What Are LEDs and How Do They Work?

LEDs, or Light Emitting Diodes, have changed the way we think about lighting because they save energy, last longer, and can be used in many different ways. Unlike old-fashioned light bulbs that make light by heating a wire, LEDs create light by moving an electric current through a special material called a semiconductor. This way of making light uses much less energy and doesn't get as hot. Because of these benefits, LEDs are used for everything from tiny lights in gadgets to big lighting systems in buildings. They come in various types and colors, each suitable for different uses. Learning how LEDs work and why they are better than traditional lights helps us see why they are becoming so popular today.Catalog

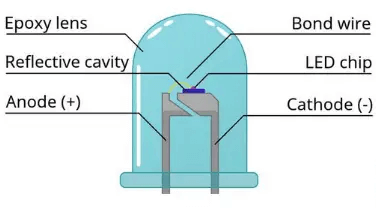

Figure 1: LEDs or Light Emitting Diodes

Definition and Basic Operation

LEDs, or Light Emitting Diodes, are devices that emit light when an electric current passes through them. Each LED is composed of two materials: a P-type with many holes (positive charge carriers) and an N-type with many electrons (negative charge carriers). When a forward voltage is applied, electrons from the N-type region gain energy and move toward the P-type region. At the P-N junction, electrons fill in the holes, releasing energy as light.

Unlike traditional light sources, such as incandescent bulbs that convert electrical energy into heat and then light, LEDs convert electrical energy directly into light. This process is much more efficient, producing less heat and using less energy. Consequently, LEDs are preferred for their energy efficiency and long lifespan, requiring less frequent replacements and offering sturdier performance.

Types of LEDs

Lamp Type LEDs (Leaded)

Figure 2: Lamp Type LEDs (Leaded)

Lamp Type LEDs (Leaded) are a basic type of Light Emitting Diodes (LEDs) with metal legs, also called leads, which connect the LED to an electrical circuit. These LEDs are usually covered by a small, colored plastic bulb. This bulb has a few functions. It spreads the light more evenly, so it doesn’t shine in just one direction. It also protects the tiny parts inside the LED from damage and keeps out dust and moisture.

Leaded LEDs have a simple design, which makes them very useful and easy to use in many electronic projects. Because of this straightforward design, they are often used as indicator lights to show if a device is on or off. You can also find them in digital displays, like those on calculators and clocks, where they help show numbers and other information.

For decorative lighting, leaded LEDs are a favorite because they are easy to set up and can be used to create many different lighting patterns. The metal legs make it simple to attach them to circuit boards or connect them using breadboards for testing. This makes them popular with both hobbyists and professional engineers. They come in many colors and sizes, adding to their usefulness in creative and practical lighting setups.

Chip Type LEDs (Surface Mount)

Figure 3: Chip Type LEDs (Surface Mount)

Chip Type LEDs (Surface Mount) are a modern improvement in LED technology, made to be attached directly onto printed circuit boards (PCBs). They are much smaller and more efficient than traditional Lamp Type LEDs, making them perfect for small electronic devices like smartphones, tablets, and LED TVs.

The main benefit of Chip Type LEDs is their small size and efficiency. Because they are compact, they can be placed close together on PCBs. This allows for the creation of complex electronic designs that do many different things. This close placement is very helpful for modern devices that need to work well within a small space. Chip Type LEDs also use energy better. They turn more electricity into light with less heat, which makes them last longer and use less power. This is especially useful in devices that run on batteries, where saving energy is very important.

The surface mount technology (SMT) used for Chip Type LEDs allows machines to place them quickly and accurately on circuit boards. This speeds up the manufacturing process and lowers production costs. Also, this method ensures that LEDs are placed consistently and reliably, which is important for the devices to work properly and last a long time.

Both types of LEDs operate on the same basic principle: producing light when an electrical current passes through a special material inside them. The choice between Lamp Type and Chip Type LEDs depends on project requirements such as size, efficiency, and integration ease.

Wavelength and Color

The color of an LED is determined by the materials used to make it, which emit different colors of light when electricity flows through them. Two main factors influence an LED's color:

Peak Wavelength (λP)

Figure 4: Graph Showing the Peak Wavelength (λP) of an LED

Peak Wavelength (λP) is the wavelength at which an LED emits the most light. For example, a red LED usually shines brightest at around 630 nanometers. This means the LED produces its strongest red light at this wavelength.Knowing the peak wavelength is very useful for different applications. It determines the color and brightness of the LED light. To find the peak wavelength, we measure the LED's light spectrum and locate the point where the light is the most intense. For instance, in screen technology, the exact peak wavelength helps produce the right colors. In plant lights, the peak wavelength should match the wavelengths that plants absorb best to help them grow better.

The peak wavelength also affects how LEDs are made. Engineers can change the materials and design of the LED to get the desired peak wavelength, making the LED work better for specific uses. This involves choosing the right semiconductor materials because these materials determine the energy and wavelength of the light emitted.

Dominant Wavelength (λD)

Figure 5: A Chart Showing the Dominant Wavelength (λD) of an LED

Dominant Wavelength (λD) is a basic idea in the study of color, especially when understanding how human eyes see light from LEDs and other light sources. The dominant wavelength is the color that people see most clearly when they look at a light source, even if that light is made up of several different colors. This measurement matters because human vision combines these multiple colors into one main color that we perceive. When an LED emits light, it usually does so across a range of colors. These individual colors mix together, and the dominant wavelength is the color that stands out the most to the human eye. Finding this color is not always easy because it depends on the specific mix and strength of the different colors. This process involves detailed calculations that consider how sensitive human eyes are to different parts of the light spectrum.

To find the dominant wavelength, a device called a spectrometer is used to study the light from the LED. The data collected shows how strong the light is at each color. This information is then plotted on a chromaticity diagram, which is a chart that represents colors based on human vision. The dominant wavelength is found by drawing a line from a central white point on the diagram through the coordinates of the light source and extending it to the edge of the chart. The point where this line meets the edge is the dominant wavelength.

Knowing the dominant wavelength is very useful in fields where precise color is needed, such as in display technology, lighting design, and any area where accurate color matching is required. By controlling the dominant wavelength, manufacturers can create LEDs that emit specific colors suited for different purposes, like helping plants grow better with certain light colors or producing bright and realistic colors on screens.

Creating White Light with LEDs

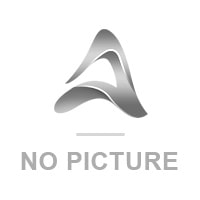

Figure 6: Two Methods for Creating White Light with LEDs

Creating white light with LEDs involves two main methods, each with its own advantages and uses.

One method involves combining red, green, and blue (RGB) LEDs. By carefully adjusting the intensity of these three primary colors, they can be mixed to create white light. This technique is commonly used in devices that need precise color control and accurate color representation, such as full-color LED displays and decorative lighting. Although this method offers excellent control over color output, it is more complex and expensive compared to the blue LED with yellow phosphor approach. It requires advanced control circuits and calibration to ensure the colors mix correctly to produce white light.

The other method uses a blue LED paired with a yellow phosphor coating. When the blue LED is turned on, it excites the yellow phosphor, making it emit yellow light. The combination of the remaining blue light and the emitted yellow light produces white light. This method is popular because it is simple and cost-effective, making it suitable for a wide range of lighting applications. However, it can sometimes result in a white light with a slight blue or cool tint, which might not be ideal for every situation.

Each method is chosen based on the desired balance between cost, complexity, and color quality. The RGB LED method is selected for applications that require precise color tuning and high-quality light output, while the blue LED with yellow phosphor method is often preferred for its simplicity and affordability.

LED Lighting Efficiency

LEDs use much less energy than traditional incandescent bulbs, saving up to 90% of energy. They produce light by passing an electrical current through a small chip, lighting up tiny light sources called LEDs. Unlike incandescent bulbs, which produce light by heating a filament until it glows, LEDs generate light with much less energy.

LEDs have parts called heat sinks that help deal with the heat they make. These heat sinks take in and spread out the heat to keep the LEDs working well. Good heat management makes LEDs last longer and keeps them bright. If the heat isn't handled well, LEDs can wear out quicker and become dimmer. How long LEDs last and how well they work depend on how good they are and how well their heat sinks work.

Lifespan and Degradation

Lifespan and breakdown are main points in understanding LED (Light Emitting Diode) performance. Unlike regular bulbs, which usually burn out suddenly, LEDs slowly become dimmer over time. This slow dimming process is called lumen depreciation.

Lumen depreciation happens because the materials inside the LED wear out, causing it to produce less light. We usually measure an LED's life by the point at which its brightness has dropped to 70% of its original level. For example, if an LED starts at 1000 lumens, its useful life is considered over when its brightness falls to 700 lumens.

Several things can cause lumen depreciation in LEDs, such as temperature, electrical stress, and the quality of the materials used to make them. High temperatures can speed up the wearing out of LED parts, making them dim faster. Similarly, electrical stress, like too much current or voltage, can shorten an LED's life by causing extra damage to its internal parts.

The quality of the materials used to make LEDs also greatly affects how long they last. LEDs made with better materials and construction methods tend to last longer and dim more slowly. On the other hand, lower quality LEDs may dim more quickly and have a shorter useful life.

Lumen depreciation happens when LEDs lose brightness over time. This can be caused by several main factors:

• Excessive heat can damage the internal parts of the LED. Heat sinks help manage this heat, but if they don't work well, the LED parts can get harmed.

• High electrical currents and voltages can wear out the components inside the LED. This wear and tear can make the LED less bright.

• The materials used in LEDs, especially white ones, can degrade over time. This material breakdown also leads to a loss of brightness.

• Environmental conditions like moisture and dust can affect LEDs. Moisture can cause parts to rust or short-circuit, and dust can block light or interfere with the LED's operation.

Applications of LEDs

LEDs, or Light Emitting Diodes, have changed the lighting industry a lot because they are versatile and efficient. They can be used in many ways, from regular light bulbs to built-in fixtures. One of the main benefits of LEDs is their small size, which allows for creative and innovative lighting designs. This makes LEDs perfect for both replacing traditional light bulbs and being built into custom fixtures, providing long-lasting and energy-saving lighting solutions.

In hybrid lighting solutions, LEDs are combined with traditional lighting designs. These systems often have replaceable LED parts within specially designed fixtures, making it easy to maintain and upgrade them. This combination takes the best parts of both old and new lighting technologies, improving the overall user experience.

LEDs can be used in many different places, from homes to industrial settings. Their energy efficiency is a big advantage because LEDs use less power compared to traditional lights. This means lower energy bills and a smaller impact on the environment. Also, LEDs last longer, so they don't need to be replaced as often, saving time and money.

Thermal Management in LEDs

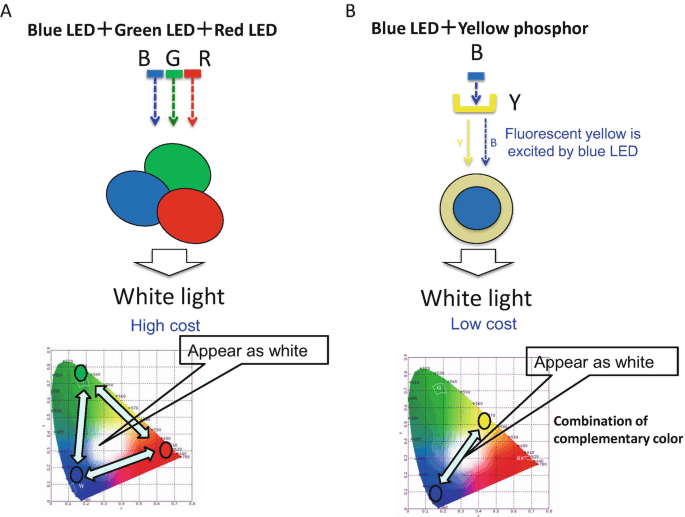

Figure 7: Thermal Management in LEDs

Proper heat management is very helpful for how well LEDs work and how long they last. When LEDs are used, they produce heat. If this heat is not managed well, it can quickly damage the LEDs, making them less efficient and shortening their life.

A major part of managing LED heat is the heat sink. Heat sinks help by soaking up and spreading out the heat away from the LED chip’s connection with the circuit board, making it cooler. How well a heat sink works depends a lot on what it is made of and its design.

Materials like aluminum and copper are often used for heat sinks because they can move heat away efficiently. Also, the design of heat sinks usually includes features like fins, which increase the surface area that can release heat. This larger surface area helps the heat sink to spread out the heat from the LED, keeping the LED cooler and making sure it works well for a long time.

Differences Between LED and Traditional Lighting

LEDs offer several advantages over traditional incandescent and CFL (Compact Fluorescent Lamp) lighting, particularly in light direction and color range:

• Directional Lighting: LEDs emit light in a specific direction, ideal for targeted lighting needs like reading lamps or spotlights. In contrast, incandescent and CFL bulbs emit light and heat in all directions, often requiring reflectors or shades to focus the light, resulting in energy wastage.

• Color Options: LEDs provide a wide range of colors, including amber, red, green, and blue. White light can be created by mixing different colored LEDs (e.g., red, green, and blue) or using phosphor-coated LEDs that emit white light when blue or ultraviolet light passes through the phosphor. This wide color range allows LEDs to meet various lighting needs, from warm, cozy lighting to bright, daylight-like illumination.

How LEDs Work?

Figure 8: Structure of an LED

LEDs (Light Emitting Diodes) work like diodes and give off light when they are forward biased. In this setup, the negative side (cathode) is connected to the negative terminal of a power source, and the positive side (anode) is connected to the positive terminal. This arrangement lets electrons from the N-region gain energy and move toward the P-region. When these electrons cross the junction and meet holes in the P-region, they release energy as light.

The color of light an LED emits depends on the semiconductor materials used. For example, gallium arsenide produces infrared light, while gallium phosphide can produce green or red light. These differences in color come from the various energy levels of the materials, which decide the wavelength of the light given off.

An LED is built with a lead frame, often called an anvil, that is connected to the cathode terminal. This frame holds the semiconductor material. The P-region of the semiconductor is placed near the surface to make sure more light comes out of the LED instead of being trapped inside. This design helps to increase the brightness and effectiveness of the LED.

Conclusion

LEDs have many advantages over traditional lights. They use less energy, last longer, and provide better light quality. LEDs work by moving electrons through a semiconductor, directly turning electrical energy into light with very little heat. They can produce different colors based on the materials used, and the different designs of Lamp Type and Chip Type LEDs make them even more useful. As technology improves, LEDs keep getting better, offering more benefits and being used in more ways. By understanding how LEDs work and their benefits, it's clear why they are becoming the preferred choice for lighting in our homes, offices, and beyond.

Frequently Asked Questions [FAQ]

1. How does the LED display work?

An LED display works by using many small lights called light-emitting diodes (LEDs). These tiny lights glow in different colors to create pictures and text. Electronic circuits control these lights, turning them on and off quickly to show the desired images and patterns.

2. What are the two main things LEDs are used for?

LEDs are mainly used for lighting and displays. For lighting, they offer bright and energy-saving light for homes, streets, and vehicles. For displays, they are used in screens for televisions, computers, and billboards.

3. What is the principle of LED and its work?

The principle of an LED is based on a process called electroluminescence. When an electric current flows through the LED's material, it gives off light. This happens because the electric energy causes electrons to combine with other particles, releasing energy as light.

4. Why are LEDs important?

LEDs matter because they save energy, last a long time, and are good for the environment. They use less electricity than traditional lights and have a much longer life, so they don't need to be replaced as often.

5. What are the advantages of LEDs?

The advantages of LEDs include using less energy, having a longer lifespan, being more durable, being smaller in size, and turning on and off faster. They also produce less heat and come in many colors, making them useful for different purposes.