PC817 Optocoupler: Operation, Benefits, and Common Uses

The PC817 optocoupler is a small yet powerful device used to keep electrical circuits separate while allowing signals to pass between them. This tiny component is widely used in electronics to protect sensitive parts of a circuit from high-voltage spikes, electrical noise, and interference. In this article, we’ll explore what the PC817 optocoupler is, how it works, and the different ways you can use it in your circuits.Catalog

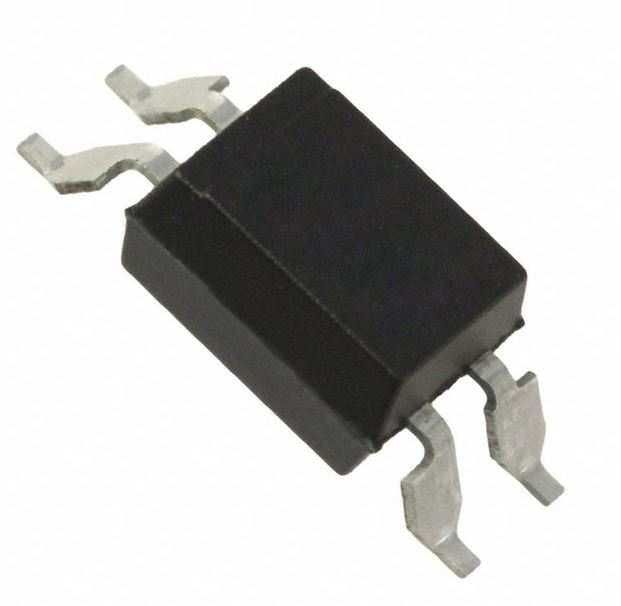

PC817 Optocoupler

The PC817 optocoupler is a device designed to create electrical isolation between two separate circuits. It uses a combination of a light-emitting diode (LED) and a phototransistor to transfer signals, ensuring that the circuits remain electrically independent from one another. This separation is useful in protecting low-voltage control signals from potentially damaging high-voltage disturbances, making it ideal for motor drive systems or similar applications where safeguarding sensitive circuits is necessary.

The PC817 can handle currents up to 50mA and an input voltage of up to 30V. With this capability, it effectively manages electrical noise and sudden voltage spikes, which are common in environments with heavy electrical interference. It’s often used in industrial settings where electronic systems operate close to large power equipment that can cause disruptions. This component’s resilience to electrical noise makes it a reliable choice for ensuring consistent performance in challenging conditions.

One common use of the PC817 is in power supply circuits, where it separates the primary and secondary sections. This isolation prevents electrical surges from affecting sensitive components or disrupting control systems. Similarly, in microcontroller interfaces with devices that are sensitive to power fluctuations, the PC817 helps maintain stable control logic. This stability is crucial in environments where power fluctuations are frequent.

The PC817 is widely used in safety mechanisms across various industries to prevent disruptions caused by electrical interferences. Modern automation systems, which require precise control and isolation, also rely on optocouplers like the PC817 to ensure reliability. In these scenarios, even minor voltage variations can cause significant problems, so having a dependable isolating component like the PC817 helps maintain system integrity and operational efficiency.

Operation of PC817 Optocoupler

The PC817 optocoupler works by creating an optical link between its infrared (IR) light-emitting diode (LED) and a phototransistor. This optical coupling enables safe and efficient signal transfer between circuits while keeping them electrically isolated. Here’s a breakdown of how it operates and the benefits it offers.

When a voltage is applied to the IR LED inside the optocoupler, it emits infrared light. The amount of light it produces is directly related to the input current, making the light intensity proportional to the input signal. This property allows the optocoupler to effectively transfer signals based on the input it receives.

Positioned next to the IR LED, the phototransistor detects the emitted light and, in response, generates a corresponding electrical current. This current then drives other circuits, ensuring the transmitted signal remains clear and unaffected by external electrical noise. Because of the phototransistor’s sensitivity, it can accurately convert the optical signal back into an electrical form, minimizing any signal loss.

One key advantage of the PC817 optocoupler is its ability to maintain electrical isolation between input and output. This isolation helps protect sensitive components from high voltage spikes and noise, which is particularly useful in applications like motor control circuits and power supplies. By keeping the low voltage control signals isolated, the optocoupler ensures steady and reliable performance in these scenarios.

PC817 Long Run in Circuit: How to Maintain Safety

The PC817 optocoupler functions by creating an optical link between its internal components: an infrared (IR) LED and a phototransistor. When the IR LED emits light, the phototransistor detects this light and activates the corresponding circuit. This allows signals to pass between different parts of a circuit without direct electrical contact, making the PC817 a reliable choice for isolating circuit sections. To ensure safe and long-term use, it’s crucial to operate the optocoupler within the manufacturer’s specified limits. Exceeding these ratings can lead to overheating and damage, so staying within the recommended boundaries is essential for maintaining performance and longevity.

A simple way to protect the internal LED is by placing a current-limiting resistor on pin 1. This helps regulate the current flowing through the LED, keeping it below 50mA, which not only prevents potential damage but also extends the optocoupler’s lifespan. Choosing the right resistor value for your operating voltage ensures a stable circuit operation and reduces the risk of overloading. Another factor to consider is temperature management. It’s best to keep the PC817 within its recommended operating range of -30°C to 100°C, and for storage, between -55°C and 125°C. In hot environments, using cooling solutions or positioning the optocoupler away from heat sources can help prevent overheating and ensure reliable performance.

Proper placement within the circuit is also important for maintaining the device’s stability. Positioning the optocoupler in a way that minimizes exposure to mechanical strain, vibrations, or shocks will protect its functionality over time. A well-planned layout that supports good heat dissipation is equally beneficial, as it helps reduce thermal stress and ensures the PC817 continues to perform reliably even in challenging conditions.

Diverse Uses of the PC817 Optocoupler

The PC817 optocoupler offers a wide range of uses due to its ability to isolate different parts of a circuit electrically. This isolation makes it suitable for many different applications.

Switching Power Supplies

When used in switching power supplies, the PC817 provides a barrier between the control circuitry and high-voltage output circuits. This isolation reduces the risk of electrical hazards and contributes to stable operation by keeping high-voltage spikes from affecting the control side. As a result, sensitive components are protected, and the system remains reliable over time.

Isolated Signal Transmission

In industrial control systems, the PC817 optocoupler helps prevent ground loops and reduces signal interference, especially in areas with a lot of electrical noise. By isolating the signals, it ensures accurate data transmission and reliable operation of industrial equipment. This makes it possible to control and monitor equipment with minimal disruptions, even in challenging environments.

Motor Control

The PC817 optocoupler serves as a link between low-voltage logic circuits and motor drivers, shielding the logic circuits from voltage spikes that can occur during motor operation. This setup helps protect delicate components and extend the lifespan of the control circuits, making it ideal for use in automation and robotics where reliable motor operation is necessary.

Isolated Interface for Microcontrollers

When connecting microcontrollers to external devices like relays or switches, the PC817 ensures a safe interface. By isolating the microcontroller from high voltages, it preserves the microcontroller’s functionality and reduces the risk of damage. This isolation makes it easier to use microcontrollers in various control and automation systems, ensuring dependable performance.

Signal Isolation in Audio Equipment

In audio systems like amplifiers and mixers, the PC817 optocoupler provides signal isolation to prevent ground loops and cut down on interference. This helps maintain the clarity of audio signals, ensuring high-quality sound reproduction. The use of optocouplers in these applications helps prevent unwanted noise and interference from affecting the audio output.

Medical Devices

Medical devices such as patient monitors and defibrillators rely on the PC817 optocoupler for electrical isolation. This isolation is necessary to safeguard patient safety and ensure that the devices operate correctly. By preventing electrical faults, the PC817 helps maintain the reliability of these critical medical systems.

Isolated Data Communication

In data communication systems that are sensitive to electrical interference, the PC817 ensures secure and stable connections. It helps maintain data integrity and prevents communication errors, making it useful in complex digital communication setups where consistent data transmission is needed.

Battery Management Systems

The PC817 is also used in battery management systems (BMS) for electric vehicles and renewable energy setups. It isolates the control electronics from high battery voltages, preventing damage and ensuring that the BMS operates reliably over time. This makes it a valuable component in energy storage solutions, contributing to their safety and effectiveness.

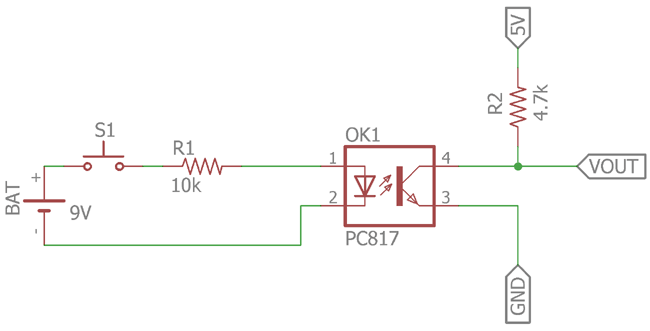

PC817 IC Optocoupler Circuit

The PC817 optocoupler circuit works by using a phototransistor triggered by an IR LED to isolate different parts of a circuit. This design helps improve safety and performance by maintaining electrical separation between various sections.

When you activate the IR LED using a switch, it gets powered by a 9V battery, and a 10K resistor is used to limit the current flowing through the LED. The LED’s light then activates the phototransistor, causing it to conduct and turning off the load on the secondary side. This process shows how optical isolation can shield sensitive components from high-voltage spikes and reduce signal interference.

The circuit’s performance relies on keeping the phototransistor’s collector current below 50mA and choosing the correct resistor values to control the LED’s current and set the phototransistor’s gain. In practical applications, like switching power supplies, optocouplers are commonly used to provide feedback isolation. Accurate calibration of the resistor values ensures stable performance and quick response.

To optimize the PC817 circuit, you should consider the effect of ambient light and how the IR LED and phototransistor are positioned. Ensuring a clear optical path and reducing external light interference can significantly boost the circuit’s reliability. You can also integrate feedback mechanisms to adjust the LED’s intensity under changing conditions, which will help maintain consistent performance and stability.

Key Features of the PC817 Optocoupler

Optical Isolation

The PC817 uses LEDs and photodetectors to keep input and output circuits electrically separate. This separation helps protect the system from noise and high-voltage spikes that could disrupt functionality. For example, in industrial machinery, this feature is effective in shielding sensitive control circuits from power surges.

Compact Form Factor

With its small size, the PC817 is perfect for densely packed circuit boards and applications with limited space. This compact design fits well in modern consumer electronics, where maximizing space is a priority.

Energy Efficiency

The PC817 requires low drive currents for its LEDs, which reduces overall power usage. This energy-saving feature is particularly beneficial in portable and battery-operated devices, as it helps prolong battery life.

High Isolation Voltage

The PC817 provides high voltage insulation between input and output circuits, enhancing safety. This makes it suitable for situations where strong electrical separation is needed to prevent electric shocks or interference, such as in medical devices.

Fast Signal Transmission

With quick response times, the PC817 is ideal for applications that require fast signal processing. This feature can improve system performance in automation systems where precise timing is needed.

Multi-functionality

The PC817 is a versatile component that can switch voltages, isolate signals, and shift levels for both analog and digital applications. Its flexibility makes it a valuable solution for various electronic designs.

Robust Reliability

The PC817 is built for long-term performance and can withstand demanding conditions. This durability is beneficial for applications like automotive systems, which require reliable operation over extended periods.

Extensive Applicability

The PC817 finds use in a wide range of applications, including industrial automation, medical equipment, and automotive electronics. Its adaptability to different sectors shows its capability to function effectively in various environments. For instance, it plays a key role in automated assembly lines by helping maintain operational consistency.

Economic Viability

The PC817 is an affordable option for electrical isolation compared to other methods. This cost-efficiency is an attractive feature for large-scale manufacturing, where keeping production costs low is a constant consideration.

Conclusion

The PC817 optocoupler is a versatile tool that can be used in many different electronic setups to provide electrical isolation and reliable signal transmission. Whether you’re working on motor controls, power supplies, or data communication systems, this component can help keep your circuits safe and running smoothly. By understanding its uses and operating conditions, you can make the most of the PC817 in your projects and achieve stable performance even in demanding environments.

Frequently Asked Questions [FAQ]

1. What are the typical applications of PC817 optocouplers?

PC817 optocouplers are used in automation, telecommunications, medical devices, automotive electronics, and consumer electronics. They help isolate circuits to reduce noise, prevent signal interference, and enable voltage-controlled switching. Common uses include protecting equipment in industrial automation, maintaining data transmission in telecommunications, and stabilizing power supply in medical devices.

2. What is the maximum isolation voltage of a PC817 optocoupler?

The maximum isolation voltage varies depending on the model, typically ranging from several hundred to several thousand volts. This high voltage helps protect equipment from electrical noise and transients in industrial settings and prevents high-voltage arcs in photovoltaic systems.

3. Are PC817 optocouplers polarity sensitive?

PC817 optocouplers are not inherently polarity sensitive, but correct pin configuration is required for proper functionality. Miswiring can lead to malfunction or failure, making it crucial to follow datasheets and design specifications accurately.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

Why Choose the Renesas TW2864 for Your Video System

on October 9th

PCM5242 vs ESS DACs: A Complete Audio Performance Comparison

on October 9th

Popular Posts

-

What is GND in the circuit?

on January 1th 2864

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2438

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2044

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 6th 1803

-

Comparison Between DB9 and RS232

on January 1th 1740

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1693

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1634

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1505

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1485

-

CR2450 vs CR2032: Can The Battery Be Used Instead?

Lithium manganese batteries do have some similarities with other lithium batteries. High energy density and long service life are the characteristics they have in common. This kind of battery has won the trust and favor of many consumers because of its unique safety. Expensive tech gadgets? Small appliances in our homes? Look around and you'll see them everywhere. Among these many lithium-manganes...on January 1th 1477