Comparative Guide to Analyzing rheostat and Potentiometers

In today's electronic and electrical systems, regulating current and voltage is key to achieving precise control and functional versatility. Rheostats and potentiometers are two basic types of variable resistors. Although they both have the function of adjusting resistance, they are fundamentally different in design concepts, structural structures, and application scenarios. This article will take an in-depth look at how these two devices work, their advantages, their specific applications in electronic circuits, and how they complement each other.Catalog

What is a rheostat?

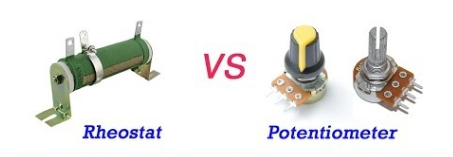

A rheostat is a commonly used adjustable resistor used to control the flow of electricity in a circuit. Its working principle is simple: it regulates the flow of current by changing the internal resistance. This feature is particularly valuable in applications that require precise control of current, such as adjusting the brightness of a lamp, the speed of a motor, or the temperature of a heater.

The construction of a varistor usually consists of two main terminals. One terminal is fixed, while the other terminal is connected to the movable slider. By moving this slider, the user can adjust the current flow by changing the length of the path the current takes through the varistor. For example, when dimming a desk lamp, the user can directly experience the light gradually brightening or dimming as the knob is turned, and this change is directly related to the real-time adjustment of the rheostat resistance.

Working principle of rheostat

The construction of a varistor usually consists of a coil of resistive wire wound around an insulating core. Its operation depends on the electrical connection of the resistance wire and the position of the sliding contacts. The varistor is equipped with two active terminals; one is fixed to one end of the resistance wire and the other is connected to the sliding contact. As this contact slides along the resistive wire, it changes the effective length of the wire through which current flows, thus changing the resistance. This mechanism allows the rheostat to adjust the current flow by increasing or decreasing resistance without directly changing the voltage. This design allows for precise control of current flow.

What is a potentiometer?

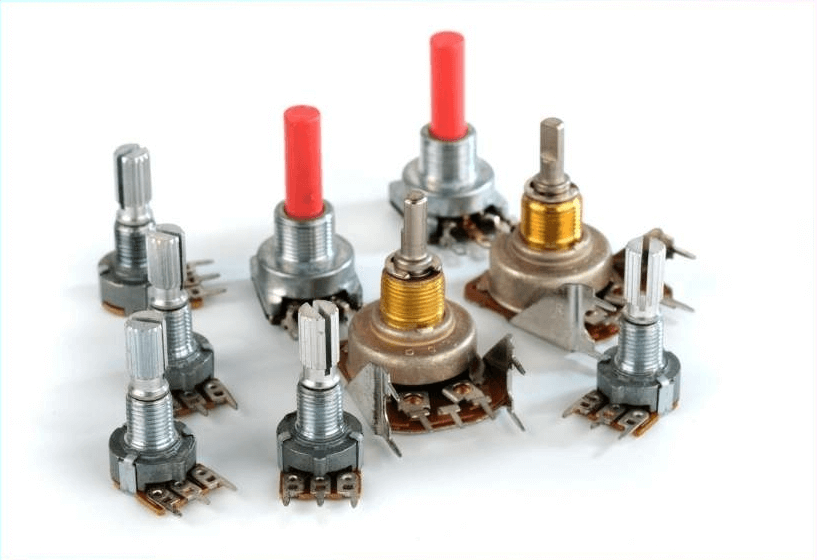

A potentiometer is an adjustable resistor with three terminals that is primarily used to change the voltage distribution in a circuit. The assembly consists of a resistive element, a movable slider (also called a wiper), and two fixed terminals. The resistive element is usually made of materials such as carbon, cermet, or conductive plastic, while the slider is usually made of highly conductive materials such as brass or nickel.

In order to adjust the voltage between the two fixed terminals, the position of the slider on the resistive element needs to be changed. This adjustment process is very simple and provides instant feedback: as the user moves the slider, they can directly observe the change in output voltage. This direct interaction allows precise control of voltage, making potentiometers more suitable for applications requiring voltage tuning.

Working principle of potentiometer

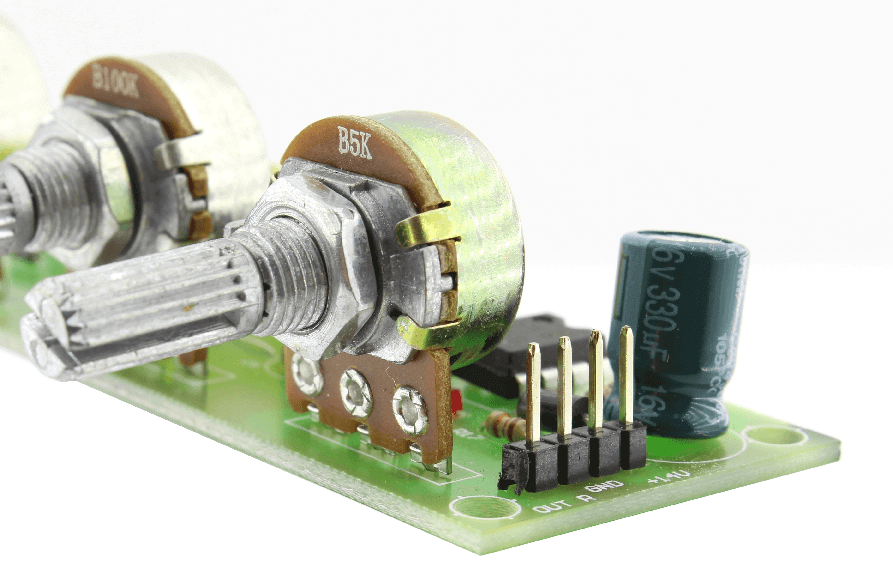

The operation of a potentiometer is centered around a resistive element and a sliding contact. Resistive elements are typically made from carbon, cermet, or conductive plastics, materials that effectively create voltage drops and control current flow. Sliding contacts are usually made of highly conductive materials such as copper or nickel, which ensure reliable current transfer when moving over a resistive element.

When a voltage is applied between the two fixed terminals of a potentiometer, a voltage gradient is established along the resistive element. By manually or automatically adjusting the position of the sliding contact on the resistive element, the user can vary the resistance between the contact and one of the fixed terminals. This adjustment directly changes the voltage output of this terminal, allowing the potentiometer to accurately control the voltage output in the circuit.

Relationship between rheostat and potentiometer

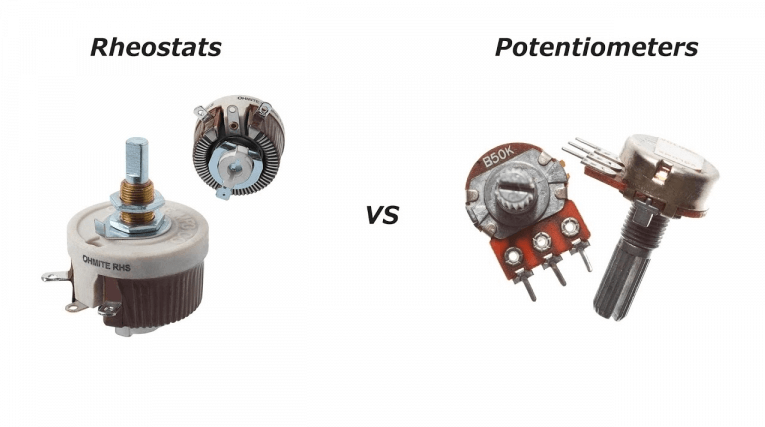

Rheostats and potentiometers are both variable resistors, but they serve different purposes and have different configurations. Both devices use resistive elements to adjust electrical characteristics in circuits, but they are optimized for different functions.

Rheostats are mainly used to control current. They usually have two terminals and a resistive path. By moving the contacts along a resistive path, the user can change the path length and thus regulate the current flow. This adjustment directly affects the amount of current flowing through the circuit, making rheostat ideal for applications requiring variable current levels, such as motor speed controllers.

Potentiometers are often used to control voltage. It generally has three terminals and divides the voltage in the circuit through resistive elements. A movable contact (cursor) selects a point along the component to set the output voltage. Potentiometers are therefore useful for applications that require precise voltage regulation, such as volume control in audio equipment.

|

Characteristic |

Rheostat |

Potentiometer |

|

Number of Terminals |

Two (Two terminals for external

connections) |

Three (Two fixed end terminals and one

wiper/slider) |

|

Function |

Controls current in a circuit |

Measures or adjusts voltage and

resistance |

|

Typical Applications |

Dimming lights, motor speed control |

Volume control in audio equipment,

sensors |

|

Voltage Division |

Generally not used for voltage division |

Commonly used as a voltage divider |

|

Adjustment Mechanism |

Adjusts the length of a resistive wire |

Adjusts the wiper position along a

resistive track |

|

Connection Type |

Two external terminals |

Two external terminals and one wiper

terminal |

|

Voltage Output |

Not designed to produce voltage output |

Produces variable voltage or resistance

output |

|

Control Mechanism |

Adjusts the length of resistive wire |

Taps into different points along the |

What they have in common: Both devices allow dynamic resistance changes. Users can manually adjust electrical parameters and directly control the current or voltage in the circuit.

Advantages of potentiometers over rheostat

Potentiometers offer significant advantages over rheostats, especially in terms of versatility, accuracy, and functionality. Here’s a detailed breakdown of these benefits:

Wider resistance and voltage adjustment range: Potentiometers are designed to provide continuous adjustment over the entire resistance range, from zero to maximum. Unlike rheostats, which typically regulate current, potentiometers use a three-terminal design to achieve precise voltage distribution and regulation. Allowing more complex control in applications requiring fine voltage regulation.

High Precision and Versatility: The potentiometer's precision engineering allows for fine control in complex circuits. For example, they can be used for tone control in audio equipment or calibration in high-precision instruments. At the same time, the potentiometer can also provide multiple outputs through various voltage divider points, making it suitable for more complex electronic control systems.

Easy to Integrate and Durable: The potentiometer is designed for easy integration with electronic boards. They come in various sizes and shapes for easy use in different devices. In addition, materials such as ceramics and advanced composites are chosen so that they can withstand high temperatures and pressures, reducing wear and ensuring stable performance over the long term.

Reduce Heat Generation and Improve Signal Fidelity: Potentiometers are optimized to minimize energy loss and heat generation, preventing circuit overheating, especially in high-frequency applications. Thanks to the design of its structure, it enhances the signal transmission path, reduces distortion, and improves signal fidelity, which is very friendly for applications requiring high signal integrity.

Advantages of rheostat over potentiometer

Rheostats have clear advantages in certain scenarios, especially where high-power applications and structural robustness are required. The following is a detailed analysis of the advantages of varistors, with special emphasis on the actual experience and effects during operation:

High power handling capabilities: Rheostats can handle greater current and power due to the use of thicker resistance wire or extensive heat dissipation structures. For example, in applications such as motor speed control or large heating equipment, varistors can reliably manage power levels of up to several kilowatts. Implementing this functionality using potentiometers is often challenging because their construction and materials are often not suitable for high-power tasks.

Cost-Effectiveness and Simplicity: Rheostats are relatively cheap to manufacture, in part because of their simple construction. They usually consist of several basic components, which not only reduces production costs but also makes maintenance and replacement simpler and more economical.

Durability and excellent heat dissipation: Rheostats are typically made of materials that are resistant to high temperatures and corrosion, allowing them to operate reliably over the long term in harsh environments. Their larger physical size not only enhances mechanical strength but also optimizes heat dissipation. This prevents the device from overheating and extends its lifespan.

Optimized load control: In applications that require continuous regulation of high energy output, rheostat provides more direct and efficient control. In actual use, operators can quickly respond to changes in system demand by adjusting the rheostat, such as changing the temperature of an industrial heating system or changing the speed of an electric motor. This responsiveness ensures that energy management is both efficient and adaptable to different operating conditions.

Summary

Through a detailed analysis of the rheostat and potentiometer, we can see the unique value and application advantages of these two devices in modern electronics and electrical engineering. Rheostats excel in high-load applications due to their powerful power handling capabilities and economical efficiency, while potentiometers occupy an important position in fine voltage control due to their high accuracy and versatility. Although they overlap in some features, each device has its own irreplaceable advantages that make it the best choice for a specific application.

Hope this article is helpful to you, if you need to explore more technical knowledge about varistors and potentiometers, you can contact us.

Frequently Asked Questions [FAQ]

1. Can a potentiometer be used as a rheostat?

A potentiometer does work as a sliding rheostat. This is mainly done by using two contacts of the potentiometer: one contact is connected to one of the endpoints, and the other contact is connected to the sliding contactor (knob). In this configuration, the third contact of the potentiometer (usually the other endpoint) is not used, so the potentiometer acts as an adjustable resistor, allowing the user to change the amount of current through the load.

2. In what areas are varistors commonly used?

Varistors are mainly used to protect circuits from voltage surges that can be caused by lightning strikes, power supply fluctuations, etc. Common applications include power adapters, motor control systems, telecommunications equipment, and home appliances such as televisions and computers, which they help prevent damage to sensitive electronic components due to voltage surges.

3. How to identify the potentiometer and rheostat?

An easy way to differentiate between a potentiometer and a sliding rheostat is to check the number and configuration of terminals. Potentiometers usually have three contacts: two fixed endpoints and a sliding contact point that moves with the knob. In contrast, a sliding rheostat (being an adjustable resistor) typically has only two contacts: a fixed endpoint and a sliding contact point. If you see a three-terminal device, it's more likely to be a potentiometer; if it's a two-terminal, it's probably a sliding rheostat.

4. Is the rheostat AC or DC?

Sliding rheostat can be used in alternating current (AC) and direct current (DC) circuits. Its design allows it to adjust resistance and thus control current flow in both types of circuits. However, when selecting a sliding rheostat, it is important to consider its voltage and current rating to ensure it is suitable for the specific application, whether AC or DC.

5. How should a varistor be connected in a circuit?

The varistor should be connected in parallel in the circuit, meaning it is parallel to the component that needs to be protected (such as the power input). When the voltage in a circuit exceeds the varistor's threshold, the varistor quickly reduces its resistance to absorb the excess voltage, thereby protecting other circuit components. When making connections, be sure to correctly identify the polarity of the varistor (if any) and install it according to the manufacturer's guidelines.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

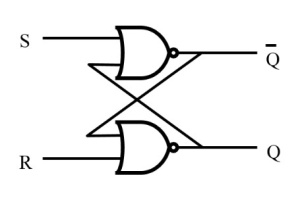

Mastering SR Latches: Symbols, Functions, and Practical Applications

on May 17th

Mastering Relay Technology: Construction, Types, Working Principles, and Testing Methods

on May 16th

Popular Posts

-

What is GND in the circuit?

on January 1th 2946

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2502

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2091

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 9th 1898

-

Comparison Between DB9 and RS232

on January 1th 1765

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1714

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1662

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1567

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1550

-

CR2450 vs CR2032: Can The Battery Be Used Instead?

Lithium manganese batteries do have some similarities with other lithium batteries. High energy density and long service life are the characteristics they have in common. This kind of battery has won the trust and favor of many consumers because of its unique safety. Expensive tech gadgets? Small appliances in our homes? Look around and you'll see them everywhere. Among these many lithium-manganes...on January 1th 1519