The Impact of Harmonics on Electrical Systems

Understanding the effects of harmonics on electrical systems is very helpful for keeping things running smoothly and safely. Harmonics are changes in the electrical wave that can cause various problems like too much heat, equipment breaking down, and less efficiency. This article explains the different types of harmonics, what causes them, and the problems they can create in power systems used in industries and businesses. We will also look at ways to fix these problems, like using special filters, transformers designed to handle harmonics, and regular checks of power quality. Our goal is to provide a clear and simple guide to managing harmonics in electrical systems effectively.Catalog

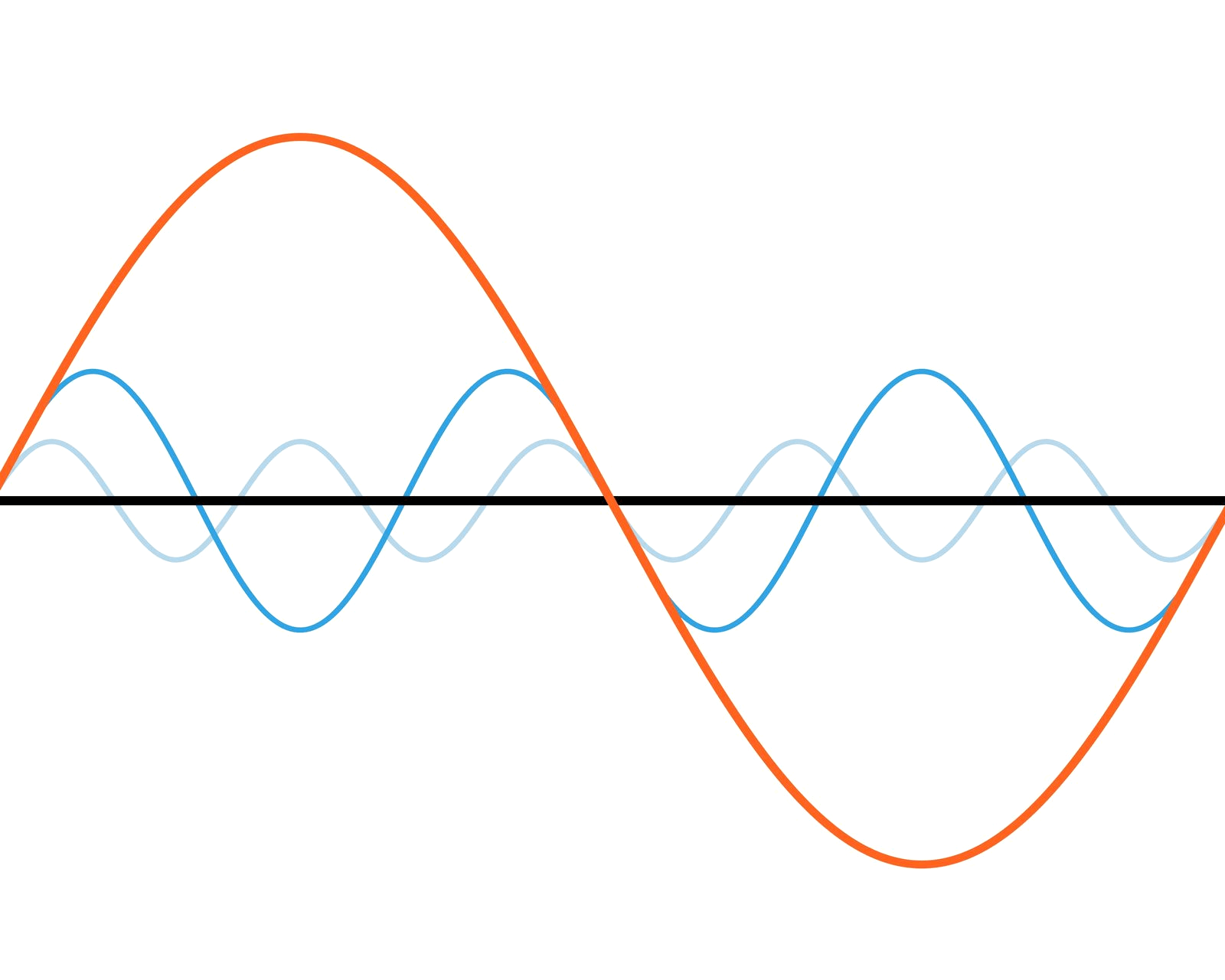

Figure 1: Harmonics

Understanding Harmonics in Power Engineering

Harmonics are currents or voltages at higher frequencies that are multiples of the basic frequency. They can cause problems like distorted waveforms, extra heating, and lower efficiency in electrical equipment. Odd harmonics, which occur at odd multiples of the basic frequency, increase distortion and heating. Even harmonics, which occur at even multiples of the basic frequency, can cause transformers to overheat. Triplen harmonics, which are a specific type of odd harmonics, can overload neutral wires and also cause transformers to overheat.

Harmonics can be divided into three types: positive, negative, and zero sequences. Positive sequence harmonics add extra heat to the system. Negative sequence harmonics reduce the power of motors and increase heat. Zero sequence harmonics cause heating in the neutral wires. Total Harmonic Distortion (THD) is a measure of the effects of harmonics, with higher values showing more distortion.

In industrial settings, devices like variable frequency drives create a lot of distortion. To reduce these problems, we can use filters and special transformers designed to handle high levels of harmonics. Regularly checking the quality of power helps find and fix harmonic problems and ensures compliance with IEEE 519 standards. Advanced tools can measure up to the 511th harmonic to help manage these issues effectively.

Types of Harmonics

Odd Harmonics

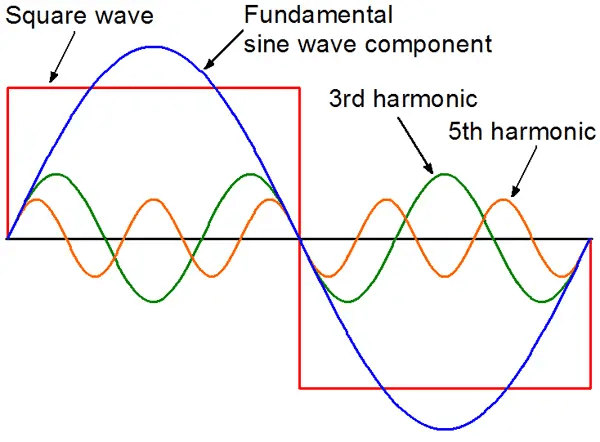

Figure 2: Odd Harmonics

Odd harmonics are harmonics that are odd multiples of the main frequency, like the 3rd, 5th, and 7th harmonics. These harmonics can cause big problems in power systems because they can harm electrical equipment and make them work poorly. When odd harmonics are present, they increase resistance losses and eddy current losses in transformers. Resistance losses, also called I²R losses, happen because the harmonic currents make the conductors heat up more. This extra heating is due to the power lost as heat because of the resistance in the conductors. Eddy current losses happen when induced currents flow within the transformer’s core, also generating heat. The presence of harmonics makes these effects worse because the transformer core faces higher frequency magnetic fields, which create more eddy currents and more heat.

High levels of odd harmonics can greatly affect how well a transformer works. To reduce the risk of overheating and possible failure, transformers often need to be derated when there are high levels of harmonics. Derating a transformer means using it at a lower capacity than its rated capacity to reduce the heating caused by the harmonics. This keeps the transformer working safely and makes it last longer. Derating involves figuring out how much harmonic content there is and calculating the extra losses caused by these harmonics. Once these losses are known, the transformer's load capacity is adjusted to keep it from overheating and ensure it works reliably.

In simple terms, derating a transformer because of odd harmonics involves a careful look at the harmonic content of the load. Engineers use power quality meters to measure the harmonic content and see how it affects the transformer. The data from these measurements is then used to figure out how much to reduce the transformer’s load to keep it operating safely.

Even Harmonics

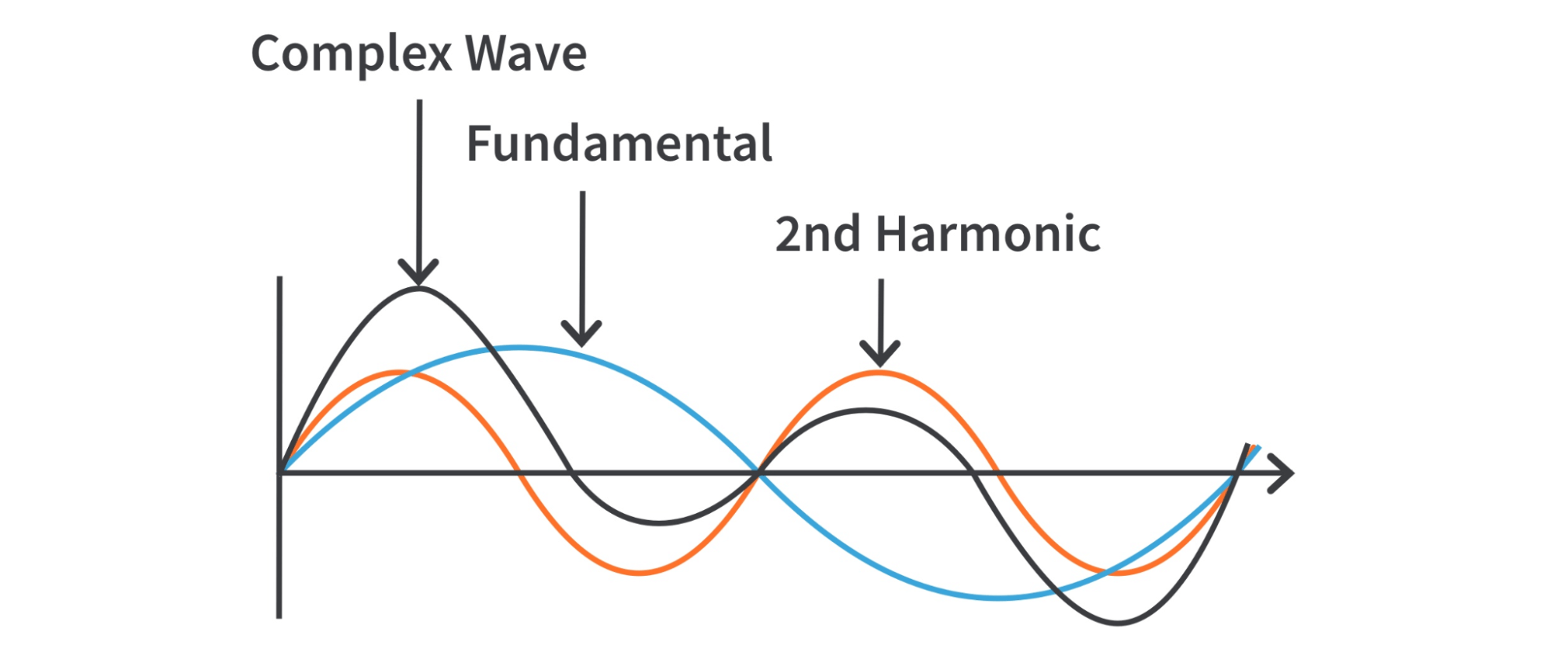

Figure 3: Even Harmonics

Even harmonics are frequencies that are even multiples of the main frequency, like the 2nd (120 Hz), 4th (240 Hz), and 6th (360 Hz) harmonics when the main frequency is 60 Hz. In power systems, even harmonics are usually small because most nonlinear loads mostly produce odd harmonics. However, the presence of even harmonics can show specific problems within the electrical system.

Even harmonics often indicate a DC offset in the system. A DC offset happens when there is a direct current (DC) component mixed with the alternating current (AC) waveform. This can be caused by half-wave rectification, which occurs due to a broken rectifier. A rectifier is a device that changes AC to DC, and when it breaks, it can produce an incomplete waveform, leading to a DC offset. The DC offset introduced by even harmonics can cause several problems in electrical systems. One major effect is transformer saturation. When a transformer experiences a DC offset, its core can become magnetically saturated during alternate half-cycles of the AC waveform. This saturation leads to an excessive draw of current, causing the transformer to overheat and possibly burn out the primary winding. Also, a DC offset can cause mechanical vibrations and noise in transformers. The magnetic saturation of the core results in strong vibration, which can be both loud and physically damaging to the transformer structure. Even a small DC offset, more than 1% of the rated current, can cause these serious problems.

Even harmonics can also be used as a diagnostic tool. Their presence in an electrical system can help identify issues related to rectifiers or other components that may be introducing a DC component into the system. By monitoring and analyzing even harmonics, engineers can detect and address problems early, preventing potential failures and ensuring the reliable operation of the power distribution system.

Triplen Harmonics

Figure 4: Triplen Harmonics

Triplen harmonics are a special type of odd multiples of the third harmonic. These occur at the 3rd, 9th, 15th, and so on. They are uniquely produced by single-phase devices and can cause significant problems in electrical systems.

One major problem caused by triplen harmonics is the overloading of neutral wires. In a balanced three-phase system, the currents in the neutral wire should cancel each other out. However, triplen harmonics from single-phase devices do not cancel out in the neutral wire. Instead, they add together, causing excessive currents. This can lead to overheating and potential damage to the neutral wire.

Triplen harmonics can also interfere with telephone lines. The high-frequency parts of these harmonics can create noise in communication lines that run parallel to power cables. This noise can reduce the quality of telephone signals and disrupt communication systems.

Another major issue with triplen harmonics is transformer overheating. Transformers are built to handle specific current and voltage levels. Triplen harmonics increase the RMS (Root Mean Square) current in the transformer windings, causing extra heating. If the transformer is not designed to handle this extra heat, it can lead to insulation breakdown and eventual failure.

To reduce the effects of triplen harmonics, special transformers called K-rated transformers can be used. These transformers are designed to handle higher harmonic currents without overheating. They have better cooling systems and are made with materials that can withstand the extra heat caused by harmonics.

Harmonic Sequence

A harmonic sequence describes how different frequencies of electric waves interact with the main wave, which helps us understand their impact on power systems. There are three main types of harmonic sequences: positive, negative, and zero.

Positive Sequence Harmonics

Positive sequence harmonics include frequencies like the 1st, 4th, and 7th harmonics. These harmonics move in the same direction as the main wave. They increase the current in the system and generate extra heat in the components. This added heat can damage the insulation, reduce the efficiency of the system, and cause components to break down sooner than expected. In motors, these harmonics disrupt the magnetic field, which makes the motor run less efficiently and shortens its lifespan. To handle these problems, it's helpful to use filters or other devices to monitor and reduce the positive sequence harmonics.

Negative Sequence Harmonics

Negative sequence harmonics include frequencies like the 2nd, 5th, and 8th harmonics. These harmonics move in the opposite direction to the main wave. They reduce the power of motors and create extra heat, which can damage the insulation, cause mechanical vibrations, and shorten the lifespan of motors and other components. Transformers can also experience increased losses and overheating due to these harmonics. Monitoring and installing the right filters can help manage the negative sequence harmonics and their adverse effects.

Zero Sequence Harmonics

Zero sequence harmonics include frequencies like the 3rd, 6th, and 9th harmonics. These harmonics do not create a rotating magnetic field but instead accumulate in the neutral wire, causing it to overheat and become damaged. This is especially problematic in systems with non-linear loads. Using special transformers and harmonic filters can help manage the extra heat and reduce the harmonic content in the system, preventing overheating and damage to the neutral wire.

Causes of Electrical Harmonics

In industrial settings, certain types of electrical equipment often cause harmonic distortion. This problem is common with devices like variable frequency drives (VFDs) and inverters. These devices change alternating current (AC) to direct current (DC) and then create a variable frequency AC output to control motor speeds accurately in various applications.

During this conversion, these devices draw current in a non-linear, uneven way, instead of the smooth, wave-like manner of regular loads. This uneven current draw adds harmonic components to the electrical system, causing voltage distortion. The main reason for this uneven current draw is the internal electronic parts, like rectifiers and switching circuits, which only draw current at certain times during the AC cycle. For example, a VFD that controls an industrial motor first changes the incoming AC to DC and then uses an inverter to create a variable frequency AC output to adjust the motor speed. The rectification stage involves switching parts that draw current in bursts, rather than continuously. This burst of current distorts the waveform, creating harmonics.

These harmonics can cause several problems in an industrial power system. They can increase heating in transformers and other electrical parts, reducing their efficiency and lifespan. Harmonic distortion can also cause sensitive electronic equipment to malfunction, increase energy losses, and potentially interfere with communication systems.

To reduce these effects, equipment manufacturers design their products to meet Electromagnetic Compatibility (EMC) standards. These standards limit the amount of harmonic distortion their devices can introduce into the power system. EMC standards ensure that individual devices do not cause excessive distortion that could affect the entire power system. However, even with EMC-compliant equipment, the combined effect of many devices running at the same time can still cause significant harmonic distortion. This makes it imperative to actively monitor and manage harmonics in industrial settings.

Problems Prone to Occur at Higher Harmonic Levels

Problems in Motors and Generators

Harmonics can cause big problems in motors and generators. The extra heat created by harmonic currents can break down the insulation and put stress on the machine parts. This can make these machines fail sooner, have a shorter life, and need more repairs. Harmonic vibrations can also cause wear and tear on the machines, making the problem worse.

Lower Efficiency

Harmonics make the resistive losses (I²R losses) in wires and transformers worse. These losses create extra heat, which makes the power system less efficient. The extra heat can speed up the aging of insulation materials, leading to more frequent failures and higher energy use.

Unplanned Circuit Breaker Trips and Blown Fuses

High harmonic levels can cause circuit breakers to trip and fuses to blow for no good reason. This happens because harmonics can cause too much heat and magnetic interference in these safety devices, making them work incorrectly. This unwanted tripping can interrupt operations, cause unplanned downtime, and need more maintenance.

Problems with Electronic Equipment

Electronic devices are very sensitive to harmonic distortion. Harmonics can cause problems in devices like computers, communication equipment, and other sensitive electronics. The interference from harmonic frequencies can mess up data, cause communication errors, and reduce performance, requiring extra filtering and protection.

Unexpected Resonances

Harmonic frequencies can mix with the natural frequencies of the power system, causing resonances. These resonances can make harmonic currents and voltages stronger, leading to overvoltages, overheating, and possible damage to equipment. Finding and fixing resonant conditions helps prevent serious failures in power systems.

Solutions to Mitigate Harmonics

Installing Filters

Filters are a practical and economical solution for reducing harmonics in power distribution systems. Harmonic filters are designed to block or reduce specific harmonic frequencies, allowing only the base frequency to pass through. This process helps in cleaning the electrical waveform and mitigating the adverse effects of harmonics.

To implement filters effectively, conducting harmonic surveys is imperative. These surveys involve using power quality analyzers to measure the levels and types of harmonics present in the system. By identifying the specific harmonic frequencies and their sources, engineers can design and install filters tailored to address the particular needs of the system. There are different types of filters available, such as passive, active, and hybrid filters, each with its specific applications and benefits. Passive filters consist of inductors, capacitors, and resistors. They are tuned to filter out specific harmonic frequencies. Passive filters are cost-effective and simple to implement but can be bulky and less flexible in dynamic systems. Active filters use power electronics to dynamically counteract harmonic distortion. They are more versatile and can adapt to changing harmonic profiles in real-time. Active filters are more expensive but provide superior performance in variable load conditions. Hybrid filters combine passive and active filter components to optimize performance and cost. They offer a balanced approach, providing effective harmonic mitigation with moderate investment.

Using High K-Factor Transformers

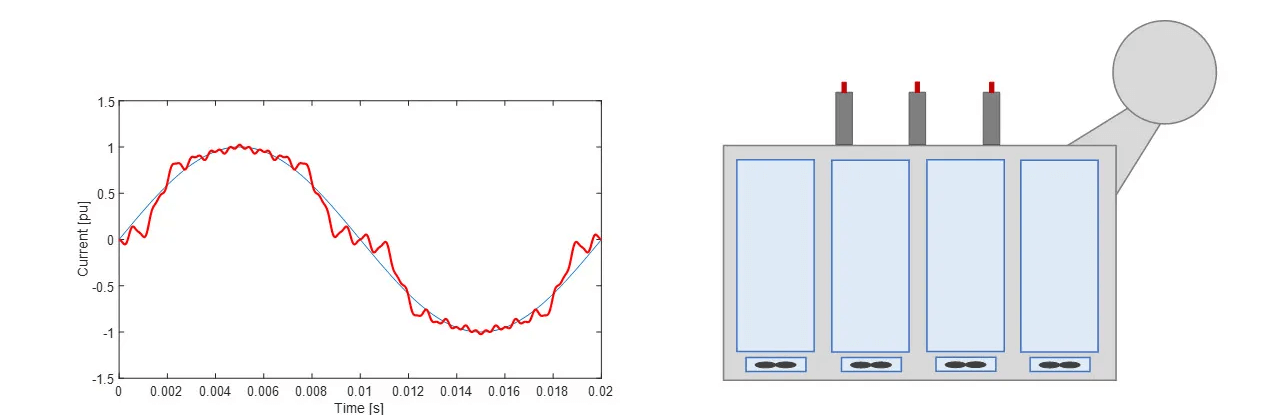

Figure 5: High K-Factor Transformer and Its Current Waveform

High K-factor transformers are made to handle the extra heat caused by harmonic currents. The "K-factor" is a rating that shows how well a transformer can deal with these currents without getting too hot. These transformers have better insulation and cooling systems to manage the extra heat from harmonics. They can get rid of the extra heat, preventing damage and making the transformer's life longer. By handling higher harmonic levels, these transformers lower the risk of overheating and failure, making the power distribution system more reliable.

Using high K-factor transformers requires careful planning. They cost more and are more difficult to install than regular transformers. The process starts with a detailed check to figure out the needed K-factor rating for the specific use. This check involves looking at the harmonic content of the load and understanding how it affects the transformer. Engineers use tools to measure the harmonic levels and calculate the extra heat caused by these harmonics.

Once the right K-factor rating is determined, the next step is to balance the long-term benefits against the initial costs. High K-factor transformers reduce maintenance needs and improve reliability, which can make up for their higher purchase and installation costs over time. However, installing these transformers is complex, so careful planning is required to minimize disruption. This includes scheduling possible downtime for replacing or installing the transformer and considering all impacts on operations.

Regular Power Quality Surveys

Regular power quality checks are needed for keeping electrical systems healthy and running well. These checks involve systematically measuring electrical properties to find and fix potential problems early. By constantly monitoring power quality, we ensure that electrical equipment works well, lasts longer, and is more reliable. Measurements should be taken at key points in the system, like where the power enters and at distribution panels. Regular data collection helps spot patterns that might show developing problems, like increasing levels of electrical noise or voltage changes. Power quality meters, which measure voltage, current, electrical noise, and sudden changes, are the main tools used in these checks. Advanced meters record data over time, giving a complete picture of power quality trends. Looking at this data helps find differences from normal conditions, allowing for timely fixes and reducing the risk of equipment breaking down.

Compliance with IEEE 519 Standards

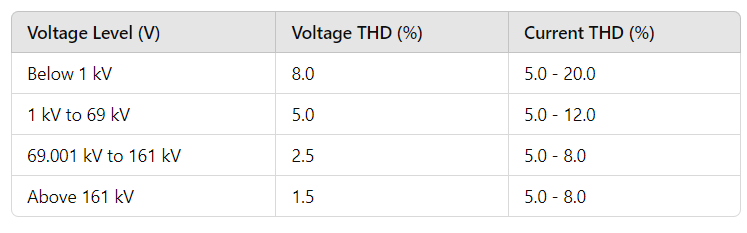

The IEEE 519 standards set rules for acceptable levels of voltage and current distortion in electrical systems. These rules help prevent damage to equipment and ensure system reliability.

The table below shows the IEEE 519-2014 standards for Total Harmonic Distortion (THD) in voltage and current for different voltage levels:

Figure 6: Table Showing Total Harmonic Distortion (THD) Limits for Voltage and Current at Different Voltage Levels

Power quality analyzers are tools that help measure harmonics up to the 511th harmonic. These analyzers provide detailed data that allows for precise monitoring and management of power quality. They help identify specific harmonic frequencies and their sizes, allowing for targeted solutions.

Regular monitoring of power quality ensures that harmonic levels stay within acceptable limits and helps detect potential problems early. Managing harmonics effectively involves finding and fixing sources of distortion, such as installing harmonic filters and upgrading transformers.

Conclusion

Harmonics in electrical systems can cause many problems, such as overheating, equipment failures, and inefficiencies. By understanding the different types of harmonics—odd, even, and triplen—and how they affect electrical parts, engineers can better predict and fix these issues. Using solutions like harmonic filters, special transformers that handle extra heat, and regular checks of power quality helps keep systems reliable and efficient. Following IEEE 519 standards ensures that harmonic levels stay within safe limits, protecting both equipment and operations. Managing harmonics well not only makes electrical systems last longer but also improves performance and reduces maintenance costs, making it a key part of modern electrical engineering.

Frequently Asked Questions [FAQ]

1. What are the dangers of harmonics?

The dangers of harmonics include overheating of electrical equipment, premature insulation failure, increased losses, malfunctioning of sensitive electronics, nuisance tripping of circuit breakers, and potential resonance conditions that can cause severe damage to components.

2. What are the effects of harmonics on power quality and losses in power distribution systems?

Harmonics degrade power quality by distorting voltage and current waveforms, leading to increased losses in transformers and conductors, reduced efficiency, overheating, and interference with sensitive equipment, which can result in operational failures and increased maintenance costs.

3. What is a major cause of harmonics in an electrical system?

A major cause of harmonics in an electrical system is the presence of nonlinear loads such as variable frequency drives, inverters, rectifiers, and other electronic devices that draw current in a non-sinusoidal manner, introducing harmonic currents into the system.

4. What is the effect of harmonics on the power factor of a distribution system?

Harmonics negatively affect the power factor of a distribution system by increasing the apparent power, causing more current to be drawn for the same amount of real power. This results in lower efficiency and higher operational costs due to increased losses and reduced capacity of the system components.

5. What are the harmonics in an electrical power distribution system?

Harmonics in an electrical power distribution system are currents or voltages at frequencies that are integer multiples of the base frequency (60 Hz in the US). They result from nonlinear loads and cause distortion in the waveform, leading to various operational and efficiency issues within the system.