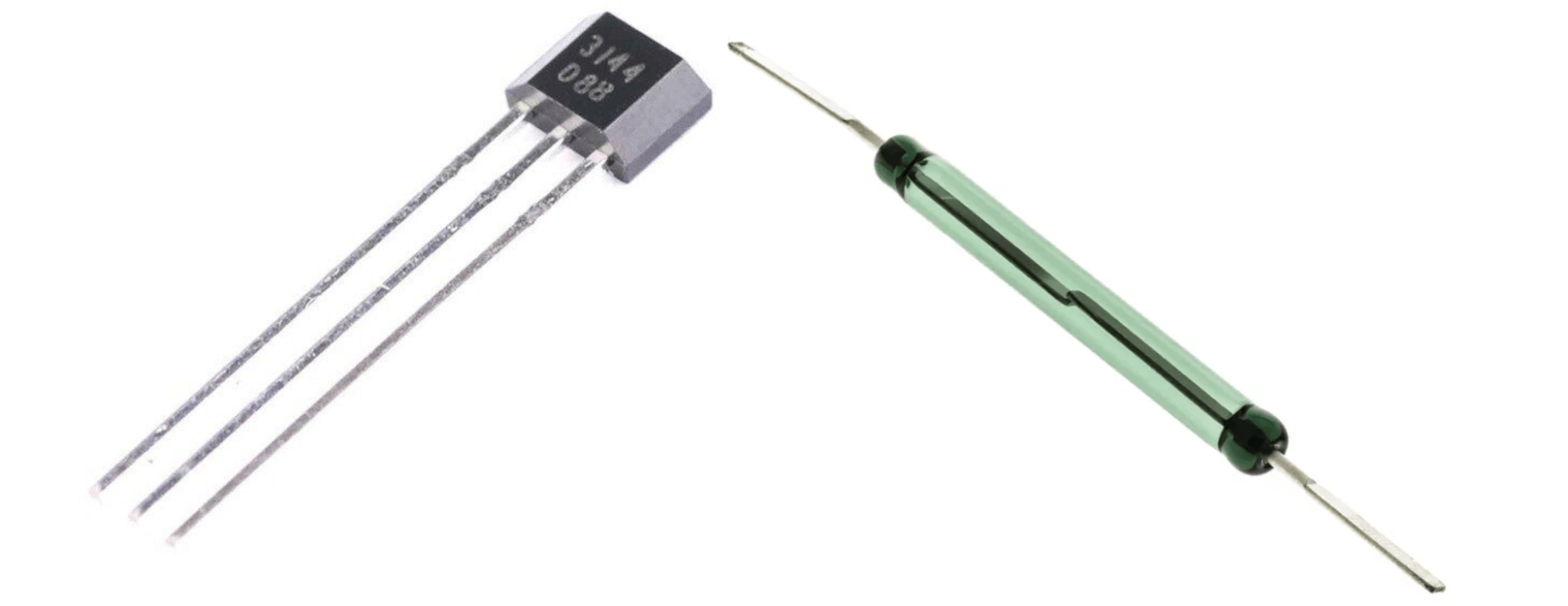

Reed Switch

Reed switches, even though they are small, play an important part in today's technology. These devices use magnets to work and can be found in many things, from home appliances to advanced medical tools. Since they were invented in 1936, reed switches have become known for being very reliable and efficient. This article explains how reed switches work, what they are made of, and the different ways they are used. It also talks about their benefits and compares them to Hall effect sensors.Catalog

Figure 1: Reed Switch

What Is a Reed Switch?

A reed switch is an electromechanical device that operates with magnetic fields. Invented in 1936 by W.B. Ellwood at Bell Telephone Laboratories, it consists of two ferromagnetic blades in a sealed glass capsule for reliable operation in various conditions.

A reed switch has two magnetic blades (reeds) inside a tightly sealed glass tube. Wires come out from both ends of the switch. The reeds are kept apart by a small space and are surrounded by a gas that doesn't react, usually nitrogen. This setup helps to prevent rust and cut down on sparks. The tips of the reeds are made from tough materials like tungsten, rhodium, or mercury. These materials help the reeds last longer and work better, especially by stopping them from wearing out and rusting. The glass tube is filled with the inert gas to prevent rusting and to lower the risk of sparks, which is very important in dangerous environments where sparks could cause fires.

Reed switches handle a wide range of voltages, currents, and frequencies, offering excellent electrical isolation and very low resistance when closed. They do not consume power when open, enhancing efficiency. Their sealed construction and simple operation ensure high reliability and longevity, capable of billions of switching cycles. They are used in household devices like washing machines and security systems, as well as medical instruments like the PillCam, demonstrating their versatility and importance in modern technology.

How Does a Reed Switch Work?

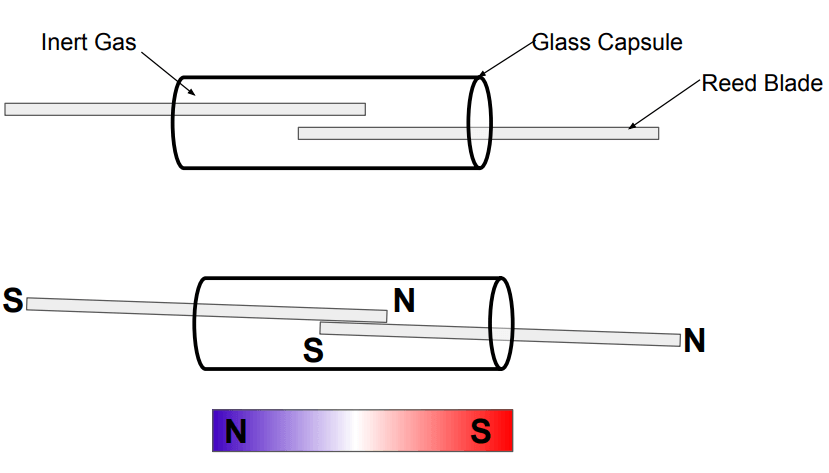

Figure 2: Reed Blade Comes in Contact in The Presence of Magnetic Field

A reed switch works using a simple but effective mechanism with magnets. It has two metal blades inside a sealed glass capsule. These blades are the main parts of the switch and are positioned very close to each other.

When a magnet comes close to a reed switch, the metal blades inside the switch become magnets too and move towards each other. This magnetic pull closes the gap between the contacts that are usually open, letting electricity flow through the switch. This way, the switch can reliably complete an electrical circuit in many different devices. In some reed switches, there is also a normally closed (NC) contact. When a magnet approaches, this contact opens, interrupting the electrical flow.

The materials used for the contacts, such as tungsten, rhodium, or even mercury, are chosen for their conductivity and durability. The entire assembly is enclosed in a glass envelope, which is filled with an inert gas like nitrogen. This gas is at a pressure lower than atmospheric pressure, creating a controlled environment inside the switch. The glass seal prevents external factors such as moisture and dust from affecting the switch. It also prevents the contacts from corroding and reduces the risk of sparks, which can occur when the contacts open or close.

Reed Switch Parts

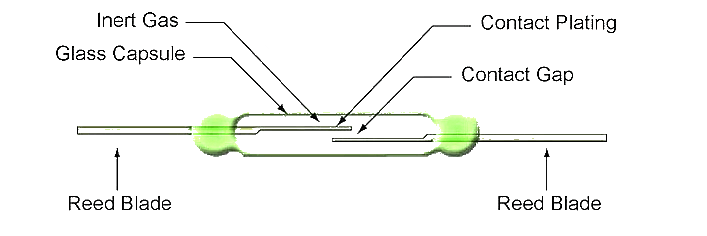

Figure 3: Reed Switch Parts

A reed switch is a simple electrical switch that works when a magnetic field is applied. It has two main metal strips (reeds) inside a glass tube. Here’s a closer look at each part of a reed switch and what they do:

Reed Blade The reed blades are thin metal strips that are the main parts of the reed switch. They are made from metals that react to magnets, like iron or nickel-iron mixtures. The reeds are very close to each other but do not touch. When a magnet is near, the reeds move towards each other, touch, and close the electrical circuit.

Glass Capsule The glass capsule is a sealed tube that holds the reeds. It keeps the reeds safe from dust, moisture, and rust, ensuring they work well. The glass also prevents electrical problems, like short circuits, keeping the switch working correctly in different settings.

Contact Plating The contact points are the ends of the reeds that touch when the switch is activated by a magnetic field. These points often have a coating of rhodium or gold to reduce resistance and prevent rust, ensuring a reliable and low-resistance electrical connection.

Contact Gap The contact gap is the small space between the reeds when no magnetic field is present. This gap makes sure the circuit stays open until a magnetic field makes the reeds touch and close the circuit.

Inert Gas The glass capsule is filled with an inert gas, usually nitrogen, to prevent rust and reduce the risk of sparks when the reeds touch. This controlled environment inside the capsule ensures the switch works well for a long time.

Reed Switch Applications

Everyday Applications

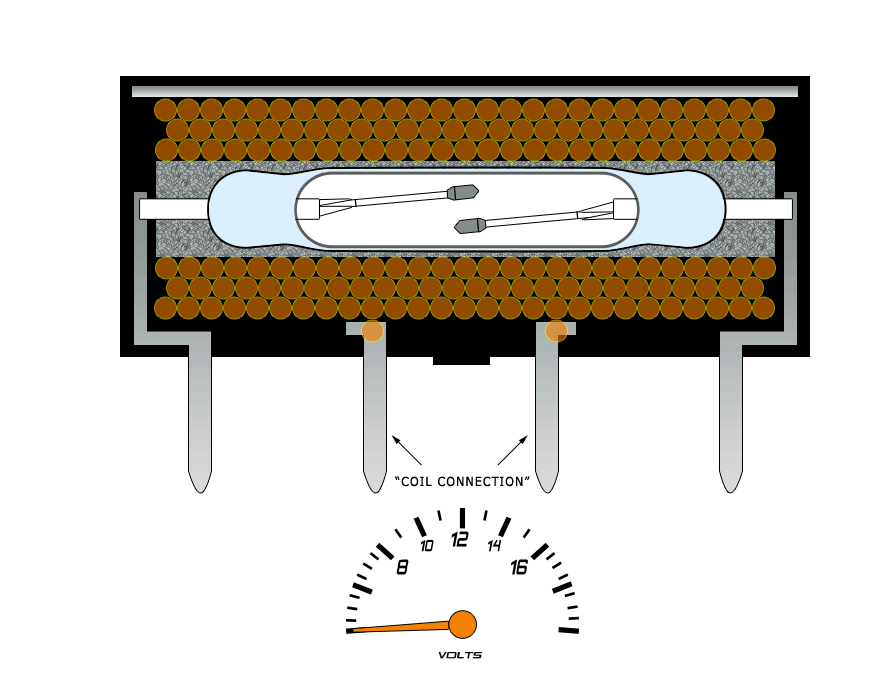

Figure 4: Reed Switch Applications in Everyday Use

Reed switches are used in many everyday devices, like cars and washing machines. In burglar alarms, they help keep homes safe. A typical burglar alarm system uses a reed switch to detect when windows or doors are opened. Here's how it works: a small magnet is placed on the moving part of the window or door, while the reed switch is installed on the frame. When the window or door is closed, the magnet is close to the reed switch, keeping the switch closed.

When the window or door is opened, the magnet moves away from the reed switch. This movement breaks the magnetic field that kept the reed switch closed. As a result, the metal blades inside the reed switch move apart, breaking the electrical circuit. This break in the circuit is detected by the alarm system, which then triggers the alarm, alerting the homeowner or security service to a possible break-in.

The simplicity and reliability of reed switches make them perfect for this use. They do not need a constant power supply to stay closed, which means they can work well with little energy. Their sealed design keeps them safe from dust, moisture, and other things that could affect how they work.

In cars, reed switches are used in various systems to improve functionality and safety. For example, they are often used in door ajar indicators. When a car door is closed, the magnet near the reed switch keeps the switch closed. If the door is opened, the magnet moves away, causing the reed switch to open and trigger the door ajar light on the dashboard. This simple mechanism helps drivers stay aware of open doors, preventing possible accidents.

In washing machines, reed switches are used to detect the position of the lid or door. When the lid or door is closed, the magnet keeps the reed switch closed, allowing the washing machine to work. If the lid or door is opened during operation, the magnet moves away, causing the reed switch to open and immediately stopping the machine. This safety feature prevents injuries and spills by ensuring that the washing machine only works when it is securely closed.

Reed switches are also used in bicycle speed sensors. In this case, a magnet is attached to one of the wheel spokes, and a reed switch is mounted on the fork. Each time the magnet passes by the reed switch, it closes for a moment, sending a signal to the bicycle's speedometer. This setup provides a simple and effective way to measure the speed of the bicycle without the need for complex electronics.

Medical Uses

Figure 5: Medical Uses of Reed Switches in The PillCam

Reed switches are used in many medical devices. One of the best examples is the PillCam, a small camera that can be swallowed. The PillCam lets doctors look inside the digestive system without needing surgery. The reed switch is a major part of how the PillCam works.

When a patient swallows the PillCam, it travels through the digestive system to take pictures. To save battery life, the device stays off until it reaches the right spot in the body. This is where the reed switch helps. Using an external magnet, the doctor can turn on the PillCam at the right moment. This delayed activation helps ensure the battery, which is small because of the device's size, lasts long enough to finish the exam.

The reed switch's sensitivity is very useful in this situation. It can sense the magnetic field from the external magnet even through the body's tissues. This ability ensures the PillCam can be activated accurately and reliably without direct contact or complex triggers. The strength of the magnetic field and the reed switch's sensitivity must be finely adjusted to make sure the activation happens correctly and only at the right time. The small size of the reed switch is a perfect fit for the PillCam, which needs to be small enough to be swallowed easily. The compact size of the reed switch allows it to be part of the PillCam without making it bulky or heavy. This design ensures the device is easy to swallow and can move through the digestive tract without causing discomfort or blockage.

Advantages of Reed Switches

Reed switches offer many benefits that make them better than other types of sensors, like Hall effect sensors.

Great Electrical Protection: The parts of a reed switch are well-protected from the outside environment and from each other. This stops unwanted electrical currents from passing through, making sure the device works safely and reliably. This is very useful in situations where precise electrical control is very important.

Low Electrical Resistance: When the switch's contacts close, they create a direct, low-resistance path for the current to flow. This means there is very little power loss and higher efficiency, which is very useful in situations where saving energy and high efficiency are needed.

Flexibility in Handling Different Conditions: Reed switches can handle a wide range of voltages, loads, and frequencies. Unlike some sensors that need specific conditions to work, reed switches can operate in many electrical situations. This flexibility makes them good for many uses, from low-power signaling in electronic devices to controlling high-power circuits in industrial machines.

High Reliability: Reed switches are made to work for billions of cycles without breaking down. The way the reed switch works, with the physical movement of its parts, is designed to handle repeated use without wearing out. This durability ensures long-term reliability and reduces the need for frequent maintenance or replacement. This is very useful in situations where downtime is costly or unacceptable.

Sealed Construction for Safety and Durability: The contacts are enclosed in a glass casing filled with an inert gas like nitrogen, which protects them from rust and wear. This airtight sealing keeps out dust, moisture, and other contaminants that could affect the switch's operation. As a result, reed switches can be used in harsh or explosive environments where regular switches might fail due to exposure to harmful elements or where a spark could cause a fire.

Comparison of Reed Switch with Hall Effect Sensors

Figure 6: Comparison of Reed Switch with Hall Effect Sensors

Hall Effect Sensors and reed switches have different strengths and are good for different uses. Here is a simple comparison of their main points.

Reed switches provide better electrical isolation because they are mechanical and physically separate their contacts when open. This reduces the risk of electrical noise and interference, making reed switches better for situations where these issues matter.

Reed switches have lower electrical resistance when closed, usually as low as 0.05 ohms. This reduces power loss and heat in circuits. Hall effect sensors have higher resistance, which can be hundreds of ohms. This higher resistance can lead to more power use and heating problems, especially in high-current situations.

Hall effect sensors need more complicated circuits to work. They need a steady power supply and extra parts like amplifiers and voltage regulators to produce a useful output signal. This makes the design and cost of systems using Hall effect sensors more complex. Reed switches are much simpler and need only two wires to connect and work, acting as a direct switch in a circuit without needing external power or complex supporting circuits.

Hall effect sensors are very sensitive and respond quickly due to their solid-state nature, making them perfect for uses needing precise and fast magnetic field detection. Reed switches, while a bit slower, respond quickly enough for many practical uses and can work well in many different environments, including places where there might be explosions and harsh industrial settings.

Reed Switch Characteristics: Reliability and Long Life

Reed switches are known for being very reliable and lasting a long time. The way they move mechanically does not wear out the materials used in them, which greatly adds to their durability. This means the parts inside a reed switch do not suffer from the same damage that can cause other mechanical switches to fail. The main reason for this is the minimal physical movement involved when the switch works. The reed blades just move towards or away from each other without much mechanical friction or strain, ensuring they last a long time.

The design of reed switches includes contacts that are sealed inside a glass casing. This sealing is very important because it keeps the contacts away from the outside environment, stopping atmospheric corrosion and dirt from getting in and affecting performance. This makes reed switches especially good for use in places where inside the glass casing keeps a stable internal environment that protects the contacts from rust and other types of chemical damage.

The long life of a reed switch is also affected by the electrical load it handles. Reed switches can manage a wide range of electrical loads, from very low to fairly high currents and voltages. When used within their specified limits, reed switches can perform billions of switching cycles without failing. This is because the contact surfaces are made to resist electrical arcing and pitting, which are common reasons why other switches fail. The materials used for the contacts, like tungsten or rhodium, are chosen for their strength and resistance to wear.

• Reed switches can handle both low and high electrical loads

• They can perform billions of switching cycles if used within the recommended limits

• The contacts are made from strong materials like tungsten or rhodium to withstand wear and prevent failure

• The contact surfaces are designed to resist damage from electrical sparks, helping them last longer

When Choosing Reed Switches

Figure 7: Various Types of Reed Switches

When choosing Reed Switches, you'll find many designs and setups available. These different types are made for specific uses, ensuring each kind meets various needs. Simple reed switches are basic parts that do not need a constant power supply to work. This makes them energy-saving and useful for many purposes.

Some specialized types, like Hall-effect switches, are designed for continuous sensing tasks such as proximity sensors or speed detectors. Unlike simple reed switches, these need extra circuitry and a constant flow of electrical current to function. This makes them more complex but suitable for jobs that require ongoing monitoring and quick responses.

Popular Reed Switch Types

Arduino Reed Switches: Used in modules, counters, speedometers, and relays. These are versatile parts that work well with Arduino microcontrollers for various DIY and prototyping projects.

Waterproof Reed Switches: Made to work reliably in wet or humid environments, making them good for outdoor applications and marine equipment.

Electric Reed Switches: Used in circuits that need low to medium voltage and current switching.

NC (Normally Closed) Reed Switches: Stay closed until a magnetic field is applied, at which point they open the circuit.

Magnetic Reed Switches: Sensitive to magnetic fields and used in applications where precise magnetic field detection is very helpful.

Plastic Reed Switches: Encased in plastic housings, providing extra protection against environmental factors and mechanical damage.

High Current Reed Switches: Built to handle larger currents, making them good for industrial applications where higher power switching is needed.

Encapsulated Reed Switches: Sealed within an enclosure to protect them from harsh environmental conditions and physical damage.

Cylindrical Reed Switches: Shaped for easy integration into tubular housings, often used in security systems and position sensors.

Bistable Reed Switches: Stay in their last state (open or closed) until a magnetic field of opposite polarity is applied, making them useful in applications needing stable state retention without continuous power.

Latching Reed Switches: Similar to bistable switches, they stay in their switched state after the magnet is removed until a reverse magnetic field is applied.

Changeover Reed Switches: Have multiple contacts and can switch between different circuits, making them useful in complex switching operations.

Hamlin Reed Switches: Known for their reliability and used in various industrial and automotive applications.

Hall-Effect Sensors: Not technically reed switches but often included in similar discussions. They detect the presence of a magnetic field through the Hall effect and need continuous power and extra circuitry.

Mini Reed Switches: Small and designed for applications with limited space, such as medical devices and compact electronics.

Micro Reed Switches: Even smaller than mini reed switches, used in very compact electronic applications.

Each type of reed switch offers unique benefits tailored to specific needs, whether for industrial, automotive, consumer electronics, or specialized sensing applications. Understanding the differences between these types can help you choose the right reed switch for your specific use, ensuring good performance and reliability.

Conclusion

Reed switches are amazing because they are simple, reliable, and can be used in many ways. They are found in everyday items, help keep people safe in medical devices, and work well in tough industrial jobs. By learning how they work, what they are made of, and why they are useful, we can see why reed switches are often chosen over other options like Hall effect sensors. They can handle many different tasks, last a long time, and work efficiently, making them a must-have in today's technology. As we continue to develop new gadgets and tools, reed switches will keep making sure everything works smoothly and safely.

Frequently Asked Questions [FAQ]

1. What is a reed switch used for?

A reed switch is used in many things. It helps in security systems to detect if doors or windows are open. It is used in home appliances like washing machines to check if the lid is closed. In medical devices like the PillCam, it helps control when the device turns on. Reed switches are also used in cars for door sensors and in bicycles to measure speed.

2. How does a reed flow switch work?

A reed flow switch works by sensing if fluid is moving. It has a reed switch and a magnetic float. When fluid moves through the pipe, the float moves and brings the magnet close to the reed switch. This magnetic field causes the reeds inside the switch to come together, closing the circuit and showing that fluid is flowing.

3. Is a reed switch a relay?

A reed switch is not a relay. Both can control circuits, but a reed switch uses magnets to open or close a circuit. A relay is a switch operated by electricity that uses an electromagnet to move the switch.

4. How do you activate a reed switch?

You activate a reed switch by bringing a magnet close to it. The magnet makes the reeds inside the switch move towards each other, closing the gap and completing the circuit. When you take the magnet away, the reeds separate, opening the circuit.

5. How do you check if a reed switch is working?

To check if a reed switch is working, use a multimeter to measure continuity. Put the multimeter leads on the wires of the reed switch. When you bring a magnet close to the switch, the multimeter should show a closed circuit (continuity). When you move the magnet away, the multimeter should show an open circuit (no continuity). This shows the reed switch is working properly.