What You Need to Know About Electromagnetic Compatibility?

Electromagnetic Compatibility (EMC) is a basic consideration in the design, manufacture, and operation of electronic devices, ensuring they function harmoniously within a shared electromagnetic environment without causing or succumbing to interference. This article digs into the intricacies of EMC, tracing its historical development from a nascent concern in the post-World War II era to an ultimate component of modern electronic engineering. As digital technology proliferates and the density of electronic devices in our personal and professional spheres increases, the potential for electromagnetic interference (EMI) escalates, making robust EMC practices dangerous.This discussion explores the evolution of EMC awareness, the technical foundations of achieving electromagnetic harmony, and the rigorous standards and testing protocols that underpin effective EMC strategies. Through a detailed examination of emission control, susceptibility management, and mitigation techniques like shielding and grounding.

Catalog

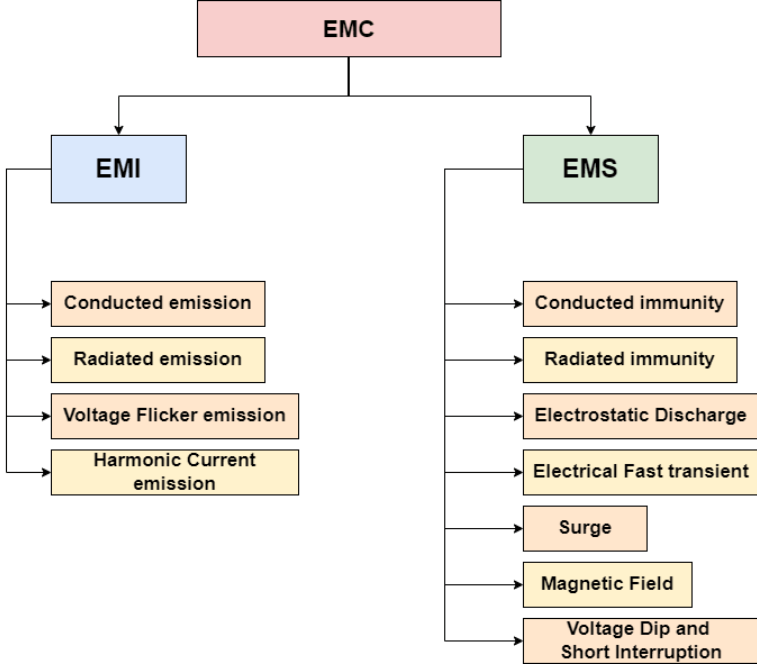

Figure 1: Electromagnetic Compatibility (EMC)

Principles of Electromagnetic Compatibility (EMC)

Electromagnetic Compatibility (EMC) refers to the ability of electronic devices and systems to function properly within their intended electromagnetic environments without causing or being affected by electromagnetic interference. This ensures that electronic equipment does not emit harmful electromagnetic energy that could disrupt nearby systems and is not overly sensitive to interference from other devices.

As the number and complexity of electronic devices continue to grow, the risk of electromagnetic disturbances increases. This makes achieving EMC more challenging than ever. Adhering to EMC standards is useful for maintaining the reliability and performance of electronic systems.

Analyzing EMC thoroughly is noteworthy to ensure consistent device functionality across various environments. This involves careful design, comprehensive testing, and strict certification processes. These steps help mitigate the risks associated with electromagnetic interference, ensuring that devices work as intended, even in environments with potential electromagnetic challenges.

Cultivating EMC Awareness

Electromagnetic Compatibility (EMC) awareness has grown substantially since the post-World War II boom in electronic devices. Primarily, issues like radio interference were seen as minor quirks of technology. However, as electronics became basic to grave sectors such as the military and aerospace, the dangers posed by electromagnetic interference (EMI) became too significant to ignore.

In the 1970s, the introduction of sensitive digital circuits and logic devices highlighted the urgent need to incorporate EMC into design practices. This shift led to the development of strict international standards and regulations aimed at minimizing EMI risks. Organizations like the European Community took the lead in establishing these guidelines to ensure electronic devices could operate safely and reliably.

Today, with the widespread use of mobile communications and advanced digital technologies, EMC has become a core aspect of electronic design and manufacturing. This evolution reflects a deep consideration of the necessity to carefully manage electromagnetic interactions in our increasingly connected and digital world.

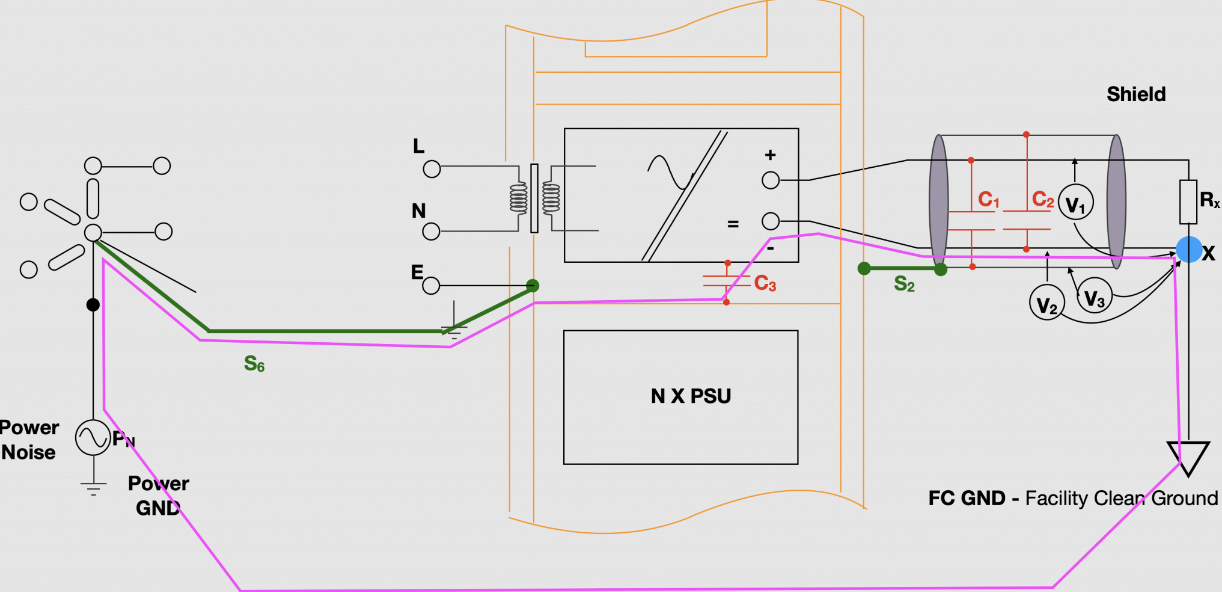

Figure 2: EMC Basics

Considering the Basics of Electromagnetic Compatibility

The primary goal of Electromagnetic Compatibility (EMC) is to ensure that multiple electronic devices can function together in the same environment without causing harmful interference. Achieving this involves two key strategies: controlling emissions and managing susceptibility.

Emission control focuses on limiting the electromagnetic energy a device emits, so it doesn't interfere with nearby equipment. On the other hand, susceptibility management, or immunity, involves strengthening a device's ability to resist external electromagnetic disturbances.

Balancing these strategies is used in EMC engineering. It requires careful design and implementation to ensure devices not only minimize their electromagnetic impact on their surroundings but also remain robust against potential interference. Maintaining this balance is suitable for the reliable performance of advanced electronic systems, especially in environments with a high concentration of electromagnetic activity.

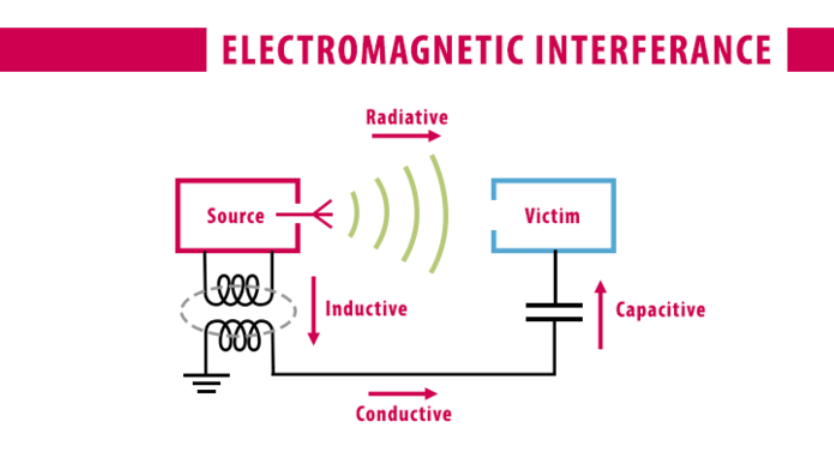

Figure 3: Electromagnetic Interference (EMI)

The Impact of Electromagnetic Interference in Electronics

Managing Electromagnetic Interference (EMI) is required to ensure Electromagnetic Compatibility (EMC). EMI refers to any unwanted electromagnetic energy that disrupts the operation of electronic devices. It can manifest as continuous interference, such as stable radio frequencies or ongoing oscillations, or as impulse interference, which consists of sudden, brief bursts of energy caused by events like lightning strikes or electrostatic discharges.

To combat EMI effectively, it's used to understand the pathways through which it affects electronic systems. These pathways can be conductive, inductive, or radiative. Conductive pathways involve direct transmission through physical connections, inductive pathways arise from magnetic fields inducing currents in nearby circuits, and radiative pathways occur when electromagnetic waves travel through the air.

Engineers use this analyzation during the design phase to anticipate and mitigate potential EMI issues. By proactively addressing these interference pathways, they can enhance the device's electromagnetic compatibility, leading to improved reliability and performance in environments with varying electromagnetic activity.

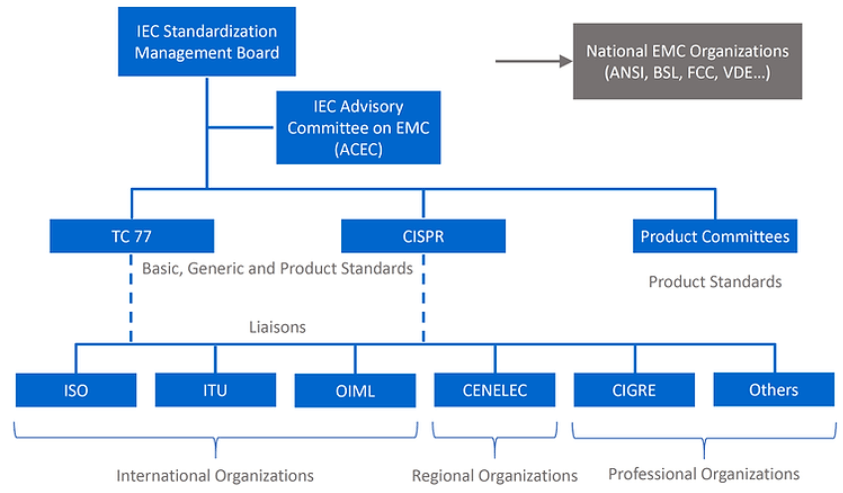

Figure 4: EMC Standards

Mastering EMC Standards for Compliance and Safety

As electronic technologies have advanced, so have the standards designed to ensure devices operate safely and effectively with minimal electromagnetic interference. In the early days, disruptions like taxi radiotelephones interfering with household TV signals were common, highlighting the need for strong EMC regulations.

Today, EMC standards are a basic part of designing and manufacturing electronic devices. They provide clear guidelines that products must follow to ensure they function reliably and don't cause or suffer from interference in various applications, ranging from consumer gadgets to serious industrial systems. These standards reduce the risk of electromagnetic interference and help maintain the integrity and trustworthiness of devices in increasingly complex electromagnetic environments.

Key Aspects of EMC Testing and Certification

Ensuring EMC compliance allows electronic equipment to operate safely and reliably in its electromagnetic environment. This process involves rigorous testing and certification to verify that the equipment complies with established standards.

The testing phase includes a variety of standardized assessments to evaluate both the electromagnetic emissions a device produces and its ability to withstand external interference. Key tests focus on radiated and conducted emissions, as well as immunity to electromagnetic disturbances. These evaluations are suitable to confirm that a device complies with strict international EMC requirements.

Once a device successfully passes these tests, it receives certification—a serious milestone that allows it to enter various markets. The method of testing can differ depending on factors like cost, available resources, and technical needs. Some companies opt for in-house testing, others rely on third-party laboratories, and some use pre-certified components. Each approach has its own set of benefits and challenges, influencing both the efficiency of achieving compliance and the product’s readiness for the global market.

Identifying Common Sources of EMI in Electronic Devices

Effectively identifying and managing sources of Electromagnetic Interference (EMI) is beneficial for ensuring that electronic devices operate reliably and comply with Electromagnetic Compatibility (EMC) standards. EMI can originate from various internal components and external factors, each requiring specific strategies for mitigation.

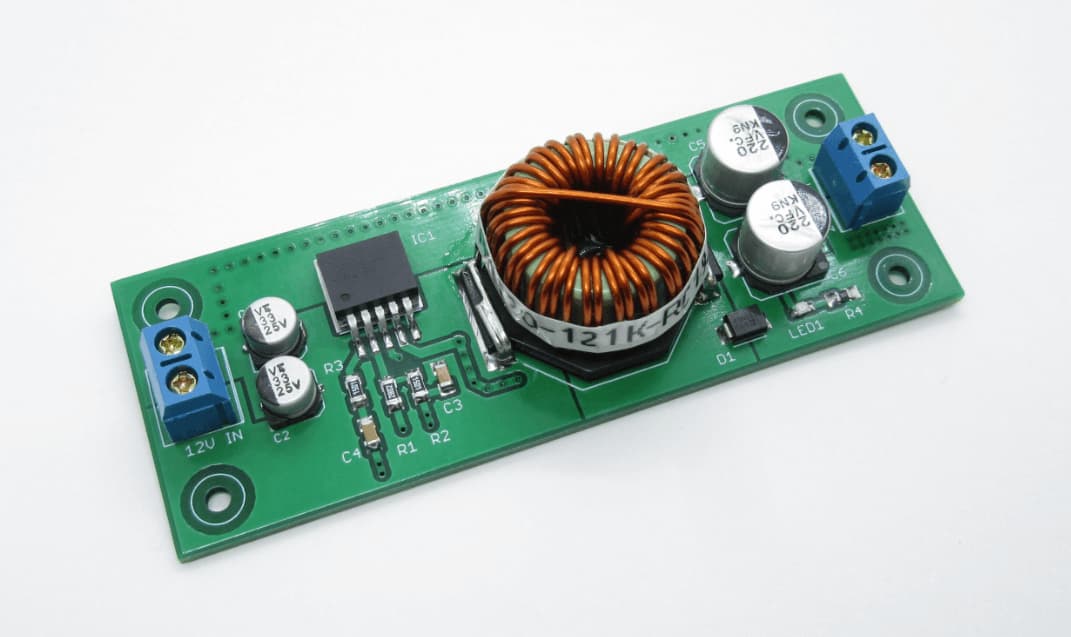

Figure 5: Power Supplies

Power supplies are major contributors to EMI due to the high-frequency noise generated by their switching actions. To reduce this noise, designers can use low-noise switching regulators, incorporate EMI filters like ferrite beads or choke coils, and apply proper layout techniques to minimize loop areas that can act as antennas.

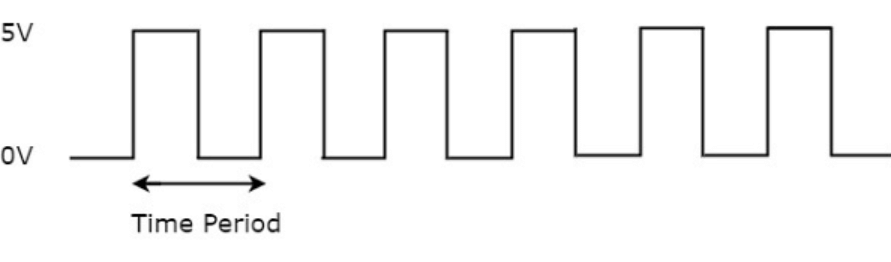

Figure 6: Clock Signals

Clock signals, which regulate the timing of digital circuits, are prone to generating EMI because of their repetitive high-frequency switching. Mitigating EMI from clocks can involve selecting clocks with low jitter, using spread spectrum clocking to distribute the energy over a wider frequency range, and shielding or isolating clock lines to reduce their emissions.

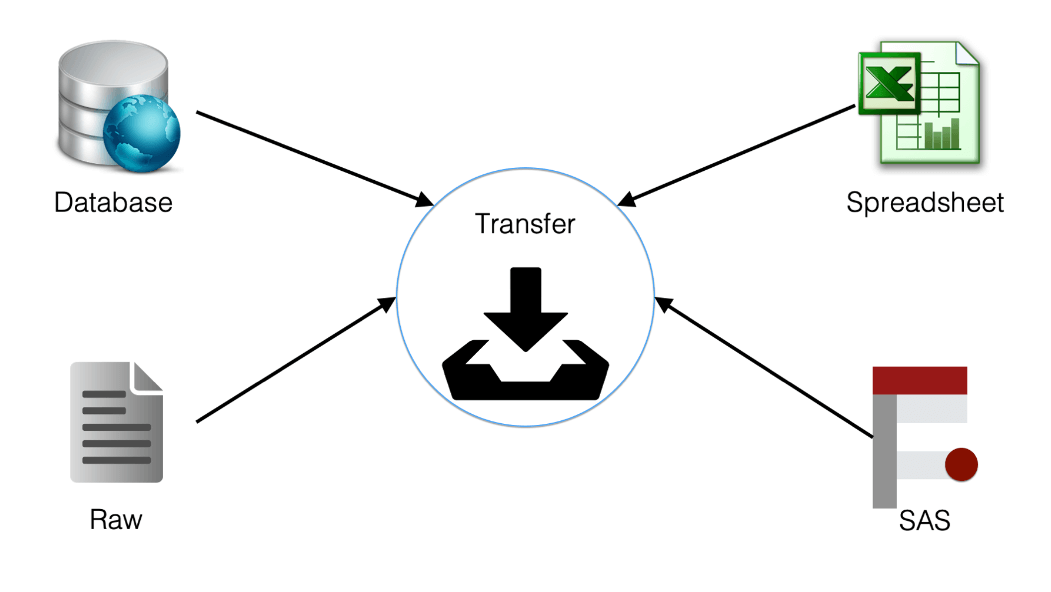

Figure 7: Data Transfer Lines

Data transfer lines are dynamic for communication between components but can also emit or conduct unwanted electromagnetic signals. To manage EMI from these lines, shielded cables can be used, and differential signaling can help cancel out noise. In addition, maintaining controlled impedance on PCB traces and avoiding parallel routing reduces cross-talk and emissions.

Figure 8: Switching Regulators

Switching regulators, which efficiently convert voltages, can introduce noise through their switching processes. To mitigate this, designers may choose regulators that operate at higher switching frequencies, above the sensitive frequency range of nearby components or use snubber circuits to dampen high-frequency oscillations.

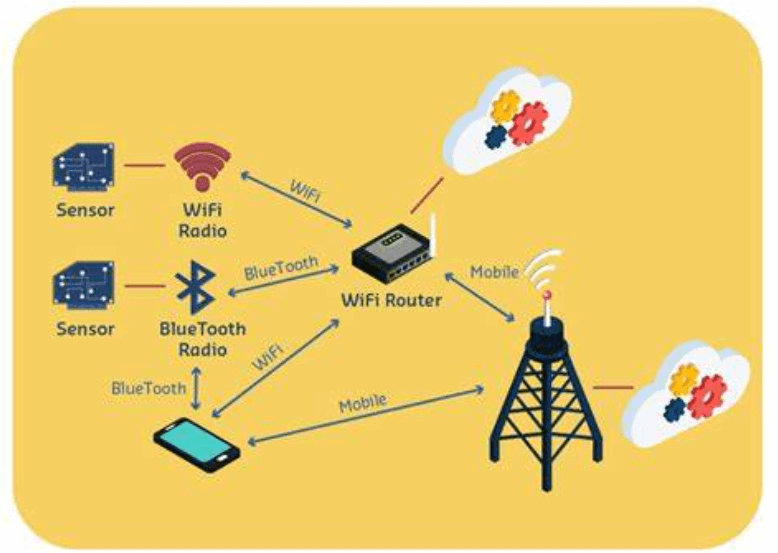

Figure 9: Wireless Communication Modules

Modules like Wi-Fi, Bluetooth, and cellular radios are common sources of EMI that can interfere with other device components. Effective strategies include physically separating these modules from sensitive circuits, applying selective shielding, and carefully designing and placing antennas to minimize interference.

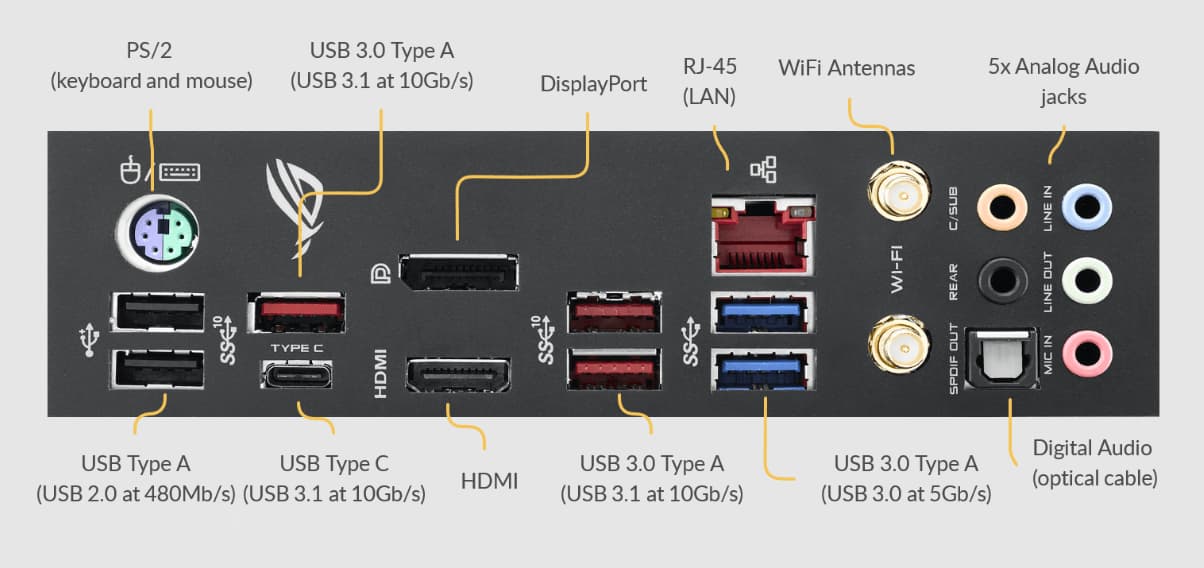

Figure 10: Connectors and Ports

External ports and connectors can serve as entry or exit points for EMI. Mitigating this requires using filtered connectors, adding shielding around connectors, and ensuring that all ports are properly grounded.

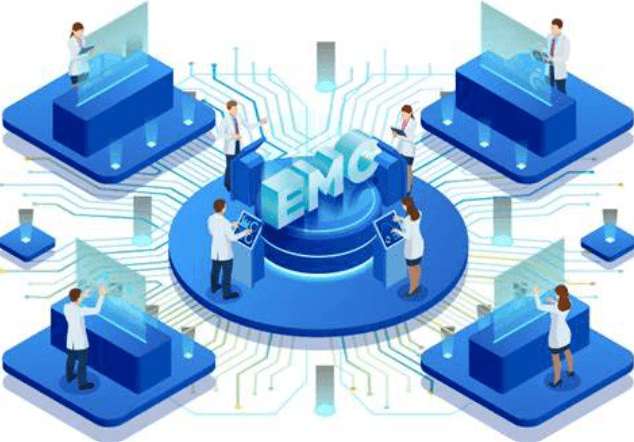

Figure 11: Mechanical Switches and Relays

These components can generate transient EMI during switching operations. To reduce their impact, designers can implement snubber circuits, use arc suppression techniques, or switch to solid-state alternatives, which are less prone to generating EMI.

Effective Techniques for Minimizing EMI in Electronic Designs

Reducing Electromagnetic Interference (EMI) is basic for ensuring that electronic devices meet Electromagnetic Compatibility (EMC) standards. This involves several strategic design practices that help devices function reliably without causing or being affected by electromagnetic disturbances.

• Grounding

Effective grounding is noteworthy for controlling EMI. By providing a safe path for electrical currents to return to their source, grounding stabilizes signal integrity and reduces noise that can contribute to interference. It serves as a reference point for all components in a circuit, ensuring that signals remain stable and less prone to disruption.

• Shielding

Shielding involves surrounding components or cables with conductive or magnetic materials to protect against electromagnetic emissions. This technique prevents external electromagnetic fields from interfering with the internal circuits of the device and also contains the emissions produced by the device itself, reducing its impact on other nearby electronics.

• Filtering

Filters are basic for removing unwanted frequencies from a circuit. By incorporating components like ferrite beads, inductors, and capacitors, designers can selectively block high-frequency noise while allowing desired signals to pass through. This is especially significant in power supplies and signal lines, where noise can significantly affect performance.

• PCB Layout and Component Selection

The physical arrangement of components on a printed circuit board (PCB) and the selection of those components plays a serious role in controlling EMI. Careful routing of traces, maintaining proper spacing between components, and using multi-layer PCBs with dedicated ground and power layers can significantly reduce electromagnetic coupling and minimize signal interference.

• Signal Integrity Analysis

Ensuring that signals propagate correctly through a device is settling for avoiding functional failures and reducing susceptibility to interference. This often involves using simulation software and advanced computational models to analyze and optimize signal paths within the circuit.

• Thermal Management

High temperatures can worsen EMI issues, particularly in densely packed electronics. Effective thermal management—using heat sinks, fans, or thermal pads—helps maintain appropriate operating temperatures and reduces thermal noise, which can contribute to EMI.

• Software Solutions

In some cases, software can be used to predict and mitigate EMI issues during the design phase. Algorithms can simulate electromagnetic fields and their interactions within the circuit, providing insights that help optimize the design for better EMC performance before the hardware is finalized.

Figure 12: Shielding and Grounding Strategies for EMC Compliance

Advanced Shielding and Grounding for Optimal EMC Compliance

Shielding and grounding are required techniques for achieving EMC compliance, particularly in environments prone to significant electromagnetic interference.

Shielding involves encasing sensitive electronic components in materials that block external electromagnetic fields. This prevents these fields from inducing unwanted currents or voltages within the device. Common shielding materials include metal enclosures, conductive paints, and metallic foils, each selected based on its ability to block specific types of electromagnetic radiation.

Grounding stabilizes electrical potentials by connecting electronic circuits to a common reference point, either on the earth or within the device itself. This connection provides a safe path for unwanted currents, helping to minimize noise. Effective grounding methods include using grounding wires, straps, and buses to create a low-resistance path to Earth, ensuring that excess currents dissipate without affecting the device's performance.

Figure 13: EMC in Industrial and Medical Environments

EMC Considerations in Industrial and Medical Environments

In industrial and medical settings, maintaining strict Electromagnetic Compatibility (EMC) is required due to the high stakes involved. A failure in EMC can lead to serious equipment malfunctions, which could jeopardize safety, disrupt operations, and lead to significant financial losses. In healthcare, such failures could even endanger lives.

To address the specific electromagnetic challenges in these environments, sector-specific EMC standards are in place. These standards ensure that devices operate reliably under demanding conditions.

Effective EMC management in these dangerous areas requires a combination of robust shielding techniques, precise electronic design, and continuous EMC testing. Shielding protects sensitive equipment from external electromagnetic interference, while careful design minimizes the risk of internal interference. Regular testing ensures that devices continue to meet the stringent standards required for safe and reliable operation.

Conclusion

The realm of Electromagnetic Compatibility (EMC) represents a risky frontier in electronic design and engineering. As we have seen, EMC encompasses a comprehensive range of strategies and standards designed to mitigate the risks posed by electromagnetic interference (EMI) and ensure that electronic devices perform reliably and safely in increasingly complex electromagnetic environments.

In addition, the ongoing evolution of EMC standards reflects a proactive approach to addressing the challenges posed by advanced digital technologies and their integration into dangerous sectors such as healthcare and industry. As electronic systems become more intricate and ubiquitous, the principles of EMC remain a cornerstone of technological innovation and safety, ensuring that devices not only coexist without interference but also uphold the highest standards of performance and reliability in any electromagnetic setting.

Frequently Asked Questions [FAQ]

1. What is an example of EMC?

An example of Electromagnetic Compatibility (EMC) can be seen in modern smartphones. These devices are designed to function without causing interference to other electronic devices around them, such as radios or pacemakers, while also being immune to the electromagnetic emissions from those same devices.

2. What is the function of EMC?

The primary function of EMC is to ensure that electronic devices operate as intended in their electromagnetic environment without causing or experiencing interference. This involves both the emission of electromagnetic energy, which must be controlled to avoid disrupting other devices, and immunity, which is the device's ability to operate correctly when exposed to electromagnetic disturbances.

3. What is Electromagnetic Compatibility EMC?

Electromagnetic Compatibility (EMC) is a discipline in electrical engineering that deals with the unintended generation, propagation, and reception of electromagnetic energy. The aim is to enable electronic devices to operate in their intended environments without mutual interference.

4. Why is EMC needed?

EMC is focal because it ensures the reliable operation of electronic equipment nearby. In environments dense with electronic devices, like hospitals, offices, or industrial settings, EMC prevents devices from interfering with each other, which could lead to malfunctions or failures that are potentially hazardous.

5. What is the benefit of EMC?

Ensuring EMC in devices offers several benefits including increased reliability, improved safety, and compliance with legal standards. Devices that adhere to EMC standards contribute to a safer and more efficient use of the electromagnetic spectrum, reducing the risk of interference with dangerous equipment and systems.