TB6600HG Stepper Motor Driver: Specifications, Features and Applications

Catalog

TB6600HG description

TB6600HG is a PWM chopper type single-chip bipolar sinusoidal microstepping motor driver. It can achieve forward and reverse rotation control through 2-phase, 1-2-phase, W1-2-phase, 2W1-2-phase, and 4W1-2-phase excitation modes. 2-phase bipolar stepper motors are driven solely by a low-vibration, high-efficiency clock signal.

Alternatives and equivalents:

• TB6600FG

• L6258EX

Specifications of TB6600HG

• Part Status: Active

• Packaging: Tray

• Package / Case: HZIP-25

• Manufacturer: Toshiba

• Operating Supply Current: 4.2 mA

• Operating Supply Voltage: 2 V to 5.5 V

• Load Voltage Rating: 8 V to 42 V

• Number of Outputs: 2 Outputs

• Pd - Power Dissipation: 40 W

• Mounting Style: Through Hole

• Package Length/Width/Height: 29.3mm(Max)/4.5mm/15.7mm

• Product Category: Motor / Motion / Ignition Controllers & Drivers

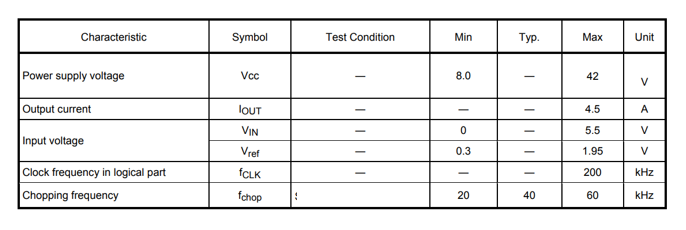

Operating conditions of TB6600HG

(TA = -30°C to 85°C)

Note: Two Vcc terminals should be programmed the same voltage. The maximum current of the operating range can not be necessarily conducted depending on various conditions because output current is limited by the power dissipation PD. Make sure to avoid using the IC in the condition that would cause the temperature to exceed Tj (avg.) =107°C.

The power supply voltage of 42 V and the output current of 4.5 A are the maximum values of operating range. Please design the circuit with enough derating within this range by considering the power supply variation, the external resistance, and the electrical characteristics of the IC. In case of exceeding the power supply voltage of 42 V and the output current of 4.5 A, the IC will not operate normally.

How to connect TB6600HG to the control system?

Power connection: First, make sure to provide appropriate power supply to TB6600HG. When powering TB6600HG, you usually need to connect two pins: VCC (positive power supply) and GND (ground wire). The VCC pin is responsible for providing the voltage required to drive the chip, while the GND pin serves as the reference ground level. We need to ensure that the power supply is stable and meets the specifications of the TB6600HG.

Signal connection: According to the specific needs of the control system, we need to connect the control signal to the corresponding pin of the TB6600HG driver chip. These control signals usually include direction control signals and step pulse signals, etc., which are responsible for instructing how the motor acts, including the direction of rotation and the speed of rotation.

Motor connection: We need to be particularly careful when connecting the motor to the TB6600HG driver chip. The two wires of the motor, usually red and black, represent the positive and negative poles of the motor respectively. The red wire usually connects to the positive terminal of the motor, while the black wire connects to the negative terminal.

Feedback connection (optional): If an encoder is used for feedback control, we also need to connect the output signal of the encoder to the control system. This typically includes the outputs of Phase A, Phase B, and Phase Z (if available).

Grounding: We need to ensure that the common ground wire of all equipment is connected correctly to avoid interference and damage.

Initialization settings: After the connection is complete, we need to initialize the settings of the TB6600HG to ensure that it works correctly. This may include setting current limits, stepping modes, etc.

TB6600HG product features

• Adopt an enlarged radiator for good heat dissipation

• Subdivision setup instructions are printed on the back of the board

• With output short circuit protection function, worry-free use

• Adopt 6N137 high-speed optical coupling to ensure high speed without loss of synchronization

• Output current is steplessly adjustable to meet your various application needs

• Using common anode input mode, there are two input terminals, making wiring more convenient

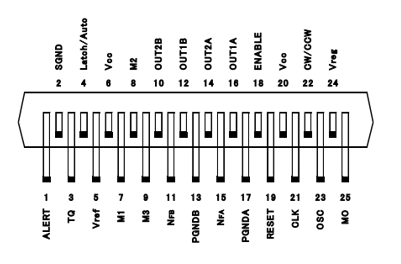

Pin configuration of TB6600HG

Function description of TB6600HG

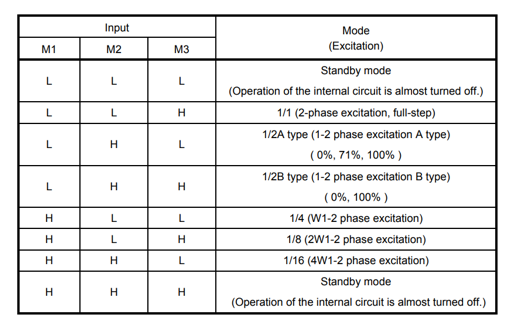

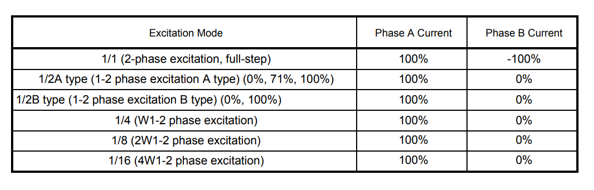

Excitation settings

The excitation mode can be selected from the following eight modes using the M1, M2 and M3 inputs. When M1, M2, or M3 inputs are shifted during motor operation, a new excitation mode initiates from the initial mode, potentially disrupting the continuity of the output current waveform.

Note: To change the exciting mode by changing M1, M2, and M3, make sure not to set M1 = M2 = M3 = L or M1 = M2 = M3 = H.

Standby mode

The operation mode moves to the standby mode under the condition M1 = M2 = M3 = L or M1 = M2 = M3 = H. The power consumption is minimized by turning off all the operations except protecting operation. In standby mode, output terminal MO is HZ. Standby mode is released by changing the state of M1=M2=M3=L and M1=M2=M3=H to other state. Input signal is not accepted for about 200 μs after releasing the standby mode.

Decay mode

Charging and discharging a current in PWM mode typically require about five cycles in OSCM. The 40 percent fast decay mode is initiated by inducing decay within the final two cycles of fast decay mode, with the ratio of 40 percent remaining consistently fixed. The relation between the master clock frequency (fMCLK), the OSCM frequency (fOSCM) and the PWM frequency (fchop) is shown as follows:

fOSCM = 1/20×fMCLK

fchop = 1/100×fMCLK

When Rosc=51kΩ, the master clock=4MHz, OSCM=200kHz, the frequency of PWM(fchop)=40kHz.

Initial mode

When RESET is used, the phase currents are as follows.

Current direction is defined as follows.

OUT1A → OUT2A: Forward direction

OUT1B → OUT2B: Forward direction

Application of TB6600HG

Listed below are some applications of TB6600HG.

• Tail lights

• Hospitality buildings

• Large outdoor LED display

• Alternative to HID lights

• Industrial high-bay lights

• Large format LED backlighting

• Display LED backlighting

• Camera-enabled smartphones

• Step-up or step-down driver topologies

Common faults and solutions of TB6600HG

The following lists some common faults about TB6600HG and their solutions to help you take quick action when encountering faults and safeguard the normal operation of the device.

Failure one: Driver chip overheating

The TB6600HG chip itself is too hot, probably due to excessive load or poor heat dissipation conditions.

Solution: Enhance heat dissipation

We need to add heat sinks or fans on the driver chip and motor to ensure that they can fully dissipate heat while working. At the same time, we need to keep the environment around the driver chip and motor well ventilated to avoid overheating.

Failure two: Motor rotates in the wrong direction

After the motor receives the drive signal, the direction of rotation is not in line with the expected, it may be the control signal is wrong or the drive chip is not properly configured.

Solution: Check the control signal

We need to carefully check the control signals sent to the TB6600HG to ensure that the direction control signal and pulse signal are correct. If a microcontroller is used to send the signals, please check the program code and pin configuration.

Failure three: Motor fails to rotate

The motor does not respond after receiving the drive signal, it may be that the driver chip is not working properly or there is a problem with the connection between the motor and the driver chip.

Solution: Check the power supply and connection

We need to make sure that the power supply of the TB6600HG is normal and the connection between the motor and the driver chip is solid. We check the voltage and current in the circuit by using a multimeter to make sure they are in the normal range.

Failure four: Serious motor heating

The motor generates excessive heat during operation, which may be caused by excessive current or poor heat dissipation.

Solution: Adjust the current setting

If the motor is generating serious heat, we can try to reduce the output current of the driver chip. By adjusting the current setting pin of TB6600HG, we can effectively limit the size of the output current, which in turn reduces the burden on the motor and ensures stable and safe operation of the motor.

Frequently Asked Questions [FAQ]

1. What is the operating temperature range of TB6600HG?

The operating temperature of TB6600HG ranges from -30°C to 85°C.

2. What is TB6600HG?

TB6600HG is a type of stepper motor driver, designed to control stepper motors in various applications such as CNC machines, 3D printers, robotics, and automation systems.

3. What are the key features of TB6600HG?

TB6600HG features include adjustable motor current, step resolution settings, built-in overheating protection, and opto-isolated inputs for signal control.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

Detailed Analysis and Application Guide for the UCC27517DBVR High Performance Low Side Driver

on September 3th

STM32F030K6T6 Comprehensive Guide: High Performance ARM Cortex-M0 Microcontrollers

on September 3th

Popular Posts

-

What is GND in the circuit?

on January 1th 3272

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2815

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 20th 2642

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2265

-

Comparison Between DB9 and RS232

on January 1th 1882

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1846

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1808

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1801

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1799

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 20th 1782