on January 15th

523

7-Segment Display: Pin Assignment, Operating Principle, and Datasheet

The Seven Segment Display, a classic in the realm of display devices, boasts a history as intriguing as its structure is straightforward. Its invention marks a cornerstone in electronic displays, driven by simplicity, clarity, and ease of control. In this article, we delve deep, unraveling the seven-segment display's principles, history, structure, and pin configuration. We explore its function selection, type classification, and working principle. We decode its encoding method and chart its extensive application fields, all while analyzing how this technology adapts and evolves in the ever-changing electronic display landscape.

Catalog

Figure 1: Seven-Segment Display

This device, rooted in LED technology, is a marvel of engineering simplicity and utility. Seven LED units, each a "segment," arrayed in a figure of eight, often accompanied by an extra dot for decimals or colons. Each segment, independently controlled, combines to display numbers 0 to 9, letters, and symbols. This ingenious design lends itself to a variety of uses—from digital clocks to calculators, from electronic panels to hexadecimal displays.

Technically speaking, it's all about current control. LEDs light up as electrons and holes merge, emitting photons. Control the electricity, and you control the message. Historically, the concept dates back to the early 20th century, intertwined with telegraph technology's evolution. Pioneers like Carl Kingsley played pivotal roles, setting the stage for the seven-segment display's rise over dot-matrix predecessors.

Comparatively, dot matrices rely on dot arrays for character display, whereas seven-segment displays use segment combinations—simpler, and more readable. Technological strides transformed the display from mechanical turntables and light-emitting tubes to today's LED brilliance. Modern iterations boast low power, long life, and high reliability, with visual enhancements like color variation and brightness adjustment.

The journey of the seven-segment display mirrors the broader narrative of display technology—constant striving for efficiency, economy, and intuitiveness. While newer technologies like LCD and OLED have their niches, the seven-segment display holds its ground, unmatched in delivering simple, intuitive digital information.

A seven-segment display, at its core, consists of seven light-emitting diodes (LEDs) arrayed to form the shape of an "8", with each LED acting as a distinct segment (typically labeled A to G). These segments can craft numbers from 0 to 9 and various letters and symbols through diverse combinations. The efficiency of LEDs, predominantly emitting light rather than heat, stands in stark contrast to traditional PN junction diodes, making them a preferred choice in display technology. Differing from liquid crystal displays (LCDs), LED displays emit light directly, whereas LCDs create images by manipulating a backlight to traverse a liquid crystal layer.

When we dissect the structure, seven-segment displays branch into two categories: common anode and common cathode. In the common anode configuration, the anodes of all LED segments are interconnected; conversely, in the common cathode type, it's the cathodes that are unified. The selection between these types hinges on the circuit's design and the underlying control logic.

Figure 2: Seven-Segment Display

Control over each LED segment is meticulously executed through specific pins. Consider a typical seven-segment LED display: beyond the pins governing the seven main segments, there's often an additional pin dedicated to the decimal point (denoted as DP). Here's an illustrative pin configuration for a standard seven-segment LED display. In practical scenarios, managing these pins generally involves a microcontroller or an integrated circuit, like a BCD to seven-segment decoder. This decoder translates binary-encoded numbers into the corresponding display on the seven-segment LED. For instance, to showcase the number "2", the decoder activates segments a, b, g, e, and d.

The following is an example pin configuration for a standard seven-segment LED display:

|

Pin number

|

Pin name

|

Description

|

|

1

|

e

|

Controls the lower left LED

|

|

2

|

d

|

Controls the bottom LED

|

|

3

|

DP

|

Controls decimal point LED

|

|

4

|

c

|

Control the lower right LED

|

|

5

|

g

|

Controls the middle LED

|

|

6

|

b

|

Control the upper right LED

|

|

7

|

a

|

Controls the top LED

|

|

8

|

f

|

Control the upper left LED

|

|

9/10

|

Common

|

Common anode/common cathode connection

point

|

Boasting a simplistic structure yet endowed with potent functionality, the seven-segment display, through various pin configurations and control logic, adeptly exhibits numbers and simple characters across a spectrum of electronic devices. Compared to LCDs, LED displays can be brighter and clearer in some applications, especially where low power consumption and high contrast are important.

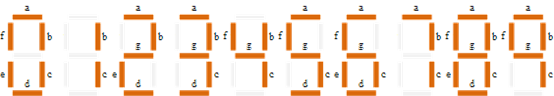

Figure 3: Digital Segments for all Numbers

Seven-segment displays, primarily utilized for showcasing numbers and certain characters, are composed of seven LED segments arranged in an "8" formation, augmented by an eighth LED for the decimal point. This configuration makes them particularly adept at displaying decimal numbers, including those with decimal points. In complex scenarios, like multi-digit displays, this is achieved by aligning multiple seven-segment displays in parallel.

At the heart of these displays lies the LED (Light Emitting Diode), a solid-state optical device operating on the electroluminescence principle of the pn junction. When current flows through an LED, excited electrons and holes merge, releasing energy as visible light. The LED's color hinges on the semiconductor material and specific impurities used in the pn junction. For instance, red LEDs might use aluminum gallium arsenide (AlGaAs), while green or blue LEDs might employ indium gallium phosphide (InGaN).

Selecting LEDs for a seven-segment display involves several critical considerations.

Cost-Effectiveness: With varying prices among LED types, selection should align with application requirements and budget constraints.

Lifespan: While LEDs are renowned for longevity, lifespan can differ substantially based on type and quality.

Size: LED size dictates display size and resolution; smaller LEDs suit compact designs, and larger ones fit applications needing bigger displays.

Color Selection: LED color impacts both aesthetics and visibility, with red and green LEDs generally more noticeable across environments, unlike some less discernible colors like blue in daylight.

Compatibility with Electronic Components: The voltage and current specifications of LEDs must be compatible with other circuit components to ensure system stability and efficiency.

The efficacy and impact of seven-segment displays in the digital display arena largely depend on LED selection. Proper choice of LEDs enhances display performance, ensuring cost efficiency and long-term reliability, blending a mix of technical precision with practical considerations in a concise, clear-cut manner.

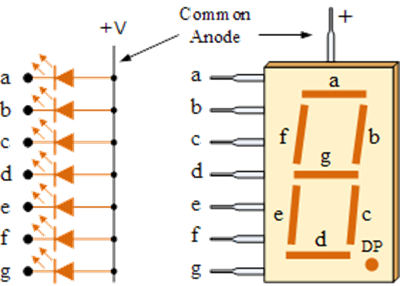

Seven-segment LED displays bifurcate into two primary categories: common anode and common cathode, distinguished by their LED connections and circuit configurations.

Common Anode Display: Here, the anodes (positive terminals) of all LED segments converge at a common point, typically linked to the power supply's positive terminal. Each LED segment's cathode (negative electrode) is managed via a control circuit. To illuminate a specific segment, its cathode must be grounded or receive a negative voltage. The common anode setup simplifies circuit design; all anodes are united, necessitating just one connection to energize all segments.

Figure 4: Common Anode Configuration

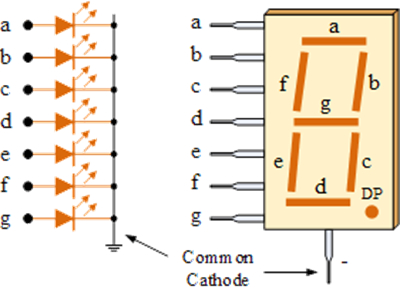

Common Cathode Display: In this variant, the cathodes of all LED segments are interconnected, usually to the power supply's negative terminal. Activating a segment requires applying a positive voltage to its anode. This model fits certain circuit designs better, particularly when segment control hinges on the anode.

Figure 5: Common Cathode Configuration

Circuit design demands distinct driving logic for each type. For common anode displays, controllers must deliver ground or negative voltage for LED illumination. Common cathode displays, on the other hand, require controllers to supply positive voltage. Practically speaking, common-anode displays often gain preference. They align seamlessly with positive logic systems (like TTL circuits), lighting up when the output soars high. Moreover, they're adept at handling higher source currents, making them ideal for high-current-demand applications.

The decision between display types rests on the specific application's circuit design and control logic. Sometimes, the streamlined design and compatibility of common-anode displays win out. Other times, the unique circuit benefits of common-cathode displays make them the superior choice. In any case, in order to achieve the best display performance and circuit efficiency, to achieve the fusion of technical precision and practical application, we must choose the appropriate type.

At the heart of a seven-segment display lie seven LED units, meticulously arranged in an "8" pattern, accompanied by an extra LED for the decimal point. These LEDs illuminate based on the intrinsic properties of their semiconductor materials. Delving into how these units function, each one is a diminutive light-emitting diode, glowing when forward-biased. This biasing is crucial; it allows electron movement between the p-region and n-region of the semiconductor. As electrons transition from a high to a low energy level, they emit photons - visible light. This process, known as electroluminescence, is central to the LED's operation.

The intensity of an LED's glow hinges on the forward current's magnitude. Higher currents heighten electronic transitions and, consequently, light output. However, they also amplify the LED's thermal load, potentially curtailing its lifespan. Therefore, precise current control is imperative. This is typically achieved through a current-limiting resistor or a constant-current drive circuit, integrated between the LED and the power source.

To manifest numbers or characters, the seven-segment display's circuit selectively activates or deactivates specific LED segments. For instance, displaying "1" necessitates lighting only the upper and lower right segments (b and c). Control of these segments often managed via a microcontroller, a seven-segment decoder, or simple logic circuits, is pivotal. The circuit's primary role is to supply the appropriate forward current to each LED, orchestrating its illumination in accordance with the display requirements.

Circuit design for these displays necessitates careful consideration of LED current and voltage specifications, display type (common anode or common cathode), and effective current control and distribution strategies. The underlying principle of a seven-segment display is a tapestry of sophisticated electronic engineering. It weaves together LED electroluminescence, brightness control techniques, and intricate circuit design to yield a clear, reliable digital and character display.

In the realm of seven-segment displays, the crux of displaying diverse numbers and characters lies in a specific encoding method. These methods meticulously dictate which LED segments should illuminate to craft the desired numeral or character. Each part of the display is usually labeled a, b, c, d, e, f, g, with an additional dp for the decimal point. The type of display, be it a common anode or common cathode, fundamentally influences the encoding method.

Figure 6: Seven-Segment Display

Delving into common anode displays, the mechanism is straightforward yet precise. Here, a segment lights up when its pin connects to the ground, necessitating a 'low' setting to display a particular number. Take "0", for example. To represent this, segments a, b, c, d, e, and f are activated, while g remains dormant. Thus, "0" translates to the encoding "0111111", with its hexadecimal counterpart being 3F.

Conversely, common cathode displays invert this logic. A segment illuminates upon receiving positive voltage, requiring a 'high' setting for each desired segment. Applying this to "0", its encoding is reversed to "1000000", mirrored in hexadecimal as 40. These encodings, integral in practical applications, often involve microcontrollers or dedicated decoder chips. A typical example is a BCD (Binary Decimal) to seven-segment decoder, which autonomously selects the correct segments based on input, alleviating the burden of manual coding.

Here is an example of typical encoding of the numbers 0 through 9 on common anode and common cathode displays:

|

Digital

|

common anode coding (gfedcba)

|

common cathode coding (gfedcba)

|

|

0

|

0111111

|

1000000

|

|

1

|

0000110

|

1111001

|

|

2

|

1011011

|

0100100

|

|

3

|

1001111

|

0110000

|

|

4

|

1100110

|

0011001

|

|

5

|

1101101

|

0010010

|

|

6

|

1111101

|

0000010

|

|

7

|

0000111

|

1111000

|

|

8

|

1111111

|

0000000

|

|

9

|

1101111

|

0010000

|

In this encoding matrix, each digit's gfedcba configuration corresponds to the seven LEDs. For instance, "0111111" signifies all but the g segment lit, showcasing "0". Implementing these codes in a real circuit requires direct programming into a microcontroller or decoder, a crucial step in controlling the display.

Circuit design and programming hinge on a profound understanding of these codes. Different encoding schemes not only influence circuit design but also the complexity of the control logic. In any project involving a seven-segment display, mastering these codes is essential. Accurate coding paves the way to achieving the desired display functionality, blending technical know-how with practical application.

Seven-segment displays, renowned for their simplicity and ease of operation, find extensive use across a spectrum of electronic devices. These range from rudimentary digital displays to more elaborate information presentations. The method of application flexibly adapts to the intricacies and functional demands of the project at hand. In basic applications, the utility of a seven-segment display emerges in its ability to be driven directly by a 7-segment counter integrated circuit (IC), such as the CD4026. This particular IC, a counter/decoder, is engineered to drive a seven-segment display directly, translating input counting pulses into visible numbers.

This approach sidesteps the need for complex microcontroller or microprocessor support. Its usefulness shines in simple digital display projects such as digital counters and clocks. Contrastingly, more complex endeavors, like displaying varied characters or dynamic effects, necessitate pairing seven-segment displays with a microcontroller (MCU) or microprocessor (MPU). Here, each LED segment’s pins interconnect with the MCU/MPU’s input and output (I/O) pins, while the common anode or cathode pin links to power or ground, depending on the display type.

This setup allows the microcontroller to precisely dictate the state of the I/O pins, thereby controlling the display. For instance, displaying "0" on a common cathode display requires illuminating all segments except "g", achieved by setting the I/O pins to 11000000 (binary). The logic for a common anode display stands in stark contrast.

Whether it's a counter IC or a microcontroller at the helm, orchestrating a seven-segment display necessitates meticulous programming of the circuit's state. In microcontroller use, this typically involves crafting specific code. This code dictates the activation sequence of I/O pins and how the display morphs in response to incoming data. The versatility of seven-segment displays, spanning from straightforward counting to intricate character and graphic representations, hinges on selecting the apt driving methodology and control strategy. It is important for designers and engineers to master the nuances of different control technologies and coding. It's the key to devising an efficient and impactful display solution.

Seven-segment displays, revered for their unique functions and advantages, find widespread use in myriad fields. They span from the straightforward task of basic information display to the more demanding realm of complex data presentation. Their appeal lies in the blend of simplicity, cost-effectiveness, and superb readability. In the sphere of public information display and control panels, these displays are particularly prized. The visibility of large fonts is very important here, for example on public transport information boards, elevator floor indicators, and countless control panels. In these contexts, the sizeable font and lucidity of seven-segment displays are indispensable for clear public directives and messaging.

Small electronics companies benefit immensely from these displays too. Their cost-effectiveness and programmable control simplicity make them a go-to choice for products like economical digital timers, thermometers, and counters. It's not just about basic displays, though. When the situation calls for portraying more intricate numerical values or sensor data, the seven-segment display often joins forces with the four-segment variant. This combo caters to extra functionalities, useful in displaying measurements and status indicators in laboratory instruments or industrial control systems.

Then there's their suitability for low-light scenarios. In dim environments, their brightness and legibility are unmatched, making them ideal for outdoor night-time equipment, security system displays, and emergency indicators. The versatility of seven-segment displays extends their reach to a vast array of projects. Electronic clocks, water levels, various measuring tools, and experimental apparatuses all benefit from their integration. Their ubiquity in consumer electronics is mirrored in their widespread application in the industrial, medical, and scientific research spheres.

These displays, with their hallmark easy-to-read large font, cost efficiency, and broad usage spectrum, have cemented themselves as a fundamental element of electronic display technology. Their presence, ranging from household appliances to complex industrial systems, is ubiquitous. Over time, the importance of seven-segment displays only continues to escalate, highlighting their enduring relevance in an ever-evolving technological landscape.

The seven-segment display, emblematic of electronic engineering history, stands not just as a beacon of technological innovation but as a testament to technology's adaptability in daily and industrial realms. Its journey from a nascent idea to a cornerstone in myriad devices today highlights its enduring reliability and practical efficiency. This display, ubiquitous in both household and complex industrial systems, melds ease of readability, cost-effectiveness, and broad utility into an essential component of electronic display technology.

Its design, an elegant blend of simplicity and efficacy, harnesses seven LED segments to craft visuals of numbers and some letters. This design accomplishes clear communication and slashes manufacturing and upkeep expenses. The seven-segment display's durability and energy thriftiness render it ideal for long-haul uses like public information boards and household appliance panels.

Yet, as new contenders like LCDs and OLEDs emerge, the seven-segment display's realm evolves. Its unique merits, particularly in cost and energy efficiency, anchor its relevance in specialized niches. Peering into the future, as electronic technology marches forward, the seven-segment display is poised to continue its distinct legacy. It promises to contribute to technological progress in a more intelligent, integrated guise, echoing the narrative's intertwining of the simple and the complex.

Share: