The Complete Guide to Motor Drives and More

A motor driver is an electronic device that converts electrical energy into mechanical energy. Therefore, motor drives allow you to use electricity for automated work. If your project requires the use of motor drivers, then understanding motor drivers will help protect your project. This article will help you understand how motor drives work, their features, types, and the basic components involved in connecting them.

Definition and Importance of Motor Drivers

Key Characteristics of Motor Drivers

Main Components of Motor Drives

Common Types of Motor Drives

Working Principle of Motor Drivers

The Necessity of Motor Drivers

The Importance of Motor Drives in Applications

Application of H-Bridge Circuit

Steps to Build a Motor Drive Circuit

Summary

Definition and importance of motor driver

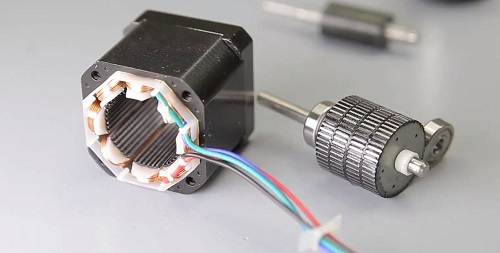

Motor Driver

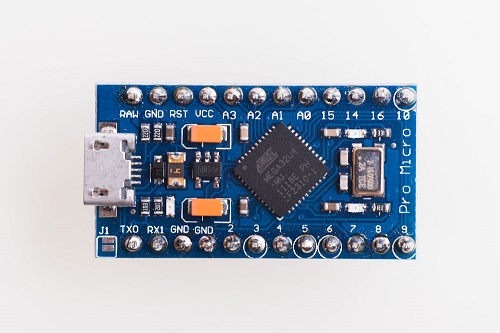

A motor driver, true to its name, is an advanced device crafted for the precise control of a motor's operation. It serves as an essential interface, linking the motor to the microcontroller. Motors, particularly those of high power, demand voltages soaring to hundreds of volts and substantial currents for operation. Contrastingly, microcontrollers typically manage only low voltages, ranging from 5 to 12 volts, with currents mere hundreds of milliamps. A direct connection between a motor and a microcontroller, absent intermediate equipment, risks overloading or damaging the latter.

Motor drivers are more than mere connectors; they are vital for voltage and current transformation. They empower microcontrollers to precisely manipulate the motor's speed, direction, and torque. Take, for example, robotic arms or electric vehicles; their performance precision, a critical aspect, hinges on this control.

At their core, motor drivers are comprised of power electronic components—transistors and diodes. They collaborate to modulate the current to the motor. Often, these components are arranged in an H-bridge configuration. This design enables bidirectional current flow, allowing motors to rotate forwards and backwards. Control is achieved via a PWM (Pulse Width Modulation) signal. This signal, originating from a microcontroller, adjusts motor speed by altering the pulse's width, thus controlling the average current to the motor.

In the market, motor drivers predominantly manifest as integrated circuits (ICs). These ICs encapsulate all necessary electronic components and often boast additional features like overcurrent protection, thermal protection, and voltage regulation. These safeguards ensure the system's overall stability and security. Selection of these drives is based on motor type—be it DC, stepper, or servo motors—and the application context, spanning industrial automation to consumer electronics.

Key characteristics of motor drivers

Selecting an appropriate motor driver involves a nuanced evaluation of various pivotal elements, demanding a profound comprehension to seamlessly align with the specific requisites of a given application. The diverse nature of motor types necessitates specialized drives, making compatibility a paramount consideration. For instance, direct current motor (DC motor) drivers exhibit prowess in handling stable currents and voltages, while stepper motor drivers mandate intricate monitoring of the motor's rotational steps. In sharp contrast, servo motor drives boast intricate attributes such as closed-loop control, ensuring precision in position and speed regulation.

Another critical facet is the interface's inherent nature. Numerous motor drivers are meticulously crafted to seamlessly integrate with renowned microcontroller boards, such as Arduino, featuring standard digital or analog input interfaces. These interfaces empower the microcontroller to govern motor operations through explicit directives. Drives equipped with wireless capabilities, encompassing Bluetooth or Wi-Fi modules, dominate projects necessitating remote control or integration into smart home systems. The wireless connectivity facilitates the reception of commands from smartphone apps or remote servers.

Voltage and current compatibility emerge as imperative considerations when harmonizing a motor drive with a specific motor and its application. The drive must adeptly manage the motor's maximal current and voltage requisites, mitigating the peril of overload or suboptimal motor performance. Additionally, applications demanding peak performance may necessitate drivers endowed with advanced power management features, encompassing current limiting, thermal protection, and voltage regulation. These features ascertain safety and stability across diverse operational conditions.

In practical scenarios, beyond these fundamental properties, variables like size, efficiency, cooling capabilities, and cost may exert influence, contingent upon the project's scope. These meticulous considerations collectively play a pivotal role in judiciously selecting a motor driver that impeccably aligns with the distinct needs of a given project.

Main components of motor drive

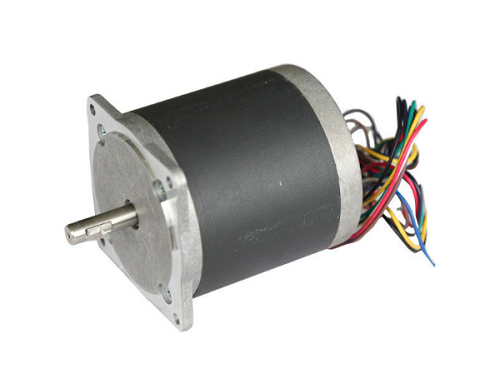

The motor, undeniably the heart of the motor drive system, is critical in applications demanding precision, such as robotics and precision manufacturing equipment. Servo motors, renowned for their high-precision control of position, speed, and acceleration, are commonly employed in these fields. In contrast, Direct Current motors (DC motors), particularly brushless DC motors (BLDC), are favored in applications requiring continuous rotation, like power tools and fans.

The controller, functioning as the system's brain, typically comprises a microcontroller or microprocessor. It shoulders the responsibility of interpreting input signals—speed, direction, position instructions—and accordingly, generates commands to steer the motor. In more sophisticated setups, specialized motion controllers execute complex algorithms, such as PID control (proportional-integral-derivative control), enhancing motion control precision.

The motor drive circuit plays a pivotal role in both servo motor and DC motor systems, acting as a current amplifier. It boosts the microcontroller's output signal to a level potent enough to drive the motor. This circuitry, often involving H-bridges, MOSFETs, and transistors, is adept at managing high-power loads and modulating motor direction and speed.

The power supply unit, supplying essential power to both the motor and controller, significantly influences system performance. Its stability and efficiency are paramount. The choice of power supply depends largely on the motor type and power requirements; for instance, servo motors might need alternating current (AC), while DC motors require direct current (DC).

Connections and interfaces ensure precise signal transmission and efficient electrical energy flow between motors, controllers, drive circuits, and power supplies. Additionally, these systems often integrate with external devices like sensors, displays, or remote control interfaces for enhanced functionality.

Finally, advanced motor drive systems may incorporate additional components like sensors (position and speed), cooling systems (radiators or fans), and protective elements (overcurrent and overheating protection). These additions significantly elevate the drive system's precision, stability, and safety.

Common types of motor drives

Motor Drive Applications

In the expansive domain of motor propulsion, the defining element lies in the intricate control mechanisms and the particular motors catered to by each variant. Let's delve into some noteworthy deviations:

Direct Electric Current Motor (DC Motor) Drives: Tailored for utilization with DC motors, encompassing brushless DC motors (BLDC), these propulsion systems achieve fundamental speed control through voltage modulation or pulse width modulation (PWM). An exemplar is the L293, a widely utilized DC motor driver proficient in supervising the direction and speed of two motors simultaneously.

Stepper Motor Driver: This driver excels in finely adjusting the step length of a stepper motor, ensuring meticulous position and speed control. It functions by directing alternating current between the motor phases, guiding each step of the stepper motor.

Servo Motor Drives: Acknowledged for their prompt response in speed, position, and acceleration control, these propulsion systems often employ a closed-loop control system. They adeptly accommodate variations in position and speed, enabling high-precision motion control. Servo drives play a pivotal role in robotics, automated machinery, and precision manufacturing.

Specific integrated circuit (IC) drivers: Streamlining integration with microcontrollers, these drivers offer features such as overcurrent protection and fault diagnostics. An illustrative example is the DRV8833, a meticulously crafted IC driver for controlling small DC or stepper motors.

High-power motor drives: Tailored to meet the substantial current and voltage requisites of large motors, these propulsion systems suit applications demanding robust power output, such as electric vehicles or sizable industrial machinery. They utilize flexible electronic components like IGBTs (Insulated Gate Bipolar Transistors) and high-power MOSFETs.

Programmable Motor Driver: In contrast to the aforementioned types, this driver provides a customizable interface for users to program control parameters. It caters to specific control needs based on project requirements, making it apt for intricate applications in automation engineering and R&D projects.

This exploration into motor propulsion showcases their diversity and specialized applications. Each type brings a unique set of capabilities to the table, addressing the intricate needs of various industries and projects.

Working principle of motor driver

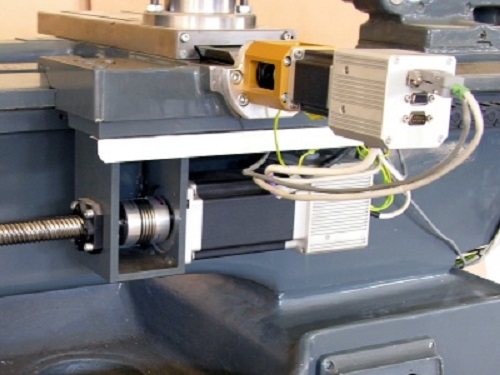

motor drive

At the heart of each motor function is a microcontroller or microprocessor, which acts as the brains of the technology as a whole. These clever devices can produce control signals from program instructions or user input including speed, direction and position. In an automation scenario, after receiving sensor data, the controller generates instructions to guide the motor to operate.

The microcontroller's low-power digital signals are converted in the motor driver to a high-power output tailored specifically for motor engagement. This transition is typically implemented in mechanisms such as H-bridge circuits or complex power MOSFETs.

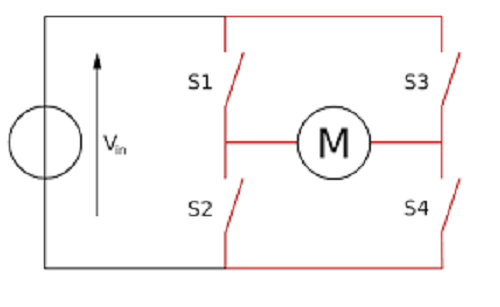

The H-bridge circuit is a key component in motor drives, especially DC motor drives. It consists of four switches (usually transistors) in an "H"-shaped structure, which can change the current flow direction of the motor and thereby control the direction of the motor. At the same time, the modulation of these switches is performed via precise PWM technology, enabling fine control of motor speed.

Enter pulse-width modulation (PWM), a tactical conductor that controls the average current in a motor by cleverly manipulating power within an H-bridge circuit. In addition to simply adjusting the supply voltage, PWM enables the microcontroller to sophisticatedly manage motor speed.

Close inspection reveals that there are input pins and control logic inside the motor driver, with each pin tasked with receiving a different control signal from the controller. These pins are responsible for coordinating functions such as motor start/stop, direction control, and speed regulation, becoming the tools for the drive's internal logic circuits to interpret the signals and convert them into carefully executed motor control operations.

In the world of complex motor drive systems, sensors become silent observers – measuring position, speed or current – to scrutinize the status of the motor. This rich data forms the basis of closed-loop control, ensuring motor operation follows predefined parameters. As a protective measure, a range of safety features, including overload, overheating and voltage anomaly protection, protect motors and complex circuits.

The necessity of motor driver

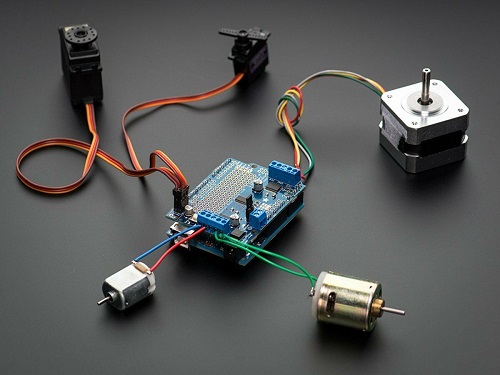

Part of the Arduino Project

Incorporating an intermediary motor driver between the microcontroller and the motor emerges as a pivotal undertaking, primarily due to the stark contrast in their voltage and current requisites. Microcontrollers typically operate on diminutive voltages (e.g., 3.3V or 5V) and currents at the milliamp level—an urgency that sharply diverges from the exigencies of motors, which may necessitate elevated voltages (up to hundreds of volts) and currents of greater magnitude (several amps or more).

The direct connection between the motor and the microcontroller carries the inherent risk of overload and potential damage. Consequently, the motor driver assumes the crucial role of a conversion medium, adeptly transforming the low-power signals emanating from the microcontroller into the robust output signals demanded by the motor.

A primary function of the motor driver is to reconcile the disparages in voltage and current between microcontrollers and motors. The microcontroller, accustomed to low voltages and currents, finds itself in a stark dichotomy with the motor's requirements. The motor driver acts as a pivotal intermediary, ingeniously transmuting the microcontroller's low-power signal into the high-powered output essential for the motor, mitigating the latent risks of overload and damage.

Moreover, motor drivers wield substantial influence in enhancing control precision across various dimensions such as speed, direction, and acceleration. This precision assumes paramount significance in applications demanding meticulous motion control, including but not limited to robotic arms, automated machinery, and precision positioning systems.

Another realm where motor drivers assert their significance lies in safeguarding microcontrollers. Motors have the propensity to generate deleterious voltage spikes or reverse currents during initiation or cessation, posing an imminent threat to microcontrollers. Motor drives often feature protective circuitry, encompassing isolation, overvoltage, and overcurrent safeguards, erecting a formidable defense against potentially detrimental signals and preserving the integrity of the microcontroller.

Energy efficiency takes center stage, especially in motor drives that utilize pulse width modulation (PWM) technology. These drives harmonize the power consumption of motors with greater efficiency, which not only saves energy but also reduces the risk of motor damage due to overheating. The motor drivers have a variety of interface features that simplify connectivity to a wide range of microcontrollers and external control systems. This includes seamless integration with computers, remote controllers or other automation devices, demonstrating its versatility in adapting to complex systems.

Another aspect that stands out is the provision of feedback and monitoring in advanced motor drives. These drives typically incorporate sensor feedback mechanisms for real-time monitoring of motor status, including parameters such as speed, position and temperature. This feedback is integral in closed-loop control systems and helps in automatic tuning and preemptive fault detection.

The importance of motor drives in applications

Servo motor close-up

Incorporating a motor driver between a microcontroller and a motor emerges as a pivotal necessity. This imperative arises not only from the frequently incongruent voltage and current prerequisites of the two components but also from the multifaceted functions the motor driver assumes within the system.

Voltage and Current Harmony: Microcontrollers typically operate at diminished voltages, such as 3.3V or 5V, with currents measured in milliamps. In contrast, motors may necessitate elevated voltages, at times ranging from tens to hundreds of volts, and augmented currents, reaching several amps or beyond. A direct linkage between a motor and a microcontroller poses a peril of overloading and detriment to the latter. Herein, the motor driver acts as an adept intermediary, skillfully transmuting the microcontroller's low-power signals into robust signals apt for motor operation.

Improved control accuracy: Motor drives facilitate more detailed control of parameters such as speed, direction, and acceleration. This detailed control capability is indispensable in applications that require complex motion control (such as robotic arms, automated machinery, or precision positioning systems).

Safeguarding the Microcontroller: Motors have the propensity to generate deleterious voltage spikes or reverse currents, particularly during initiation or cessation phases, posing a threat to the microcontroller. Motor drivers frequently incorporate protective circuitry, encompassing isolation, overvoltage, and overcurrent protection, to shield the microcontroller from these adverse effects.

Optimization of Energy Consumption: Motor drives, especially those harnessing PWM (Pulse Width Modulation) technology, excel in governing motor power consumption. This not only fortifies energy efficiency but also alleviates the peril of motor impairment due to overheating.

Diversity in Interface: Motor drives proffer an array of interfaces, facilitating connections to diverse microcontrollers and external control systems such as computers, remote controllers, or other automation apparatus. This versatility assumes a cardinal role in the amalgamation of intricate systems.

Feedback and Surveillance: Sophisticated motor drives may encompass sensor feedback, enabling real-time monitoring of the motor's status, encompassing speed, position, temperature, and more.

Such feedback proves indispensable in closed-loop control systems, fostering automatic adjustments and contributing to fault prevention.

Application of H-bridge circuit

H-bridge circuit

The H-bridge circuit, a cornerstone in motor control, boasts extensive applications across diverse fields. Its functionality and application spectrum can be explored as follows:

Composition: A typical H-bridge comprises four switching elements, often transistors, which may be MOSFETs or bipolar types. These components are strategically arranged to mimic the letter "H," with the motor connecting at the circuit's central segment.

Motor Direction Control: The H-bridge alters the motor's current direction by varying the transistors' switching states. For instance, activating two transistors on one side of the circuit while deactivating the opposite pair induces a specific current flow, spinning the motor in one direction. Reversing this transistor combination causes the motor to rotate oppositely.

Speed Adjustment: Beyond directional control, the H-bridge also regulates motor speed, predominantly via pulse width modulation (PWM). PWM modulates the duration of current flow (duty cycle) at a high frequency, controlling the motor's average power and consequently, its speed.

Application Range: The H-bridge circuit's precise control capabilities make it suitable for various applications. It's utilized in small-scale DC motors in toys and household appliances and in larger-scale endeavors like electric vehicles and industrial control systems.

Integrated Drivers: The market offers integrated H-bridge drivers, amalgamating circuitry, control logic, and protective functions. These integrated solutions simplify design, enhance reliability, and often incorporate features like overload, thermal protection, and voltage stabilization.

Design Challenges: Despite its effectiveness, designing with H-bridges presents challenges. These include ensuring rapid and safe transistor switching, preventing shoot-through (simultaneous conduction leading to short circuits), and managing the heat from high-frequency switching.

Steps to build a motor drive circuit

Building a motor drive circuit requires meticulous planning and precise implementation. Let's delve into the steps involved, focusing on a circuit that employs the L293D motor driver and Arduino UNO:

Component Preparation: Start by gathering the essentials - an Arduino UNO (or a compatible microcontroller), the L293D motor driver, one or more DC motors, a power source (like a battery or power adapter), jumper wires, and any additional sensors or auxiliary components.

Understanding the L293D: The L293D, a widely-used motor driver, can handle up to 600mA and includes overcurrent protection. It features several pins for motor control (input and output), power, and grounding.

Circuit Diagram Design: Crucial to the process is creating or consulting a circuit diagram. This blueprint should illustrate the connections between the Arduino's digital output pins and the L293D's input pins, and the motor and power supply's integration with the L293D.

Power Connection: Attach the power source to the L293D's power pins. Remember, the Arduino UNO’s power supply might be insufficient for direct motor drive, necessitating an external power supply.

Arduino-L293D Connection: Employ jumper wires to link the Arduino's digital output pins to the L293D's input pins. This setup enables programmable control over the motor's direction and speed.

Motor Connection: Attach the motor's leads to the L293D's output pins. If you're operating multiple motors, ensure correct connection to each L293D channel.

Arduino Programming: Develop Arduino code for motor control. This typically involves pin initialization, setting the PWM value for speed control, and managing motor rotation direction.

Testing and Debugging: Prior to powering the circuit, meticulously verify all connections. Post-upload of the code to the Arduino, test and observe the motor's behavior, making adjustments and optimizations as necessary.

Safety Measures: Ensure the circuit's safety by using a suitably rated power source, avoiding short-circuit risks, and incorporating fuses or current limiters where needed.

Summary

In short, motor drivers are an integral part of modern electronic systems and have become very commonplace as technology has advanced. From basic H-bridge circuits to advanced integrated circuit drivers, motor driver designs cover a wide range of technology levels to suit different types of motors and application requirements. We hope that this article has been useful to you. Please feel free to contact us with any questions or services regarding this article or any of our articles.