Navigating Terminal Blocks: A Comprehensive Overview of Connector Types

Terminal block connectors serve as serious components within both residential and industrial electrical systems, playing a key role in establishing and maintaining robust, efficient, and safe electrical connections. These connectors come in various designs, each tailored to meet specific requirements and environmental conditions. Terminal blocks are designed to offer ease of use, high durability, and adaptability, catering to the diverse needs of electrical installations. From their ultimate role in facilitating wire connections to their sophisticated configurations in high-demand applications, terminal blocks ensure that electrical systems operate with increased safety and efficiency. This article explores the basic aspects of terminal blocks, including their types, selection criteria based on electrical and mechanical considerations, and the significant benefits they offer within complex wiring systems. By digging into the specifics of terminal blocks, we gain insights into their integral role in enhancing the functionality and safety of electrical systems across various settings.Catalog

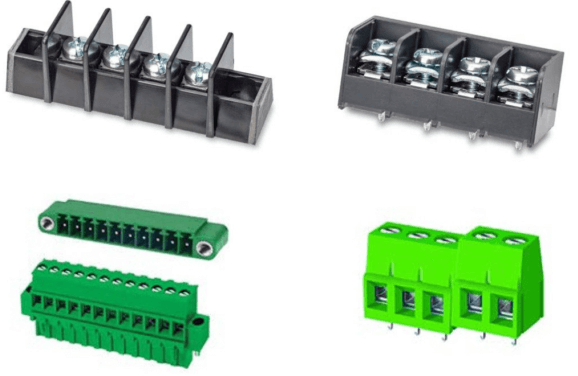

Figure 1: Terminal Blocks Connectors

Exploring Terminal Block Connectors

Terminal block connectors are dynamic components in both residential and industrial electrical systems. They enable the connection of individual wires to circuits or systems efficiently. These connectors are valued for their simple design and effectiveness, and they come in various shapes, sizes, and ratings to suit different needs. Typically, terminal blocks function as single-pole connectors, accommodating one wire per terminal, unlike multi-pole connectors that can handle multiple wires.

These connectors are especially useful where connections need to be semi-permanent, requiring regular maintenance, troubleshooting, or changes. They are common in environments where wiring may need periodic replacement or where systems frequently undergo maintenance. Terminal blocks have a durable insulating body, usually made of plastic, which insulates the electrical contacts to prevent accidents.

To secure wires, different mechanisms are used, with the screw type being the most common. In this method, a wire is placed and fastened with a screw. The approach can vary depending on the wire gauge. Thicker wires might be clamped directly against a solid metal base for better stability, while thinner wires are often pinched against a metal insert with a lever or flat screw. Some modern terminal block models use a screw-less design with a lever mechanism to clamp the wire, making connection and disconnection easier in systems that frequently change.

Different Types of Terminal Blocks

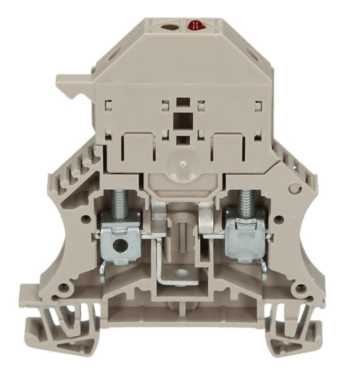

Figure 2: Screw Terminals

Screw terminals use screws to securely fasten wires. They are common in both residential and industrial settings with moderate electrical needs. These terminals provide a strong, stable connection without the need for soldering, as long as the screws are properly tightened. It’s significant not to over-tighten the screws, as this can damage the wire and compromise the connection's safety and effectiveness.

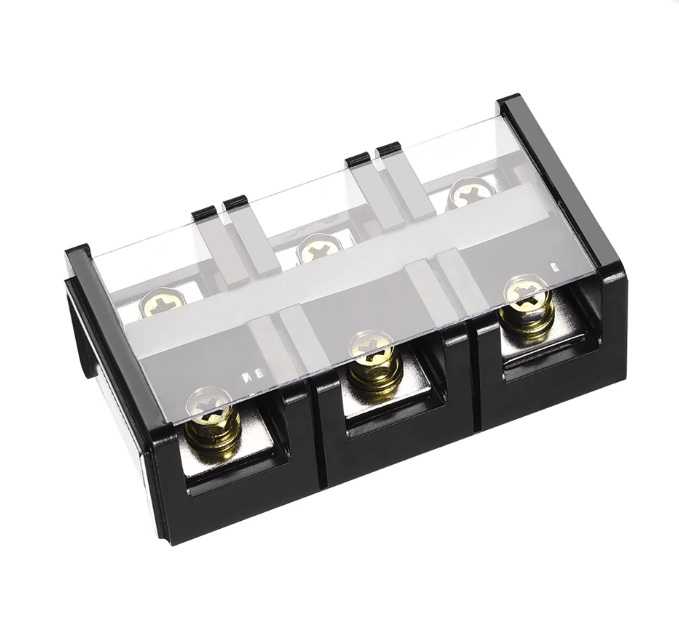

Figure 3: Barrier Terminals

Barrier terminals also use screws to secure wires but have physical barriers between each connection. These barriers are used in high-voltage applications to prevent electrical arcs and short circuits. Often equipped with protective covers, barrier terminals offer enhanced safety and durability, making them suitable for challenging electrical environments.

Figure 4: Push-fit Terminals

Push-fit terminals feature a spring-loaded mechanism that holds wires in place, allowing for easy wire insertion and removal. This design simplifies installation and maintenance, eliminating the risk of over-tightening. Push-fit terminals are ideal for locations where frequent adjustments are not practical.

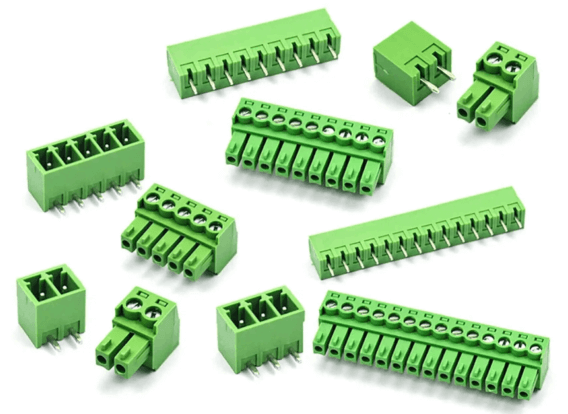

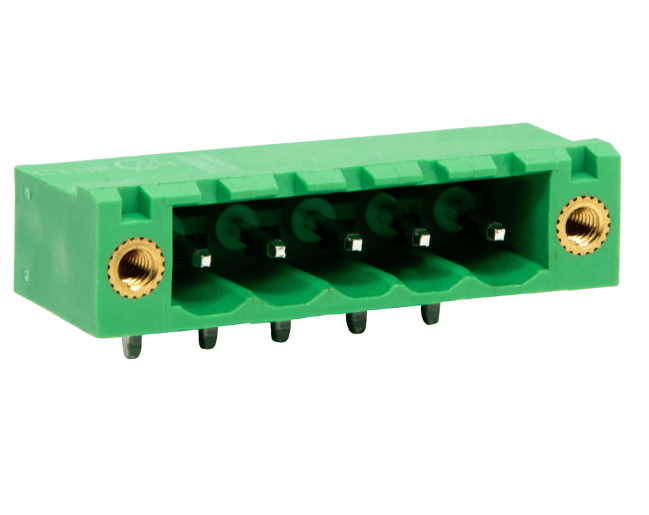

Figure 5: Pluggable Terminals

Pluggable terminals have a dual-interface design, with a wire connection on one end and a mating socket on the other. This setup allows for safe and easy disconnections, facilitating efficient hot-swapping. Pluggable terminals are perfect for systems that require regular maintenance or alterations, providing a balance of security and adaptability for dynamic electrical systems.

Choosing the Right Terminal Block

Choosing the right terminal block involves understanding the specific electrical needs of the application, including current and voltage requirements, as well as the environmental conditions.

• Current Requirements: A settling factor is the terminal block's current handling capacity. Select a block that can manage at least 150% of the maximum expected current. This precaution helps prevent overheating and potential damage.

• Voltage Requirements: Voltage considerations are also significant. To avoid risks like dielectric breakdown in high-voltage setups, choose a terminal block that can handle the system's peak voltage plus a margin for potential surges. This ensures system integrity.

• Type and Size of Wire: The type and size of the wire being used affect terminal block performance. Multi-strand wires work well with screw terminals due to their flexibility, while single-strand wires are better suited for push-fit connectors, providing stable connections.

• Environmental and Mechanical Considerations: The operating environment significantly impacts terminal block selection. Consider factors like humidity, temperature fluctuations, chemical exposure, and mechanical vibrations. Ensure the terminal block can withstand these conditions to maintain durability and performance.

Mechanical Considerations for Terminal Blocks

When selecting terminal blocks, consider the mechanical criteria that influence their design and functionality. These include wire entry orientation, wire securing methods, and module configuration.

• Wire-Entry Orientation: The orientation of the wire entry can be horizontal, vertical, or angled at 45 degrees, depending on the spatial constraints of the installation site. Each orientation offers unique benefits for accessibility and efficient use of space.

• Wire-Securing Method: Various methods are used to secure wires in terminal blocks, including screw terminals, push buttons, and direct push-in techniques. Each method has specific advantages in terms of ease of installation and connection reliability. Screw terminals are traditional and provide a solid hold, push buttons to simplify the process, and direct push-in techniques are fast and secure.

• Module Type: Terminal blocks are available as interlocking modules or single-piece designs. Interlocking modules allow for customizable configurations and flexibility in the number of poles, while single-piece blocks offer greater strength and durability, making them ideal for high current loads or elevated temperature environments.

• Wire-to-Housing Method: Advancements in terminal block technology have led to the development of pluggable connections. These allow wires to be easily inserted into a housing and connected or disconnected from another stationary housing. This method is particularly useful in scenarios that require frequent disconnections and reconnections without disrupting the entire setup.

Electrical Specifications for Terminal Blocks

Selecting the right terminal block involves considering several key specifications. These include orientation, contact count, pitch, current rating, voltage rating, and wire compatibility.

Firstly, the orientation of the terminal block, whether horizontal, vertical, or angled, affects installation space and accessibility. Choosing the right orientation allows for efficient use of space and ease of maintenance.

Secondly, the number of contacts or terminals determines how many wires can be connected.

Thirdly, the pitch, or spacing between terminals, impacts the density of connections. A smaller pitch can save space but may be harder to work with, while a larger pitch is easier to handle but requires more space.

Fourthly, the current rating indicates the maximum current the terminal block can handle safely. Selecting a terminal block with a current rating that exceeds the maximum expected current by at least 50% helps prevent overheating and potential damage.

Fifthly, the voltage rating specifies the maximum voltage the terminal block can safely accommodate. It's authoritative to choose a terminal block that can handle the system’s peak voltage plus a margin for potential surges.

Finally, compatibility with the wire size and type is a must. Different terminal blocks are designed to work with various wire gauges and types, such as multi-strand or single-strand wires. Ensuring compatibility helps maintain a secure and stable connection.

Classifying Terminal Blocks by Function

Terminal blocks are used in electrical systems, connecting components like Variable Frequency Drives (VFDs), Programmable Logic Controllers (PLCs), and sensors. They are specialized in various types to meet specific operational needs, enhancing both safety and efficiency. Here's a closer look at different terminal block types:

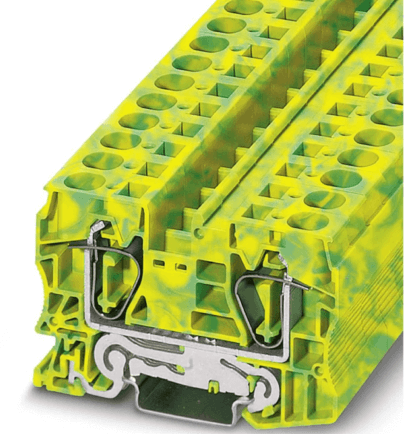

Figure 6: Ground Terminal Blocks

Ground terminal blocks are dynamic for safety. They connect wires to a grounding path, preventing electrical faults and enhancing system stability. This ensures any stray currents are safely diverted to the ground, protecting both the system and users.

Figure 7: Fuse Terminal Blocks

Fuse terminal blocks incorporate overcurrent protection directly within the terminal block. This design simplifies the circuit by eliminating the need for separate fuse holders. It ensures that in the event of an overcurrent situation, the fuse will blow, interrupting the circuit and protecting the components from damage.

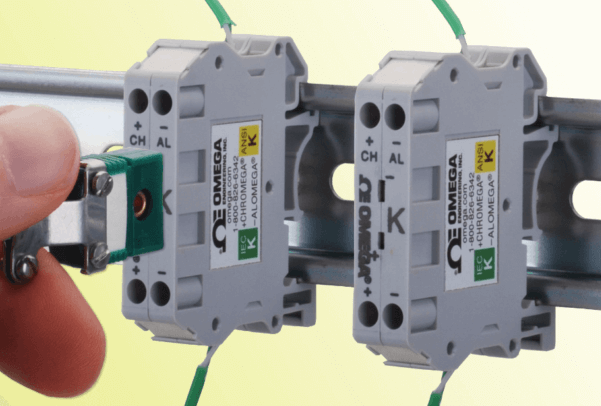

Figure 8: Thermocouple Terminal Blocks

Thermocouple terminal blocks are designed to reduce electrical interference from the contact of dissimilar metals. They ensure accurate temperature readings by maintaining the integrity of the thermocouple connections.

Figure 9: Molded Case Circuit Breaker (MCCB) Terminal Blocks

MCCB terminal blocks are built for high-demand applications, providing robust electrical protection. They facilitate secure and stable connections, enhancing the safety and reliability of serious systems. Their design ensures that they can handle high current loads without compromising on performance.

Benefits of Using Terminal Blocks in Modern Electrical Installations

Terminal blocks are the ultimate components in electrical engineering, offering numerous advantages over conventional wire connectors. They enhance both functionality and safety in electrical systems. Here’s a detailed look at the benefits they provide:

|

Benefits of Using Terminal Blocks |

|

|

Improved Organization and

Accessibility |

Terminal blocks help organize wiring by

neatly securing and separating different connections within an electrical

panel. This organization makes it easier to access specific sections for

maintenance or troubleshooting, reducing downtime and simplifying the

management of complex wiring systems. |

|

Enhanced Safety |

By clearly separating connections,

terminal blocks minimize the risk of accidental contacts that could lead to

short circuits or electrical shocks. They often come with touch-proof

designs, further mitigating risks for technicians and ensuring a safer working

environment |

|

Simplified Assembly and Installation |

Designed for ease of use, terminal blocks

feature plug-in connections that speed up wiring installations. This

plug-and-play approach allows for quicker assembly and disassembly, which is

particularly advantageous during upgrades or repairs, significantly reducing

labor time and costs. |

|

Increased Durability and Reliability |

Made from robust materials, terminal

blocks can withstand harsh conditions, including high temperatures and

vibrations, making them suitable for various industrial applications. Their

design ensures a secure connection that is less likely to loosen over time,

enhancing the overall reliability of the electrical system |

|

Versatility and Scalability |

Terminal blocks come in various types and

sizes, catering to a wide range of electrical currents and voltages. This

versatility allows them to handle different wire sizes and types, from thin

control wires to thick power cables, accommodating the needs of both

small-scale electronic devices and large industrial machinery. |

|

Cost-Effectiveness |

While the initial cost of terminal blocks

may be higher than some traditional connectors, their ease of installation,

low maintenance requirements, and long-term reliability can lead to lower

overall costs. By reducing potential downtime and minimizing the need for

frequent replacements or repairs, terminal blocks offer a cost-effective

solution for many electrical systems. |

|

Ease of Troubleshooting and

Maintenance |

The organized structure of terminal

blocks makes it easier to identify and resolve issues, such as faulty

connections or damaged wires. Each connection point is isolated, simplifying

the process of measuring voltage drops and inspecting individual components

without disrupting the entire system. |

Conclusion

To sum up, terminal blocks epitomize innovation and practicality in electrical engineering, bringing structured organization, enhanced safety, and remarkable adaptability to electrical systems. The detailed exploration of terminal block types—from simple screw terminals to sophisticated molded case circuit breaker (MCCB) blocks—underscores their versatility and tailored applicability across diverse electrical applications. Analytic factors such as current and voltage requirements, environmental conditions, and wire compatibility play key roles in selecting the appropriate terminal block, ensuring that each electrical setup is optimized for safety and efficiency.

Furthermore, the benefits of using terminal blocks, such as improved safety measures, simplified assembly, and increased system reliability, highlight their value in reducing operational risks and maintenance costs. By integrating the right terminal blocks, professionals can achieve a balance between operational demands and safety, leading to more reliable and effective electrical systems. Terminal blocks not only support the dynamic needs of modern electrical infrastructures but also enhance the overall manageability and safety of electrical installations, making them requisite in the field of electrical engineering.

Frequently Asked Questions [FAQ]

1. What are the different types of terminal connectors?

Terminal connectors come in various types to suit different electrical and mechanical needs. Common types include:

Ring Terminals: These have a circular end for secure attachment around a screw or stud.

Spade Terminals: Shaped like a fork, they allow quick connections without completely removing the screw.

Butt Connectors: Used to join two wires end-to-end.

Disconnects: Enable quick disconnection of wires without desoldering or cutting.

2. How to use terminal connectors?

Remove a small section of insulation from the end of the wire;

Place the stripped wire into the metal part of the connector;

Secure the wire in place by crimping the metal sleeve with a crimping tool or by soldering for a more permanent connection.

3. What is the purpose of terminal connectors?

Terminal connectors are used to securely join wire ends to equipment, other wires, or terminals. They provide a reliable and conductive electrical connection that can be assembled and disassembled without damaging the wire.Q4. What is the difference between a terminal and a connecter?

A terminal is a point of connection that facilitates the joining of more than one wire to a single connection point.

A connector typically refers to the entire device that joins electrical circuits together, which may include multiple terminals.

5. What is a connector in transportation?

In the context of transportation, a connector usually refers to infrastructure that links different modes or routes of transportation together. For example, a bus service that connects a suburban area with a main train station is a transportation connector. These facilitate the movement of people or goods by bridging gaps between different transportation networks.