The Role of IMPATT Diodes in Modern Electronics

The Impact Ionization Avalanche Transit-Time (IMPATT) diode represents a cornerstone in microwave frequency generation technology, renowned for its high-power output and broad frequency range. This technology has carved a niche in applications demanding robust high-frequency signals, from radar systems to satellite communications. The operational principles of IMPATT diodes axis on the avalanche multiplication and transit-time delay phenomena, where a high reverse bias voltage incites avalanche breakdown, followed by the rapid transit of charge carriers through the diode's high-field region. This article explores the intricate dynamics and configurations of IMPATT diode operations, detailing their unique current-voltage characteristics and comparing their performance with other semiconductor devices like Gunn diodes. In addition, this article examines the serious design and fabrication processes behind these diodes' efficacy in high-frequency applications, highlighting their advantages and inherent limitations within various technological spheres.Catalog

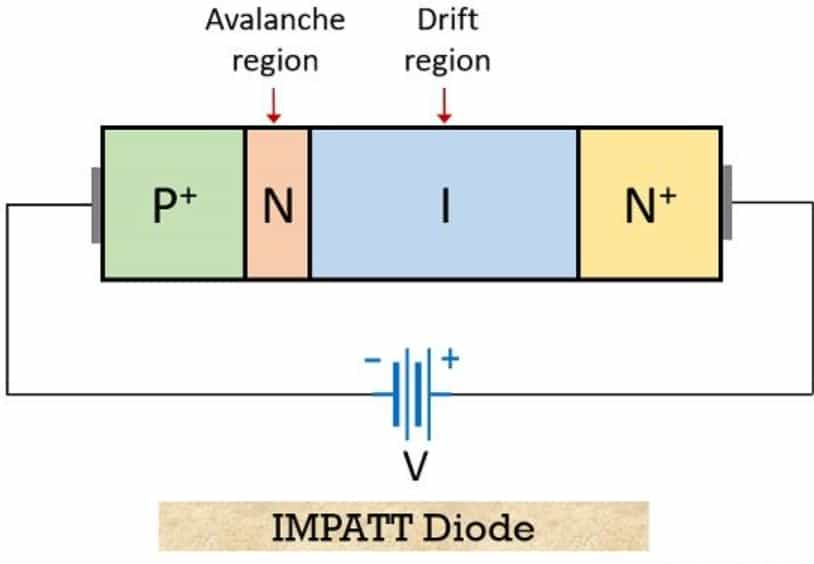

Figure 1: IMPATT Diode

Basics of IMPATT Diode

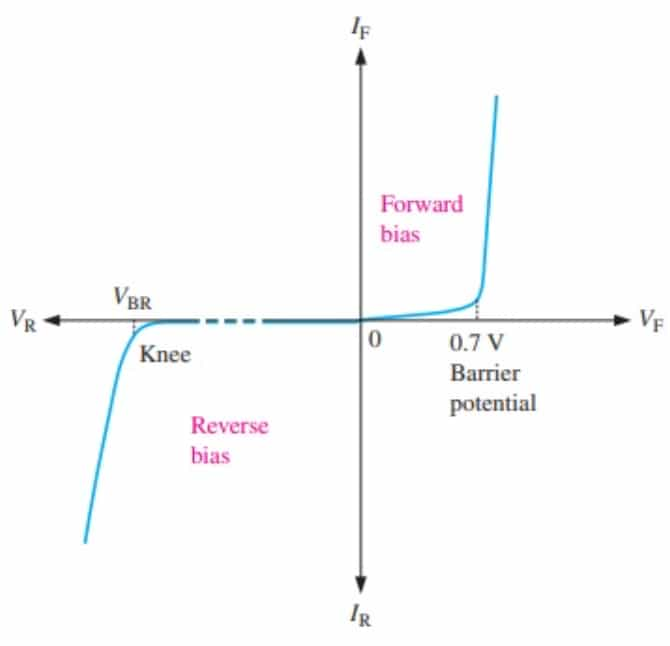

IMPATT diodes behave differently from standard PN junction diodes, especially in their current-voltage (I-V) characteristics. These diodes are designed to allow current flow in the forward direction only after reaching a specific activation voltage. However, when a reverse bias is applied, it blocks current flow until the voltage exceeds the diode's breakdown threshold, leading to avalanche breakdown and the onset of reverse current. This behavior is insistent for generating microwave frequency signals.

To trigger avalanche breakdown in an IMPATT diode, a carefully controlled reverse bias is applied. This bias is set precisely to induce breakdown near the highly doped P-region (P+). At the PN junction, the narrow gap between the regions creates a strong electric field, resulting in a steep voltage gradient. This field rapidly accelerates charge carriers, causing them to collide with the crystal lattice. These collisions generate additional carriers, creating a chain reaction known as avalanche breakdown. This rapid carrier multiplication only occurs when the applied voltage is high enough to propel the particles to the needed speed.

The IMPATT diode is divided into two key functional regions: the avalanche region and the drift region. In the avalanche region, charge carriers (electrons or holes) are generated. These carriers then move through the drift region, with their transit time determined by the thickness of this area. The separation of these regions maximizes the performance of the diode and its ability to efficiently generate microwave signals.

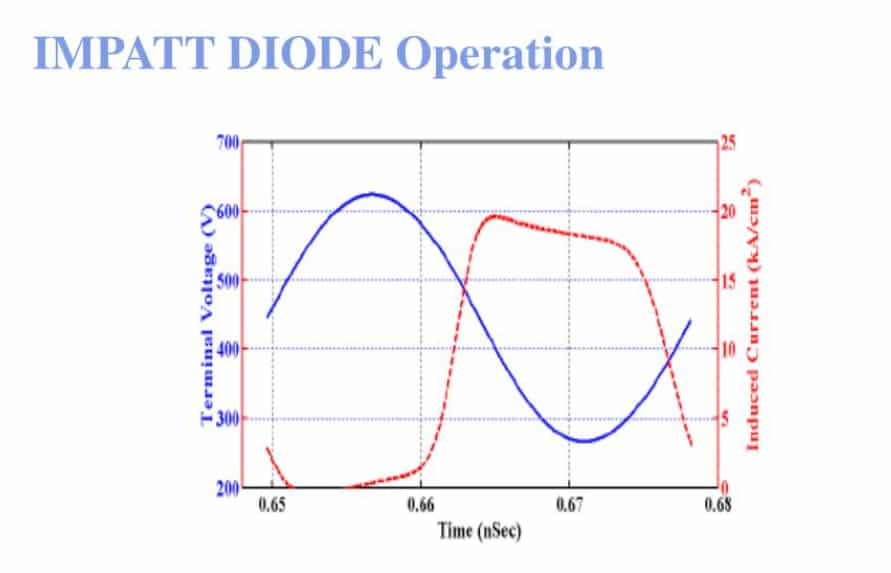

Figure 2: IMPATT Diode Operation

How IMPATT Diodes Work?

IMPATT diodes utilize their unique negative resistance characteristics to produce and sustain high-frequency oscillations. Unlike their direct current (DC) behavior, their alternating current (AC) operation at these frequencies introduces significant phase differences between the current and voltage. Notably, the current and voltage are 180° out of phase, a result of two specific delays: injection delay and transit time delay.

The process begins when a sinusoidal voltage, approaching the avalanche breakdown threshold, is applied to the diode. However, the generation of charge carriers does not align perfectly with the voltage peaks. This misalignment occurs because the interaction between the electric field and carrier density is phase-dependent. As a result, carriers continue to multiply even after the voltage has peaked, driven by the lingering presence of existing carriers. This leads to a noticeable phase delay, known as injection phase delay, where the current lags behind the voltage by approximately 90°.

As electrons move through the N+ region, they contribute to the external current, visible in the waveform's peaks. This phenomenon is dangerous for generating a stable, repeating waveform, which is suitable for consistent microwave signal production. Every operational cycle of the IMPATT diode involves these complex interactions, which are dynamic for its successful application in scenarios requiring precise timing and phase control.

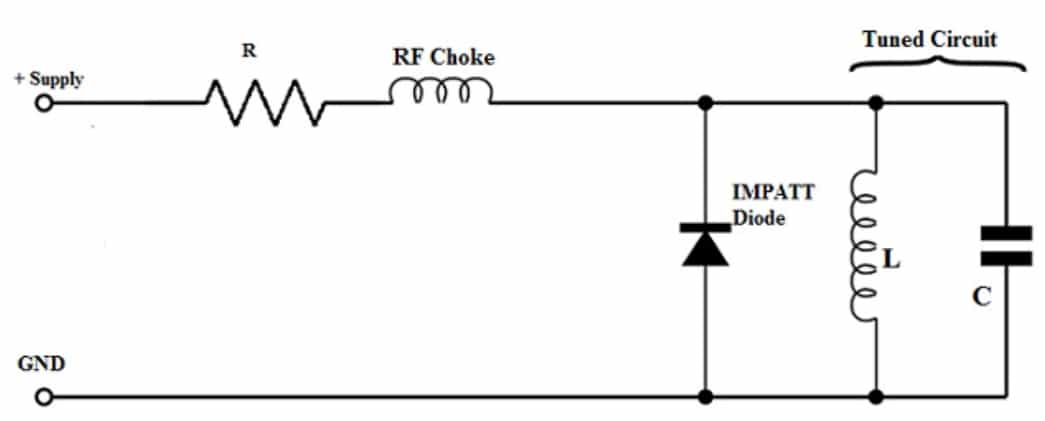

Figure 3: IMPATT Diode Circuits

Analysis of IMPATT Diode Circuits

IMPATT diodes are primarily used in circuits operating above 3 GHz, where they excel in generating high power outputs—often exceeding ten watts. This high-power capability is achieved by coupling the diode with a finely tuned circuit set near the breakdown voltage. IMPATT diodes outperform other negative resistance devices at these frequencies, making them a preferred choice in such applications.

In a typical circuit setup, the power supply connects through a current-limiting resistor and an RF choke, which isolates the DC component from the radio frequency signal. The diode is placed strategically across the tuned circuit, often within a waveguide cavity. When voltage is applied, the diode begins oscillating, leading to the generation of high-frequency signals.

One significant challenge in using IMPATT diodes is controlling the high levels of phase noise that arise from the avalanche breakdown process. This issue is partially mitigated in diodes made from Gallium Arsenide, which has more closely matched ionization rates for holes and electrons compared to Silicon. This difference in material properties reduces phase noise, enhancing the diode's performance in high-frequency circuit designs.

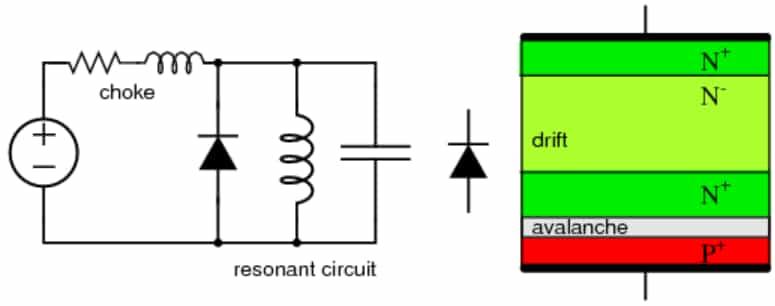

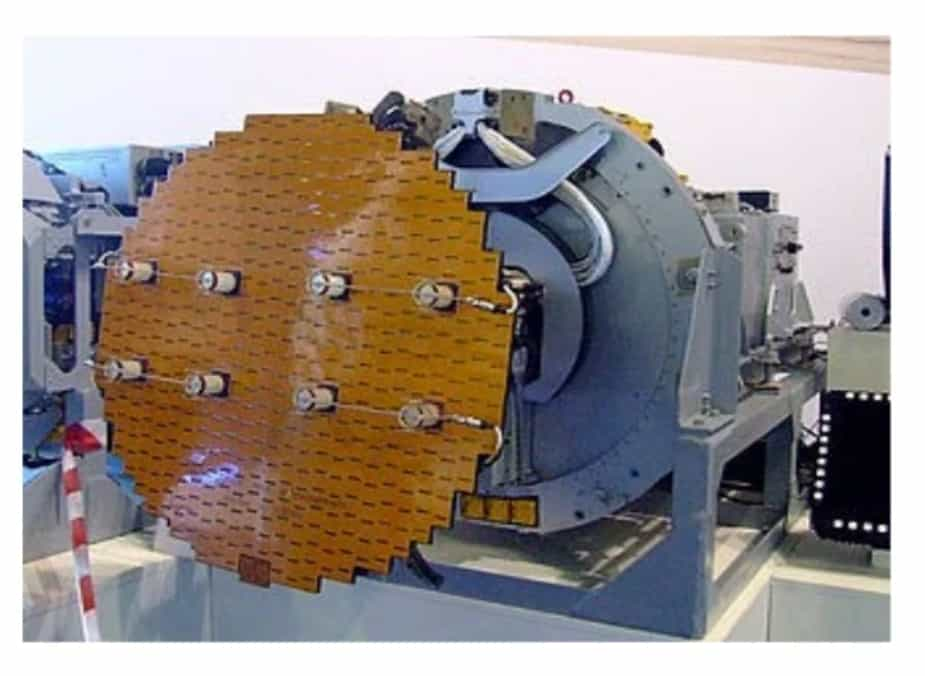

Figure 4: Construction of IMPATT Diodes

Constructing High-Performance IMPATT Diode

Building an IMPATT diode for high-frequency microwave applications involves a carefully designed structure and selection of materials. Silicon (Si) and Gallium Arsenide (GaAs) are commonly used due to their effectiveness in handling transit time effects and enabling efficient avalanche breakdown, both of which are dangerous for high-frequency operation. At the heart of the diode is the PN junction, where the p-type and n-type semiconductors meet, and where the avalanche breakdown occurs within the active region.

When a reverse bias is applied, a depletion region forms, which is free of charge carriers. This region is demanding because it controls the electric flow and intensifies the avalanche effect by preventing premature carrier discharge. Adjacent to this, the transit time region is carefully designed to control the speed and trajectory of high-energy carriers, maximizing the diode's efficiency in generating microwave signals.

Metal contacts, usually made from aluminum or gold, are attached to the diode for electrical connections. These contacts are dynamic for applying the required bias voltage and for extracting the microwave signal. To ensure the diode's durability and reliability, it is encased in protective packaging. This packaging not only facilitates the diode's integration into circuits but also protects it from environmental factors, enhancing its performance in demanding applications.

Fabrication Process of IMPATT Diodes

Creating an IMPATT diode involves a carefully planned series of manufacturing steps to ensure high performance. The process starts with selecting a high-quality silicon substrate. This substrate is meticulously cleaned and treated to remove any impurities and defects, which is settling for achieving consistent, high-quality layers in the final device.

The next key step is photolithography, where a light-sensitive material is used to transfer precise patterns onto the substrate. A specially designed mask helps define the grave areas that will form the diode's active and passive regions. Once the pattern is in place, various deposition techniques are used to apply layers of metals or oxides, chosen for their specific electrical and physical properties.

These layers are then shaped through etching processes, which carve out the diode’s intricate architecture. To fine-tune the diode’s electrical properties, dopants are introduced into the material. This doping is followed by thermal annealing, a heating process that activates the dopants and repairs any structural damage caused by earlier steps. The final assembly of the diode includes adding insulating layers and metal contacts, which are required for making the needed electrical connections. Each diode then undergoes rigorous testing to ensure it functions correctly and can withstand the conditions it will face in actual use.

Figure 5: Current-Voltage Characteristics of IMPATT Diodes

Current-Voltage Characteristics of IMPATT Diodes

IMPATT diodes exhibit unique current-voltage (I-V) characteristics, especially when subjected to reverse-bias conditions. As the voltage increases and approaches a specific threshold, the diode enters avalanche breakdown, transitioning into a state of negative resistance. This behavior is focal to its role as a microwave oscillator. In this phase, a rise in voltage leads to a surprising decrease in current—a counterintuitive effect dominant to the diode’s operation. After this initial drop, the current starts to increase again, influenced by the transit time of charge carriers moving through the diode.

Distinctions Between IMPATT and Gunn Diodes

IMPATT and Gunn diodes are both dynamic in microwave and RF technology, but they operate on different principles, leading to distinct applications and performance characteristics.

Figure 6: IMPATT Diodes

These diodes operate through avalanche multiplication and transit-time delay. When a high reverse bias voltage is applied, it triggers avalanche breakdown, where charge carriers (electrons and holes) multiply rapidly due to impact ionization. As these carriers drift through the diode's high-field region, they generate microwave frequency signals. These diodes can operate across a wide frequency range, from GHz to THz, making them suitable for high-frequency applications that require substantial power output. However, their operation tends to generate significant noise, which can be problematic in systems where signal purity is a must. The avalanche process in IMPATT diodes generates a lot of noise due to the random nature of charge carrier multiplication and recombination. In addition, these diodes are less efficient, consuming more power and generating more heat during operation. Due to their high-power output, IMPATT diodes are often used in radar transmitters, communication broadcast transmitters, and other high-power microwave applications. They are especially useful in situations where long-range signal transmission and penetration power are dangerous.

Figure 7: Gunn Diodes

In difference, Gunn diodes rely on the transfer of electrons between different energy bands (or valleys) within a semiconductor, a phenomenon known as the Gunn effect. This effect creates a domain of high electric field that moves through the diode, producing microwave radiation. Unlike IMPATT diodes, Gunn diodes do not require avalanche breakdown. Typically used in the GHz range, Gunn diodes produce less power than IMPATT diodes but have much lower noise levels. This makes them ideal for applications where high signal clarity and stability are more perilous than raw power. Gunn diodes are more efficient because they operate at lower voltages and dissipate less power as heat. Their noise levels are also significantly lower, making them preferable for precision applications. Gunn diodes are typically used in local oscillators, FM microwave transmitters, and applications that require stable, low-noise performance. They are particularly valuable in sophisticated radar and communication systems where signal clarity is more significant than power.

Pros and Cons of Using IMPATT Diodes

Pros

Broad Frequency Range: IMPATT diodes can operate across a wide frequency spectrum, from gigahertz (GHz) to terahertz (THz). This versatility makes them useful in a variety of applications, from commercial communication systems to advanced radar technology.

Compact Size: Their small size allows IMPATT diodes to be easily integrated into space-constrained designs, providing greater flexibility in the design of electronic devices and systems.

Silicon Compatibility: IMPATT diodes are compatible with standard silicon-based semiconductor fabrication processes. This compatibility means they can be produced using well-established, cost-effective, and scalable manufacturing methods, making them easier to integrate into many circuit designs and fostering widespread adoption.

Cons

High Noise Levels: A significant drawback of IMPATT diodes is their high noise output, especially phase noise, which can negatively impact signal quality in precision applications. This issue is particularly challenging in environments where signal clarity is unsafe, such as high-definition radar systems and sensitive communication links.

Limited Frequency Tuning: Once fabricated, IMPATT diodes operate at a relatively fixed frequency, offering limited tuning capabilities. This lack of flexibility can be a disadvantage in systems that require dynamic frequency adjustments, such as adaptive communication networks and electronic warfare systems.

Complex Manufacturing: Producing IMPATT diodes involves intricate doping and fabrication processes to create the high-field avalanche region. This complexity increases production costs and extends development times, which can be a drawback in fast-paced technology markets.

Uses of IMPATT Diodes in Modern Technology

IMPATT diodes, known for their ability to efficiently generate and amplify high-frequency microwave signals, have a broad range of applications across various fields.

Figure 8: Oscillators

IMPATT diodes are often used in microwave oscillators due to their capability to generate frequencies typically between 3 GHz and 100 GHz. These oscillators are beneficial for applications that require stable, high-frequency signals, such as in local oscillators for radar systems and communication equipment.

Figure 9: Amplifiers

Beyond signal generation, IMPATT diodes are also effective in amplifying microwave signals. This makes them valuable in transmitter circuits where boosting signal strength is substantial for long-distance communication.

Figure 10: Satellite Communications

IMPATT diodes are important in satellite communication systems, where they generate high-power microwave signals needed for transmitting data over long distances between satellites and ground stations.

Figure 11: Terrestrial Microwave Links

These diodes are also used in earth-based microwave link systems, such as those in cellular backhaul networks, where their high-frequency and high-power capabilities are required for broadband communication.

Figure 12: Doppler and Pulse Radar

IMPATT diodes are dynamic components in radar systems, particularly in Doppler and pulse radars. They provide the high-power microwave radiation desired to detect and measure objects at great distances, which is beneficial in aviation, maritime, and automotive applications.

Figure 13: Frequency Multipliers

IMPATT diodes can function as frequency multipliers, increasing the frequency of an input signal. This application is serious in frequency synthesis and signal processing, where high-frequency output is required from a lower-frequency input.

Figure 14: Spectroscopy

In spectroscopy, IMPATT diodes generate coherent microwave radiation used to analyze the molecular composition of materials, aiding in chemical analysis and environmental monitoring.

Figure 15: Plasma Physics

The high power and frequency capabilities of IMPATT diodes make them useful in plasma research, where they help excite or control plasma states in experimental setups, impacting both scientific research and practical applications like semiconductor manufacturing.

Figure 16: Diagnostic Imaging

In medical technology, the precise and powerful microwave emissions from IMPATT diodes are harnessed for diagnostic purposes, particularly in imaging techniques that require high resolution.

Conclusion

To sum up, IMPATT diodes stand as key components in the realm of microwave technology, endowed with the capability to generate and amplify signals across a vast frequency spectrum from GHz to THz. While their advantages include high power output and compatibility with silicon-based fabrication processes, they are not without drawbacks. The significant phase noise and limited frequency tuning inherent in IMPATT diodes pose challenges in precision applications where signal clarity is dominant.

Despite these limitations, the versatility and robust performance of IMPATT diodes ensure their continued relevance in a wide array of applications, from complex radar systems to communication networks. Future advancements may well hinge on material science innovations and circuit design enhancements that could mitigate their noise levels and extend their operational flexibility, thus broadening their applicability in the ever-evolving landscape of high-frequency electronics.

Frequently Asked Questions [FAQ]

1. What is the power output of the IMPATT diode?

IMPATT diodes are capable of generating high power in the microwave frequency spectrum. Typically, they can output power ranging from a few watts up to several hundred watts, depending on the specific design and operating conditions.

2. What causes the diode to explode?

A diode can explode due to excessive current flow, which leads to overheating and potential failure of the material structure. This excessive current can be caused by a short circuit, applying a voltage higher than the diode’s rated capacity, or rapid changes in voltage (voltage spikes).

3. What happens when a diode turns on?

When a diode turns on, it starts to conduct current from its anode to the cathode, but only when the anode is more positive relative to the cathode. This allows current to pass through the diode only in one direction, blocking any current that tries to flow in the opposite direction.

4. What is the working principle of IMPATT diode?

The IMPATT diode operates by generating a high-frequency microwave signal. It does this through a process called impact ionization and avalanche transit-time effect. The diode uses a reverse-biased p-n junction to create a high electric field. This field accelerates carriers to energies high enough to cause impact ionization, generating additional carriers and leading to an avalanche multiplication. The delay in carrier transit time across the junction produces a phase shift required for microwave oscillations.

5. What can damage a diode?

Several factors can damage a diode, including:

Overheating: Excessive current or environmental temperature can exceed the thermal capacity of the diode.

Overvoltage: Applying a voltage across the diode greater than it is designed to handle can cause breakdown and failure.

Reverse Biasing: While diodes are designed to block current in the reverse direction, excessive reverse voltage can lead to reverse breakdown, permanently damaging the diode.

Electrical Noise or Spikes: Sudden spikes in voltage can cause instantaneous high currents that damage the diode structure.

Physical Damage: Mechanical stress or damage during handling can also impair a diode’s functionality.