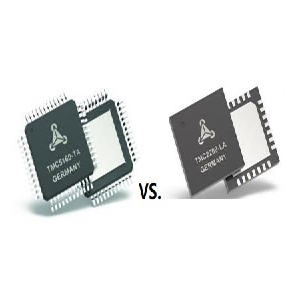

Breaking Down the Differences: TMC5160 vs. TMC2209 Stepper Drivers

The TMC2209 is designed to deliver ultra-silent performance for two-phase stepper motors. This motor driver IC is chosen for applications where operating noise must be minimized. Meanwhile, the TMC5160 is a powerhouse among stepper motor controllers and driver ICs, boasting advanced serial communication interfaces. This article will reveal the contrasts between the TMC5160 and the TMC2209, exploration includes a thorough review of their pinouts, detailed accounts of their features, applications, and their seamless integration with other components.Catalog

Overview of TMC5160 and TMC2209

The TMC2209, known for its superbly quiet operation, is designed for two-phase stepper motors. It is backward compatible with previous drivers like the TMC2208, enabling effortless upgrades. The primary feature of the TMC2209 is its ability to function silently, making it ideal for applications, minimizing noise, including 3D printers and desktop CNC machines. In contrast, the TMC5160 shines as a robust stepper motor controller recognized for its serial communication capabilities. This feature allows for highly sophisticated motor control, supporting more complex and fine-tuned operations. One remarkable attribute of the TMC5160 is its versatile ramp generator, enabling automatic target positioning. This integration greatly reduces the need for manual calibration and fine adjustments, enhancing workflow efficiency.

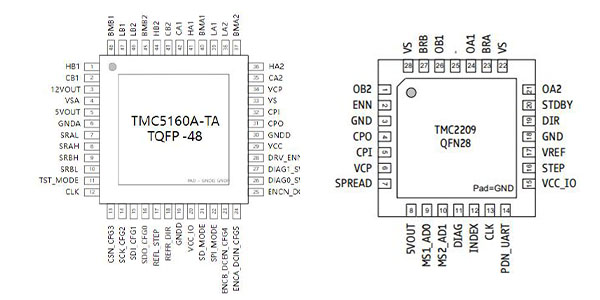

Pinout of TMC5160 and TMC2209

Features of TMC5160 and TMC2209

TMC5160 Feature & Benefit

The TMC5160 is designed for two-phase stepper motors with coil currents spanning from 1A to several tens of amps, making it adaptable for a multitude of uses. Key attributes are motion controller with a SixPoint Ramp, Step/Dir Interface with micro-step interpolation, and operating voltage ranging between 8-60V DC. Its SPI and UART interfaces offer flexible connectivity options. Additionally, the encoder interface and dual reference switch inputs elevate precision. The TMC5160 supports a resolution of 256 micro-steps per full step, ensuring seamless movement and meticulous control.

StealthChop2 technology facilitates ultra-quiet operations. This attribute is valued in environments where noise minimization profoundly affects work, play, or therapy. Besides, advanced load control techniques such as DcStep, StallGuard2, and CoolStep maximize performance under fluctuating conditions. The inclusion of passive braking, a comprehensive protection system, and compact packaging (TQFP48 or QFN) further enhances its robust and adaptable design. These features render the TMC5160 suitable for a broad spectrum of precision-centric applications, from industrial automation to high-performance 3D printing.

TMC2209 Feature & Benefit

The TMC2209 caters to two-phase stepper motors with a peak current of up to 2.8A (2A RMS). It suits less demanding applications in comparison to the TMC5160. Despite its lower current capacity, notable features include STEP/DIR Interface with configurable micro-steps (8, 16, 32, or 64), smoothness through MicroPlyer interpolation ensuring 256 micro-steps, and StealthChop2 technology for silent operation.

It operates within a voltage range of 4.75-29V DC. Internal sense resistors simplify the design by eliminating the necessity for additional components. Passive braking and freewheeling are complemented by energy-saving standby features that are used in trimming down overall power consumption. The IC also boasts extensive protection and diagnostics, ensuring reliability and durability. Its compact form, incorporating a large heat slug, provides effective thermal management, making it suitable for space-limited and thermally sensitive applications.

Empirical data derived from desktop 3D printers underline the TMC2209's proficiency in decreasing energy consumption while upholding performance. This showcases its aptness for home and smaller office environments, where energy efficiency increasingly takes precedence. An interesting perspective is that systems featuring TMC2209 drivers consistently exhibit not only diminished operational noise but also improved longevity due to reduced thermal strain, mirroring a balance between performance and sustainability.

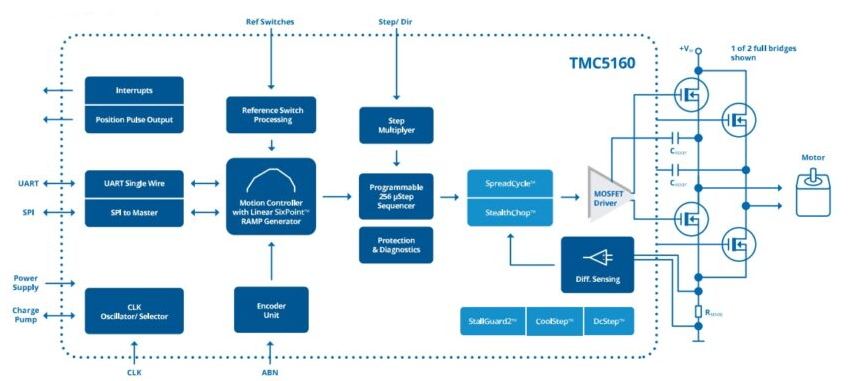

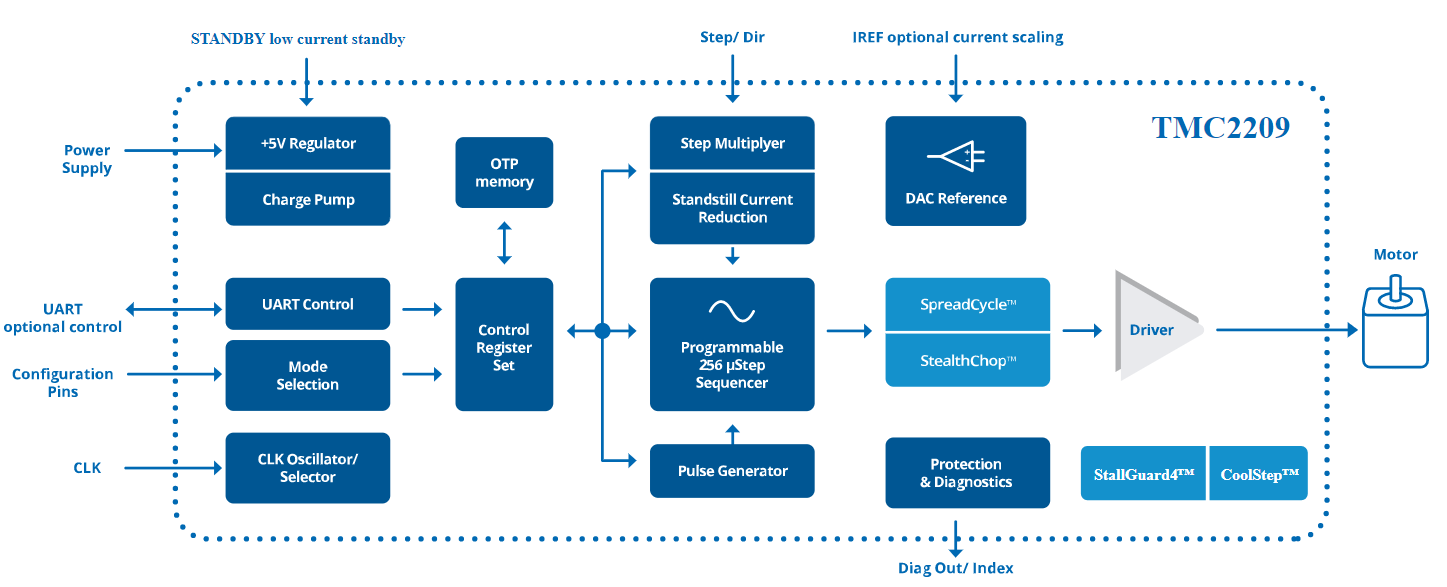

Block Diagram of TMC5160 and TMC2209

The TMC5160 excels in delivering comprehensive motion control solutions with robust external MOSFET driver stages and top-tier current regulation. Such attributes make it well-suited for a broad spectrum of applications, ranging from battery-powered systems to high-current embedded solutions. By interpreting target positions, the TMC5160 automates motor movement and incorporates a suite of advanced features that ensure efficient, precise, and quiet motor operation. In comparison, the TMC2209 is remarkable in scenarios requiring up to 2A motor current per coil. It uses SpreadCycle and StealthChop2 to optimize motor performance, reducing motor noise and minimizing standby power dissipation. This efficiency results in shorter design cycles and more competitive product development timelines.

Application of TMC5160 and TMC2209

TMC5160 Application

In robotics, where high-performance capabilities offer the backbone for complex, coordinated movements, the TMC5160 proves great for automated tasks. The meticulous control it affords ensures robotics operate seamlessly. Industrial drives benefit greatly from the TMC5160 as it manages motor control with minimal noise and exceptional reliability, boosting efficiency and operational productivity For textile and sewing machines, the TMC5160 delivers unparalleled precision, ensuring consistent and defect-free outputs. This consistency elevates product quality and speed, which is good in the highly competitive textile industry. Packing machines require smooth motion control to maintain the integrity of packaged goods. The TMC5160 provides this smoothness, safeguarding product quality during packaging.

In lab automation systems, the TMC5160’s precise motor control guarantees accurate and repeatable results, which are important for research reliability. High-speed 3D printers, dependent on speed and accuracy to create detailed prototypes and final products rapidly, find the TMC5160 an invaluable component. The precision offered supports the efficacy of these advanced machines. Liquid handling systems in both laboratory and industrial environments leverage the TMC5160 for precise fluid control. Fields such as pharmaceuticals and biochemical analysis demand such high-accuracy applications.

Medical devices benefit from the TMC5160’s reliable performance and low electromagnetic interference for patient safety and device efficacy. Office automation devices see their functionality enhanced due to the TMC5160’s quiet operation and precise control, creating a more convenient workspace. CCTV systems, ATMs, and pumps and valves all employ the TMC5160, resulting in improved surveillance clarity, reliability of financial transactions, and efficient fluid management. Each of these applications demonstrates the TMC5160’s extensive utility.

TMC2209 Application

The TMC2209 is crafted for seamless integration and heightened efficiency, making it an ideal choice for system upgrades and new designs across various fields. In 3D printers, its low power consumption and quiet operation transform by reducing operational costs and minimizing noise pollution. Office and home automation devices greatly benefit from the TMC2209’s straightforward implementation and reliability, adding to the ease and functionality of daily activities. Textile machines using the TMC2209 achieve greater operational efficiency and face fewer maintenance issues, leading to consistently high product quality.

CCTV systems gain from the TMC2209’s quiet operation, which is use in settings where background noise can interfere with audio clarity. ATMs utilize the TMC2209 to ensure smooth and reliable performance, which is great for secure and efficient financial transactions. HVAC systems use for indoor air quality and comfort, capitalize on the TMC2209’s energy-efficient and quiet motor control, enhancing environmental comfort. Battery-operated equipment sees improvements in both longevity and efficiency thanks to the TMC2209’s low-energy consumption, increasing the practicality and sustainability of portable devices.

Application Circuit of TMC5160 and TMC2209

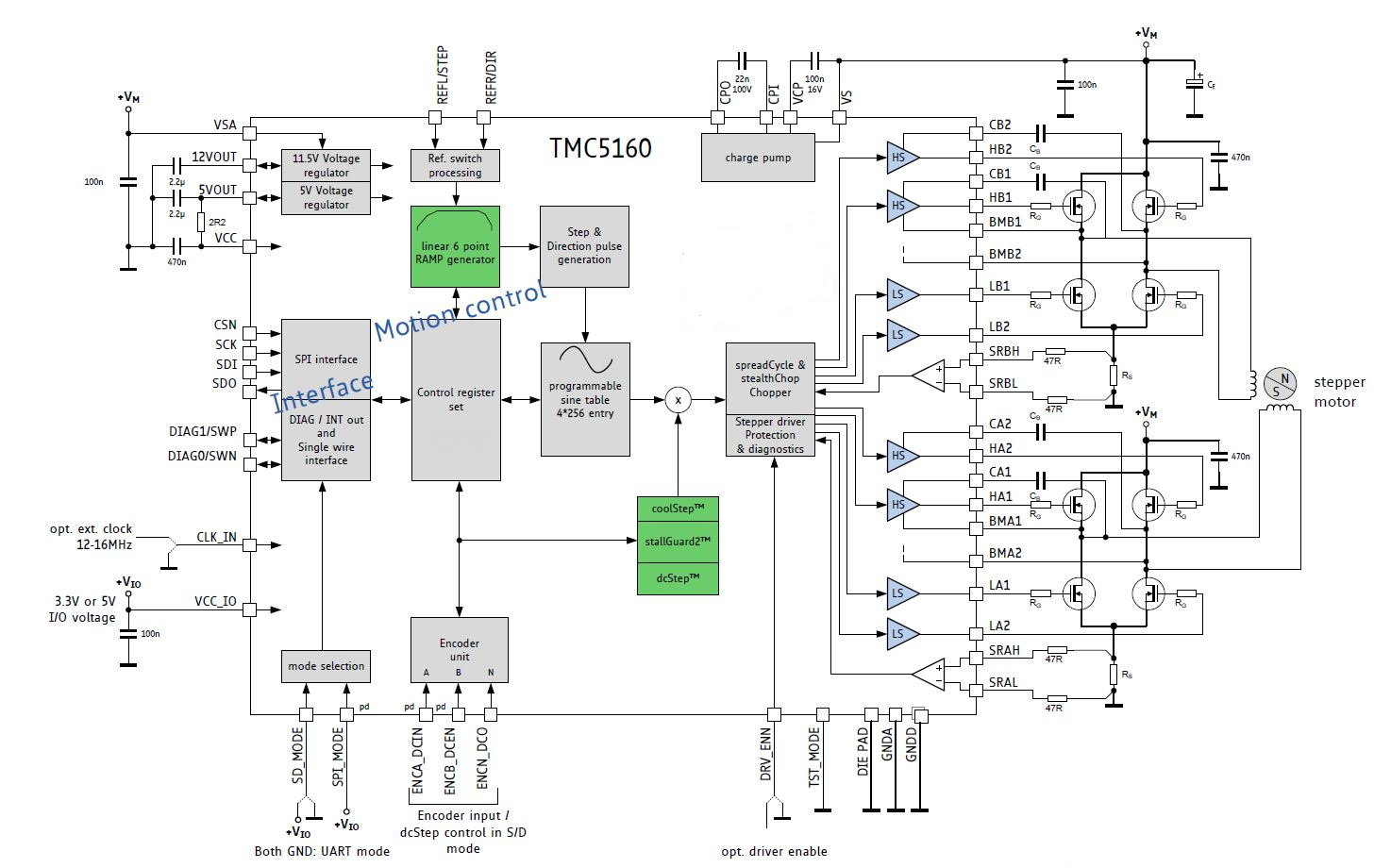

TMC5160 Application Circuit

The TMC5160 integrates motor control logic, eliminating the necessity for external software involvement. This self-reliant design features a six-point ramp generator, enhancing motor performance. Features like StealthChop, DcStep, CoolStep, and StallGuard2 provide versatile and efficient motor control. The TMC5160 supports higher voltages and motor currents, outperforming predecessors like the TMC2100, TMC2130, and TMC5130 families. These developments make the TMC5160 well-suited for demanding applications, where precise control and adaptability are needed. Industries like robotics and CNC machines notably benefit from these capabilities. StealthChop technology ensures noise-free operation in settings where whisper-quiet functioning is a necessity. Practical usage shows integrating StallGuard2 can reliably predict mechanical overloads, preventing damage and extending motor lifespan.

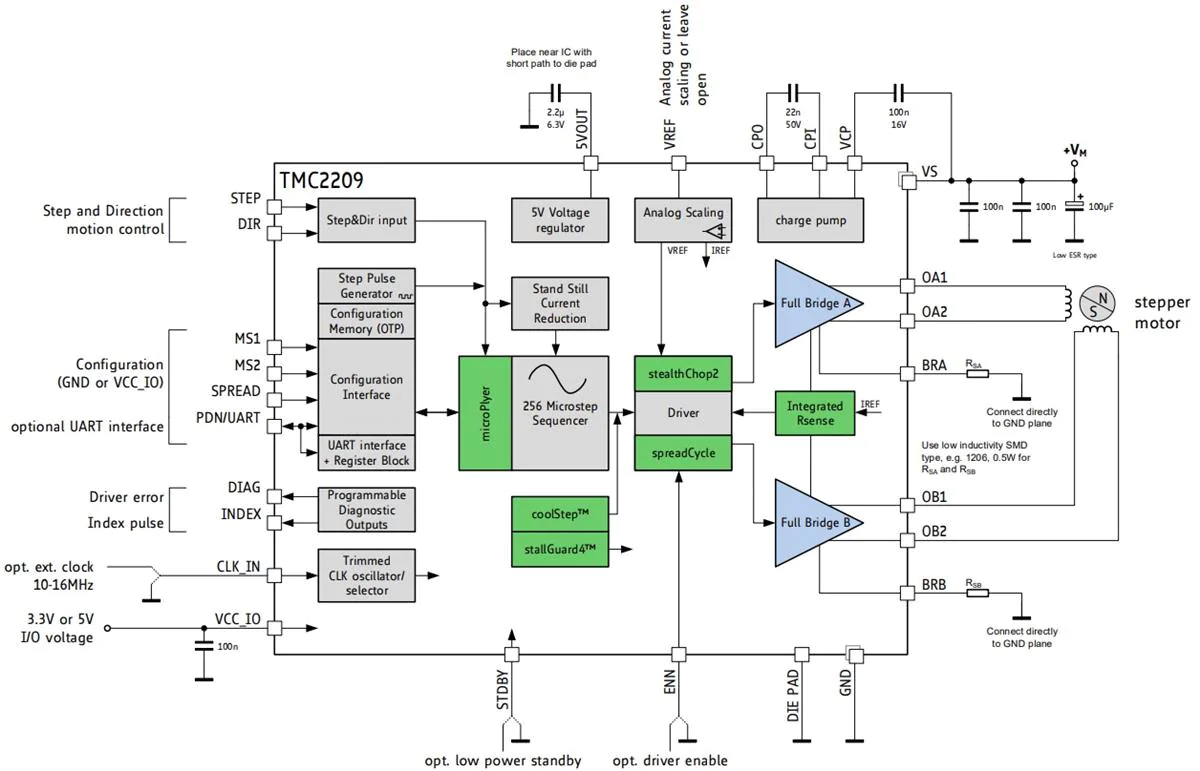

TMC2209 Application Circuit

The TMC2209, with its limited control pins, prioritizes simplicity and efficiency. Despite its straightforward design, it offers configurable micro-step resolutions (8, 16, 32, or 64) to meet various precision demands. Known for high precision, energy efficiency, reliability, and smooth operation, TMC2209 is a hallmark of TRINAMIC products. Here, efficient power management and low heat dissipation make the TMC2209 ideal for applications where energy conservation and reliability are required. For instance, 3D printing applications benefit from reduced vibrations and noise, enhancing print quality. Others find its energy efficiency boosts the longevity and stability of their devices.

Conclusion

The TMC2209 utilizes the UART interface, offering enhanced control over motor operations. The TMC5160, connected through SPI, extends additional functionalities similar to those provided by the TMC2209, with the added robustness of SPI communication. Both the TMC2209 and TMC5160 series are recognized for their advanced StealthChop2 technology, known for delivering exceptional performance under higher accelerations. This mode is valuable in applications requiring silent operation and smooth motor control.

Frequently Asked Questions [FAQ]

1. What is the TMC2209?

The TMC2209 is an ultra-silent motor driver integrated circuit (IC) that specializes in minimizing noise and vibration in stepper motors. Its high efficiency makes it ideal for environments demanding quiet and smooth operation, such as 3D printers and high-precision machinery.

2. What is a TMC5160?

The TMC5160 is a high-power stepper motor controller known for offering advanced motor control capabilities. It can manage high currents and comes equipped with multiple motor control functions. This makes it a go-to solution for industrial and robotics applications requiring robust performance.

3. What is completely within the TMC5160?

The TMC5160 includes all stepper motor control and logic components, offering a simplified system design. It features integrated current control, motion controller capabilities, and a variety of diagnostic functionalities, all consolidated into a single chip.

4. What are the TMC5160’s unique enhancements enabled by?

The TMC5160’s unique enhancements stem from its system-on-chip (SoC) integration, which combines multiple functionalities within a single chip. This integration boosts performance and enables advanced diagnostics, efficient power management, and improved motion control precision.

5. What is the most critical setting on the TMC2209?

The most influential setting on the TMC2209 is the micro-step resolution. Adjusting this setting impacts the motor’s smoothness and accuracy of movements. Fine-tuning this parameter allows precise control of the motor's position and speed for applications where high detail and minimal noise are desired.

6. How to cool the SilentStepSticks?

TMC2209: Attach a small heat sink to the top PCB side for currents up to 1A RMS. For higher currents, use a cooling fan to handle the extra thermal load, addressing real-world needs for sustained performance.

TMC5160: Ensure adequate air circulation around the device for currents up to 2A RMS. When dealing with currents exceeding 2A RMS, and when cooling external MOSFETs and shunt resistors, a cooling fan becomes necessary. This is in line with standard practices in high-power electronics to maintain reliability and longevity under heavy operational demands.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

LM317 Voltage Regulator : Pinout, Circuit, Comparison with LM7805, and Datasheet Overview

on October 15th

Everything You Need to Know About the BC549 Transistor

on October 15th

Popular Posts

-

What is GND in the circuit?

on January 1th 2824

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2399

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2009

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 5th 1757

-

Comparison Between DB9 and RS232

on January 1th 1723

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1674

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1613

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1489

-

CR2450 vs CR2032: Can The Battery Be Used Instead?

Lithium manganese batteries do have some similarities with other lithium batteries. High energy density and long service life are the characteristics they have in common. This kind of battery has won the trust and favor of many consumers because of its unique safety. Expensive tech gadgets? Small appliances in our homes? Look around and you'll see them everywhere. Among these many lithium-manganes...on January 1th 1469

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1437