A Complete Guide to the 28BYJ-48 Stepper Motor

The 28BYJ-48 stepper motor is a compact and reliable motor used in everyday devices like cameras and DVD players. This article will guide you through its features, uses, and how it works.Catalog

Introduction to 28BYJ-48 Stepper Motor

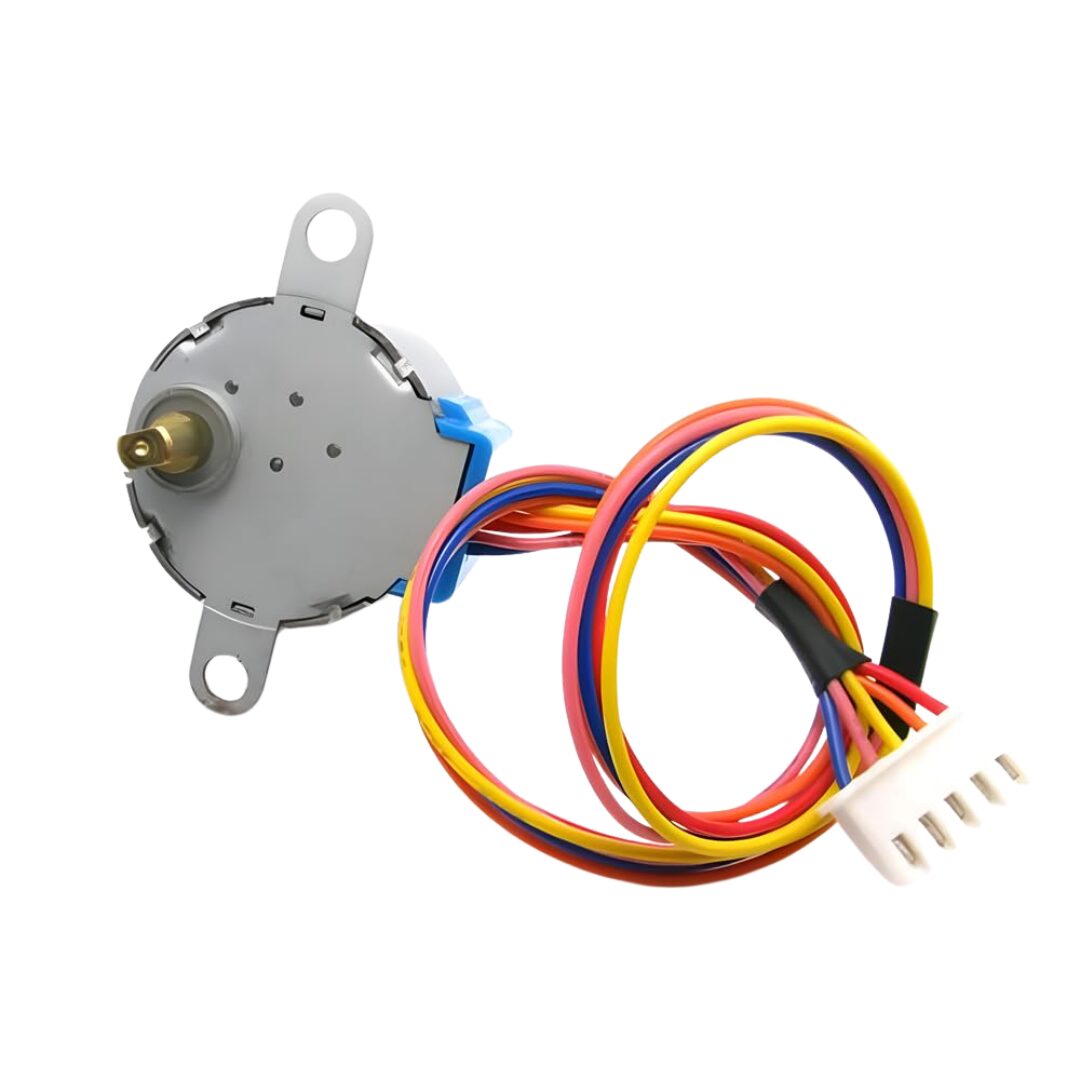

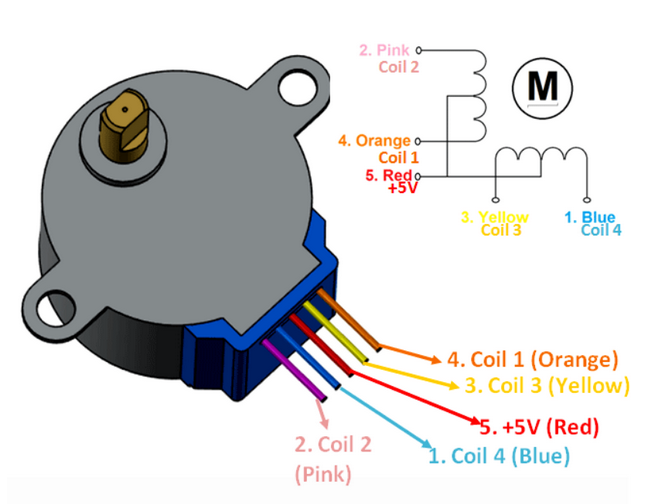

The 28BYJ-48 stepper motor is a small, reliable motor used in many everyday devices. Its compact design and ability to rotate in precise steps make it perfect for tasks that need careful movement control. You’ll often see it in gadgets like DVD players, security cameras, or even small automated machines. The motor has four coils, each rated at 5 volts, which means it’s simple to connect and control using common microcontrollers. Because of its steady and controlled movements, it’s a great choice for projects where you want things to move in small, accurate increments.

28BYJ-48 Pin Configuration

| No. | Pin Name | Wire Color | Description |

| 1 | Coil 1 | Orange | This motor has a total of four coils. One end of all the coils is connected to +5V (red) wire and the other end of each coil is pulled out as wire colors Orange, Pink, Yellow, and Blue respectively. |

| 2 | Coil 2 | Pink | |

| 3 | Coil 3 | Yellow | |

| 4 | Coil 4 | Blue | |

| 5 | 5V | Red | We should supply +5V to this wire; this voltage will appear across the coil that is grounded. |

Features of 28BYJ-48 Stepper Motor

Rated Voltage

The 28BYJ-48 stepper motor operates on a rated voltage of 5 VDC, making it compatible with most standard microcontroller setups. This low voltage requirement ensures it’s easy to integrate into various projects.

Number of Phases

This motor has four phases, allowing for precise control over its movements. Each phase can be energized in a sequence to achieve smooth and accurate steps.

Stride Angle

With a stride angle of 5.625°/64, the motor divides each rotation into very small steps. This high resolution makes it suitable for applications that need careful positioning.

Pull-In Torque

The motor provides a pull-in torque of 300 gf.cm, giving it enough strength to handle light mechanical loads while maintaining precision in its movements.

Insulated Power

The motor is designed to handle an insulated power of 600 VAC for 1 second at 1mA, adding to its durability and ensuring reliable operation under standard conditions.

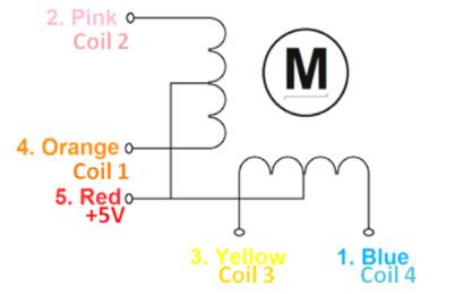

Unipolar Coil Design

The motor uses a unipolar 5-lead coil configuration, simplifying the wiring process and making it easier to control with common driver circuits.

Applications of 28BYJ-48 Stepper Motor

CNC Machines

The 28BYJ-48 stepper motor is often used in CNC machines where precise movements are necessary for tasks like engraving or cutting. Its accuracy makes it ideal for such applications.

Precise Control Machines

Devices requiring controlled, small-scale movements, such as 3D printers or automated calibration systems, benefit from the motor’s detailed step control.

Security Cameras

In security cameras, this motor is used to pan and tilt the camera for better coverage. Its precise stepping allows smooth transitions between viewing angles.

DVD Players

The motor is commonly found in DVD players, where it enables smooth and accurate disc positioning for reading and writing data.

Car Side Mirror Adjustment

In vehicles, the motor assists in tilting and adjusting side mirrors. Its ability to handle light loads and move in small steps makes it perfect for this task.

Where You Can Use the 28BYJ-48 Stepper Motor

The 28BYJ-48 stepper motor is widely used in devices where precise movement is needed. You'll commonly find it in DVD players, motion cameras, and similar electronics. Its design, featuring a four-coil unipolar configuration and a step angle of 5.625°/64, allows for accurate control, making it ideal for applications requiring small, precise movements. However, since it operates on 5 volts, it's better suited for low-torque tasks. For projects needing higher torque, you might consider alternatives like the Nema17 motor.

Usage Guide for 28BYJ-48 Stepper Motor

To make the 28BYJ-48 stepper motor work effectively, you’ll need a driver IC like the ULN2003. This is because the motor draws a considerable amount of current, which the driver helps manage safely. The motor has four coils, each connected to a specific wire: Orange, Pink, Yellow, and Blue. One end of all these coils is linked to a Red wire, which receives a constant +5V supply.

| Motor Wire Color | Sequence to Rotate in clockwise Direction | |||||||

| Step 1 | Step 2 | Step 3 | Step 4 | Step 5 | Step 6 | Step 7 | Step 8 | |

| Orange | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 |

| Yellow | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 1 |

| Pink | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 |

| Blue | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 |

| Red | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

As shown in the table, the motor rotates when the coils are energized in a logical sequence. To energize a coil, one end is connected to +5V (via the Red wire), while the other end is grounded. When both ends of a coil are at +5V, it won’t activate because there is no voltage difference to energize it.

By controlling the sequence of grounding each coil, the motor takes precise steps. A microcontroller or digital circuit can be used to program this sequence, ensuring the motor moves smoothly. Following the correct pattern of energizing the coils is what makes the motor operate reliably.

28BYJ-48 Specifications

Technical specifications, features, characteristics, and components with comparable specifications of MikroElektronika 28BYJ-48

| Type | Parameter |

| Factory Lead Time | 4 Weeks |

| Mounting Hole Spacing | 1.378" (35.00mm) |

| Coil Resistance | 50 Ohm |

| Voltage Rated | 5VDC |

| Series | 28BYJ-48 |

| Size / Dimension | Round - 1.100" Dia (28.00mm) |

| Part Status | Active |

| Moisture Sensitivity Level (MSL) | 1 (Unlimited) |

| Termination | Wire Leads |

| Type | Permanent Magnet Gear Motor |

| Termination Style | Wire Leads with Connector |

| Coil Type | Unipolar |

| Step Angle | 0.088° |

| Steps per Revolution | 4096 |

| Features | Flatted Shaft |

| Diameter - Shaft | 0.197" (5.00mm) |

| Length - Shaft and Bearing | 0.394" (10.00mm) |

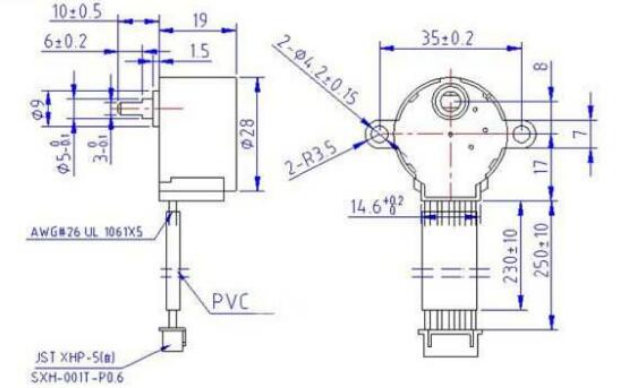

28BYJ-48 Packaging Details

About the Manufacturer of 28BYJ-48

The 28BYJ-48 is produced by MikroElektronika, a well-known company that creates tools and software for microcontroller development. They specialize in offering complete solutions that are easy to work with, especially for those working with microcontrollers like PIC, AVR, and STM32. MikroElektronika focuses on making their products accessible and practical, so they’re widely used by people designing everything from small electronics projects to more advanced systems. The company’s reputation for quality ensures that their components are reliable and easy to integrate into your projects.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

Frequently Asked Questions [FAQ]

1. What makes the 28BYJ-48 stepper motor popular?

The 28BYJ-48 is widely used because it’s compact, reliable, and easy to work with. Its four-coil design allows it to take precise steps, making it a great choice for devices like DVD players, cameras, and small automation projects. It’s also powered by a low 5V supply, which makes it compatible with many microcontrollers.

2. How is the 28BYJ-48 stepper motor controlled?

This motor is controlled by sending a specific sequence of electrical signals to its coils. These signals energize the coils in a pattern, causing the motor to move in small steps. A microcontroller or driver circuit like the ULN2003 is used to manage this sequence.

3. What tasks is the 28BYJ-48 stepper motor suitable for?

The motor is ideal for tasks that require precise movements, such as adjusting the position of a camera, moving a small CNC machine, or tilting car side mirrors. Its design lets you control the position with accuracy, making it a reliable option for these applications.

4. How many steps does it take for the 28BYJ-48 to complete one rotation?

In full-step mode, the 28BYJ-48 takes 32 steps to complete one full rotation. This is because each step moves the motor by 11.25°. In applications needing finer control, half-step or micro-stepping can be used for even smaller movements.

Guide to the IRLML6402 Transistor: Pin Configuration, Features, and Datasheet

on November 15th

Exploring the Functions of the LTC7000MPMSE#TRPBF

on November 15th

Popular Posts

-

What is GND in the circuit?

on January 1th 3267

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2814

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 20th 2631

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2265

-

Comparison Between DB9 and RS232

on January 1th 1881

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1846

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1804

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1799

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1793

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 20th 1782