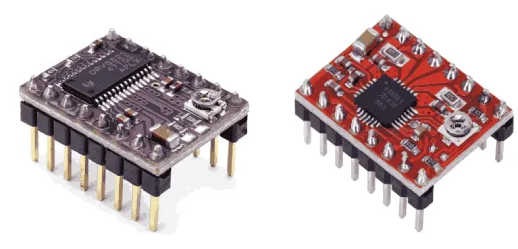

DRV8825 vs A4988 Comparison Guide

When choosing a stepper motor driver for your project, understanding the differences between popular options like the DRV8825 and A4988 is key. These drivers are widely used in applications such as 3D printers, CNC machines, and other motion control systems. This article will explore the features, benefits, and use cases of each driver to help you decide which one suits your needs best.Catalog

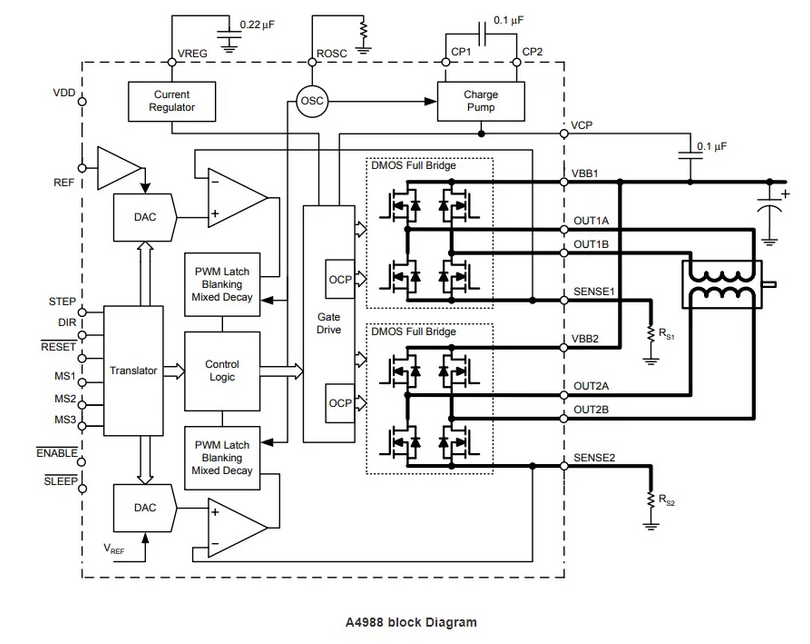

Understanding the DRV8825 Motor Driver

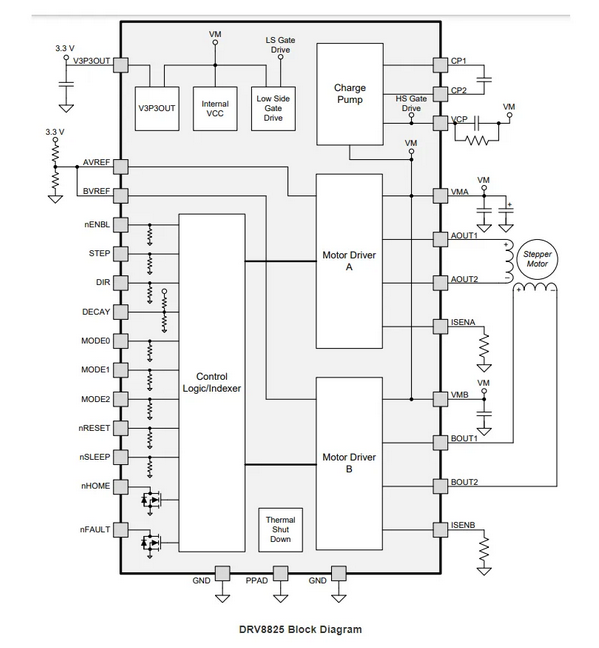

The DRV8825 motor driver is a versatile component used in applications like printers, scanners, and other automation equipment. It combines technical precision with practical utility, making it a reliable choice for controlling stepper motors.

The device features dual H-bridge drivers and a micro-stepping indexer, making it ideal for driving bipolar stepper motors. With the use of N-channel power MOSFETs in an H-bridge configuration, the DRV8825 can handle up to 2.5A per channel at 24V, as long as it has proper thermal management. This setup reduces voltage drop and heat generation while enhancing overall efficiency, particularly in high-current applications where MOSFETs outperform traditional bipolar junction transistors.

The micro-stepping indexer allows for steps as fine as 1/32, which enables smooth and precise motor control. This precision is particularly valuable in fields like 3D printing, where the accuracy of the motor directly influences the quality of the final product.

For motor control, the STEP/DIR interface offers flexibility and ease of use, supporting modes ranging from full step to 1/32 step. Configurable decay modes—slow, fast, and mixed—help optimize motor performance, addressing common issues like step loss and motor resonance. These features make the DRV8825 straightforward to integrate into systems that require precise and responsive motor control.

Thermal management is a key consideration when using the DRV8825 at its highest current ratings. Effective solutions like heat sinks or active cooling are recommended to maintain safe junction temperatures. Keeping these temperatures under control ensures reliable and long-lasting performance.

The driver also includes several built-in protection features, such as overcurrent and short-circuit protection, to safeguard both the motor and connected circuitry from potential wiring faults or load fluctuations. Additional features include undervoltage lockout, which prevents operation with insufficient voltage, and a thermal shutdown that temporarily disables the device if temperatures become too high.

In addition, a low-power sleep mode helps conserve energy and extend the driver’s lifespan. Fault conditions are indicated through the nFAULT pin, ensuring that any operational issues can be quickly addressed.

Introduction to the A4988

The A4988 is a compact microstepping motor driver designed to provide precise control over bipolar stepper motors. It supports various stepping modes, including full steps, half steps, quarter steps, one-eighth steps, and one-sixteenth steps. With the ability to handle up to 35V and deliver up to 2A of output drive, it suits a wide range of applications. The A4988’s integrated current control system ensures smooth transitions between slow and mixed decay modes, enhancing its adaptability and performance.

One of the standout features of the A4988 is its STEP input, which simplifies pulse signal generation without the need for complex programming. This makes it ideal for scenarios where precise control is needed, as it speeds up development and minimizes potential errors in signal generation, providing a reliable solution for various projects.

The A4988’s mixed decay mode further improves its performance by initially operating in fast decay and then switching to slow decay. This approach reduces audible motor noise, making it perfect for environments where quiet operation is necessary, such as in medical equipment or consumer electronics. Mixed decay mode also improves the accuracy of each step, which is essential for applications that demand precision, such as robotics or automation systems. By finely managing the current flow, the A4988 reduces positional errors, leading to smoother and more consistent performance.

Additionally, the mixed decay mode helps conserve power, which is beneficial for battery-operated devices. The A4988’s efficient power management extends battery life and reduces operational costs, making it an effective choice for applications where power consumption is a key consideration.

A4988 and DRV8825 Characteristics

Features

| Features | DRV8825 | A4988 |

| Microstepping Levels | 1, 1/2, 1/4, 1/8, 1/16, 1/32 | 1, 1/2, 1/4, 1/8, 1/16 |

| Maximum Current | Up to 2.5A | Up to 2A |

| Voltage Range | 8.2V to 45V | 8V to 35V |

| Typical Rs Value | 0.1 Ohm | 0.05 Ohm or 0.1 Ohm or 0.2 Ohm |

| Step Pulse Timing | Adjustable | Fixed |

| Applications | Robotics, Printers, Scanners, Factory Automation, etc. | Robotics, 3D Printing, CNC Machining, Textile Machinery, etc. |

| Cost | Generally higher | Generally lower |

| IC Packaging | 9.7x6.4mm 28HTSSOP | 5x5mm 28-lead QFN |

| Output | Low Rds(on) output | PWM Microstepping Motor Driver |

| Current Decay Modes | Automatic current decay mode detection/selection, Mixed and slow current decay modes | Multiple attenuation modes: Mixed decay, Slow decay, Fast decay |

| Microstepping Modes | Five selectable stepping modes: full step, 1/2, 1/4, 1/8, and 1/16 | Built-in micro-stepping indexer, Up to 1/32 micro-stepping |

| Power Consumption | Synchronous rectification for low power consumption | Low current sleep mode |

| Protection | Internal UVLO, Cross-current protection, Ground short circuit protection, Load short-circuit protection | Overcurrent Protection (OCP), Thermal Shutdown (TSD), Undervoltage Lockout (UVLO), Fault Status Indication Pin (nFAULT) |

| Logic Supplies | 3.3 and 5 V compatible logic supplies | Built-in 3.3V reference output |

| Drive Current | — | Maximum drive current of 2.5A at 24V and T A = 25°C |

| Interface | — | Simple STEP/DIR interface |

| Additional Features | Thermal shutdown circuitry | Small package and footprint |

A4988 VS DRV8825 Block Diagram

A4988 VS DRV8825 Applications

A4988 Applications

• Robotics: Used in small robotics projects like low-power robotic arms and small autonomous vehicles due to its compact size and straightforward control.

• 3D Printing: Manages motors responsible for moving the print bed and extruder head, making it suitable for smaller 3D printers.

• CNC Machining: Effective in lightweight CNC machines like desktop engravers and hobby-grade CNCs.

• Textile Machinery: Handles small stepper motors for embroidery and stitching in textile machines.

• Medical Equipment: Powers precise movements in devices such as syringe pumps and small actuators.

• Educational and Hobbyist Projects: A popular choice for educational kits and DIY projects because of its affordability and ease of use.

• Security Camera and Gimbal Mechanisms: Controls smooth motion in security cameras and stabilizing mechanisms in gimbals.

DRV8825 Applications

• Robotics: Suitable for higher-torque robots like robotic arms and heavy-duty autonomous vehicles.

• Printers and Scanners: Ensures smooth and accurate motion in professional and industrial-grade printers and scanners.

• Gaming Machines: Powers motors in arcade and gambling machines, providing reliable movement.

• Factory Automation: Drives mechanisms in conveyor belts, robotic manipulators, and other automated systems.

• Currency Processors and ATMs: Manages reliable motor control in currency counting machines and ATMs.

• Video Surveillance Cameras: Controls pan and tilt movements in high-end surveillance cameras.

• Office Automation Machines: Powers motors in devices like copiers and shredders for precise operation.

Conclusion

In summary, the DRV8825 and A4988 are both solid choices for stepper motor control, each offering distinct features. The DRV8825 is preferred for higher resolution and current handling, while the A4988 is a good option for those looking for a budget-friendly solution. By understanding the strengths and characteristics of each, you can choose the driver that best fits your specific application.

Frequently Asked Questions [FAQ]

1. What is the Main Difference Between A4988 and DRV8825?

The DRV8825 provides a higher step resolution (1/32 steps compared to the A4988’s 1/16 steps) and has a lower RDS(on-resistance), making it more efficient and reducing heat generation. The DRV8825 also supports a wider working voltage range (8.2V to 45V, while the A4988 operates between 8V and 35V). The A4988 uses a QFN package, which is smaller but more difficult to solder compared to the DRV8825’s HTSSOP package.

2. DRV8825 vs A4988: Which One Should You Choose?

The DRV8825 is generally more expensive due to its advanced features and performance. However, if you need a budget-friendly and dependable option, the A4988 might be more suitable. For applications that require higher precision, quieter operation, and smoother performance, the DRV8825 is the better choice.

3. What Are the DRV8825 and A4988?

The DRV8825 and A4988 are stepper motor driver ICs commonly used in robotics, CNC machines, 3D printers, and other motion control systems. They help regulate the current and control the direction of the stepper motor.

4. Which Driver Should You Choose for Your Application?

Choose the DRV8825 if you need higher micro-stepping resolution, better current handling, or prefer features like overcurrent and thermal management. Choose the A4988 if you’re looking for a more affordable solution with standard micro-stepping capabilities that works well in many common stepper motor applications.

5. Where Can You Find More Information About the DRV8825 and A4988?

You can find more detailed information by referring to the datasheets provided by the manufacturers, such as Texas Instruments for the DRV8825 and Allegro Microsystems for the A4988. Additionally, online forums, community resources, and manufacturer websites offer valuable insights and support for using these drivers effectively in your projects.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

D882 Transistor Explained with Practical Applications

on October 9th

Why Choose the Renesas TW2864 for Your Video System

on October 9th

Popular Posts

-

What is GND in the circuit?

on January 1th 2861

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2437

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2040

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 6th 1799

-

Comparison Between DB9 and RS232

on January 1th 1740

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1693

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1632

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1505

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1485

-

CR2450 vs CR2032: Can The Battery Be Used Instead?

Lithium manganese batteries do have some similarities with other lithium batteries. High energy density and long service life are the characteristics they have in common. This kind of battery has won the trust and favor of many consumers because of its unique safety. Expensive tech gadgets? Small appliances in our homes? Look around and you'll see them everywhere. Among these many lithium-manganes...on January 1th 1477