A Guide to the A3144 Magnetic Hall Effect Sensor

Hall sensors, often referred to as Hall effect sensors, utilize the Hall effect principle to detect and measure magnetic fields and their variations. These sensors are widely employed in various domains due to their precision and reliability in magnetic field detection. This discussion will explore the A3144 Hall sensor, emphasizing its operational parameters. We'll delve into its distinct characteristics, which render it a valuable component in diverse applications involving magnetic fields.Catalog

The Basics of Hall Sensors

A Hall sensor, operating on the principles of the Hall effect, is primarily employed to detect motor winding phase positions and translate this data into electrical signals. Through the interpretation of signals from the Hall element's output, a driver can determine the rotor's position. This enables precise commutation and facilitates the motor's operation, creating a rotating magnetic field that sustains motor performance.

Hall sensors play a role in discerning the relative positioning between a motor's stator and rotor, allowing for electronic phase changes. Depending on their application methods, these sensors can be classified into linear and switching types. Linear hall sensors, provide a continuous voltage output proportional to the magnetic field strength. Switching hall sensors, offer a digital on/off output once the magnetic field surpasses a certain threshold.

Unveiled by Edwin Hall in 1879, this phenomenon manifests when a current-carrying conductor is exposed to a magnetic field, generating a potential difference perpendicular to both the current and magnetic field. Hall sensors exploit this inherent property to detect magnetic fields, thereby providing positional information of motor components.

The A3144 Hall Effect Sensor Overview

Manufactured by Allegro Microsystems, the A3144 Hall Effect sensor is a good instrument in the realm of magnetic field detection. This digital output sensor excels in translating fluctuations in magnetic fields into distinct electrical signals. Specifically, when a magnetic field is detected, the sensor's output switches to a low state, whereas in the absence of a magnetic field, it remains high. It operates effectively in a temperature range spanning from -40°C to 150°C, seamlessly integrating into systems that need precise position, magnetic field, and speed detection.

The sensor’s dynamic nature makes it a preferred choice across various industries. In automotive systems, it precisely monitors cam and crankshaft positions, enhancing engine performance and efficiency. Its contributions in industrial automation include monitoring the rotational speeds of machinery, bolstering operational safety and efficiency. Its ability to endure wide temperature variations further tests its resilience in harsh environmental conditions, making it suitable for outdoor applications. The A3144’s contribution to renewable energy systems, such as wind turbines, cannot be overlooked. By monitoring the rotational speed of turbine blades, it helps in optimizing energy output, demonstrating the sensor’s adaptability and importance in modern energy solutions.

Replacements and Equivalents

• A3142

• HAL508SF

• OH090U

• SS49E

• US1881

Who Manufactures the A3144 Hall Effect Sensor?

Allegro Microsystems, recognized for designing and producing the A3144 Hall Effect Sensor, excels in the realms of engineering, development, and marketing of sensor ICs and specialized analog power ICs. The components engineered by Allegro are admired for their great contributions to the automotive and industrial sectors, underlining the company's strong market footprint.

Allegro's diverse product lineup is organized into three major categories: SENSE, REGULATE, and DRIVE. These sensors such as current sensors, switches, and magnetic speed sensors, help industries monitor various parameters with accuracy and reliability, leading to better efficiency. For example, in the automotive industry, these sensors ensure precise measurement of speed and position, which is best for safety and optimal vehicle performance. Allegro Microsystems' use of advanced integrated circuits (ICs) in automotive and industrial applications marks great progress in both performance and reliability. Their deep understanding of user needs and challenges drives continuous innovation in sensor technology and power management, allowing them to meet current market demands while also anticipating future industry trends.

Features of the A3144 Hall Effect Sensor

Compact Design and Space Efficiency

The A3144 Hall effect sensor features a minimalistic design that smoothly fits into various circuit board applications. This compactness not only conserves valuable space but also enhances the elegance of the electronic layout. In complex systems where every millimeter counts, this thoughtful design facilitates more efficient and streamlined electronic constructs.

Magnetic Sensitivity and Detection Accuracy

The sensor boasts a remarkable ability to detect small permanent magnets. This high sensitivity ensures precise detection of magnetic fields, which proves to be useful in scenarios that demand accurate position sensing. The A3144's reliability in recognizing even the most subtle changes in magnetic fields makes it a go-to for precision instruments, where each fraction of accuracy carries weight.

Built-in Reverse Voltage Protection

Equipped with built-in reverse voltage protection, the sensor is shielded from potential harm due to incorrect power supply connections. This protective mechanism enhances the sensor's durability and reliability—traits that reduce the chances of operational failures. By incorporating this feature, the sensor is well-suited for environments where power supply inconsistencies might pose a threat, extending its lifespan and ensuring continuous performance.

Operational Temperature Range

Its wide operational temperature range, spanning from -40°C to 150°C, showcases the sensor's robustness. This makes it apt for both industrial and automotive applications, where devices are subjected to considerable temperature fluctuations. In harsh environments, facing temperature variations is commonplace. The A3144's resilience in such extremes ensures unyielding performance, whether in chilling cold or searing heat.

Unidirectional Sensitivity

The A3144 Hall effect sensor's unidirectional sensitivity, which responds solely to changes in magnetic fields in one direction, offers a clear and unambiguous signal. This trait proves invaluable in applications requiring directional sensing, such as pinpointing the position of a gear or tracking the movement of a mechanical part. When paired with precise calibration, unidirectional sensitivity guarantees the delivery of accurate data, free from unwanted noise, catering to tasks where clarity and precision are non-negotiable.

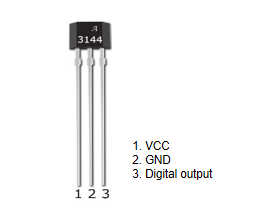

Pin Layout of the A3144 Hall Effect Sensor

The A3144 sensor features a triad of pins, each serving a distinct role for proper sensor operation:

• Pin 1 (VCC): This pin is responsible for connecting to the power supply, energizing the sensor and allowing it to function efficiently.

• Pin 2 (Ground): Acts as the grounding pin, it connects to the circuit ground. This completes the electrical loop that the sensor requires for proper operation.

• Pin 3 (Output): When the sensor detects a magnetic field, it outputs a high signal through this pin. The output voltage aligns with the operating voltage provided to Pin 1 (VCC).

Recommendations for Enhanced Sensor Performance

Place a 10k ohm pull-up resistor between Pin 1 (VCC) and Pin 3 (Output). This will ensure a consistent high output state even when no magnetic field is present, creating a stable reference for your sensor readings.

Include a 0.1uF capacitor between Pin 2 (Ground) and Pin 3 (Output). By doing this, you can mitigate electrical noise and achieve a smoother, more reliable output signal.

Functionality and Structure of the A3144 Hall Effect Sensor

Micro-Signal Amplifier

The micro-signal amplifier boosts the initial weak signal from the Hall element, ensuring it is strong enough for subsequent processing. This amplification is valued in industrial and automotive applications.

Schmitt Trigger

The Schmitt trigger converts the amplified analog signal into a clear digital output. This transformation provides a stable and noise-resistant response with electromagnetic interference. The stable output is great for maintaining consistency.

Temperature Compensation Circuit

Temperature variations can influence the Hall effect sensor's performance. The temperature compensation circuit mitigates these effects, aligning the sensor’s operational characteristics with its calibrated condition. This adjustment is beneficial in outdoor applications, where temperature fluctuations are frequent.

Reverse Power Protection Circuit

Reverse polarity in power supply connections can cause damage to electronic components. The reverse power protection circuit prevents such incidents, thereby extending the sensor’s durability and reliability.

Voltage Regulation Circuit

The voltage regulation circuit ensures the A3144 operates within its specified voltage range, protecting it from possible damage due to voltage variations. This regulation is useful when the sensor is integrated into systems with potentially unstable power sources.

Hall Element

The Hall element is the core of the A3144 sensor. When exposed to a magnetic field, it generates a voltage signal proportional to the field’s strength. This principle is applied in various scenarios, such as speed sensing in automobiles, where the Hall effect provides accurate and reliable data.

Open-Collector Output Stage

When an S-pole of a magnet is placed near the A3144, the sensor produces a low-potential pulse signal. This interaction is used in rotational speed sensing, where the Hall sensor converts changes in the rotational magnetic field into electrical signals. Upon removing the magnetic pole, the sensor output returns to a high potential voltage, effectively resetting its state. This reset capability is use for applications like brushless DC motors, where continuous monitoring and state reset ensure operational stability.

Advantages and Disadvantages of the A3144 Hall Effect Sensor

Advantages

Its compact size lends itself to diverse installations, from consumer electronics to industrial machinery. This small footprint allows for integration into tight spaces without compromising other system components. The sensor’s stability against environmental changes ensures consistent performance, whether in fluctuating temperatures or high-humidity environments. Its high sensitivity to weak magnetic fields allows for detection in applications where other sensors might fail. An added advantage is its rapid response to magnetic field alterations, making it suitable for real-time monitoring and control systems. The sensor's non-mechanical contact design promotes wear resistance, extending its operational lifespan.

Disadvantages

Despite its many strengths, the A3144 Hall Effect Sensor is not without its limitations. One notable drawback is its sensitivity to the direction of the magnetic field, which demands precise placement for accurate readings. Installation might require trial and error, particularly in complex environments. Another limitation is its restricted measurement range, that can be a hindrance in applications requiring broader detection capabilities. Furthermore, the sensor's inherent nonlinearity necessitates careful calibration, especially in high-precision applications where accuracy is required. This could involve additional time and resources to implement corrective measures, including the use of sophisticated algorithms or supplementary hardware to achieve the desired precision levels.

Implementing the A3144 Hall Effect Sensor

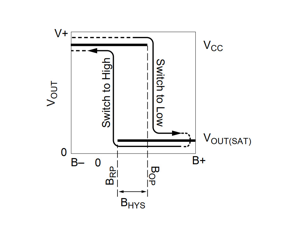

When a south pole magnetic field surpasses the operating threshold (BOP), the A3144 output transitions to low. Conversely, upon sensing a reduction in the magnetic field below the release point (BRP), the output reverts to high. The sensor's hysteresis ensures distinct output switching, even in the presence of external mechanical vibrations and electrical noise.

The notion of hysteresis in the A3144 Hall Effect Sensor plays a role in its functionality. By establishing separate operating and release points, hysteresis ensures steady output readings. This quality is advantageous in environments rife with mechanical vibrations and electrical noise, as it reduces the likelihood of incorrect switching.

Magnetic flux density is denoted as positive for south poles and negative for north poles. This differentiation assists in comparing field strengths. This understanding not only enhances the sensor's functionality but also facilitates the comprehension of varying magnetic environments.

Distinguishing between different magnetic field strengths enables effective calibration and adjustment of the sensor across various scenarios. For instance, in magnetic field mapping and diagnostics, the ability to accurately differentiate magnetic variations across a given space or object becomes beneficial. This precision ensures the accurate portrayal of magnetic fluctuations, aiding in numerous practical applications.

Applications of the A3144 Hall Effect Sensor

Magnetic Circuit Breakers

The integration of the A3144 Hall Effect sensor in magnetic circuit breakers enhances their reliability and accuracy. This sensor’s aptitude for magnetic field detection ensures precise monitoring of electrical currents. It prevents overcurrents and safeguards electrical systems. The sensor continuously observes the magnetic field generated by the electrical current passing through the breaker. This constant vigilance allows for prompt responses to any abnormal fluctuations, ensuring smooth and secure operations.

Magnetic Door Alarm Systems

Utilizing the A3144 Hall Effect sensor in magnetic door alarm systems markedly improves security frameworks. The sensor detects the disruption in the magnetic field when a door is opened or closed, triggering a timely alarm. This sensitivity helps in promptly alerting personnel to unauthorized access. In both residential and commercial settings, deploying these sensors has proven instrumental in reducing unauthorized entries and bolstering overall property security.

BLDC Motor Pole Detection

In BLDC motor applications, the A3144 Hall Effect sensor is best for precise pole detection. The sensor accurately identifies magnetic poles, ensuring optimal motor performance and efficiency. This precision is use for applications demanding high reliability and control such as in electric vehicles and industrial machinery. Deploying these sensors in motors has led to a longer operational life and reduced maintenance costs by providing accurate feedback to the control systems.

Automation Systems

Incorporating the A3144 Hall Effect sensor in automation systems enhances control precision and operational efficiency. These sensors are good for monitoring the positions of various components, ensuring seamless operations. For example, in automated manufacturing processes, the sensor's ability to detect and measure magnetic fields allows for precise machinery movements. This enhancement leads to increased productivity and reduced error rates.

Magnetic Field Navigation

In navigation systems in robotics and autonomous vehicles, the A3144 Hall Effect sensor elevates positional accuracy by detecting magnetic fields. Its high sensitivity to magnetic fields helps in providing precise directional data. This results in improved navigation and a reduced risk of positioning errors.

Game Controllers

A3144 Hall Effect sensors are increasingly integrated into gaming controllers, enriching the user experience. These sensors enable the precise detection of joystick movements, offering seamless control and responsiveness. This leads to a more immersive gaming experience by providing players with accurate and real-time feedback. Modern game controllers embrace these sensors, enhancing overall gameplay satisfaction and precision.

Frequently Asked Questions [FAQ]

1. What is the use of A3144?

The A3144 is a digital output Hall sensor. When it detects a magnetic field, it outputs low; otherwise, it stays high. A pull-up resistor ensures it remains high without magnetic presence. Common applications includes, motor speed measurement, and proximity detection.

2. What is the Hall-effect of A3144?

The Hall effect in the A3144 generates an electrical signal in response to a magnetic field. When a magnetic field is detected, the output transitions to a low state. Without a magnet, it stays high, supported by the pull-up resistor. This principle is widely used in contactless switches, and rotational sensing systems.

3. How does the A3144 Hall-effect sensor work?

The A3144 sensor switches its output to a low state on detecting a magnetic field and remains in a high state without one. This requires a pull-up resistor to maintain high output when no magnet is present. Such sensors are integral in scenarios providing reliable readings in dynamic environments, such as automotive ignition timing, and industrial machinery monitoring.

4. What is a linear Hall-effect sensor?

Linear Hall effect sensors are extensively utilized in the automotive sector for detecting position elements such as throttles and brakes. They also useful in industrial applications. Uses include monitoring conveyor belts, cylinders, gears, and other moving parts. These sensors offer analog output proportional to magnetic field strength, enabling precise control and feedback in advanced automation and robotics.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

Understanding PT2399 Chips With its Echo Effects and its Delays

on September 25th

SS8050 NPN Epitaxial Silicon Transistor: High Performance for Small Signal Amplification and Switching

on September 25th

Popular Posts

-

What is GND in the circuit?

on January 1th 3264

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2812

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 20th 2628

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2262

-

Comparison Between DB9 and RS232

on January 1th 1879

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1840

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1801

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1794

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1789

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 20th 1778