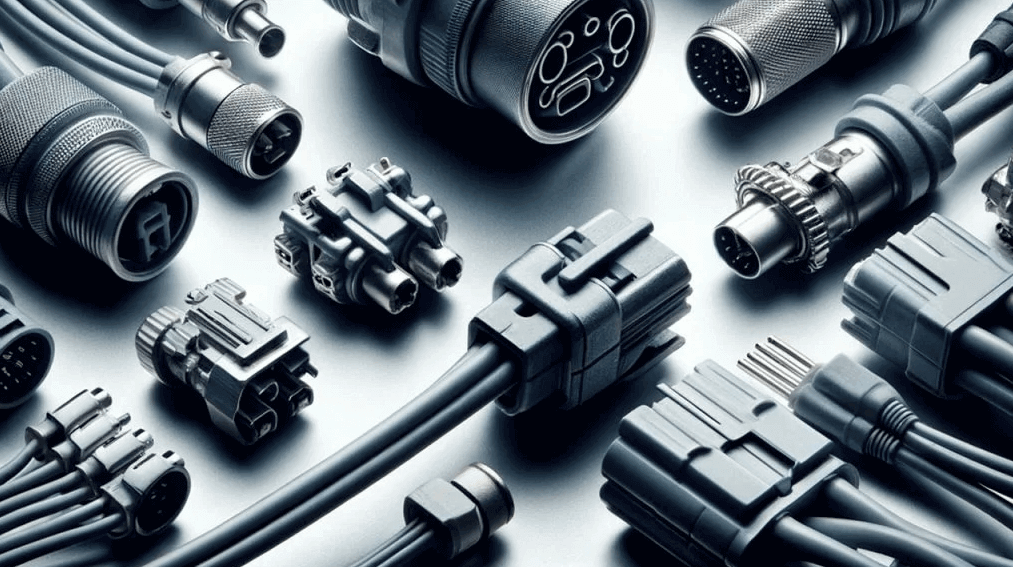

Pigtail Connectors Guide - Definition, Operating Principles and Construction, Types

In exploring key components in modern electrical systems, pigtail connectors demonstrate their central role in enabling efficient, flexible connections. This connector, composed of precision-engineered wires, connectors, and insulation, not only simplifies the electrical installation process of vehicles and electronic equipment but also greatly enhances the scalability and maintainability of the system. In this article, we will delve into the definition of pigtail connectors, their working principles, types, and how to choose pigtail connectors.Catalog:

1. What is a pigtail connector?

The pigtail connector is a key component in the vehicle's electrical system. It consists of a small length of cable or wire. Its main function is to conveniently extend the electrical connection. It allows you to quickly add or replace without rewiring. equipment. Through its unique layout, the pigtail connector makes it easier to install additional electrical components, whether it is lighting fixtures or audio systems, without the need to completely modify the existing electrical wiring, greatly optimizing the flexibility of the vehicle's electrical system. city and scalability.

2. Working principle and structure of pigtail connector

Pigtail connectors are composed of three essential parts that work together to expand and maintain electrical systems effectively.

Wire Component: The wire in the pigtail connector transmits electric current. These wires are usually made from high-quality copper or aluminum, which ensures excellent electrical conductivity and durability. In multi-core pigtails, each wire is independently insulated to prevent interference and short circuits. The thickness and material of the wire depend on the current it needs to carry and the environment in which it will be used. For instance, thicker wires are used for high-current applications, while thinner wires are suitable for signal transmission or low-current devices.

Connectors: Each end of the pigtail has connectors that can be either male or female to interface with different devices or circuit boards. These connectors are precisely designed to ensure quick and secure insertion or removal, simplifying installation and maintenance. Often, connectors are designed with anti-mating features, such as different shapes or color markings, to help users correctly match the interfaces.

Insulation: The wires and connectors are wrapped in high-quality insulation materials, such as polyvinyl chloride (PVC), silicone, or Teflon. These materials prevent electrical short circuits and protect users from electric shocks. The insulation layer also resists environmental factors like temperature, humidity, and chemical corrosion, ensuring the reliability of the pigtail connector in various conditions.

In practice, installing pigtail connectors is straightforward. For example, when adding a new audio system to your vehicle, first ensure that the pigtail connector's interface matches the audio system's input. Next, plug one end of the pigtail connector into the audio system's jack and connect the other end to a power source or the existing electrical system. The entire process doesn't require professional tools, and thanks to color codes or shape markings, even non-professionals can complete it easily.

3. Application scope and advantages of pigtail connectors

Pigtail connectors are an important tool for enhancing convenience, flexibility, organization and safety in electrical installations. The following is a detailed analysis of the application range and advantages of pigtail connectors:

Detailed explanation of advantages

Convenience: Pigtail connectors are designed for ease of use. Most are plug-and-play, simplifying the installation process. Users do not need to perform technical tasks such as complex wiring or welding. For example, when installing a new car audio system, you simply plug the pigtail connector into your existing electrical outlet and audio equipment. This allows you to enjoy an upgraded sound experience in minutes without the need for additional tools or expertise.

Flexibility: Pigtail connectors are available in a variety of lengths and connector types to meet different installation needs. They can be used in anything from simple household appliances to complex industrial equipment. For example, shorter pigtails can connect desktop computer peripherals, while longer pigtails are suitable for larger spaces, such as high-mounted lighting in industrial warehouses.

Organization: Pigtail connectors help maintain a neat and organized space by neatly securing and guiding wires. This not only improves the aesthetics of the space, but also reduces safety hazards caused by tangled or exposed wires.

Safety: High-quality pigtail connectors are designed with rugged insulation and structural safety in mind. They use heat- and fire-resistant materials to ensure that all electrical connection points are properly protected against faults such as short circuits and electrical fires.

Application scenarios

Lighting Systems: In a home or office environment, pigtail connectors can quickly connect LED strips or other lighting devices to a power source. Simply connect one end of the pigtail to a power outlet and the other end to the LED strip. Not only does it make installation quick, but it also makes it easy to adjust or change lighting configurations as needed.

Audio and Video: For setting up audio and home theater systems, pigtail connectors can extend or reconfigure speaker lines or connect various media playback devices, such as connecting a video game console to a monitor or TV. This ensures clear signal transmission and reduces signal interference.

Sensors and Security Systems: In security system installations, pigtail connectors simplify the wiring of sensors such as smoke detectors, door and window sensors, or motion detectors. By using pigtails, installers can easily plug these devices into a central monitoring system without requiring extensive electrical modifications to the building.

General Electronics: Pigtail connectors can also be used to connect a variety of small appliances or tools, such as power tools, portable charging equipment, or other electronic devices.

4. Types and selection of pigtail connectors

There are many types of pigtail connectors, each designed for specific applications and technical needs to ensure an efficient and safe electrical connection. Let's discuss the types of pigtail connectors from four aspects.

By connector type

Wire-to-wire connectors: These connectors connect two or more wires together. They make connections simple, simplifying installation and maintenance.

Wire-to-board connectors: These connectors are designed to secure wires to a printed circuit board (PCB) and often have a locking mechanism to ensure a secure and shock-proof connection. They are ideal for electronic devices that require wires to be soldered directly to the circuit board.

Wire-to-device connectors: These connectors connect wires directly to devices such as sensors, switches, or motors. They have specific shapes and sizes to ensure a perfect fit into device ports, providing a safe and stable electrical connection.

Waterproof Pigtail Connectors: Designed for outdoor or wet environments, these connectors provide superior sealing to prevent moisture damage. During installation, you will feel a tighter fit at the connection points, usually accompanied by a satisfying "click" sound, indicating a successful seal.

Quick Connect Pigtail Connectors: These connectors feature a quick release mechanism for quick and easy connection and disconnection. They are suitable for applications that require frequent replacement or maintenance, such as medical or testing equipment.

By application

Power Connectors: These connectors are designed to meet different current and voltage requirements, ensuring safe and efficient power transfer. For example, in a home theater system, the power connector must handle higher currents to keep the system stable.

Audio/Video Connectors: Including types such as RCA, XLR, or TOSLINK, these connectors ensure high-quality audio and video signal transmission. When connecting these devices, you'll notice a tight and precise fit between the plug and socket.

Data connectors: such as USB, Ethernet or HDMI pigtails for high-speed data transfer. Make sure the connector ports are clean and undamaged to maintain data transfer speed and quality.

Sensor Connectors: Used for specific types of sensors, these connectors are often small and delicate and require precise operation to ensure accurate signal transmission.

According to wire gauge

Coarse Gauge: These wires can handle high currents and are suitable for appliances or motors.

Thinner specs: These are ideal for delicate tasks like lighting or low-power electronics.

By material

PVC: This material is well insulating and cost-effective, making it suitable for indoor and low-risk applications.

Silicone: Silicone is known for its flexibility and resistance to high temperatures, making it ideal for outdoor or high-temperature environments.

Teflon: Teflon offers the highest levels of heat resistance and chemical stability, making it suitable for use in industrial and harsh environments.

5. How to choose the appropriate pigtail connector

Selecting the appropriate pigtail connector is a critical step in ensuring the efficiency and safety of your electrical system. In order to select the best pigtail connector for a specific application, the following detailed technical details should be carefully considered.

Purpose and application scenarios

First, determine the purpose and environment in which the connector will be used. For outdoor applications, choose a waterproof and weather-resistant model. For audio equipment, choose high-fidelity connectors to ensure clear signal transmission. Knowing the specific requirements can help narrow down your choices.

Device compatibility

Check whether the pigtail connector specifications match your device interface. Incompatible connectors may result in weak connections or poor electrical performance. For example, when connecting a new sensor, make sure the connector fits precisely into the sensor port to prevent loosening or leaking.

Electrical requirements

Understand the electrical requirements of the system, such as voltage, current, and frequency. Choose connectors that can handle the maximum load to avoid overheating or safety issues. For example, make sure the connector can support the power requirements of your home theater system to maintain stable operation.

Quality and durability

Choose high-quality pigtail connectors made from corrosion-resistant and high-strength materials, such as gold-plated copper or stainless steel. These materials provide stable performance in a variety of conditions. Check manufacturing standards and durability testing to evaluate long-term reliability.

Material selection

Materials play a key role in connector performance. PVC is flexible and suitable for indoor environments, while silicone and PTFE are better suited for harsh environments and provide additional thermal and chemical stability. Select materials based on the environmental conditions in which the connector will be used.

Easy to install

Choose connectors that are easy to install. The quick-connect design allows quick replacement without the need for special tools, saving time and labor costs. This is especially useful for scenarios that require frequent maintenance, such as medical equipment.

Compliance with regulatory standards

Verify that the selected pigtail connector complies with local and international safety standards, such as UL, CE, or RoHS certification. Compliance with these standards ensures product safety and environmental performance.

Cost-effectiveness

There are both initial purchase costs to consider, as well as long-term maintenance costs. While the initial cost of high-quality connectors may be higher, their durability can reduce the frequency of replacement, thus lowering long-term expenses.

6. Summary

Combined with the wide range of applications and selection strategies for pigtail connectors, pigtail connectors have become a popular choice for many electrical applications due to their versatility and ease of installation. With the advancement of technology and expansion of the market, the design and functions of pigtail connectors are also constantly evolving to adapt to more complex and harsh application environments. So whether you consider the durability of its structure during the selection process or evaluate its cost-effectiveness, informed decisions will ensure the continued performance and safety of your electrical system while also optimizing long-term operating costs. If you are facing wiring challenges, please consider these handy little friends, I believe they will bring different creativity to your project.

Frequently Asked Questions [FAQ]

1. How to use pigtail connector?

- Confirm electrical requirements and connector types: Determine the type of equipment or cables that need to be connected. Check the voltage, current and interface type (such as RCA, HDMI, etc.) and select the matching pigtail connector.

- Prepare the connection surface: Make sure the wires or device ports you want to connect are clean and free of dust. This step is very important to ensure the reliability of the electrical contact.

- Connect the pigtail: Connect one end of the pigtail connector to the electrical interface of the device. There is usually a clicking sound when plugged in, which is a sign that the connection is securely in place. Make sure the connection is stable and not loose.

- Connect to mains power or another cable: Connect the other end of the pigtail to a power supply or another cable. If you are connecting to a cable, you may need to use wire caps or terminal blocks to ensure a secure connection, in which case it is a good practice to encapsulate the exposed wires with electrical tape or heat shrink tubing.

- Test Connections: Before starting use, test the connections for proper electrical functionality. This can be done by measuring the voltage or actually running the device.

2. What is the purpose of pigtail connectors?

The primary purpose of pigtail connectors is to provide a safe, fast electrical connection that allows electrical equipment to be added, replaced or repaired without rewiring. They are particularly suitable for hard-to-reach locations or tight spaces, making installation and maintenance easier and more efficient.

3. What are the most common and widely used pigtail connectors?

- Wire-to-wire connectors: these connectors are widely used to connect two wires and are especially common in home appliances and automotive electronics.

- Wire to board connectors: commonly used in electronics manufacturing such as connecting wires to printed circuit boards. These connectors are designed with a locking mechanism to ensure stability and vibration resistance.

- Waterproof pigtail connectors: useful in outdoor or wet environments, such as garden lighting systems or outdoor sound systems.

- Quick release pigtail connectors: This type of connector is especially designed for devices that require frequent connections and disconnections, such as medical test equipment or modular electronics.