The Ultimate Guide to Tactile Switches

In the rapidly evolving landscape of electronic components, tactile switches represent a pinnacle of user interface technology, offering unparalleled feedback and precision. These switches, integral to a myriad of devices, from consumer electronics to advanced industrial systems, ensure user actions are acknowledged through physical sensations such as a click or a tactile bump.

This article digs into the sophisticated design and functionality of tactile switches, contrasting them with other types of switches like push buttons and elucidating their serious roles in various applications. It also explores the nuances of their operation, structural components, and the criteria dynamic for choosing the appropriate switch for specific uses. By dissecting the mechanical and technical intricacies, this analysis illuminates the substantial benefits tactile switches provide in enhancing user interaction and operational efficiency in technological devices.

Catalog

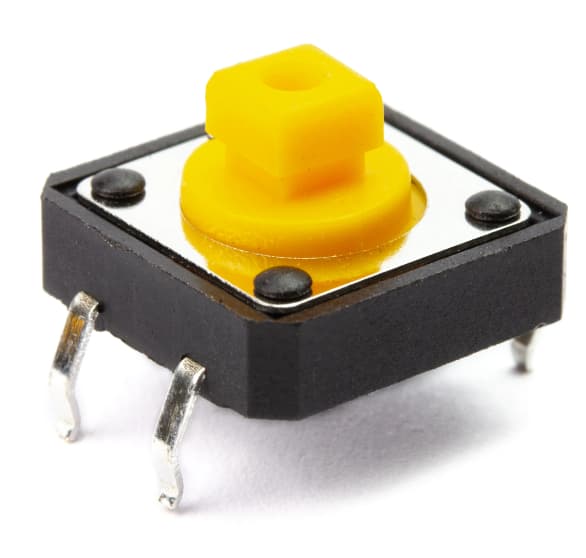

Figure 1: Tactile Switches

Exploring Tactile Switches

A tactile switch is a common element in modern electronics, valued for its ability to offer physical feedback to the user. This feedback comes as a noticeable click or a tactile sensation, signaling that the circuit has been successfully closed and the current is flowing. This immediate feedback reassures the user that the intended electronic response has been activated. Once the switch is released, the circuit opens, stopping the current flow.

Tactile switches are primarily used for momentary tasks. They remain active only while pressure is applied. When the pressure is removed, the switch returns to its inactive state, breaking the circuit. This feature makes them ideal for functions requiring precise and temporary control.

Today, tactile switches are insistent in various fields, including consumer electronics and industrial systems. They are prized for their reliability and ease of use, making them requisite in devices that require consistent and immediate user feedback.

Comparing Tactile Switches and Push Button Switches

Tactile switches and push button switches perform similar functions but have several key differences. Both types of switches control the flow of current, but they do so in distinct ways to suit different applications.

Figure 2: Tactile Switch

Tactile switches are designed for momentary use, meaning they only allow current to flow while the actuator is pressed. They feature minimal actuator travel and provide immediate, noticeable feedback—either auditory (a click) or haptic (a sensation)—confirming circuit engagement. This quick response is used for tasks requiring precise control over short, repetitive actions.

Figure 3: Push Button Switch

Push button switches, on the other hand, can facilitate sustained current flow. A single press engages the circuit, and a second press disengages it. This makes them suitable for applications where continuous operation is needed without the need to hold down the switch.

Tactile switches are typically smaller and optimized for low-voltage applications, making them ideal for direct integration into printed circuit boards (PCBs). Push button switches are more versatile in their mounting options, including panel mounts. They might not always provide the immediate feedback that tactile switches offer, which can be a consideration depending on the application.

Characteristics of Tactile Switches

Tactile switches are designed to enhance both functionality and user experience in a wide range of applications. They are influential in environments where rapid data entry is needed such as computer keyboards, facilitating quick and accurate keystrokes.

In industrial settings, tactile switches are reliable for continuous operations due to their durable design. They are built to withstand frequent use and harsh conditions, ensuring consistent performance. A key feature of tactile switches is the immediate tactile and auditory feedback they provide. This feedback confirms the switch has been actuated, improving precision in tasks requiring exact responses.

Tactile switches are designed to consume low power, making them cost-effective and suitable for low-voltage applications. This energy efficiency is a significant advantage in reducing operational costs. These switches have a robust construction with fewer mechanical components, which extends their operational life. This durability minimizes the need for frequent maintenance or replacements, making them a reliable choice over time.

Figure 4: Structural Design and Operation of Tactile Switches

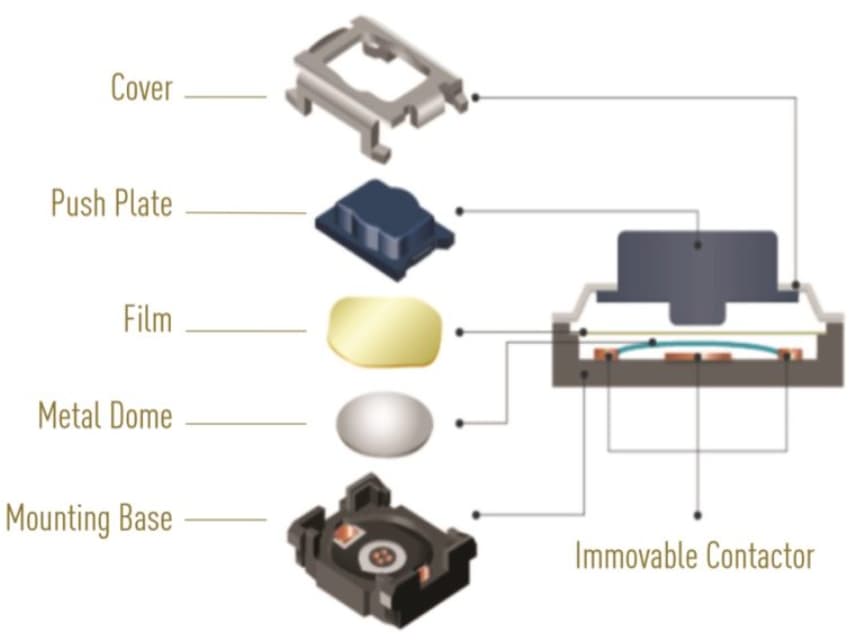

Structural Design and Operation of Tactile Switches

The structure of a tactile switch exemplifies streamlined efficiency, combining useful components to ensure durability and precise functionality.

Foundation and Electrical Contacts: At the foundation, a molded resin base houses the grave electrical contacts and terminals. This base securely attaches the switch to printed circuit boards (PCBs), ensuring stable connections.

Metal Dome Mechanism: Within the base, a resilient metal dome is strategically placed. This dome deforms slightly when pressed, creating a distinct "click" sound that indicates circuit completion. When pressure is released, the dome quickly returns to its original shape, breaking the circuit. This rapid action is noteworthy to the tactile feedback mechanism.

Plunger and Activation Force: Above the metal dome, the plunger applies the needed force to activate the switch mechanism. The plunger's role is insistent in delivering precise and responsive feedback.

Protective Cover: Encasing these components, the switch cover protects the internal workings from physical damage and environmental factors. Some designs include additional features, such as a ground terminal for extra static protection.

Selecting Tactile Switch Specifications

Choosing the right tactile switch involves more than just technical specifications. Tactile and auditory feedback significantly influence the perceived quality of a product.

|

Tactile Switch Specifications |

|

|

Activation Force |

This refers to the amount of force needed

to activate the switch. For example, automotive settings require switches

with higher activation forces to prevent accidental activations from

vibrations. In contrast, consumer electronics, especially gaming devices,

benefit from switches with lower activation thresholds for quick and

effortless responses. |

|

Voltage Capacity and Current Ratings |

These specifications ensure the switch

can handle the electrical requirements of its application. |

|

Durability and Lifecycle Expectancy |

This is quantified in terms of how many

cycles the switch can endure before failing. High durability is useful for

applications that involve frequent use. |

|

Environmental Resilience |

This includes factors such as temperature

stability and IP (Ingress Protection) ratings, which indicate the switch's

ability to withstand dust, water, and other environmental conditions. |

Various Types of Tactile Switches

Tactile switches are designed to meet a wide range of functional requirements and environmental conditions, making them versatile components in electronic devices. Here's a detailed look at their varieties:

Figure 5: Standard Tactile Switches

These are the most commonly used switches due to their straightforward design and reliable performance. They are ideal for indoor applications where there is minimal exposure to environmental elements.

Figure 6: Sealed Tactile Switches

These switches offer enhanced protection against dust, moisture, and water, making them suitable for outdoor or industrial environments. The sealing ensures they maintain functionality without compromise in harsh conditions.

Figure 7: Shapes and Sizes

Tactile switches come in various shapes such as round, square, and rectangular, allowing them to fit different device aesthetics and design requirements. This variety enables seamless integration into a wide array of product designs. Beyond basic shapes, tactile switches can be customized in color, size, and finish. This flexibility helps manufacturers maintain brand consistency and meet specific design standards.

Figure 8: Tactile Switches Built-in LEDS

Some tactile switches have built-in LEDs or other lighting solutions to improve visibility in low-light conditions. This feature is especially useful in consumer electronics like remote controls, automotive dashboards, and medical equipment.

Wiring and Installation of Tactile Switches

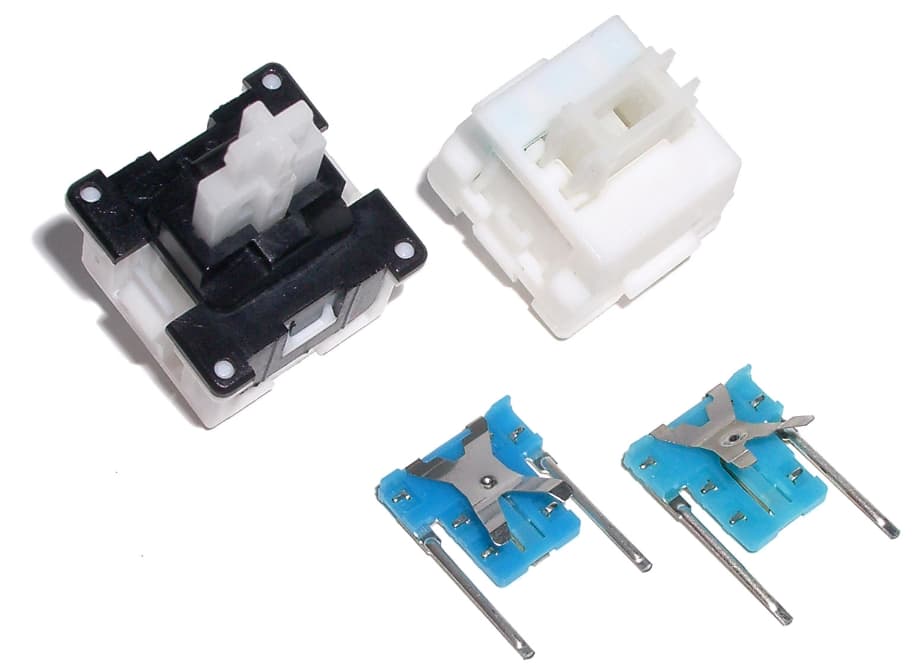

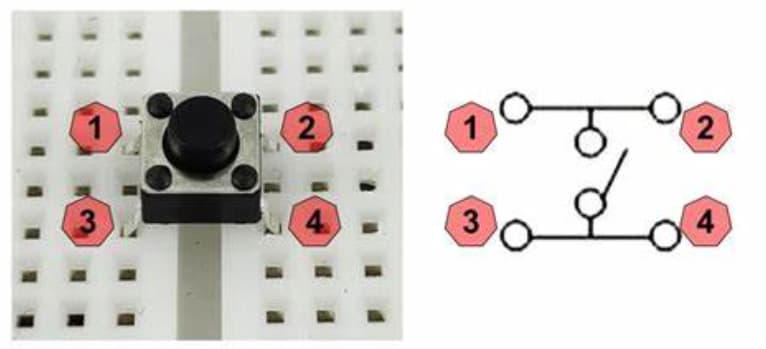

Figure 9: Four-Pin Configuration

Tactile switches commonly have four pins, which provide a secure and stable mounting on printed circuit boards (PCBs). While only two pins are required for the switch's basic operation, utilizing all four enhances the switch's reliability and durability.

Figure 10: Two-Pin Configuration

In addition to the standard four-pin model, tactile switches also come in two-pin and five-pin configurations. These variations cater to different design requirements and functionalities.

Applications of Tactile Switches

|

Applications of Tactile Switches |

|

|

Consumer Electronics |

Tactile switches are basic in consumer

electronics due to their compact form, reliability, and responsiveness. They

are key components in devices such as keyboards, game controllers, and

smartphones, providing immediate feedback that enhances the user experience |

|

Industrial Applications |

In industrial settings, the durability of

tactile switches is highly valued. They are used in control panels and

instrumentation, where they ensure consistent performance even under

demanding conditions. Their robust construction allows them to withstand

harsh environments and frequent use. |

|

Wearable Technology and Smart Body

Armor |

Wearable Technology and Smart Body

Armor The adaptability of tactile switches extends to cutting-edge applications in wearable technology and smart body armor. Their small size and resilience make them ideal for integrating sophisticated, user-centric functionalities in these advanced devices. |

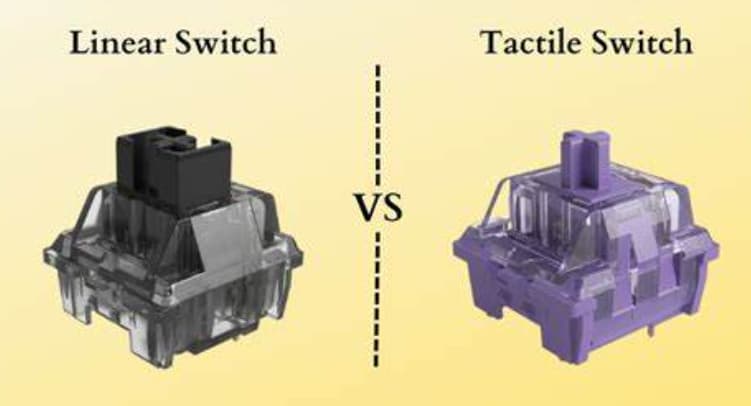

Figure 11: Linear vs. Tactile Key Switches

Choosing Between Linear and Tactile Key Switches

• Linear key switches: are known for their smooth keystroke. They provide no tactile feedback, allowing for quick, uninterrupted key presses. This characteristic makes them ideal for gaming, where rapid actuation can enhance response times significantly.

• Tactile key switches: have a noticeable bump at the actuation point, offering physical feedback. This feedback is preferred by many typists as it creates a more interactive typing experience. The tactile sensation not only enhances engagement but also improves typing precision and ergonomic comfort.

While linear switches are perfect for competitive gaming due to their smooth and quick action, tactile switches are better suited for environments where typing feel and accuracy are useful. The feedback from tactile switches can help typists type more accurately and comfortably over long periods.

Conclusion

Tactile switches, as detailed in this comprehensive examination, stand out for their basic contributions to user interface technology across diverse sectors. Their distinctive characteristics—minimal actuator travel, immediate feedback, and low power consumption—make them requisite in applications requiring precision and reliability. The structural design, which incorporates elements like a metal dome and resilient plunger, ensures durability and consistent performance, influential in environments from bustling industrial floors to the personal tranquility of home offices.

As technology continues to advance, the role of tactile switches is likely to expand, driven by their adaptability and the increasing demand for sophisticated, user-responsive devices. The ongoing development and refinement of tactile switches will further enhance their effectiveness, affirming their status as a cornerstone of modern electronic design. This exploration not only highlights the current applications and advantages of tactile switches but also sets the stage for future innovations in tactile feedback technology.

Frequently Asked Questions [FAQ]

1. How to use tactile switches?

To use a tactile switch, apply pressure directly to its button or actuator. This causes the internal mechanism to connect, completing the circuit and initiating an electrical flow. Release the pressure to break the connection, stopping the flow.

2. Where are tactile switches used?

Tactile switches are widely used in various electronic devices due to their reliability and clear feedback. Common applications include keypads on mobile devices, remote controls, consumer electronics interfaces, and push-button controls in industrial machines.

3. What are the parts of a tactile switch?

A typical tactile switch consists of the following parts:

Actuator: The part you press that moves internally.

Contacts: Metal pieces that touch to complete the circuit when the switch is pressed.

Case: The housing that contains all other components.

Spring: A mechanism that returns the actuator to its original position after being pressed

4. What is the mechanism of a tact switch?

The mechanism of a tactile switch operates on a simple principle. Pressing the actuator forces it to descend, causing the contacts within the switch to meet and close the circuit. Releasing the actuator allows a spring or similar mechanism to push it back to the open (non-contact) position, opening the circuit and stopping the current flow.

5. What sound do tactile switches make?

Tactile switches typically produce a distinctive "click" sound when activated. This sound is a result of the mechanical movement within the switch, where the contacts snap together or apart, providing audible feedback that the switch has successfully operated.