LSM9DS1TR 9-Axis Sensor: Pinout, Specifications, and Datasheet

This article takes a look at the LSM9DS1TR, a powerful motion sensor that packs three important tools in one: a 3D accelerometer, a gyroscope, and a magnetometer. Together, these parts work to track movement with impressive accuracy. The sensor can connect in a couple of different ways through I2C or SPI, making it easy to use in a wide range of projects. It's perfect for things like robots, fitness trackers, and smart navigation systems. In this article, we’ll dive into what makes the LSM9DS1TR so special and why it's helping push motion-sensing technology to exciting new heights.Catalog

What is the LSM9DS1TR?

The LSM9DS1TR represents a cutting-edge sensor module encompassing a 3D accelerometer, 3D gyroscope, and 3D magnetometer. These integrated sensors facilitate detailed motion and orientation analysis, providing a unique fusion of functionalities that cater to a plethora of applications. With connectivity options through I2C, operating up to 400 kHz or SPI interfaces, it can seamlessly adapt to various communication protocols, simplifying integration into diverse technological ecosystems. Designed to function efficiently within a temperature spectrum from -40°C to +85°C, the device continues to perform consistently under harsh environmental conditions, gaining trust in industries where dependable performance is esteemed. The incorporation of these three sensors opens doors to multiple fields, including electronics, robotics, and wearable technology. In electronics, precise motion tracking can elevate gaming or virtual reality experiences, offering smoother and more intuitive interactions that captivate senses. Robotics benefits from accurate orientation and motion detection, which are central to successful navigation and environmental interaction. Wearable technology gains an advantage from the compactness of LGA packaging, nurturing the creation of lightweight and discreet devices.

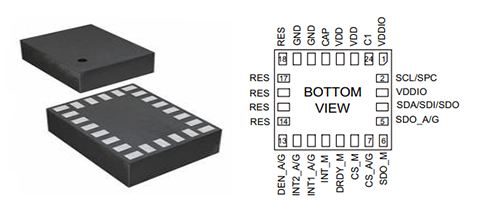

LSM9DS1TR Pin Configuration

Features of the LSM9DS1TR

Multi-Channel Detection Capabilities

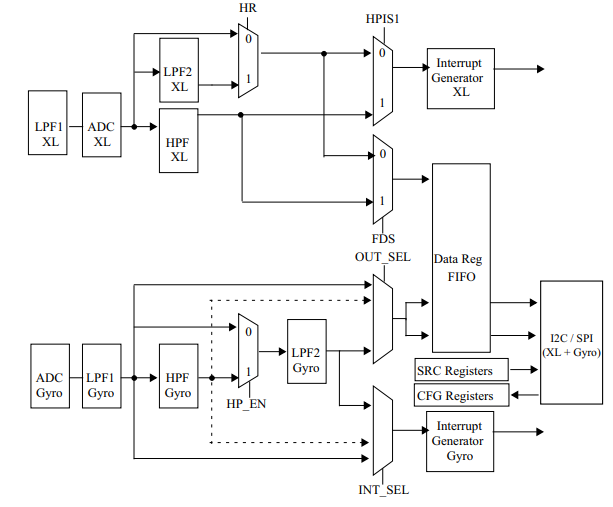

The LSM9DS1TR sensor stands out with its varied detection channels, opening doors to numerous application scenarios. It supports adjustable full scales for acceleration ranging from ±2 to ±16 g, magnetic fields from ±4 to ±16 gauss, and angular rates from ±245 to ±2000 dps, showcasing a broad spectrum of flexibility. The 16-bit high-resolution output delivers precision, aligning with the diverse needs of electronics and industrial sectors. This versatility often fulfills the desire for adaptability in dynamic environments.

Interface Options and Power Management

With support for both I2C and SPI interfaces, this sensor adapts to a range of communication protocols, meeting varied integration demands. It functions on an analog supply voltage between 1.9V and 3.6V, accommodating different settings and power conditions seamlessly. Power-saving modes boost its efficiency, which proves advantageous in battery-powered devices. Emphasizing energy efficiency resonates with efforts to extend device lifespan and cut down operational costs, a relief for stakeholders concerned with sustainability.

Advanced Functional Features

The sensor's functionalities include programmable interrupts and an embedded temperature sensor, enhancing system interaction and environmental monitoring. Features like FIFO and motion detection support complex data processing and time analysis, offering insights into dynamic movements. These functionalities can spark a sense of accomplishment for cutting-edge solutions.

Compliance with Environmental Standards

Adhering to ECOPACK® standards, the LSM9DS1TR aligns with environmentally mindful manufacturing practices. This not only meets regulatory benchmarks but also caters to the rising demand for sustainable technologies. Embracing environmentally responsible components can represent a dedication to corporate social responsibility.

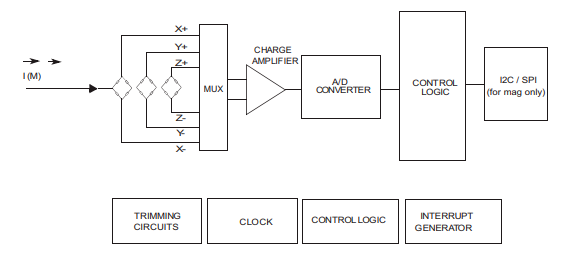

Block Diagram of the LSM9DS1TR

Alternatives of the LSM9DS1TR

|

Part Number |

Manufacturer |

Package / Case |

Number of Pins |

Min Supply Voltage |

Supply Voltage |

Max Supply Voltage |

Operating Temperature |

Output Type |

Mounting Type |

|

ICM-30630 |

TDK InvenSense |

24-TFLGA Module |

24 |

2.4 V |

3 V |

3.6 V |

-40°C ~ 85°C (TA) |

I2C, SPI |

Surface Mount |

|

LSM330TR |

STMicroelectronics |

24-TFQFN Module Exposed Pad |

24 |

- |

- |

- |

-40°C ~ 85°C (TA) |

I2C, SPI |

Surface Mount |

LSM9DS1TR Technical Specifications

|

Type |

Parameter |

|

Lifecycle Status |

ACTIVE (Last Updated: 7 months ago) |

|

Mounting Type |

Surface Mount |

|

Surface Mount |

YES |

|

Operating Temperature |

-40°C~85°C TA |

|

Part Status |

Active |

|

Number of Terminations |

24 |

|

HTS Code |

8542.39.00.01 |

|

Terminal Form |

BUTT |

|

Number of Functions |

1 |

|

Terminal Pitch |

0.43mm |

|

Base Part Number |

LSM9D |

|

Max Supply Voltage |

3.6V |

|

Analog IC - Other Type |

ANALOG CIRCUIT |

|

Length |

3.5mm |

|

Factory Lead Time |

16 Weeks |

|

Package / Case |

24-TFLGA Module |

|

Number of Pins |

24 |

|

Packaging |

Cut Tape (CT) |

|

Moisture Sensitivity Level (MSL) |

3 (168 Hours) |

|

ECCN Code |

EAR99 |

|

Terminal Position |

BOTTOM |

|

Peak Reflow Temperature (Cel) |

NOT SPECIFIED |

|

Supply Voltage |

2.2V |

|

Time@Peak Reflow Temperature-Max (s) |

NOT SPECIFIED |

|

Output Type |

I2C, SPI |

|

Min Supply Voltage |

1.9V |

|

Sensor Type |

Accelerometer, Gyroscope, Magnetometer, Temperature, 9

Axis |

|

Height Seated (Max) |

1.027mm |

|

Width |

3mm |

|

REACH SVHC |

No SVHC |

|

RoHS Status |

ROHS3 Compliant |

|

Lead Free |

Lead Free |

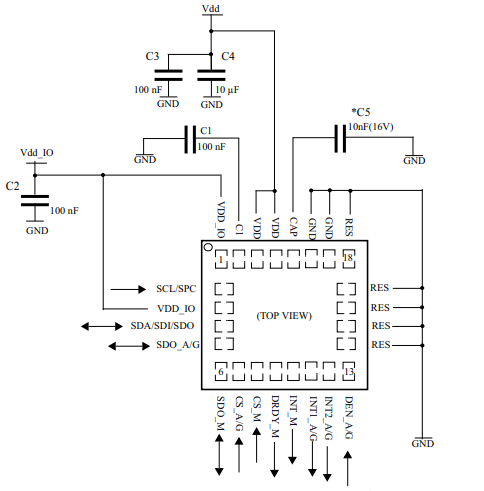

Electrical Connections Diagram

Electrical Characteristics of LSM9DS1TR

|

Symbol |

Parameter |

Test Conditions |

Min. |

Typ. (1) |

Max. |

Unit |

|

Vdd |

Supply voltage |

1.9 |

3.6 |

V |

||

|

Vdd_IO |

Module power supply for I/O |

1.71 |

Vdd+0.1 |

V |

||

|

Idd_XM |

Current consumption of the accelerometer and magnetic

sensor in normal mode (2) |

600 |

µA |

|||

|

Idd_G |

Gyroscope current consumption in normal mode (3) |

4 |

mA |

|||

|

Top |

Operating temperature range |

-40 |

85 |

°C |

||

|

Trise |

Time for power supply rising (4) |

0.01 |

100 |

ms |

||

|

Twait |

The time delay between Vdd_IO and Vdd (4) |

0 |

10 |

ms |

Absolute Maximum Ratings of LSM9DS1TR

|

Symbol |

Ratings |

Maximum Value |

Unit |

|

Vdd |

Supply voltage |

-0.3 to 4.8 |

V |

|

Vdd_IO |

I/O pins supply voltage |

-0.3 to 4.8 |

V |

|

Vin |

Input voltage on any control pin (including CS_A/G, CS_M,

SCL/SPC, SDA/SDI/SDO, SDO_A/G, SDO_M) |

0.3 to Vdd_IO +0.3 |

V |

|

AUNP |

Acceleration (any axis) |

3,000 for 0.5 ms |

g |

|

10,000 for 0.1 ms |

g |

||

|

MEF |

Maximum exposed field |

1,000 |

gauss |

|

ESD |

Electrostatic discharge protection (HBM) |

2 |

kV |

|

TSTG |

Storage temperature range |

-40 to +125 |

°C |

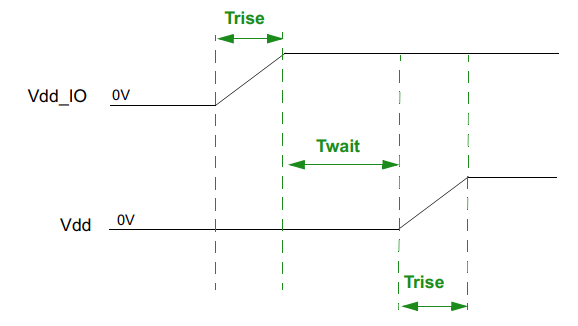

LSM9DS1TR Power-Up Sequence

The power supply timing for this device involves a few steps to ensure reliable operation. First, the rise time (called "Triose") is the period it takes for the power supply voltage (Vdd_IO) to increase from 10% to 90% of its final value. This rise time needs to be carefully controlled so that the device’s I/O lines can stabilize before the main operating voltage (Vdd) starts to increase. Once Vdd_IO has reached 90% of its target value, there’s a required delay time called "Twait." This delay allows the I/O and interface logic to settle under a steady supply voltage before Vdd begins to ramp up. The Twait period is important for avoiding configuration errors or potential damage, as it prevents the core logic and memory from being powered up too soon.

After Twait, the core voltage Vdd can begin ramping up smoothly until it reaches its operating level. This ramp-up must be gradual to prevent any voltage spikes that might disrupt the device’s internal circuits. Finally, once both Vdd_IO and Vdd have reached stable levels, the device initialization can begin. This step involves setting up internal registers, calibrating sensors, and configuring communication protocols as needed. Following these steps helps ensure that the device operates reliably within its specified electrical and operational limits. For specific details or values for Triose and Twait, refer to the datasheet or reference manual provided by the manufacturer.

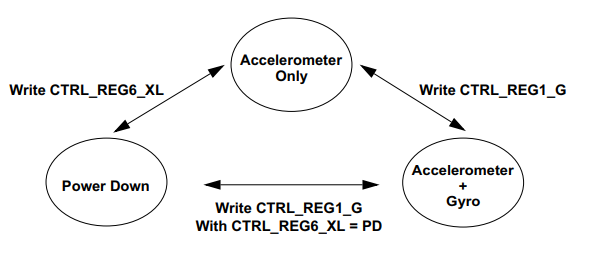

Operating Modes of LSM9DS1TR

The LSM9DS1 sensor module, which includes both an accelerometer and a gyroscope, can operate in different modes based on application needs. In Accelerometer Only Mode, only the accelerometer is active while the gyroscope stays off, making it useful for measuring linear acceleration while conserving power. In Combined Mode, both the accelerometer and gyroscope are active and run at the same Output Data Rate (ODR), which is ideal for applications that need comprehensive motion tracking, such as drones, wearable devices, or other smart devices that rely on accurate orientation, position, and movement data.

Applications of the LSM9DS1TR

Indoor Navigation and Control Systems

Recent developments in indoor navigation systems have led to notable progress, offering precise location tracking and seamless integration with smart environments. This technology is reshaping how people navigate through spaces while refining the accuracy of smart home interfaces. The detailed process of mapping indoor environments facilitates a smoother interaction, particularly advantageous in intricate spaces like large shopping malls, airports, and healthcare facilities. Here, precise navigation enhances satisfaction and boosts operational efficiency. These environments can be quite overwhelming and emotionally engaging, making such enhancements even more valuable.

Smart Interface Control

Smart interface control technology provides versatility and accessibility through sophisticated gestures and voice commands. Its practicality in everyday life is evident across various applications, including lighting systems, climate control, and security management. Advances in this area feature adaptive learning algorithms that tailor responses to preferences, adding a layer of personalization and efficiency in controlling smart devices. An illustrative example is the use of adaptive interfaces in smart thermostats, which adjust based on learned routines, thus maintaining a balance between convenience and energy conservation.

Gesture Recognition

Gesture recognition technology has steadily improved, resulting in more precise and responsive interactions. This advancement supports a smooth applications that range from augmented reality (AR) devices to virtual assistants. In gaming, gesture recognition has transformed player interaction with virtual environments. The development of multi-modal systems, which combine gesture recognition with voice and facial recognition, represents ongoing progress toward more organic and seamless machine interactions.

Gaming and Dynamic Interaction

The gaming industry leads in adopting technology that facilitates dynamic interaction, substantially enriching gameplay experiences. The inclusion of motion-sensing technology has initiated groundbreaking shifts, enabling a more engaging and physical gaming experience. As technology progresses, the potential grows for more intricate and interactive gaming experiences blending real and virtual elements. This trend is evident in the increasing use of VR and AR in gaming, offering players not just entertainment but also a canvas for creativity and innovation.

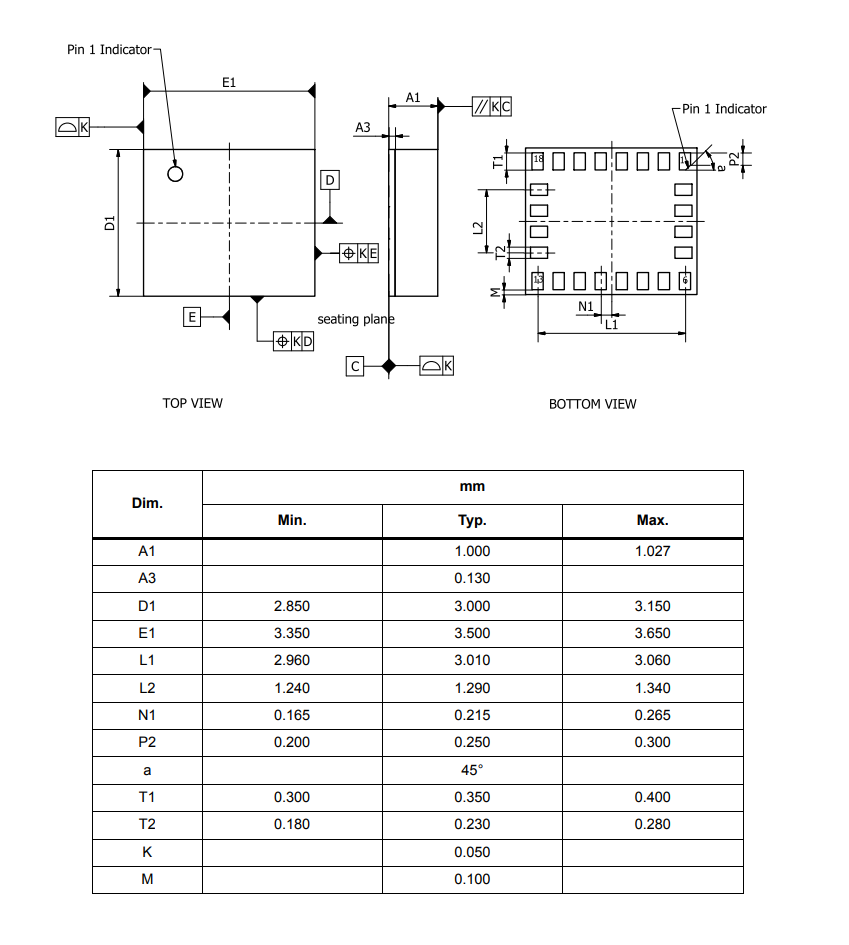

LSM9DS1TR Package

LSM9DS1TR Manufacturer Information

The LSM9DS1TR, a marvel of microelectronics crafted by STMicroelectronics, embodies the seamless integration of cutting-edge System-on-Chip technology into varied applications. This module combines accelerometer, gyroscope, and magnetometer functions, broadening motion-sensing possibilities for everything from everyday gadgets to complex industrial systems. STMicroelectronics excels in crafting efficient and high-performance solutions, continually advancing the field through relentless research and development endeavors. The company's global influence is marked by a dedication to sustainability and high standards, delivering circuits and sensors that adapt to dynamic shifts in market needs.

Datasheet PDF

LSM9DS1TR Datasheets:

Cylindrical Battery Holders.pdf

ICM-30630 Datasheets:

Cylindrical Battery Holders.pdf

Cylindrical Battery Holders.pdf

LSM330TR Datasheets:

Cylindrical Battery Holders.pdf

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

Frequently Asked Questions [FAQ]

1. What is the operating temperature range of the LSM9DS1TR?

The LSM9DS1TR functions reliably between -40°C and 85°C TA, proving its suitability across varied environmental conditions. Its versatility supports its use in both industrial sectors and electronics. In demanding settings, such as outdoor winter tasks, sustaining operational effectiveness remains a focal point. Manufacturers engage in extensive testing to ascertain that components retain their resilience and efficiency under challenging circumstances.

2. What is the supply voltage range?

Operating efficiently at a nominal supply voltage of 2.2V, the LSM9DS1TR accommodates low-power applications, thereby fostering energy efficiency. Others prioritize components with these voltage characteristics to promote extended battery life and reduced energy consumption, especially in portable devices. By fine-tuning power usage, such devices enjoy prolonged operational times, aligning with the modern emphasis on energy conservation.

3. How many pins does the LSM9DS1TR have?

With a configuration of 24 pins, this sensor module enables diverse interfacing opportunities and flexible connectivity. This pin layout ensures easy incorporation with microcontrollers, a consideration for developing multifaceted electronic systems. Others stress the importance of managing pin efficiency to enhance functionality and reduce the physical footprint of circuits, promoting elegant product designs.

4. In what form is the LSM9DS1TR packaged?

Available in Cut Tape (CT) packaging, the LSM9DS1TR is often preferred for its ease of handling in manufacturing environments. This packaging type streamlines automated assembly processes, minimizing the need for manual adjustments and errors, thus boosting production efficacy. In sophisticated manufacturing, automated setups utilize such packaging to ensure rapid processing and consistent quality in large-scale outputs.

5. What is the maximum supply voltage for the LSM9DS1TR?

Capable of tolerating a maximum supply voltage of 3.6V, the sensor provides ample flexibility to manage voltage variations typical in different power conditions. Its capability to handle diverse power inputs makes it ideal for devices experiencing variable power sources. Commonly design for voltage tolerance as a protective measure to shield components from transient overvoltage risks, thereby enhancing the device's durability and dependability in usage scenarios.

Comprehensive Guide to AT24C02 Serial EEPROM

on November 12th

A Guide to MCP1702 250mA LDO Regulator

on November 12th

Popular Posts

-

What is GND in the circuit?

on January 1th 3160

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2723

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 16th 2333

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2203

-

Comparison Between DB9 and RS232

on January 1th 1821

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1794

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1750

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1718

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1705

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 16th 1674