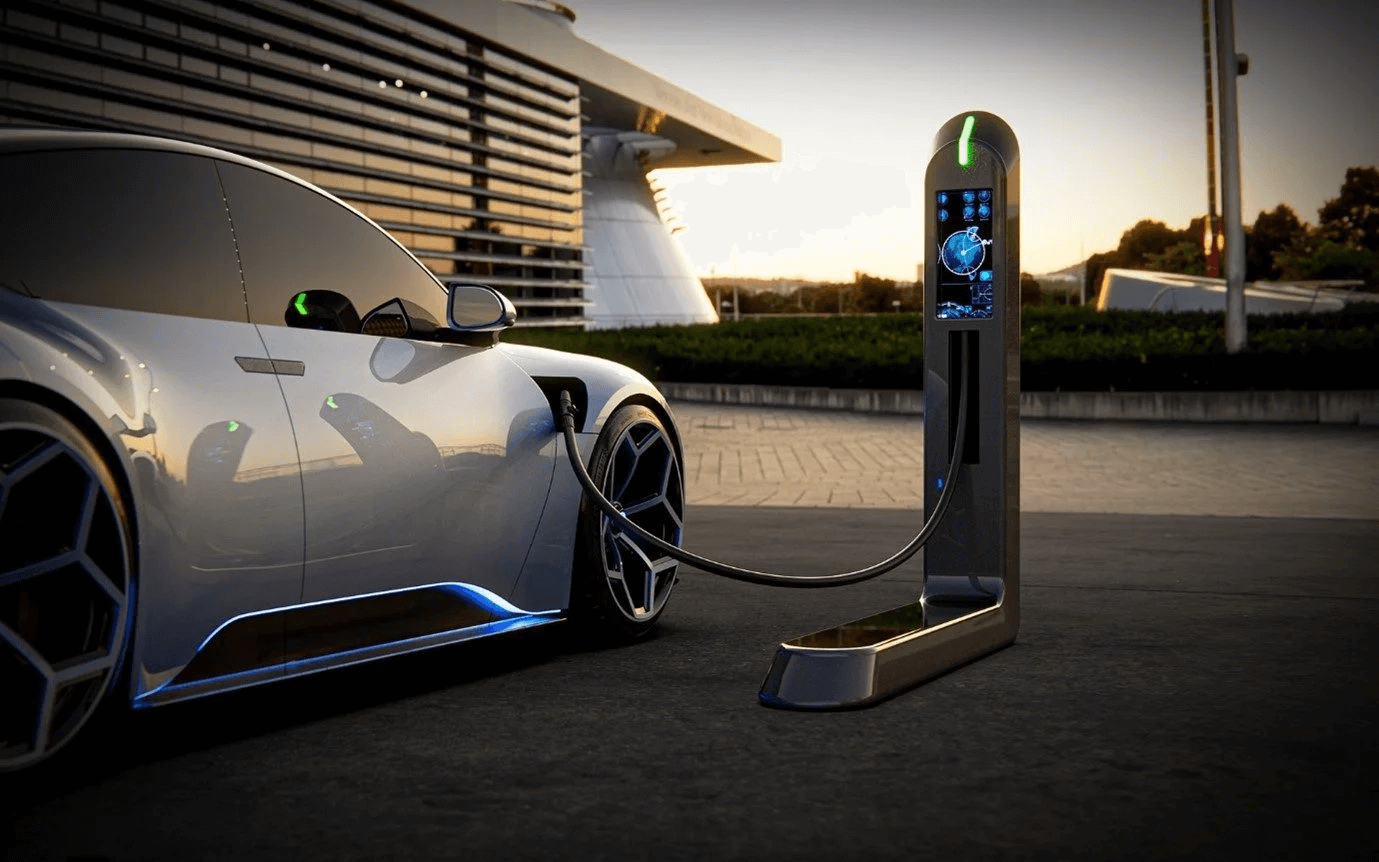

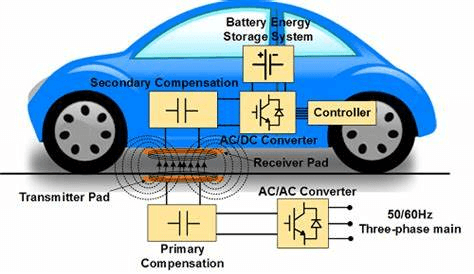

Figure 1: Electric Vehicle Wireless Charging

What Is Battery Electric Vehicles?

Battery electric vehicles (BEVs) use different types of wired and wireless charging methods. These methods are useful to reduce greenhouse gas emissions, boost energy efficiency, and lower pollution. The rise in electric vehicle (EV) adoption over the past few decades is largely due to their lower fuel costs and superior energy efficiency. This increase in adoption has driven BEVs to become a main component of eco-friendly transportation. Advancements in batteries and charging technologies since 2014 have improved fuel economy and reduced emissions. To support this growth, companies are heavily investing in the research and development of BEV charging systems.

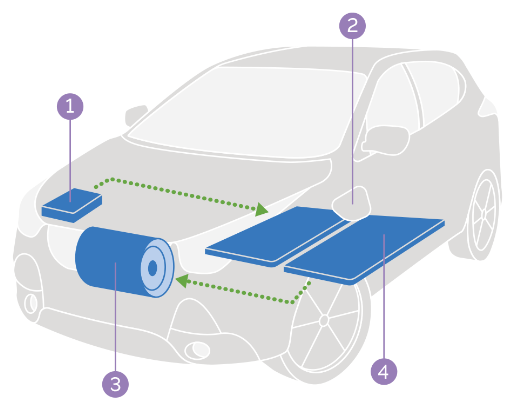

Here's a breakdown for each part:

(1) Onboard Charger

(2) Charge Port

(3) Electric Motor

(4) Battery

Figure 2: Battery Electric Vehicle Parts

How Do They Work?

Electric vehicles (EVs) represent a major leap in automotive technology, mainly due to advanced batteries and sophisticated electronic controls. At the core of most EVs is the lithium-ion battery, known for its compact size and high energy density. This battery can store an enormous amount of energy in a small space for maximizing the vehicle's range and performance. The charging process is managed by an onboard charger. This device converts alternating current (AC) from standard power sources, like a 120-volt household outlet, into direct current (DC).

Each EV has a charge port, which connects the vehicle to an external power supply. This port allows easy integration with the existing electrical infrastructure, making recharging straightforward. EVs offer an eco-friendly transportation option by eliminating tailpipe emissions and reducing environmental impact. They also provide a driving experience that is distinct from conventional vehicles, focusing on efficiency, sustainability, and cutting-edge technology.

Wired Charging Technologies

Wired charging methods involve a direct cable connection between the EV and the charging equipment, categorized into alternating current (AC) and direct current (DC) charging technologies.

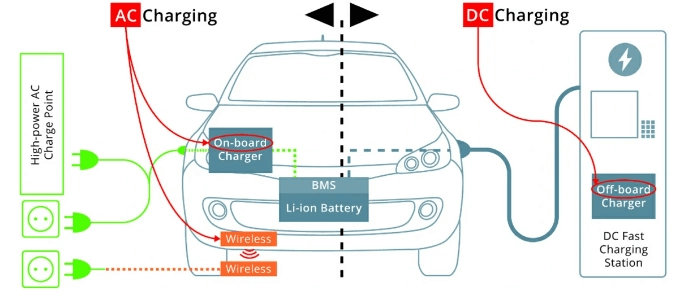

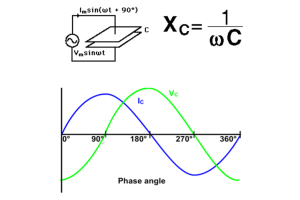

AC Charging

AC charging uses the vehicle's onboard charger (OBC) to convert AC to DC. This conversion adds weight to the system due to the inclusion of the conversion unit. AC charging achieved using either single-phase onboard slow charging or three-phase onboard fast charging systems. These systems transfer power to the OBC, which then regulates the current to reduce ripples, switching loss, and electromagnetic interference (EMI). AC charging is common in BEVs, offering power levels below 20 kW and charging times ranging from 2 to 6 hours. The OBC's weight and space requirements are obstacles even its widespread use.

Figure 3: Alternating Current (AC) and Direct Current (DC) Charging

DC Charging

DC charging technologies directly charge the battery, offering the advantage of rapid charging. These systems can be classified into off-board fast charging and off-board rapid charging. By housing the conversion unit externally, DC charging reduces the vehicle's size and weight. High-capacity batteries can be charged in less than an hour, making DC charging ideal for quick refueling. Unlike AC charging, DC charging uses off-board chargers at stations to directly feed the battery. These solutions require an expensive battery management system (BMS) and lack flexibility for multiple charging locations. Wired charging remains limited by its inherent rigidity and the safety and reliability demands of the BMS.

Locating AC and DC Charging Stations

|

Aspect |

AC

Charging |

DC

Charging |

|

Energy Source |

Alternating current (AC) from the power grid |

Direct current (DC) supplied directly to the battery |

|

Conversion Process |

Onboard converter in the EV transforms AC to

DC |

External charger converts AC to DC before

supplying the EV |

|

Common Locations |

Residential areas, workplaces |

Highways, busy public areas, increasingly in

residential settings |

|

Charging Speed |

Slower (up to 22 kW) |

Faster |

|

Usage Scenario |

Overnight or all-day charging |

Quick recharging, ideal for travelers |

|

Infrastructure |

Utilizes existing AC infrastructure |

Requires specialized DC chargers |

|

Technological Advancements |

Established and widely available |

Increasing availability, includes fast and

bidirectional charging |

|

Impact on Electric Mobility |

Convenient and accessible for routine needs |

Enhances charging speed and efficiency for

future advancements |

Wireless Charging Technologies

Wireless charging technologies eliminate the need for cables, addressing maintenance and safety issues. BEVs can charge by parking over a charging system that transmits high-frequency current. Wireless charging includes near-field, medium-field, far-field technologies and more.

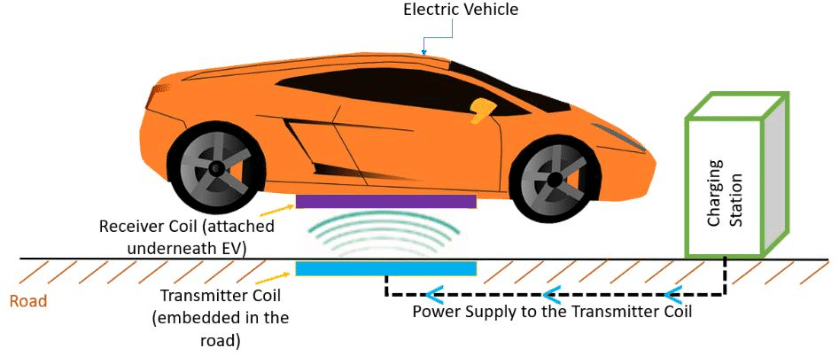

Figure 4: Wireless Charging

Near-field and Medium-field Charging

Near-field charging includes inductive, magnetic-resonant, and capacitive charging, while medium-field charging encompasses magnetic-gear charging. These methods eliminate the need for a direct connection to the vehicle, reducing costs compared to wired charging. The system converts grid-frequency AC to high-frequency AC, transmitted via a transmitter pad and received by a receiver pad attached to the BEV. These methods offer convenience and cost-effectiveness but can face efficiency issues.

Far-field Charging

Far-field charging methods, such as laser, microwave, and radio wave charging, are still in the research phase but are expected to shape the future of wireless charging technologies. Maintaining a stable connection between the transmitter and receiver is a great challenge, posing risks of losing control and efficiency.

Static Wireless Electric Vehicle Charging System (S-WEVCS)

The Static Wireless Electric Vehicle Charging System (S-WEVCS) enhances the electric vehicle (EV) experience by removing the need for physical connectors, addressing safety concerns like tripping hazards and electrical shocks. The system includes a primary induction coil embedded in the ground below parking spaces and a secondary coil on the vehicle's underside. This setup creates a magnetic field to transfer power efficiently, converting the AC received by the secondary coil into DC to charge the vehicle's battery.

S-WEVCS incorporates power control units and battery management systems that maintain constant wireless communication to optimize charging efficiency and ensure safety. These systems regulate power transmission rates and coil alignment, with air gaps ranging from 150 to 300 millimeters for optimal performance in light-duty vehicles. S-WEVCS can be installed in residential areas, commercial venues, and public transport hubs.

Figure 5: Static Wireless Charging (SWC) System

Static Inductive Charging

Static inductive charging involves two electromagnetically coupled coils: a primary coil installed on the roadway and a secondary coil on the EV. The system converts 50Hz AC energy from the grid to DC, then to high-frequency AC, which is transferred via electromagnetic induction to the vehicle. The EV's coil then converts the high-frequency AC back to DC for battery charging. This method is suitable for self-driving EVs due to its convenience, although it is less efficient than conductive charging and has limitations in terms of weight and space.

Driven by collaborative research and development between academia and industry, S-WEVCS prototypes offer power capabilities between 3.3 kW and 7.2 kW, adhering to standards like SAE J2954. Although initial installation costs range from $2,700 to $13,000, the strategic deployment of S-WEVCS promises long-term benefits in safety and convenience. As the technology evolves and becomes more affordable, its adoption is likely to increase. Allowing vehicles to charge without physical cables, S-WEVCS ensures perfect alignment between the vehicle's receiver and the transmitter embedded in the parking spot for effective power transfer. This design integrates seamlessly into daily routines, reducing physical interaction and promoting ease of use, especially in areas where vehicles are parked for extended periods. It supports efficient energy management within urban developments, enhancing user experiences and contributing positively to urban infrastructure planning.

Dynamic Wireless Electric Vehicle Charging System (D-WEVCS)

D-WEVCS addresses the range and cost challenges of battery electric vehicles (BEVs) by enabling in motion charging. The system features primary coils embedded along roadways, powered by high voltage, high-frequency AC sources. Vehicles equipped with corresponding secondary coils capture the magnetic fields to convert energy into DC, dynamically charging the battery.

This technology reduces the need for large battery capacities by about 20%, enhancing vehicle efficiency and compatibility with autonomous driving technologies. However, alignment accuracy between transmitter and receiver coils is good for maximizing energy transfer and operational efficiency. D-WEVCS can be adapted for various transport forms, from light vehicles to public buses, making it a scalable solution for modern transport infrastructures. In a recent pilot project in Sweden, a stretch of highway was equipped with D-WEVCS technology, demonstrating a reduction in battery size and extension of vehicle range. Such real-world applications highlight the transformative potential of D-WEVCS as support infrastructures evolve.

Figure 6: Dynamic Wireless Electric Vehicle Charging System (D-WEVCS)

Dynamic Inductive Charging

|

Charging

System |

Description |

Advantages |

Limitations |

Suitable

Applications |

|

Wireless Capacitive Charging Systems |

Operates at high frequencies using conductive

plates for power transfer via displacement currents. Plates embedded in the

road and vehicle. |

Compact design, cost-effective, reduces

integration costs, efficient power transfer, minimal energy loss |

Requires specific infrastructure, potential

challenges with varying air gaps |

Urban and residential settings |

|

Permanent Magnetic Gear Wireless Charging

System |

Uses synchronized permanent magnets to

transfer power mechanically. Primary magnet’s torque converted back into

electrical energy by the secondary magnet. |

Mechanical power transfer, potential for

high-efficiency conversion |

Precise alignment required, limited to static

scenarios |

Situations where precise vehicle positioning

is feasible |

|

Inductive Wireless Charging System |

Uses a primary coil to transmit power

wirelessly to a secondary coil within the vehicle across an air gap. |

Adaptable to various power ranges, suitable

for diverse applications, proven technology (e.g., General Motors'

Magne-charge) |

Limited by the size of the air gap, can be

less efficient over larger distances |

Charging stations for small to large electric

vehicles |

|

Resonant Induction Charging System |

Utilizes tuned resonant frequencies to

maximize power transfer efficiency. Operates at higher frequencies across

larger air gaps, using magnetic ferrite cores. |

High power transfer efficiency, minimal

physical contact, effective over larger air gaps |

Requires precise tuning of resonant

frequencies, potential for interference |

Wide range of electric vehicle applications |

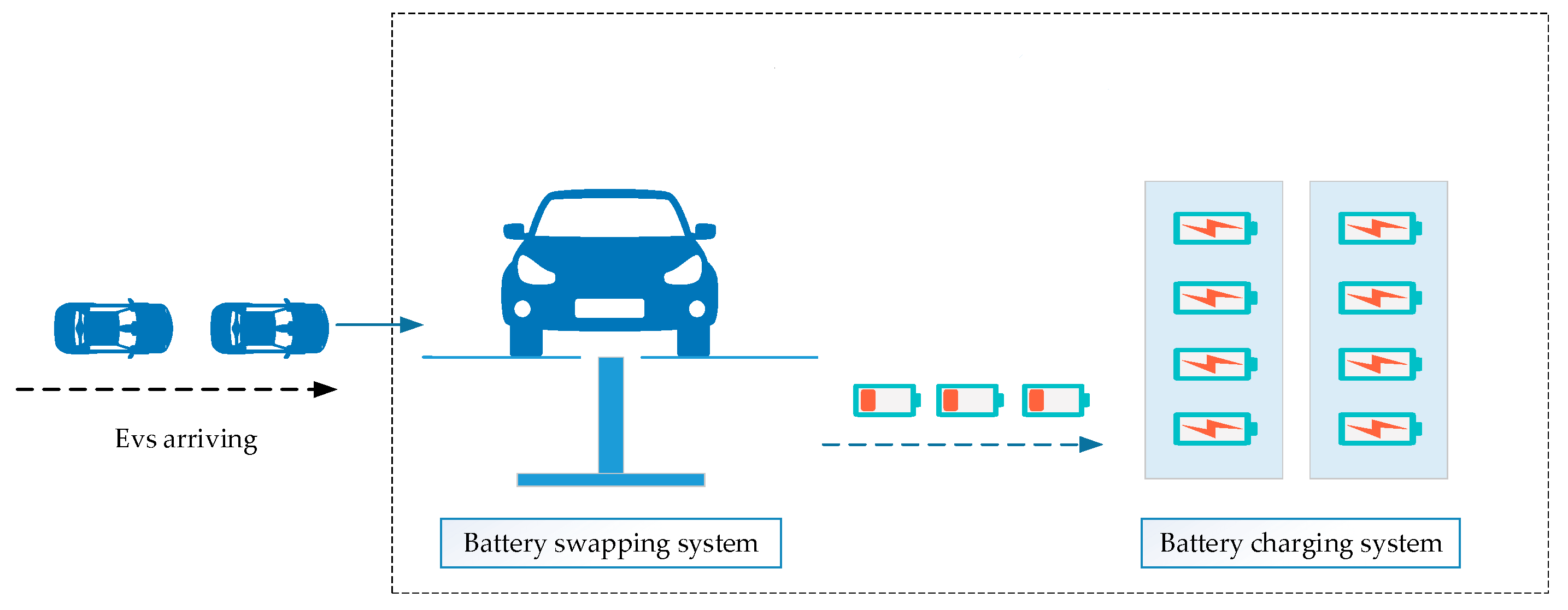

Battery Swap Technology

A big change in the electric vehicle world is battery swapping. This lets drivers quickly replace an empty battery with a charged one, similar to filling up a gas car. It saves a lot of time compared to regular charging. This method drastically reduces the time associated with conventional charging, providing a fast, gas station-like experience.

Battery swapping involves replacing depleted batteries with fully charged ones at a swapping station. It extends battery lifespan by employing a slow charging mechanism at the station. It requires a sophisticated system for monitoring battery health and usage patterns. The design of battery swapping stations prioritizes user efficiency. Drivers simply align their vehicles in a designated spot, and automated systems handle the battery swap. This process takes only a few minutes, minimizing vehicle downtime and improving the overall user experience by allowing immediate travel continuation. This addresses a major obstacle to EV adoption: long charging times.

Figure 7: Battery Swap Technology

Advantages of Battery Swapping

The main advantage of battery swapping is that it reduces the amount of time required to charge electric vehicles. Traditional charging can take hours, but battery swapping reduces this to just minutes. This makes EVs more practical for long trips and reduces "range anxiety"—the fear of running out of battery far from a charging point.

The structure for battery swapping stations is less complex and less costly than that of conventional fuel stations. This cost efficiency can lead to wider adoption in areas with limited EV infrastructure, such as rural or developing regions. Promoting a more inclusive shift to electric vehicles, battery swapping provides an environmentally friendly solution that meets the mobility needs of a diverse population.

Disadvantages of Battery Swapping

Battery swapping technology has benefits, but there are also big problems that make it less practical and hard to use widely. The initial cost of setting up swapping stations is high, potentially slowing expansion.

Operational issues also persist. Although faster than traditional charging, battery swapping is still not as quick as gasoline refueling, which can be problematic for urgent travel needs. There are also concerns about potential battery damage during swaps, which may make EV manufacturers hesitant to fully embrace this technology. High monthly fees and the need for standardized battery interfaces across different manufacturers also present challenges.

To overcome these challenges, ongoing improvements are required to ensure battery safety and integrity during swaps. Expanding the network of swapping stations for broader adoption. Various stakeholders are working to refine this technology, making it more appealing to both manufacturers and consumers, with the goal of integrating it into the mainstream automotive market.

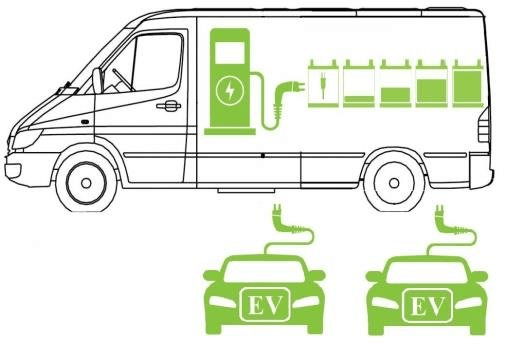

Mobile Charging

Mobile EV charging, also known as on-demand or roving charging, is a new development in the electric vehicle (EV) industry. It involves portable charging systems that can be moved to different locations to charge EVs, providing an alternative to fixed charging stations. These mobile units bring power directly to the vehicles, eliminating the need for EVs to travel to a specific location for charging. They use mobile power sources like generators or large battery packs to supply electricity to EVs wherever they are parked.

Some are vehicles equipped with multiple charging points and high-power capacity, able to quickly charge at once. Others are smaller, portable setups that can be placed temporarily in locations like parking lots, event spaces, or areas without permanent charging infrastructure. A more advanced form of mobile charging involves autonomous robots that locate and charge vehicles in parking areas. This method, a form of conduction charging, offers flexibility in charging locations and efficient use of space. Mobile charging robots enhance the efficiency of recharging in parking areas, allowing for better utilization of charging infrastructure. Users can easily find chargers using apps, supporting both overnight depot charging and pantograph charging for larger batteries and fast charging needs. Their flexibility and portability address many logistical challenges, offering a practical solution beyond the limitations of traditional charging stations.

Figure 8: Mobile Electric Vehicle (EV) Charger

Benefits of Mobile EV Charging

• Accessibility and Convenience

The main advantage of mobile EV charging is its ability to provide charging solutions directly to EV owners in areas with limited charging infrastructure. This accessibility reduces the problems associated with sparse charging options, allowing for charging in remote, temporary, or economically impractical locations for permanent setups. It eliminates the stress of finding a charging station, giving drivers peace of mind and the ability to recharge their vehicles conveniently without altering their routes.

• Rapid Deployment and Scalability

Mobile charging units are designed for quick setup and can be easily transported to areas with temporary increases in charging demand, such as events or construction sites. Their modular design allows for easy scalability, adding capacity without extensive infrastructure changes. This adaptability makes mobile EV charging an ideal solution that can grow with the increasing popularity and adoption of EVs.

• Reducing Range Anxiety

Range anxiety, the fear of running out of battery power away from a charging station, is a major barrier to EV adoption. Mobile charging units provide a practical solution by expanding the network of available charging options in areas with limited infrastructure. Their presence reassures drivers about the availability of charging resources, encouraging the use of EVs and supporting their widespread adoption.

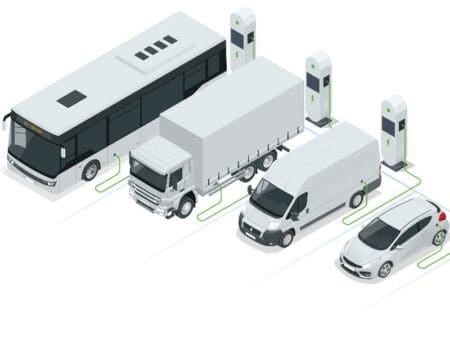

Overnight Depot Charging

Figure 9: Overnight Depot Charging

Overnight depot charging is used for both slow and fast charging, positioned at the end of the power supply and employed for nighttime charging. This method minimizes the impact on the power grid, making it an advantageous option for sustained charging. It ensures that EVs are fully charged and ready for use by the start of the next day, offering convenience and efficiency for fleet operations and private use alike.

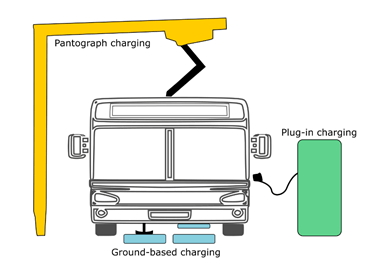

Pantograph Charging

Pantograph charging is designed for EVs with large battery capacities, such as buses and heavy vehicles. This system reduces the capital cost of the vehicle by lowering the expenditure on batteries but increases the cost of the charging infrastructure. Pantograph charging is divided into top-down and bottom-up methods. The top-down pantograph involves an off-board system mounted on the rooftop of a bus stop, while the bottom-up method involves an onboard system installed in the bus. This method provides a practical solution for quickly charging large vehicles but requires infrastructure investment and precise alignment.

Figure 10: Pantograph Charging

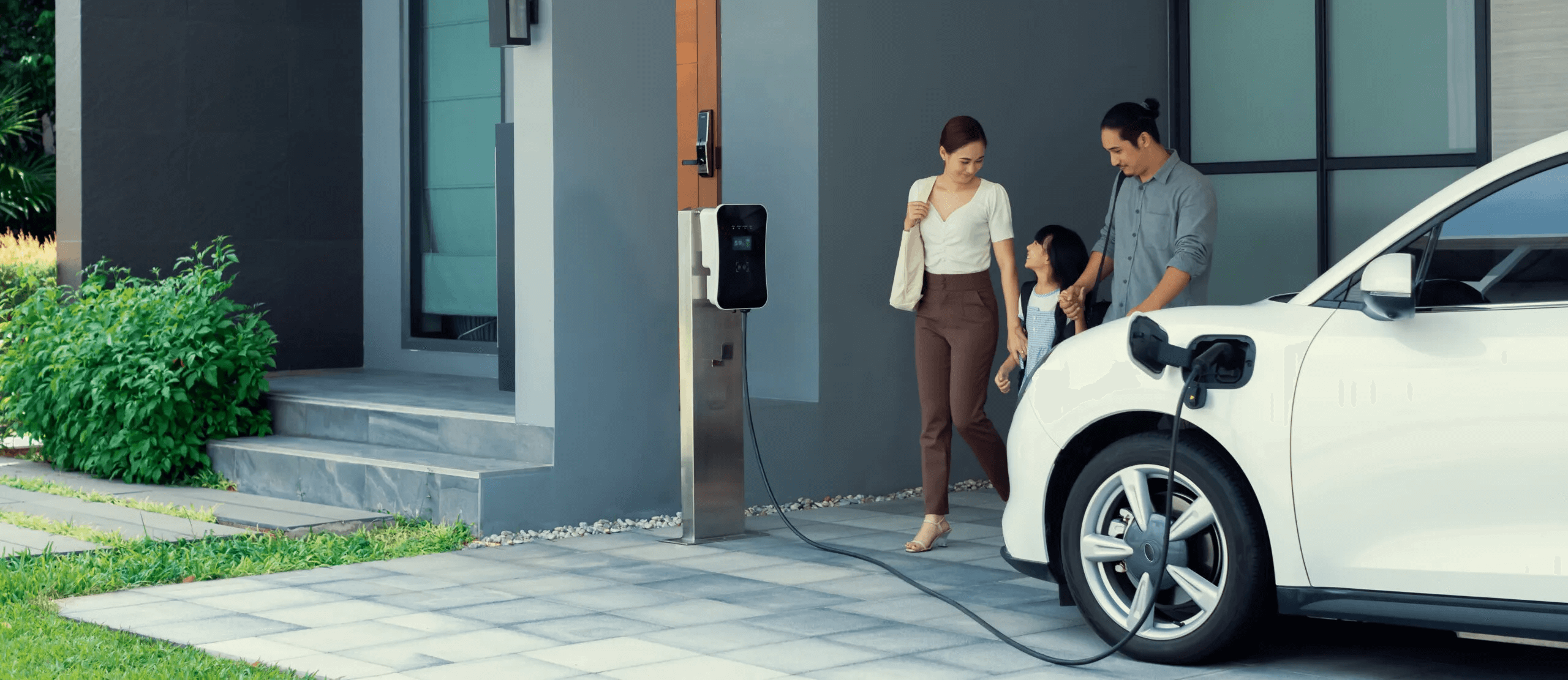

Home Vs. Public Charging

Figure 11: Home Charging

EV owners can choose between home charging and public charging stations, each offering different types and speeds of charging. Home charging, often done overnight, involves trickle charging using a standard household outlet or faster AC household charging with a wall box. Public charging stations provide more convenience and faster charging options, offering either AC or DC fast charging. DC fast chargers at public stations deliver the quickest charging times, although excessive use can shorten battery life. The choice between home and public charging depends on the user's driving habits, availability of infrastructure, and the need for fast charging.

The following table provides a comparison between the advantages and challenges associated with Public and Residential Electric Vehicle (EV) Charging Stations.

|

Category |

Advantages |

Challenges |

|

Public EV Charging |

Convenient locations (shopping centers,

workplaces, highways) |

High demand during peak hours causing long

wait times |

|

|

Reduces range anxiety for those without

private charging options |

Cost variability, often higher than

residential electricity |

|

|

Good for urban and suburban EV owners |

Limited infrastructure in rural/less

populated areas increases range anxiety and limits adoption |

|

Home EV Charging |

Convenience of overnight charging in your

garage, ensuring a fully charged vehicle every morning |

Initial setup costs (charging hardware,

possible electrical system upgrades) |

|

|

Potentially lower electricity costs,

especially with off-peak tariffs |

Slower charging compared to high-powered

public chargers |

|

|

Can increase property value |

Renters and multifamily dwellers face

additional installation challenges (permission, inadequate infrastructure) |

|

Comparative Costs of Home vs. Public Charging |

Home charging generally cheaper ($0.12/kWh

vs. $0.25/kWh for public) |

Cost variations based on local utility rates

and public network pricing |

|

|

Off-peak rates can further reduce home

charging costs |

Membership fees and occasional free public

charging can affect overall costs |

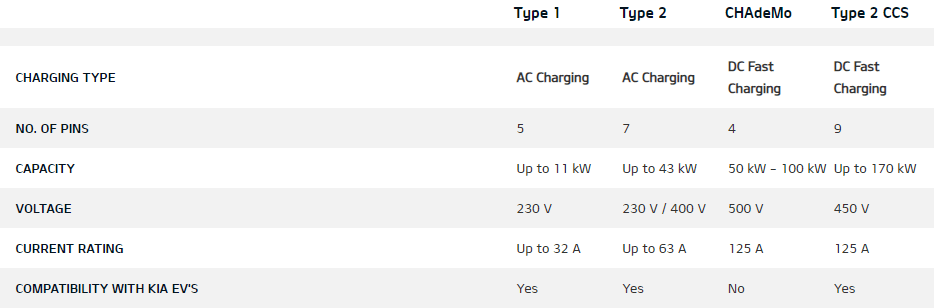

Electric Vehicle Charging Connectors and Equipment

Figure 12: Overview of the Main Connector Types

Efficient charging of electric vehicles (EVs) relies on the compatibility of specific connectors and the use of appropriate charging systems. AC charging employs Type 1 and Type 2 connectors, whereas DC fast charging utilizes CHAdeMO and SAE Combo connectors. It's good for EV drivers to know which connectors are compatible with their vehicles before visiting a charging station, as this ensures efficient and hassle-free charging for the widespread adoption of EVs.

EV charging systems are categorized into three levels: Level 1, Level 2, and Level 3 (DC fast charging). Level 1 chargers are the simplest, using a standard 120V outlet and providing limited power, making them suitable for overnight charging at home. Level 2 chargers use a 240V outlet, offering faster charging for both home and public use. Level 3 chargers, or DC fast chargers, bypass the onboard charger and deliver direct power to the battery, requiring a high-capacity power source and making them ideal for commercial fast charging stations. Each level of charging equipment provides distinct benefits, tailored to the needs of various users and charging scenarios, ensuring the efficient and widespread use of EVs.

Conclusion

This article examines the technologies and charging systems for Battery Electric Vehicles (BEVs), revealing the opportunities and challenges in the EV industry. By looking into wired and wireless charging, battery swapping, and mobile charging solutions, it's clear that the future of transportation relies heavily on these advancements. Improvements in BEV infrastructure, from homes to public spaces, aim to make EVs more accessible and practical. However, achieving a fully electric future requires overcoming technological, economic, and infrastructural challenges. Ongoing innovation and enhancement of these systems making EVs a mainstream, sustainable choice for global transportation. This narrative highlights not only the technological progress but also the environmental goals driving the shift to electric vehicles, promising a greener and more efficient future for everyone.

Frequently Asked Questions [FAQ]

1. What is the current EV charging technology?

Electric vehicles are commonly charged using one of three main technologies: Level 1, Level 2, and DC fast charging. Level 1 charging uses a standard household electrical outlet (120 volts) and is the slowest form, suited for overnight use or minimal daily driving. Level 2 charging operates on 240 volts and charges faster, making it suitable for home and public charging stations. DC fast charging is the quickest method, using direct current (DC) instead of alternating current (AC) and can charge an EV to 80% in about 30 minutes, depending on the vehicle and charger capacity. Technological advancements include wireless charging and improvements in battery technology that allow for faster charging and longer driving ranges.

2. What is the principle of electric vehicle charging?

Electric vehicle charging operates on the principle of converting AC electricity from the power grid to DC power to charge the EV's battery. Level 1 and Level 2 chargers usually convert the AC electricity to DC within the vehicle's onboard charger, while DC fast chargers provide the DC electricity directly to the battery, bypassing the car’s internal charger. This direct method allows for faster charging speeds. The charging process is managed by an electronic control unit (ECU) within the EV, which communicates with the charging station to regulate the power flow to optimize battery life and charging speed.

3. What is the best charging method for EV?

The best charging method depends on the user's needs. For everyday use, Level 2 charging strikes a balance between charging speed and equipment cost, making it the most practical for home and public use. DC fast charging is best for long-distance travel where quick charging is required. However, frequent use of fast charging can degrade the battery faster than slower methods.

4. Can you charge an electric car every day?

Yes, you can charge an electric car every day. Regular charging require to ensure the battery maintains optimal health and the vehicle is ready for use. Charging habits similar to smartphone charging—plugging in nightly—are common among EV owners. However, it's advised to maintain the battery charge between 20% and 80% to maximize lifespan and performance.

5. How long does it take to charge an EV?

The time it takes to charge an EV varies based on the charging level, the battery’s capacity, and the current state of charge. A Level 1 charger takes 8-20 hours to fully charge a battery, making it suitable for overnight charging. Level 2 chargers can take 4-6 hours for a full charge. DC fast charging can charge an EV up to 80% in approximately 30 minutes, but total time can vary among different vehicle models and charger outputs.

6. What is the main purpose of an EV charger?

The main purpose of an EV charger is to efficiently and safely convert AC electricity from the electrical grid into DC electricity that can be stored in the vehicle’s battery, facilitating the use of electric power for driving. EV chargers are designed to protect both the electrical grid and the vehicle’s battery from potential damage during the charging process, incorporating features like smart charging capabilities to optimize charging times and electricity usage.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

The Extensive Guide to High-Pass Filters in Modern Electronics

on July 2th

An In-Depth Exploration of Read-Only Memory and Its Various Types

on July 1th

Popular Posts

-

What is GND in the circuit?

on January 1th 2933

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2494

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2081

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 8th 1883

-

Comparison Between DB9 and RS232

on January 1th 1759

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1710

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1651

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1541

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1537

-

CR2450 vs CR2032: Can The Battery Be Used Instead?

Lithium manganese batteries do have some similarities with other lithium batteries. High energy density and long service life are the characteristics they have in common. This kind of battery has won the trust and favor of many consumers because of its unique safety. Expensive tech gadgets? Small appliances in our homes? Look around and you'll see them everywhere. Among these many lithium-manganes...on January 1th 1504