Switches: Types and Uses Explained

Switches are key components in electrical systems that control devices ranging from household appliances to industrial machinery. By opening or closing circuits, switches either stop or allow the flow of electrical current, which powers devices like lights, fans, and sophisticated robotic systems. The article covers the main categories of switches—electrical and mechanical—and their distinct uses. It delves into different types of switches such as toggle, pushbutton, selector, joystick, limit, and proximity switches, explaining their unique characteristics and applications. Additionally, the article focuses on various process switches used in industrial settings, highlighting their role in monitoring and maintaining safety and efficiency. Finally, it discusses the practical applications of switches and provides a conclusion on their role in various fields.Catalog

What Is a Switch?

A switch is a key electrical component that controls the operation of various devices, such as televisions, washing machines, lights, and fans. When a switch is "off," the circuit is open, stopping the flow of electrical current and turning off the device. When the switch is "on," the circuit is closed, allowing current to flow and powering the device.

Switches fall into two main categories: electrical and mechanical. Electrical switches use semiconductors for accurate control and are common in advanced electronic devices. Mechanical switches require manual operation, providing tactile feedback to indicate their position. Mechanical switches are further divided based on poles, which indicate the number of circuits the switch can control, and throws, which refer to the number of different paths the current can take.

Operating a switch varies by type. Toggle switches, often used in household lighting, provide a distinct click and resistance, confirming the action. Pushbutton switches, used in doorbells or reset buttons, involve pressing and releasing, often with a spring mechanism for momentary operation. Selector switches, found in industrial settings, use a rotary knob or lever to choose between positions, offering clear control. Joystick switches, used in cranes and robotic controls, allow multi-directional movement for intuitive control.

In industrial applications, limit switches interact with moving machine parts, ensuring safe operation by shutting down processes if parts move too far. Proximity switches detect nearby objects without physical contact, using magnetic or electromagnetic fields to sense metallic parts, making them ideal where physical contact could cause wear.

Characteristics of a Switch

Understanding the key characteristics of switches is vital before exploring the various types. These characteristics define how switches operate and their suitability for specific applications. Two primary aspects to consider are poles and throws, and the action type of the switch.

Poles and Throws

The configuration of poles and throws is a key characteristic of a switch. A pole refers to a single circuit that a switch can control, while a throw indicates the number of different paths for current flow that the switch can connect to. This configuration helps determine the switch's complexity and functionality.

• Single Pole Single Throw (SPST): An SPST switch has one pole and one throw, meaning it controls a single circuit and connects to only one path. It is the simplest type of switch, typically used for on/off operations.

• Single Pole Double Throw (SPDT): An SPDT switch has one pole and two throws. It can connect one circuit to one of two paths, allowing for more flexibility in control. This type is often used in applications where a device needs to switch between two states.

• Double Pole Single Throw (DPST): A DPST switch has two poles and one throw for each pole. It can control two separate circuits simultaneously, connecting them to a single path each. This type is useful for controlling two circuits with a single switch operation.

• Double Pole Double Throw (DPDT): A DPDT switch has two poles and two throws for each pole, enabling it to control two circuits and connect each to one of two paths. It functions like two SPDT switches mechanically linked, offering even greater control versatility.

For switches with more than two poles or throws, the specific number is often directly referenced. For instance, a switch with three poles and six throws is denoted as 3P6T. These configurations are useful in complex circuits where multiple connections and control pathways are needed.

Action: Momentary vs. Latched

The action type of a switch, whether momentary or latched, is another key characteristic. This defines how a switch behaves when actuated and released.

• Momentary Action: Momentary action switches, such as push buttons, only maintain contact while being pressed. As soon as the pressure is released, they return to their original position. This type of action is useful in applications where temporary activation is needed, like a doorbell or a keyboard key. The subtle operational detail involves the internal spring mechanism that ensures a swift and reliable return to the initial state, providing tactile feedback to the user, confirming the operation has been performed.

• Latched Action: Latched action switches maintain their position and contact until manually changed. They stay in their set state until moved back, making them ideal for applications requiring a maintained state, like a light switch or a power toggle switch. The operational experience involves a firm, sometimes tactile engagement that confirms the switch has changed state, ensuring that the desired circuit remains active or inactive without continuous pressure.

In practical applications, understanding these characteristics helps in selecting the appropriate switch for specific tasks, ensuring reliable and efficient operation. For example, in a safety-critical system, a latched switch might be chosen to ensure that an emergency stop remains active until deliberately reset. Conversely, momentary switches might be preferred in user interfaces requiring temporary activation, such as triggering specific commands in machinery or control systems.

Learn the Different Types of Switches

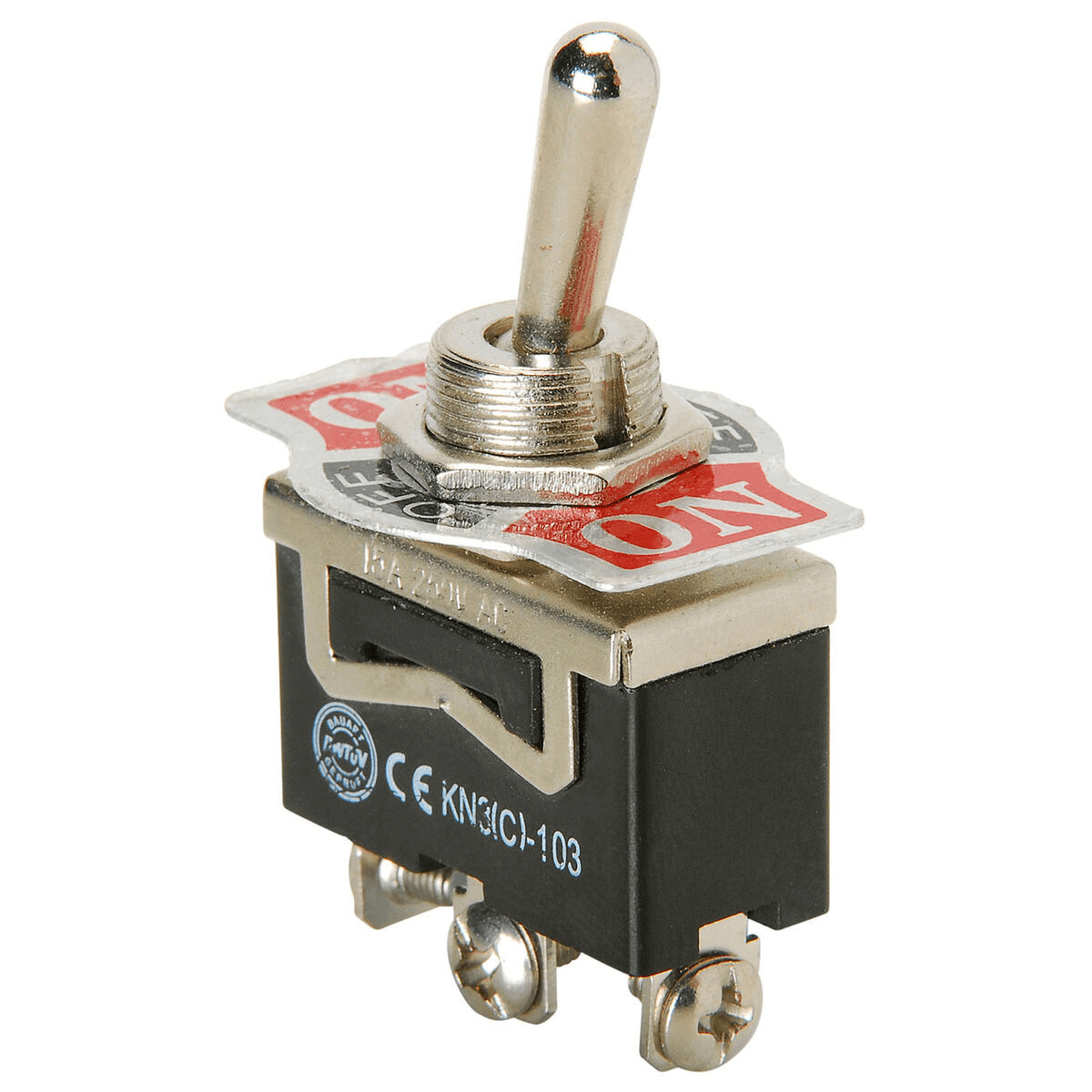

Toggle Switches

Figure 2: Toggle Switches

Toggle switches work by moving a lever to one of several fixed positions. The light switch in your home is a common example. Some toggle switches stay where you set them, while others have a spring mechanism that returns the lever to its original position for temporary use. Toggle switches are simple and reliable, making them useful in many situations.

When using a toggle switch, you move the lever up or down (or side to side) until it clicks into place. For home lighting, the "on" position completes the circuit, allowing electricity to flow and power the light. In more complex uses, like industrial machinery, the toggle switch might control different modes or safety interlocks, where the lever’s exact position ensures the correct circuit path. The movement of the lever and the clicking sound it makes provide clear feedback that the switch is working properly.

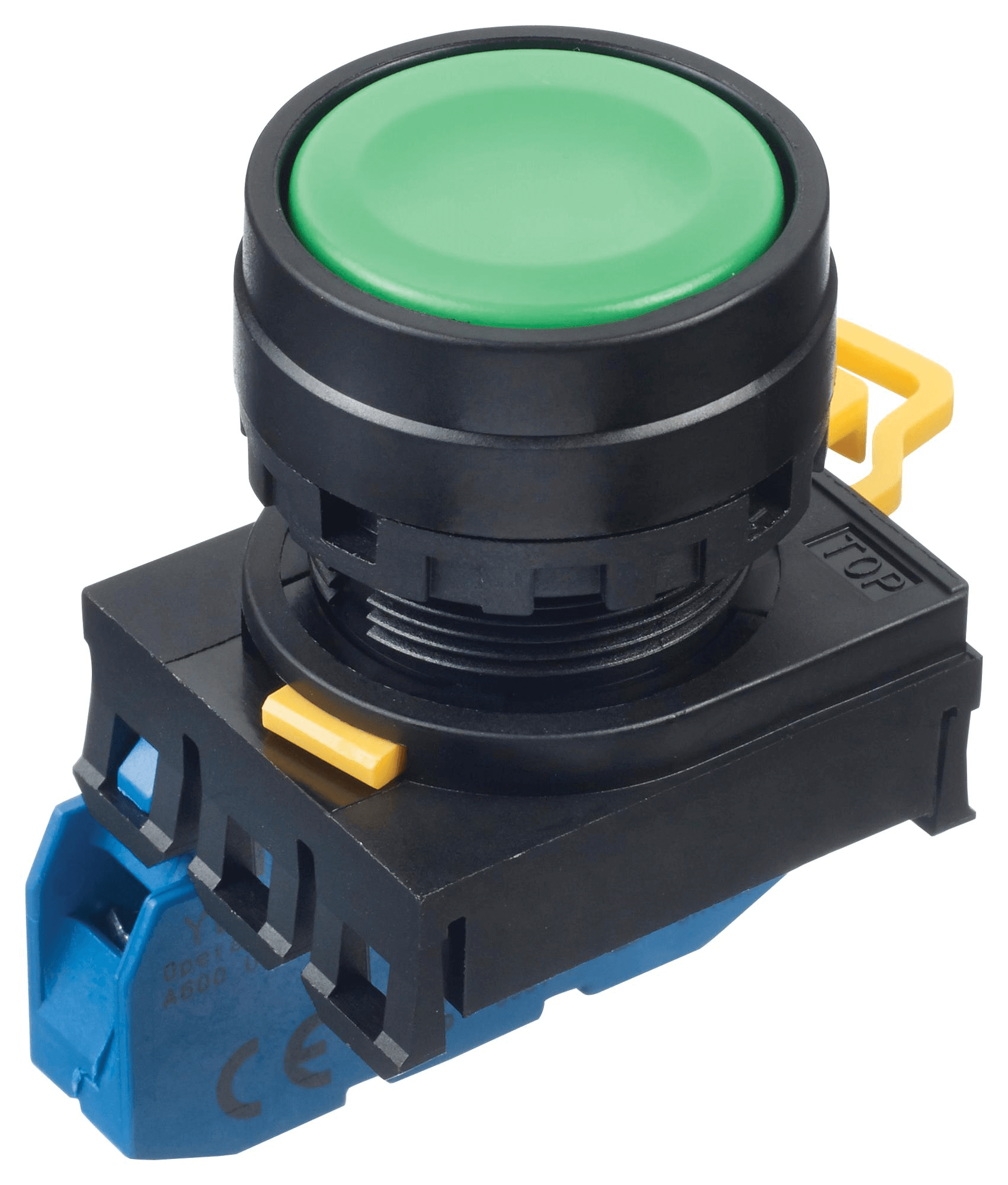

Pushbutton Switches

Figure 3: Pushbutton Switches

Pushbutton switches are simple and easy-to-use devices for controlling circuits. Pressing the button moves it to the "pressed" position, completing the circuit and allowing current to flow. Releasing the button returns it to the "unpressed" position, breaking the circuit and stopping the current. Most pushbutton switches have an internal spring that automatically returns the button to the "out" position after being pressed, making them perfect for tasks needing brief activations, such as starting motors or resetting systems.

Some pushbutton switches latch with each press, alternating between on and off states. This means the button stays "in" after being pressed and only returns to the "out" position when pressed again. This latching feature is useful for applications where a constant on or off state is needed without continuous pressure on the button.

For easier use, many pushbutton switches have a mushroom-shaped button. This design is particularly effective in emergency stop situations, where the large, easy-to-hit button ensures quick and reliable operation under stress. The push-pull action is straightforward: press the button to engage the switch and pull it back out to disengage. This clear feedback allows operators to instantly recognize the switch state, reducing mistakes and improving safety.

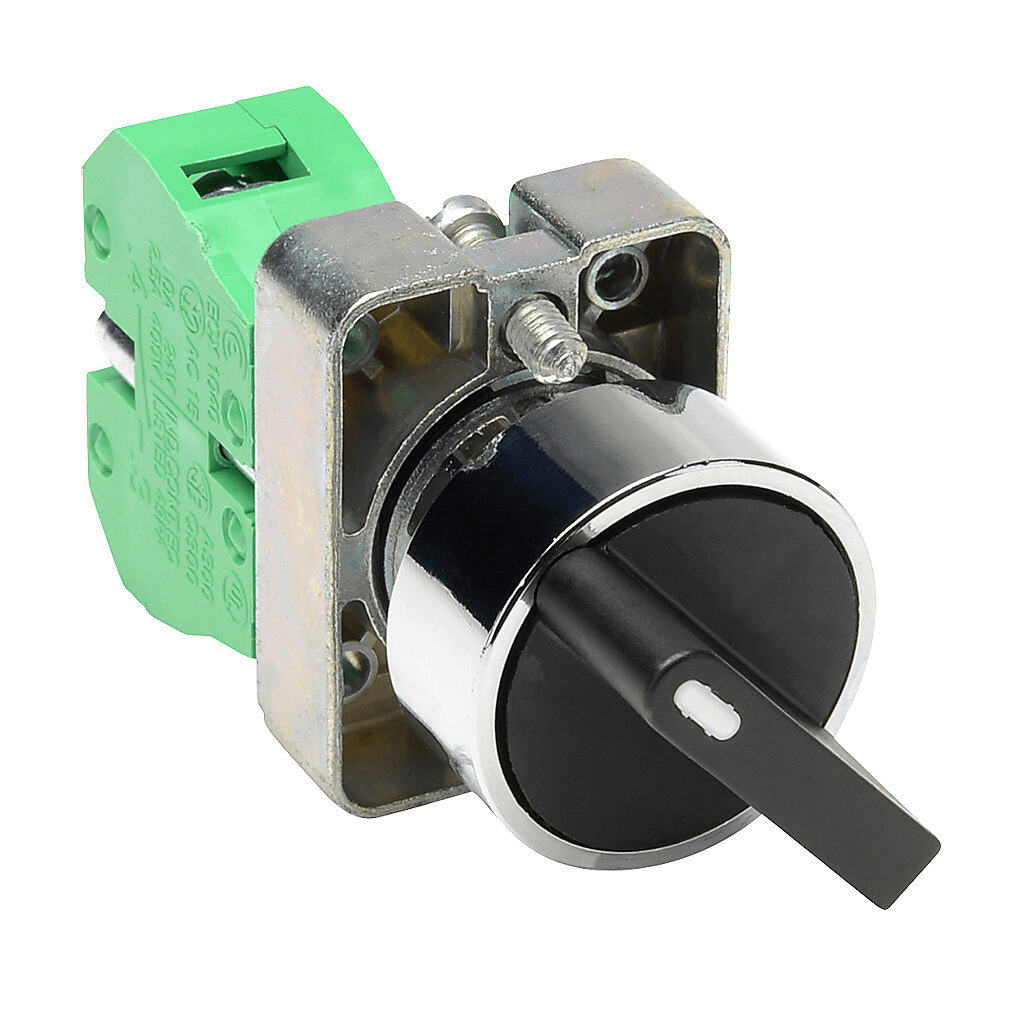

Selector Switches

Figure 4: Selector Switches

Selector switches work by turning a knob or lever to pick from multiple settings. These switches can either stay in the chosen position or return to the original position when released, thanks to a spring mechanism. They are commonly used where different operating modes or settings are required. This design provides a straightforward and effective way to change between various states.

The knob or lever on a selector switch usually has clear markings or clicks, giving the user a feel for the switch's position. For example, in industrial control panels, an operator might use a selector switch to switch between manual, automatic, and off modes. The operator can feel a distinct click as the switch moves into each position, confirming the selection without having to look.

Spring-return selector switches are handy in situations where a temporary change is needed. For instance, in machinery operation, a spring-return switch might be used to engage a function only while the lever is held in a specific position. Letting go of the lever returns it to its original state, ensuring the machine doesn't stay in an unintended mode.

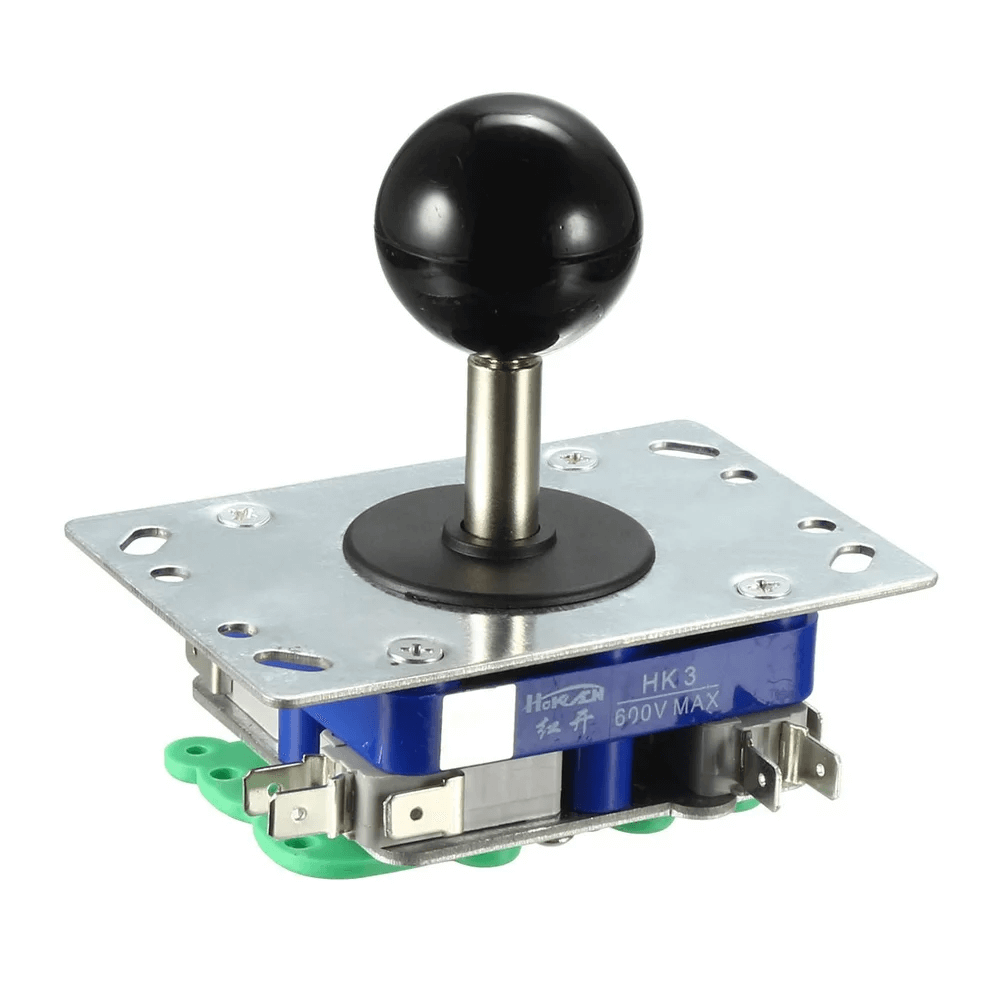

Joystick Switches

Figure 5: Joystick Switches

Joystick switches work by moving a lever in multiple directions. This movement controls different switch contacts based on the direction and distance the lever is pushed. The circle-and-dot notation on the switch symbol shows the required lever movement to activate the contact.

Joystick switches are key in crane and robot control systems. They offer easy and accurate control, allowing operators to smoothly direct machinery. When the lever moves forward, backward, or side to side, corresponding switch contacts engage, translating the operator's movements into machine actions. This responsiveness makes joystick switches very effective for complex, multi-directional tasks.

These switches can also be automated to respond to machine motion, acting as limit switches. In this role, they monitor the machine's movement and automatically cut power if it moves beyond set limits. This safety feature ensures machines do not operate outside their intended range, preventing damage and maintaining operational safety.

In practical use, an operator gripping the joystick lever can make fine adjustments by applying varying pressure. A gentle push forward might slowly move a crane arm, while a firmer push speeds up the motion. The joystick's design allows for gradual, smooth transitions, which are required for delicate operations. The tactile feedback from the lever lets the operator sense the machine's response, enabling accurate and controlled movements.

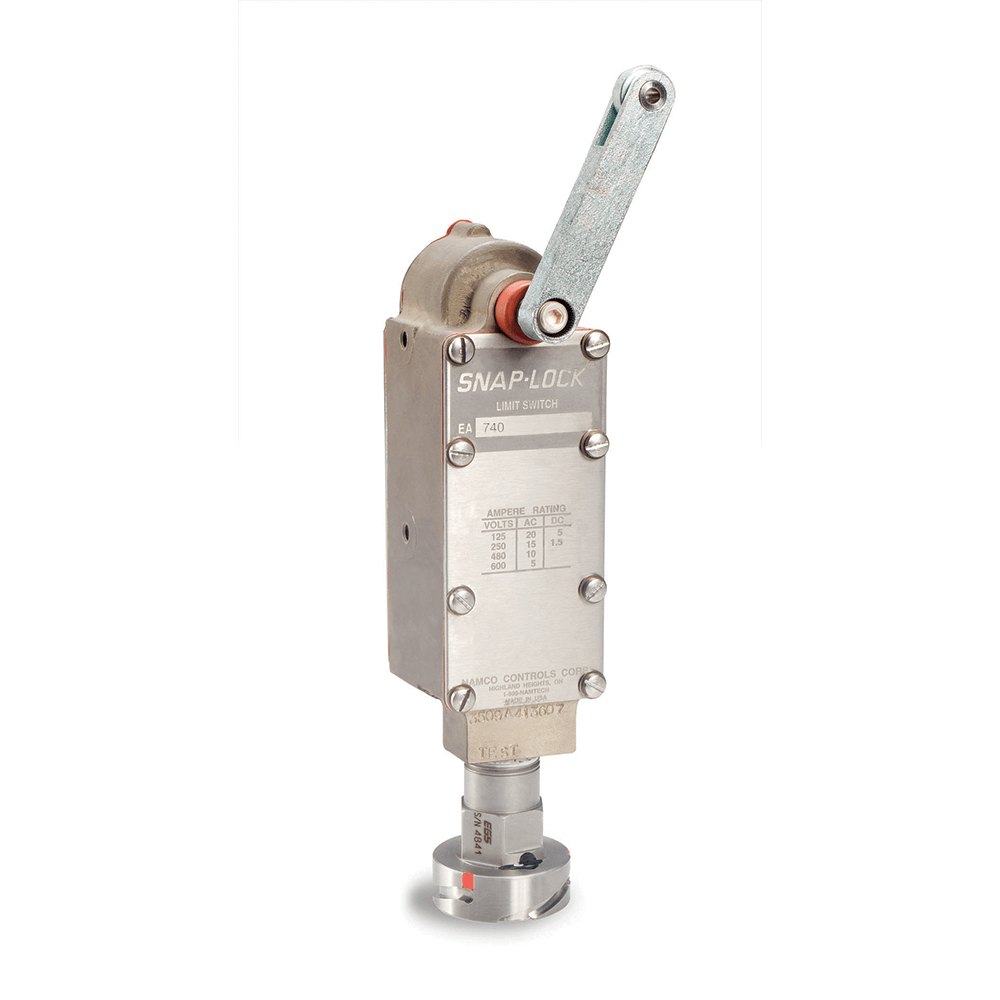

Limit Switches

Figure 6: Limit Switches

Limit switches are sturdy devices similar to heavy-duty toggle or selector switches, featuring a lever that is activated by machine parts. These levers often have a small roller bearing at the tip to reduce wear from repeated contact. In industrial settings, limit switches are key for monitoring and controlling machinery movement. They ensure machines operate safely by shutting off power or triggering specific actions when a component moves beyond a set point.

For example, in an automated conveyor system, a limit switch can be placed to detect the end of travel for an item. When the item reaches the limit switch, the lever is pushed, signaling the system to stop the conveyor or redirect the item. This mechanism helps prevent jams, overflows, and potential damage to the system.

Positioning a limit switch correctly ensures it detects movement accurately. Operators need to mount the switch so the lever consistently touches the moving part without applying too much force, which could cause early wear. Fine-tuning may be required to adjust the switch's activation point, making sure it responds appropriately. Regular maintenance involves checking for wear on the lever and roller bearing, and confirming the switch is securely fastened and properly aligned.

Limit switches are used in many applications, from elevators and escalators to robotic arms and manufacturing equipment, providing reliable feedback and control to maintain smooth and safe operations.

Proximity Switches

Figure 7: Proximity Switches

Proximity switches detect nearby metallic parts using magnetic or high-frequency electromagnetic fields. Simple versions use a permanent magnet to activate a sealed switch when a part is within about one inch. More complex versions act like metal detectors, using high-frequency currents to energize a coil and monitor the current. As a metal part gets closer, the current increases, triggering the switch.

Optical proximity switches use a light source and photocell to detect machine positions by breaking or reflecting a light beam. These switches are very useful in safety applications to detect personnel entering dangerous areas.

Proximity switches are highly valued for their ability to sense without direct contact, reducing wear and tear and increasing the lifespan of both the switch and the machinery. When installing, ensure the switch is placed at the correct distance for optimal detection. Misalignment or incorrect distance can lead to false readings or failures. Regular maintenance checks for debris or obstructions are key to maintaining accuracy and reliability.

The Different Types of Process Switches

In industrial processes, switches monitor various physical quantities. They trigger alarms, indicate when a process variable goes beyond normal limits, or shut down equipment if conditions become unsafe. Different types of process switches are designed for these purposes.

Speed Switches

Figure 8:Speed Switches

Speed switches measure how fast a shaft is spinning using either a centrifugal weight mechanism or non-contact methods like optical or magnetic sensors. These switches help keep operations running smoothly and safely by maintaining specific speed levels. The centrifugal weight mechanism works by moving weights outward as the shaft spins faster, triggering a switch when it reaches a certain speed. Optical sensors detect changes in light patterns as the shaft rotates, while magnetic sensors pick up variations in the magnetic field. Both non-contact methods offer accurate and reliable speed monitoring without direct mechanical contact, making them suitable for high-speed or delicate applications.

Pressure Switches

Figure 9: Pressure Switches

Pressure switches work by using gas or liquid pressure to activate a switch. This pressure is applied to a piston, diaphragm, or bellows, which then turns it into mechanical force to activate the switch. These switches are key parts for systems that need accurate monitoring and control of pressure levels to keep everything running safely and smoothly.

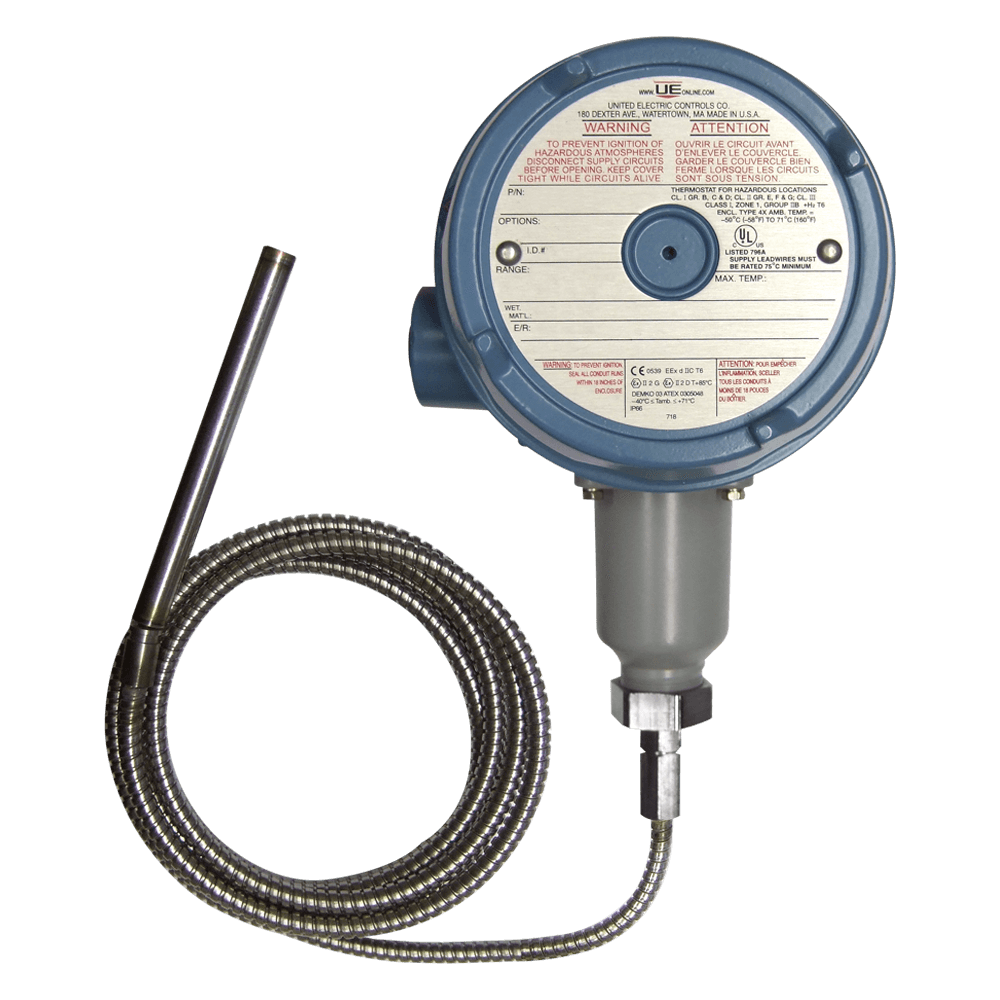

Temperature Switches

Figure 10: Temperature Switches

Temperature switches often use a bimetallic strip, which is a thin strip made of two metals that expand at different rates. When the strip heats up or cools down, it bends, activating the switch. Another type of temperature switch uses a brass bulb filled with liquid or gas connected to a pressure-sensing switch. As the bulb heats, the liquid or gas expands, increasing pressure and triggering the switch. These switches are used in applications that need accurate temperature control.

Liquid Level Switches

Figure 11: Liquid Level Switches

Liquid level switches measure the amount of liquid in a tank by using floating objects that activate a switch when the liquid reaches a certain height. For liquids that conduct electricity, the liquid can connect two metal probes in the tank, usually turning on a relay with a small current. To measure solid materials, paddle wheels or tuning forks are used. When the solid material hits the set height, it either stops the paddle wheel from moving or reduces the vibration of the tuning fork, triggering the switch.

Liquid Flow Switches

Figure 12: Liquid Flow Switches

Liquid flow switches monitor the flow rate of gas or liquid in a pipe. They often use a small paddle or vane that moves with the flow. When the fluid pushes the paddle, it triggers the switch. Some flow switches use differential pressure measurements to detect the pressure drop across a restriction in the pipe to determine flow rate. These switches help maintain system performance and safety by ensuring proper fluid flow.

Nuclear Level Switch

Figure 13: Nuclear Level Switches

Nuclear level switches detect liquid or solid materials using a radioactive source and a radiation detector placed across a storage vessel. As the material level rises, it blocks more radiation from reaching the detector. This reduction in radiation triggers a relay mechanism for measurement, alarms, or control functions. These switches are non-intrusive, with both the source and detector located outside the vessel, ensuring minimal health risks due to the low-level radioactive sources used.

Applications of Switches

Switches are versatile components used to monitor physical processes and serve as operator controls. Each type of switch has its own strengths and is best suited for specific applications. Choosing and matching switches intelligently ensures efficient and reliable operation.

Switches are key for various functions. For example, limit switches manage machine movements by stopping parts if they go beyond set boundaries, preventing damage and ensuring safety. Proximity switches detect objects without direct contact, ideal for situations where physical touch isn't possible or safe.

For human operators, the choice of switch affects usability and efficiency. Toggle switches, common in household light controls, offer a simple and reliable way to turn circuits on and off. Pushbutton switches, often found in industrial settings, provide quick, momentary actions or sustained engagement, depending on the design. These switches must feel solid and responsive to work correctly under repeated use.

Selector switches let users choose from multiple settings, often used in equipment needing mode selection. Joystick switches, used in cranes or robotic arms, require precise control and feedback, making them suitable for tasks needing fine movements in multiple directions.

In process control, speed switches monitor rotational speeds to keep equipment within safe operating ranges. Pressure switches make sure systems do not exceed safe pressure levels, protecting both equipment and operators. Temperature switches, using bimetallic strips or fluid-filled bulbs, respond to temperature changes to keep conditions optimal.

Understanding specific needs and the operational context is key when choosing switches. Each application requires careful thought about the switch's design, durability, and ease of use to make sure it works reliably and efficiently.

Conclusion

Switches are key to managing the flow of electricity in many devices and systems. From simple toggle switches in household lighting to complex joystick switches in crane controls, each type meets specific needs. Limit switches monitor machinery movements to ensure safe operation, while proximity switches detect objects without contact, reducing wear. In industrial processes, speed, pressure, temperature, and flow switches monitor various parameters to maintain safety and efficiency. Selecting the right switch means understanding the specific application requirements and ensuring reliable performance. As technology evolves, switches will continue to play a major role in advancing and optimizing electrical and electronic systems.

Frequently Asked Questions [FAQ]

1. Why are there different types of switches?

Different types of switches exist to meet specific needs. Toggle switches are used for simple on/off functions in home lighting, while joystick switches control machinery with multi-directional movement. The variety ensures each application, whether household or industrial, operates safely and efficiently.

2. What is the most common type of switch?

The most common type of switch is the toggle switch. It is widely used in household lighting because it is easy to use, reliable, and provides clear feedback.

3. Which type of switch is better?

No single switch type is better overall; it depends on the application. Toggle switches are good for basic on/off functions. Pushbutton switches are ideal for temporary actions. Selector switches are best for multiple settings, and joystick switches offer precise control in multiple directions. The best switch fits the specific task.

4. What is the purpose of a main switch?

A main switch controls the overall power supply to a system or device. It acts as a primary on/off switch, allowing safe start or stop of electricity flow. Main switches provide a quick way to disconnect power during maintenance or emergencies, ensuring safety and preventing equipment damage.

5. What is the primary function of a switch?

The primary function of a switch is to control the flow of electrical current in a circuit. By opening or closing the circuit, a switch starts or stops an electrical device, manages power distribution, and ensures safe operation.