Understanding the BTS7960B Motor Driver

The BTS7960B motor driver is a powerful and versatile component designed for applications that require precise motor control, such as robotics and industrial automation. This driver chip from Infineon integrates advanced features like high-current handling, protective circuits, and pulse-width modulation (PWM) support, making it an ideal choice for projects that demand both reliability and performance. In this article, we’ll cover the key specifications, pin configurations, and benefits of using the BTS7960B, as well as some practical tips for optimizing its performance in various use cases.Catalog

Understanding the BTS7960B Motor Driver

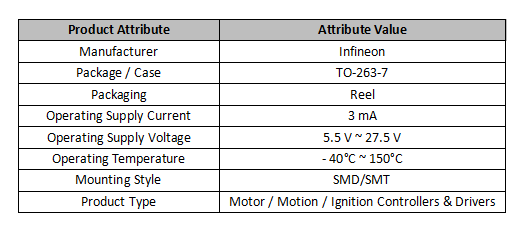

The BTS7960B is a motor driver chip developed by Infineon, often used in robotics and motor control systems. It comes in the TO-263-7 package, featuring a single output interface with seven pins and is part of the NovalithIC series. This chip integrates a p-channel high-side MOSFET, an n-channel low-side MOSFET, and a driver IC to create a robust high-current half-bridge configuration suited for demanding applications.

Built with vertical MOS technology, the BTS7960B reduces on-resistance, enhancing overall performance. The chip’s design eliminates the need for a charge pump in the high-side p-channel switching, which helps minimize electromagnetic interference (EMI). It operates with logic level inputs and offers features like diagnostics and adjustable slew rates for improved control and reliability. The BTS7960B is also equipped with safeguards that effectively manage temperature, voltage, and current variations to ensure smooth operation in various conditions.

Alternatives and Substitutes

• DRV8871

• L298N

• L293D

• L6203

• LMD18200

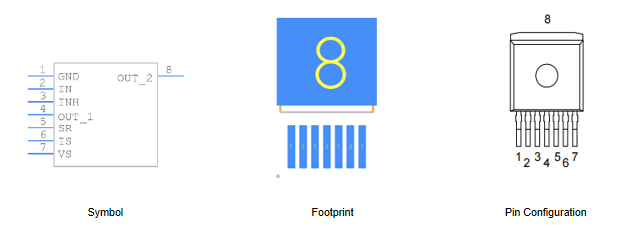

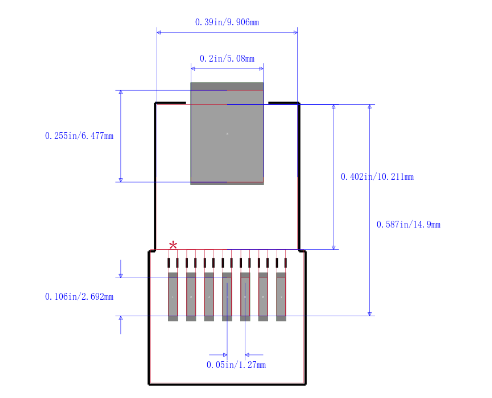

Symbol, Footprint, and Pin Configuration of BTS7960B

The BTS7960B module is equipped with seven distinct pins, each serving a specific purpose to facilitate the module's operations and overall functionality.

Pin 1 (GND)

This pin establishes the ground connection, ensuring stability within the electrical circuit. A secure grounding helps prevent voltage fluctuations and maintains consistent performance of the device.

Pin 2 (IN)

This pin is used for controlling the activation of the high or low-side switch. It plays a key role in modulating the circuit's behavior, allowing for precise signal management and effective switch operation.

Pin 3 (INH)

When set to low, this pin activates sleep mode to reduce power consumption. This feature is beneficial for energy-saving applications, such as battery-powered devices, where power management is essential.

Pin 4, Pin 8 (OUT)

These pins act as the power output channels. Understanding the current flow through these outputs is essential for designing circuits with proper load management, ensuring reliable performance across different scenarios.

Pin 5 (SR)

This pin connects to ground through a resistor to adjust the slew rate. Controlling the slew rate helps to minimize electromagnetic interference and achieve smoother transitions, which is particularly useful in high-speed applications.

Pin 6 (IS)

This pin is responsible for current sensing and diagnostics. Accurate current sensing enables real-time monitoring and provides valuable data for maintenance and adjustments, which can help prolong the device's lifespan.

Pin 7 (VS)

This pin supplies the necessary voltage to power the module. A stable and compliant voltage input is needed for keeping the electronic components reliable and preventing potential system issues.

Technical parameters

Characteristics of BTS7960B

Logic Compatibility and Temperature Range

The BTS7960B is designed with logic-based inputs that work well with modern logic circuits, making it a suitable choice for various applications. It can operate in temperatures ranging from -40°C to 150°C, allowing it to function reliably in diverse environmental conditions.

Inductive Load Handling and PWM Control

This device can handle inductive loads and supports pulse-width modulation (PWM) up to 25 kHz, providing precise control over motor operations. This feature is particularly useful in applications like electric vehicles and industrial automation, where PWM helps improve efficiency and performance.

Protective Features

The BTS7960B includes several protective features, such as current limitation and over-temperature protection. It also has short-circuit protection and undervoltage lockout (UVLO), enhancing its dependability and preventing damage in complex systems.

Easy Integration and Flexible Design

With integrated MOSFETs and compact surface-mount packages like the TO-263-8, this device is easy to incorporate into existing designs. Its compact form makes it ideal for applications with limited space, maintaining efficient energy management without compromising on performance.

Pros and Cons of BTS7960B

Advantages

The BTS7960B offers a range of safety features that make it suitable for various applications. It provides protection against overloads, temperature spikes, and short circuits, enhancing overall system durability and reliability. Its straightforward design requires few additional components, making integration simple for both experienced engineers and beginners. The device’s high energy efficiency helps reduce power consumption, which is increasingly relevant in today's focus on energy-saving solutions. This easy integration also contributes to improved system stability and performance, making it a dependable choice for deployment across different industries.

Disadvantages

Despite its strengths, the BTS7960B does come with some drawbacks. Its higher price, compared to other similar components, may not make it the first choice for projects with limited budgets. The device’s range of features requires a higher upfront investment, which might be hard to justify when funding is limited. Additionally, proper alignment of current, voltage, and resistance is needed to achieve the best performance. This requirement adds complexity to the design process, making it necessary to have a good understanding of these factors to get the most out of the device.

Enhancing BTS7960B Performance

Selecting Suitable Motors

Choosing motors that match the BTS7960B's power and current specifications helps ensure smooth operation and minimizes wear on both the motor and driver. Understanding the load characteristics and application requirements can aid in making an informed selection, ultimately improving system reliability.

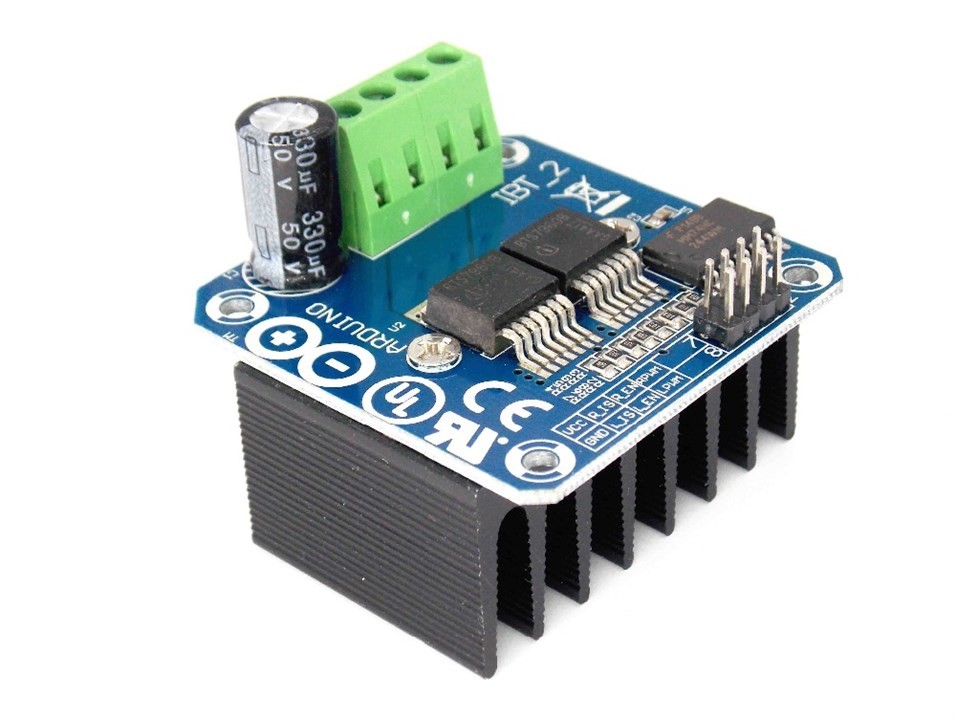

Implementing Heat Management Techniques

Given the BTS7960B's high power demands, effective heat management is necessary to prevent overheating. Adding heat sinks or cooling mechanisms can maintain system balance and performance. Regular monitoring and adjustments can further enhance stability and extend the lifespan of the components.

Optimizing Driver Circuitry

Improving the efficiency of the driver circuit can reduce energy consumption and enhance overall performance. Lowering unnecessary energy use helps maintain functionality while supporting energy-saving goals. Routine performance evaluations can reveal opportunities for fine-tuning and improvement.

Aligning PWM Control with Motor Requirements

PWM control helps manage motor speed and current. Achieving optimal performance involves setting PWM frequencies between 1-10kHz, adjusted to suit the specific needs of each motor. Aligning these settings with motor requirements can significantly boost system efficiency, particularly under varying operating conditions.

Adjusting SR Pin Resistor Configuration

Proper configuration of the resistor at the SR pin is crucial for controlling conversion rates and minimizing energy loss. Tailoring this setup to the specific application involves considering various operating factors. Drawing from experience can guide these adjustments to achieve better performance.

Different Packaging Options for BTS7960B

The BTS7960B is available in two packaging options: TO-263-7 and TO-252-15. Each serves different needs, providing specific benefits depending on the application. The TO-263-7 package is best suited for situations that require strong power handling and effective heat management. Its design helps regulate heat, which is essential in high-power environments. Automotive and industrial applications, where temperature can impact stability and performance, often favor this package. Adding thermal pads or heat sinks can further enhance its long-term reliability.

On the other hand, the TO-252-15 package is ideal for general power needs without intensive cooling requirements. Its compact size and easy integration make it suitable for consumer electronics and applications that don’t need advanced thermal management. Optimizing the layout of the circuit board can further improve its efficiency and performance with minimal cooling measures.

Both packages feature pins for power, control, and grounding, ensuring reliable performance. Arranging these pins strategically reduces resistance and maintains consistent functionality. When incorporating these packages into larger systems, factors like trace length, impedance, and connectivity can significantly impact overall performance.

Understanding how to use each packaging option effectively leads to better design choices. As technology trends move towards smaller sizes and greater power efficiency, these packaging styles will continue to adapt. This shift opens up new possibilities for innovation and design strategies, encouraging a future-focused approach to product development.

Expanded Applications of BTS7960B

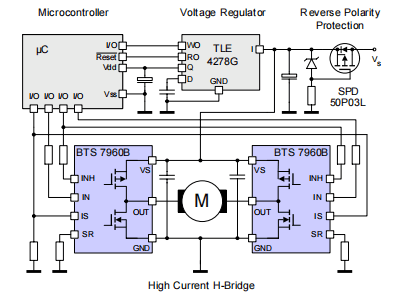

Layout Considerations

When dealing with high currents and faster switching times, special attention should be given to the PCB layout. In power bridge designs, minimizing stray inductance is essential, as it impacts the performance of high-power switching bridges. The BTS7960B does not have separate pins for power ground and logic ground, so it is important to minimize the offset between the ground connection of components such as the slew rate resistor, current sense resistor, and the ground pin of the device (GND/Pin 1). If the BTS7960B is used in an H-bridge or B6-bridge configuration, it is recommended to keep the voltage offset between the GND pins of different devices as small as possible.

Using ceramic capacitors from VS to GND near each device helps provide current to the switching stage through a low inductance path, which reduces noise and ground bounce. A suitable capacitor value for this purpose is around 470 nF. Additionally, to protect digital inputs from excessive currents caused by induced voltage spikes, series resistors in the range of 10 kΩ should be used.

Application Fields of BTS7960B

The BTS7960B can be used in a wide range of applications, including:

• Robot motion control

• Motor drives for household appliances (e.g., washing machines, air conditioners)

• Motor control systems in industrial automation

• Motor control for electric vehicles (e.g., e-bikes, scooters)

Frequently Asked Questions [FAQ]

1. What is the BTS7960B?

The BTS7960B is a dual H-bridge motor driver IC capable of controlling both DC and stepper motors. It is used in a variety of applications due to its flexibility and performance.

2. What are its temperature limits?

The BTS7960B can operate within a temperature range of -40°C to 150°C, making it suitable for various environments, whether in high-performance motors or demanding industrial settings.

3. What is its primary function?

The main function of the BTS7960B is precise motor control, along with protection against back electromotive force (EMF), which helps maintain system stability even when dealing with changing loads.

4. Where is it commonly used?

The BTS7960B is often used in motorized vehicles, industrial automation, and other applications that require precise motor control. Its versatility makes it a reliable choice for projects aiming to enhance efficiency and innovation in mechanical designs. Incorporating this IC can improve both the reliability and adaptability of engineering solutions.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

Understanding the IRFB7545PBF Power MOSFET

on October 1th

L7809CV Voltage Regulator: Features, Specifications and Uses

on October 1th

Popular Posts

-

What is GND in the circuit?

on January 1th 3298

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2828

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 21th 2704

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2271

-

Comparison Between DB9 and RS232

on January 1th 1892

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1850

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1818

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1817

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1806

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 21th 1801