BT151 SCR Functionality: Features, Pin Configuration, and Applications

Exploring the inner workings of modern power electronics and understanding the role of one-way thyristors, also known as Silicon Controlled Rectifiers (SCRs), is a must. These devices have become a cornerstone in power management systems due to their ability to control current flow with precision, manage high voltages, and ensure durability in demanding environments. From regulating motor speeds to modulating heating elements, SCRs like the BT151 are dynamic components in a range of applications. This article digs into the technical distinctions of SCRs, their practical uses, and how you can leverage them for efficient, sustainable power solutions.Catalog

Exploring One-Way Thyristors

One-way thyristors, also recognized as silicon-controlled rectifiers (SCRs), offer an efficient and compact design that excels in power management systems. Their swift response and mechanical durability endear them to a multitude of applications, showcasing the complexities for both speed and longevity in technology. SCRs are composed of three primary terminals the anode, cathode, and gate. This triad allows for meticulous control over current flow. Without gate voltage, the anode-cathode junction remains reverse-biased, preventing current passage. Introducing gate voltage renders the junction forward-biased, allowing smooth current movement and reflecting a dynamic balance akin to decision-making processes.

SCRs find practical use in controlling motor speeds, regulating power in heaters, and managing electric light intensity. Their prowess in handling high voltages and currents while maintaining robust performance is widely acknowledged. They often contribute to more efficient power distribution, paving the way for energy solutions that resonate with the pursuit of cost-effectiveness and sustainability. Optimizing SCRs involves considering heat dissipation and switching speed. Employing thermal management techniques, such as heat sinks or cooling systems, mitigates overheating risks, promoting longevity. Focusing on switching characteristics can diminish energy loss, enhancing operational reliability, much like the aspiration for efficiency and resilience.

With no moving parts, SCRs overcome maintenance challenges typical in mechanical systems. Integrating SCR technology can elevate system durability and reliability, mirroring the quest for enduring and trustworthy solutions. As the energy demand grows, continuing advancements and the integration of thyristor technology are poised to play a basic role in sustainable power management.

BT151 Overview

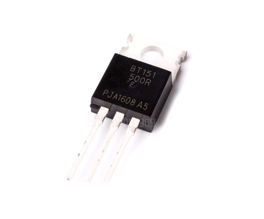

The BT151 is a 12A medium-power SCR housed in a TO-220 package, skilled in managing both AC and DC load switching. Its notable attribute, compared to transistors, is its latching capability, which allows it to maintain conduction without a gate signal until the current drops below the holding level. This becomes a valued feature in circuit designs where a stable current flow is desired without continuous input.

Alternatives and Comparable Components

BT151 Features

Enhanced Energy Management

BT151 is crafted to deliver a reduced voltage drop, suggestively enhancing energy utilization by curtailing power loss. This trait is beneficial in industrial environments focused on managing energy expenses effectively. It resonates well with your desires for efficiency and resourcefulness.

Resilient Current Capacity

Exhibiting a robust current capacity, the device adeptly manages higher loads with unwavering stability. This characteristic is highly valued in scenarios with varying power requirements, such as motor control systems and adjustable power supplies. It aligns with the need for reliability amidst unpredictability.

Cultured Structural Blueprint

Featuring an intricate four-layer PNPN configuration, BT151 efficiently manages current across both AC half-cycles. This architectural design enhances performance and supports reliability under dynamic thermal conditions, akin to navigating life's ever-changing challenges.

Superior Thermal Management

Through thermal cycles, the component showcases formidable performance, effectively controlling and regulating current flow. This ability aids in maintaining system stability and extending equipment longevity amidst fluctuating thermal conditions, much like enduring life's emotional highs and lows.

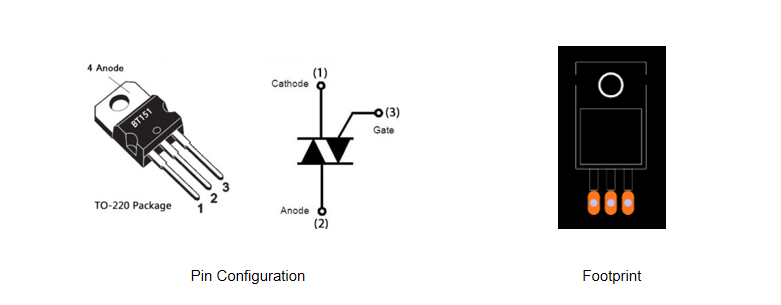

Footprint and Pin Configuration

The BT151 thyristor features three pins: anode, cathode, and gate, each contributing uniquely to its operation. Understanding the interaction and individual purposes of these pins illuminates the device's behavior.

Anode

The anode allows current to enter the device, serving as a primary terminal for charge carriers. Establishing a good connection here can enhance device efficiency and overall performance.

Cathode

The cathode acts as the exit path for electrons, facilitating conventional current flow. Its design and connection determine the smoothness of current movement, affecting the thyristor's reliability. Careful planning of the cathode's layout minimizes resistance and heat.

Gate

The gate is basic in initiating conduction between the anode and cathode by applying a small voltage. This control mechanism transitions the thyristor from non-conductive to conductive states. The gate's ability to manage timing and modulation precisely is invaluable in applications demanding accuracy.

BT151 Technical Specifications

Encased in a robust TO-252 package, the BT151 excels at heat dissipation, enhancing its performance in space-restricted environments. This design is mostly favored in demanding applications where space is at a premium, reflecting manufacturing preferences.

The BT151 manages substantial power loads with precision through a peak gate power of 5W and a gate current of 2A. Analyzing gate current control reveals its role in reducing power loss, suggestively affecting circuit design efficiency. Handling up to 650V, the BT151 is suited for high-voltage applications. Its ability to sustain an on-current of 12A supports demanding operations, dynamic for ensuring safety and reliability in high-power circuits.

The average power consumption is at a modest 0.5W, extending the BT151's utility in energy-sensitive environments. With an operational temperature range from -40 to 125℃ and storage from -40 to 150℃, it demonstrates resilience across diverse climates, which is beneficial for consistent performance. The surge on-state current capacity of 120A emphasizes its proficiency in handling transient high-current scenarios. This capability provides enhanced protection against overcurrent conditions, minimizing potential system downtime.

Evaluating the Quality of BT151 Thyristor

Accurate testing procedures pave the way for the BT151 thyristor to operate seamlessly. Begin by setting up the multimeter meticulously. Disconnect the component from any power supply to prevent misleading readings. Those well-versed in electronics find that a deep understanding of setup and methods enriches the dependability of results.

Testing Process

Multimeter Configuration: Switch to 'diode' mode.

Voltage Expectations: A forward voltage ranging from 0.6 to 0.8 volts usually signifies proper function.

Common Insights: These standard values for semiconductors suggest a healthy conduction path.

Interpreting multimeter readings requires attention to an open circuit signal, which may hint at physical or internal disruptions. When these signs arise, frequently initiate supplementary tests, like examining connected circuits, to dismiss external impacts on the readings.

BT151 Functionality

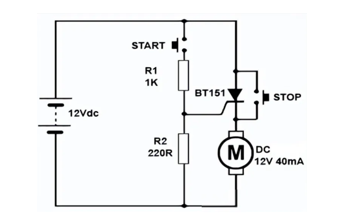

BT151 shines in handling large currents at low voltages, offering desired capabilities in AC/DC modulation. In DC applications, like linking a motor to a 12V power supply, its efficiency becomes apparent. This begins with a gate current pulse when the start switch activates. The mechanism provides smooth motor control, which ceases only when the holding current dips below the threshold—a task managed by a stop switch or similar setup.

BT151 extends beyond basic motor control, contributing to systems requiring meticulous current management. For example, in industrial safety implementations, its swift response to current fluctuations keeps operations within safe limits. This responsiveness is seen as a major attribute in systems demanding reliability and precise control. Integrating BT151 involves the careful selection of passive components that complement its function. These decisions affect not just efficiency but also the system's lifespan.

BT151 Application

BT151 demonstrates impressive adaptability and trustworthiness across a variety of fields.

Current Anomaly Detection

This component adeptly identifies and disrupts unexpected current flows, reducing risks. By integrating BT151 in environments demanding high safety standards, circuit protection is notably enhanced, curbing potential electrical failures.

Precision in Power Tools

BT151 excels in fine-tuning motor speed through adjustable firing angles. This feature enables precise operation, mainly for tasks requiring variable speed and torque, thereby enhancing performance and extending tool life.

Voltage Stability in AC Systems

Through modulation of firing angles, BT151 ensures stable voltage within circuits, used for optimal functioning of systems sensitive to voltage shifts. Its adaptability aids in maintaining steady electrical performance.

Motor Control Flexibility

By managing motor speed and direction, BT151 is focal for diverse applications from industrial machinery to consumer electronics. It ensures smooth operation and energy efficiency, prolonging motor lifespan and boosting effectiveness.

Temperature Precision in Cooktops

In cooktops, BT151 excels at precise temperature control by modulating heating elements. This results in reliable cooking performance and safety, enhancing the efficiency of kitchen appliances.

Enhanced Power Transfer

BT151 amplifies the efficiency of power devices such as chargers and adapters. Optimizing power transfer, it minimizes power loss and promotes energy-efficient consumption practices, supporting sustainability.

Frequently Asked Questions [FAQ]

1. What is the function of BT151?

The BT151 is often employed in power-switching tasks due to its ability to keep its state after activation until the current drops below a specific holding threshold. It's frequently found in circuits that demand dependable switching, like motor control systems, where stability and precision are valued.

2. What is BT151?

The BT151, a 12A medium-power silicon-controlled rectifier (SCR), is engineered to handle both AC and DC loads while managing substantial DC signals. Its versatility shines in industrial environments, where it effectively manages diverse electronic operations, showcasing its adaptable nature.

3. Is BT151 a triac?

Although the BT151 is not a triac, it shares some functional similarities in low-power AC applications. Its design supports efficient operation in circuits that necessitate exact power flow control, indicating a deeper understanding of these components can refine circuit design strategies.

4. What is the equivalent of a BT151 thyristor?

Alternatives to BT151 include the TYN208 and BT152. Other substitutes include the BTA16 and S6010, which can either replace or enhance performance based on specific circuit needs. This selection process contributes to achieving the desired circuit performance.

5. How do you test a BT151 with a multimeter?

To test, set the multimeter to 'diode' mode. Check the pin configurations and connect the terminals to the cathode and anode. This meticulous approach ensures functional accuracy and resolves potential issues effectively, importance the role of careful testing in sustaining circuit reliability.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

AT89C52 Microcontroller: Alternatives, Features, Architecture, and Uses

on September 26th

TCS3200 RGB Color Sensor: Comparisons, Structure, and Applications

on September 26th

Popular Posts

-

What is GND in the circuit?

on January 1th 3152

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2707

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 16th 2294

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2195

-

Comparison Between DB9 and RS232

on January 1th 1815

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1787

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1738

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1700

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1696

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 16th 1662