A Complete Guide to the MPX2010DP Pressure Sensor: Manufacturer, Pinout, and Applications

Pressure sensors are major to modern technological advancements and are required in monitoring and control across industries. In this article, we explore the complex details of pressure sensors, focusing on their definition, functionality, and applications. From measuring atmospheric pressure to enhancing system safety, these devices provide serious data that drive efficiency and innovation. By examining historical perspectives and cutting-edge advancements, we aim to offer a wide-ranging guide to understanding and utilizing pressure sensors like the MPX2010DP, and the importance of their significance in the automotive and healthcare sectors.Catalog

Understanding Pressure Sensors

A pressure sensor detects pressure levels and translates them into electrical signals for various applications. This capability allows these sensors to serve main roles in monitoring and control systems. A standard pressure sensor typically includes a sensitive element that measures pressure directly and electronic components that convert this measurement into an electrical output. Depending on the type, pressure sensors can be classified as gauge sensors, differential sensors, and absolute sensors.

Gauge pressure sensors are highly suitable for environments where atmospheric pressure variations need to be considered. Differential pressure sensors are often used in flow measurements and applications requiring precise pressure monitoring between two environments. Absolute pressure sensors are ideal for scenarios where absolute pressure readings are required.

Exploring the MPX2010DP Pressure Sensor

The MPX2010DP is a dual-port silicon pressure sensor, meticulously crafted for applications that include environmental controls and liquid level measurements. Celebrated for its precise and linear voltage output in response to applied pressure, it eradicates the necessity for external compensation. This removes complexity from system architecture, enabling a more streamlined design process.

With a through-hole mounting design, the sensor can be placed vertically on circuit boards, making efficient use of valuable space and adding to its practicality in compact setups. Operating seamlessly within a temperature range of -40°C to 150°C, the MPX2010DP is built to withstand harsh conditions, ensuring dependable performance even under extreme environmental stress. Furthermore, its 4-pin configuration enhances ease of integration, allowing for straightforward and robust connectivity in various electronic systems.

Who Manufactures the MPX2010DP Pressure Sensor?

NXP Semiconductors, renowned for producing the MPX2010DP pressure sensor, has a rich legacy beginning as the semiconductor division of Philips in 1953. Rebranded in 2006, NXP is headquartered in Eindhoven, Netherlands. The company’s groundbreaking innovations radiate through various sectors, such as smart homes, connected vehicles, industrial IoT, and communication infrastructures, influencing modern technology on multiple fronts.

NXP employs over 30,000 individuals globally, tapping into a diverse talent pool to fuel technological progress. Collaborative efforts with major companies, such as Samsung, Apple, Sony, Siemens, and Foxconn, emphasize their capacity to deliver state-of-the-art solutions. NXP stays ahead of technological trends and efficiently addresses emerging market demands.

NXP's dedication to spearheading advancements in smart technologies shines through their extensive applications. In smart home environments, their semiconductor solutions enable secure connections and efficient energy management. Connected vehicle systems often benefit from NXP’s advanced sensor technologies, enhancing in-vehicle experiences. Industrial IoT solutions developed by NXP contribute to operational efficiency and robust communication infrastructures.

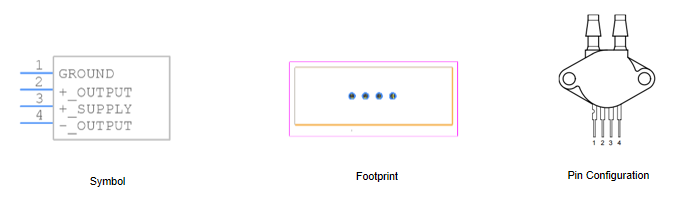

Symbol, Footprint, and Pin Configuration of MPX2010DP

The MPX2010DP sensor features a four-pin configuration that broadens its applicability across a spectrum of electronic systems.

- Pin 1 (GND): Ground. Acts as the sensor's reference point, finalizing the circuit's return path.

- Pin 2 (+Vout): Positive Voltage Output. Conveys the sensor's output signal, reflecting the measured parameter.

- Pin 3 (Vs): Power Supply. Provides the operating voltage, ensuring the sensor's precise functionality.

- Pin 4 (-Vout): Negative Voltage Output. Works with the positive output, suitable for differential measurements.

MPX2010DP Pressure Sensor Features

The MPX2010DP pressure sensor offers a refined blend of a monolithic silicon diaphragm integrated with strain gauges and thin-film resistors. This combination elevates both accuracy and stability, making the sensor ideal for applications that demand precise pressure measurements. It provides a highly accurate linear voltage output, directly proportional to the applied pressure, which is valuable in various serious settings.

High Accuracy and Stability

The sensor's sensitivity is heightened by the integration of strain gauges and thin-film chips on a silicon diaphragm. This ensures it delivers consistent performance over time. Precision and reliability are used in environments where measurement errors can lead to substantial issues, especially in medical devices or automotive applications. Industries consistently rely on sensors that offer unwavering accuracy to avoid malfunctions and safeguard both safety and efficiency.

Laser Trimming for Span and Offset Alignment

Laser trimming technology is employed to fine-tune both span and offset alignment in the MPX2010DP. This detailed process corrects minor manufacturing variations, enhancing sensor uniformity and performance. Similar to adjusting mechanical components in engineering to eliminate tolerances, the precision of laser trimming delivers consistent sensor outputs. This allows for greater confidence in the sensor readings across multiple applications.

Temperature Compensation

To ensure measurement precision across various conditions, the sensor incorporates temperature compensation mechanisms. Fluctuations in temperature can suggestively impact sensor performance. The ability to function accurately under varying thermal conditions opens up wider application possibilities—from climate control systems to industrial automation. Temperature compensation thus ensures reliability and broad utility in diverse settings.

Ease of Use in Automated Assembly

The sensor’s tape and reel format support effortless integration into automated assembly processes. This packaging method streamlines installation, reducing manual handling and errors. In modern manufacturing, where precision and efficiency are requisite, easy-to-handle components ensure that production lines operate smoothly. Adopting such automated systems minimizes human error and maximizes throughput, reflecting the sensor's convenience in contemporary manufacturing environments.

MPX2010DP Pressure Sensor Technical Parameters

|

Product Attribute |

Attribute Value |

|

Manufacturer |

NXP

Semiconductors |

|

Package

/ Case |

4-SIP

Module |

|

Packaging |

Tray |

|

Part

Status |

Active |

|

Accuracy |

1% |

|

Operating

Pressure |

10

kPa |

|

Operating

Temperature |

-40°C

~ 125°C |

|

Supply

Voltage |

10V ~

16V |

|

Operating

Supply Voltage |

10V |

|

Output

Type |

Analog |

|

Port

Type |

Dual

Axial Barbed |

|

Mounting

Style |

Through

Hole |

|

Pin

Count |

4 |

|

Product

Category |

Pressure

Sensors |

Methods for Assessing the MPX2010DP Pressure Sensor Quality

Examining the quality of the MPX2010DP pressure sensor entails a series of detailed steps to verify its functionality and accuracy.

Bridge Detection for Circuit Verification

Firstly, initiate the process with bridge detection via a Wheatstone full-bridge circuit. This technique allows for verification of the sensor’s internal circuitry through precise measurements. Use a multimeter to check the input and output impedance. If the multimeter shows infinite impedance, it indicates a potential open circuit or incorrectly configured pins. Such meticulous impedance measurements help identify internal issues, ensuring there are no basic connectivity problems.

Pressure Detection and Sensitivity Evaluation

Secondly, advance to pressure detection by powering the MPX2010DP sensor. Introduce a controlled pneumatic pressure source and observe the voltage variations at the sensor's output. Substantial voltage changes in response to applied pressure confirm the sensor's sensitivity. This test highlights the sensor's accuracy and is a testament to its suitability for applications where precision is respected and dependability is cherished.

Uses of MPX2010DP Pressure Sensor

Monitoring Serious Systems

The MPX2010DP pressure sensor demonstrates its adaptability by effectively overseeing dangerous systems within various industries. In aircraft, it meticulously tracks hydraulic and oxygen systems, playing a major role in enhancing safety and performance. Understanding the fluid dynamics within hydraulic systems facilitates timely maintenance and preemptive troubleshooting, securing operational reliability.

Automotive Engine Performance

In automotive settings, the MPX2010DP sensor is major for measuring air intake pressure within engines. This precise measurement provides a comprehensive assessment of engine performance and fuel efficiency. By optimizing air-fuel mixture ratios through real-time data, it aids in reducing emissions and improving engine durability.

Environmental Monitoring

The MPX2010DP's capabilities extend to meteorology, where it monitors atmospheric pressure and water levels. Accurate pressure data are useful for predicting weather patterns and planning for climatic changes. Its robust design ensures reliability even in harsh conditions, making it invaluable for meteorologists and environmental scientists. Water resource managers use the sensor to monitor water pressure in reservoirs and pipelines, promoting efficient water distribution and early leak detection.

Medical Applications

In medical fields, the MPX2010DP sensor is basic for monitoring main signs like blood pressure and respiration. Its precision enhances patient care by providing reliable data for dangerous medical decisions. Integration of these sensors into medical equipment improves the safety and reliability of devices used in surgeries and intensive care units. Medical device manufacturers continuously seek such innovations to elevate the accuracy and functionality of health monitoring systems.

Frequently Asked Questions [FAQ]

1. What is an MPX10DP Pressure Sensor?

The MPX10DP is a dual-port, uncompensated silicon pressure sensor tailored for environmental and level control systems. This sensor delivers precise, linear voltage outputs directly proportional to the pressure applied. Such characteristics make it exceptionally suitable for applications demanding meticulous pressure readings.

2. What Are Some Common Applications for the MPX10DP Sensor?

The MPX10DP finds extensive use across several sectors HVAC systems, medical devices, industrial process controls, and automotive systems. In HVAC systems, accurate pressure monitoring contributes to optimal system performance and energy efficiency, creating a comfortable indoor environment. In automotive applications, it aids in measuring air pressure in engine manifolds and monitoring fuel tank pressure, enhancing vehicle performance.

3. What Should I Do if the Output Voltage of the MPX2010DP Sensor is Not Within the Specified Range?

If the output voltage of the MPX2010DP sensor deviates from the specified range, recalibration is conclusive. Start by applying a known differential voltage, then fine-tune the readings by the actual output. This procedure ensures the sensor's accuracy, which is requisite in scenarios such as medical devices where precise pressure readings can suggestively impact patient safety and well-being.

4. How Does a Pressure Sensor Work?

A pressure sensor operates by translating pressure into a minor electrical signal, often in the form of a 4-20 mA or 0-5 V signal. This translated signal is then relayed and displayed, earning them the term 'pressure transmitters.' The underlying mechanism relies on the deformation of the sensor's diaphragm under pressure, altering its electrical resistance proportional to the applied pressure. This method plays a major role in various industry's automotive systems maintaining correct tire pressure enhances safety and fuel efficiency. Industrial controls ensure optimal system operation through precise pressure measurements.

About us

ALLELCO LIMITED

Read more

Quick inquiry

Please send an inquiry, we will respond immediately.

Everything You Need to Know About the TNY268PN Power Switcher

on September 28th

2N5486 Transistor: Pin Configuration and Common Applications

on September 28th

Popular Posts

-

What is GND in the circuit?

on January 1th 3098

-

RJ-45 Connector Guide: RJ-45 Connector Color Codes, Wiring Schemes, R-J45 Applications, RJ-45 Datasheets

on January 1th 2667

-

Understanding Power Supply Voltages in Electronics VCC, VDD, VEE, VSS, and GND

on November 14th 2202

-

Fiber Connector Types: SC Vs LC And LC Vs MTP

on January 1th 2179

-

Comparison Between DB9 and RS232

on January 1th 1801

-

What Is An LR44 Battery?

Electricity, that ubiquitous force, quietly permeates every aspect of our daily lives, from trivial gadgets to life-threatening medical equipment, it plays a silent role. However, truly grasping this energy, especially how to store and efficiently output it, is no easy task. It is against this background that this article will focus on a type of coin cell battery that may seem insignificant on the...on January 1th 1773

-

Understanding the Fundamentals:Inductance Resistance, andCapacitance

In the intricate dance of electrical engineering, a trio of fundamental elements takes center stage: inductance, resistance, and capacitance. Each bears unique traits that dictate the dynamic rhythms of electronic circuits. Here, we embark on a journey to decipher the complexities of these components, to uncover their distinct roles and practical uses within the vast electrical orchestra. Inductan...on January 1th 1726

-

CR2430 Battery Comprehensive Guide: Specifications, Applications and Comparison to CR2032 Batteries

What is CR2430 battery ?Benefits of CR2430 BatteriesNormCR2430 Battery ApplicationsCR2430 EquivalentCR2430 VS CR2032Battery CR2430 SizeWhat to look for when buying the CR2430 and equivalentsData Sheet PDFFrequently Asked Questions Batteries are the heart of small electronic devices. Among the many types available, coin cells play a crucial role, commonly found in calculators, remote controls, and ...on January 1th 1671

-

What Is RF and Why Do We Use It?

Radio Frequency (RF) technology is a key part of modern wireless communication, enabling data transmission over long distances without physical connections. This article delves into the basics of RF, explaining how electromagnetic radiation (EMR) makes RF communication possible. We will explore the principles of EMR, the creation and control of RF signals, and their wide-ranging uses. The article ...on January 1th 1667

-

Comprehensive guide to hFE in transistors

Transistors are crucial components in modern electronic devices, enabling signal amplification and control. This article delves into the knowledge surrounding hFE, including how to select a transistor's hFE value, how to find hFE, and the gain of different types of transistors. Through our exploration of hFE, we gain a deeper understanding of how transistors work and their role in electronic circu...on November 14th 1621