Liquid Crystals: From Discovery to Everyday Screens

Imagine a world where the clear pictures on your TV, the bright display on your phone, and even the colorful screens on digital billboards all come from the same source. This world is real, thanks to the science of liquid crystals—a special material that acts like both a solid and a liquid. Liquid crystals were discovered over a century ago, and they have since become the backbone of modern display technology. What started as a curious observation of a substance that seemed to melt twice has grown into the advanced Liquid Crystal Displays (LCDs) we use every day. In this article, we will explore the discovery, growth, and many uses of liquid crystals, showing how this once mysterious material became a common part of our daily lives.Catalog

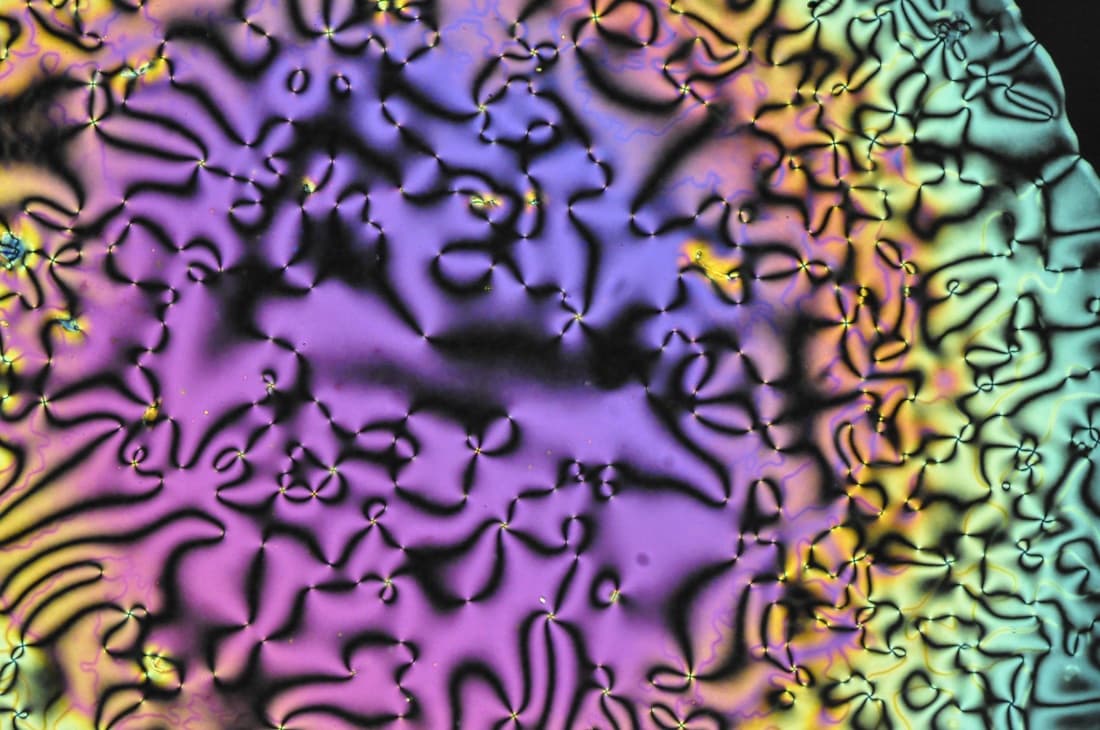

Figure 1: Close-up Image of Liquid Crystals Under a Microscope

The Discovery of Liquid Crystals

The story of liquid crystals began in 1888 when Friedrich Reinitzer, an Austrian botanist, was experimenting with a compound called cholesteryl benzoate, found in carrots. During his research, Reinitzer noticed something unusual. As he heated the compound, it seemed to melt twice. First, at 294°F (145°C), the substance melted into a cloudy liquid. Then, when the temperature rose to 353°F (179°C), it became a clear liquid. What made this even more fascinating was how the cloudy liquid interacted with light—it could reflect polarized light and even change its direction.

Unsure of what he was seeing, Reinitzer asked German physicist Otto Lehmann for help. Under Lehmann’s microscope, the cloudy liquid showed tiny structures that suggested the material had qualities of both liquids and solids. It flowed like a liquid but also had an organized structure like a solid. Lehmann’s continued research led him to an important conclusion: this was a new state of matter, which he called a “liquid crystal.”

Understanding Liquid Crystals and Their Applications

Liquid crystals are special materials that have qualities of both solids and liquids. They aren't just found in labs; they can also be found in many natural substances. For example, liquid crystals exist in beetle shells, DNA, human bones, wood, and even slug slime. Scientists have been fascinated by these materials and have studied them deeply to find out how they could be used in technology.

A big step forward in understanding liquid crystals came in the early 1960s, thanks to chemist Richard Williams at RCA Laboratories. He noticed that when he applied an electric field to a thin layer of liquid crystals, it made them form striped patterns, which were later called "Williams' domains." This discovery played a major role in the development of liquid crystal display (LCD) technology.

But there was a problem: the liquid crystals needed high temperatures to work properly, which made them difficult to use in everyday electronic devices. The high temperatures made it hard to bring this technology into the real world.

This challenge was eventually overcome by George H. Heilmeier, another scientist at RCA, who worked with chemists Joel E. Goldmacher and Joseph A. Castellano. They found out that by changing the structure of the liquid crystal molecules—specifically by adjusting the number of carbon atoms—they could get the liquid crystals to work at room temperature. This discovery allowed them to create the first liquid crystal displays that could be used in everyday electronics.

The ability to operate at room temperature made it possible for liquid crystal technology to be used widely. Today, LCDs are everywhere—in televisions, computer monitors, smartphones, and digital watches. The development of liquid crystal technology shows how careful study and problem-solving can lead to new inventions that change the way we live.

Early Development of LCD Technology

The early development of Liquid Crystal Display (LCD) technology began with the use of a method called Dynamic Scattering Mode (DSM). This method worked by applying an electric charge to liquid crystal molecules, which caused them to shift and scatter light. This scattering of light created visible images, making DSM the basis for the first working LCDs. In 1969, RCA introduced the first commercial LCD products, such as animated advertising displays, rearview mirrors that reduced glare, and gasoline pump readouts. These early uses showed what LCD technology could do and set the stage for further improvements.

At the same time, James Fergason and his team at Westinghouse Electric Corporation were making progress in studying the heat-related properties of liquid crystals. Their research led to new ideas like liquid crystal thermometers and devices for optical imaging. Fergason didn't stop there; he went on to start the International Liquid Crystal Company (ILIXCO), which played a major role in the LCD market. One of ILIXCO's noteworthy products was the first LCD watch, a product that showed just how useful and marketable LCD technology could be.

How Do LCDs Work?

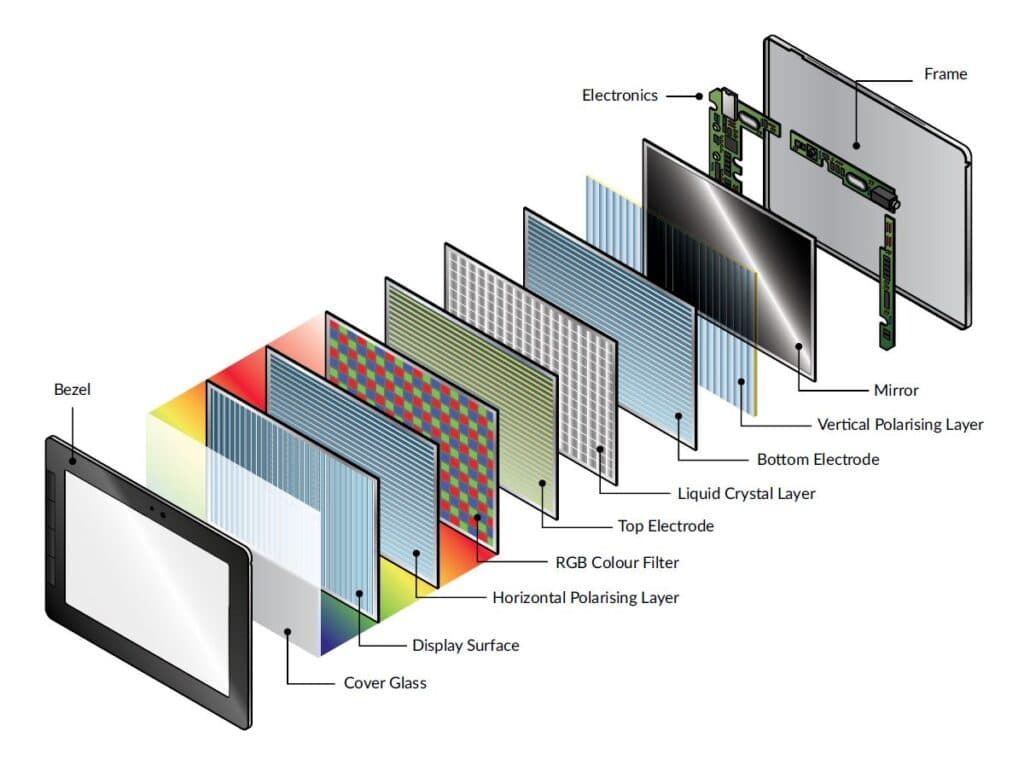

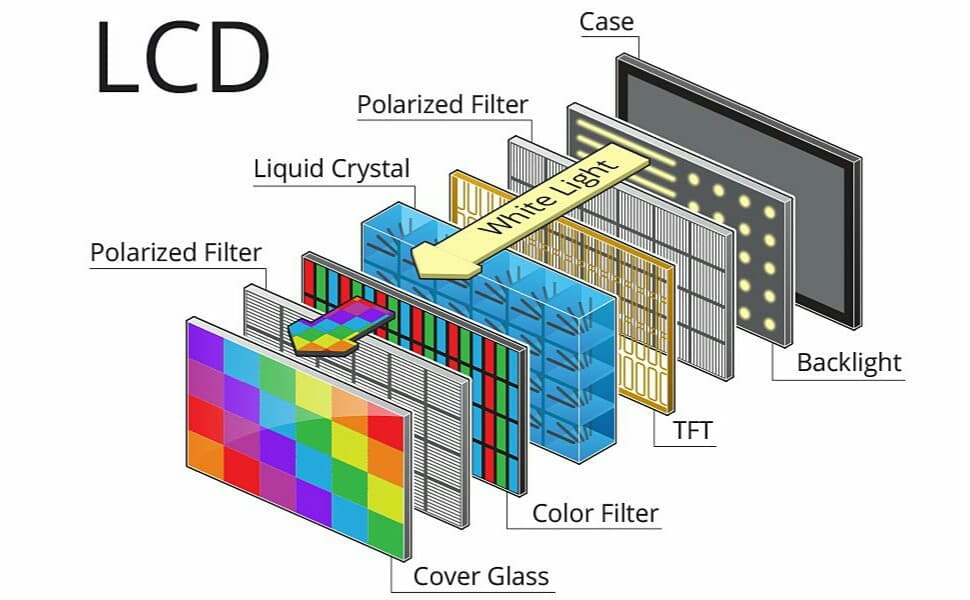

Figure 2: Diagram of Layers and Components of an LCD (Liquid Crystal Display)

The image shows how a Liquid Crystal Display (LCD) is put together and how it works to create pictures on a screen. At the front is the bezel, which is the frame that holds the display in place. Behind the bezel is the cover glass, the protective layer you touch when using the display. Underneath the cover glass is the display surface, where the images you see are formed.

Beneath the display surface is the RGB color filter, which splits light into red, green, and blue parts. These colors mix in different ways to create the full range of colors on the screen. The liquid crystal layer is found below this filter. Liquid crystals in this layer are controlled by electricity, which changes their position to either block or let light through. The polarizing layers around the liquid crystal layer help manage the light that passes through.

At the back of the display is the backlight, which lights up the screen. Some designs also have a mirror behind the backlight to bounce light back into the screen, making it brighter.

LCDs work by controlling how light passes through these layers to create images. Each tiny dot on the screen, called a pixel, is split into three smaller parts (subpixels)—one red, one green, and one blue, as shown by the RGB color filter in the image. By adjusting how bright each subpixel is, the screen can show different colors.

The backlight, shown at the back in the image, shines light through the screen's layers. The liquid crystals, influenced by an electric current, decide how much light gets through, which in turn affects the brightness and color of the image you see. The image clearly shows how each part, from the backlight to the RGB filter, works together to create the final picture on the screen.

There are two primary types of LCD technologies: Passive Matrix and Active Matrix.

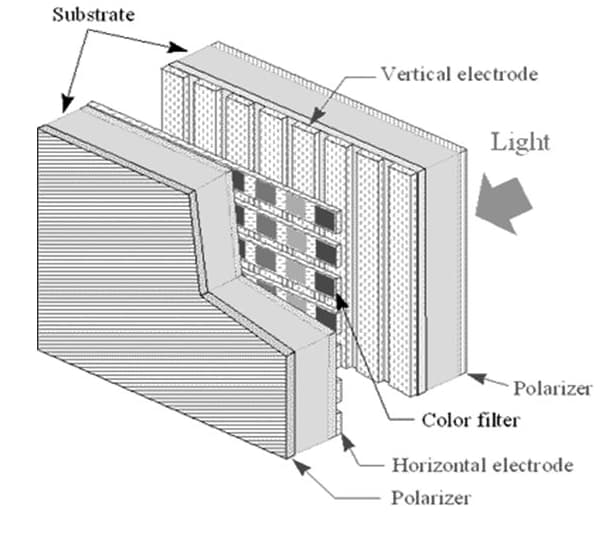

Figure 3: Passive Matrix LCD Pixel Grid

In a Passive Matrix LCD, the pixels are arranged in a grid, with horizontal and vertical lines intersecting at each pixel. The vertical lines are called vertical electrodes and the horizontal lines are called horizontal electrodes. These electrodes are connected to a substrate layer, which supports the structure of the LCD.

When electricity is applied to a specific row and column, the electrodes at that intersection activate the liquid crystal at that particular pixel. The liquid crystal changes its alignment in response to the electric charge, either allowing light to pass through or blocking it. This light then passes through a color filter to create the desired color.

The polarizer layers, one before the liquid crystal layer and one after, help control the light's orientation. As the light passes through these polarizers and the liquid crystal layer, the image starts to form. The process requires the entire grid to be scanned row by row, which can slow down the display's response time.

Because of this row-by-row scanning method, Passive Matrix LCDs tend to have slower response times. This can lead to blurriness in fast-moving images, making these displays less suitable for tasks that require sharp, high-quality visuals.

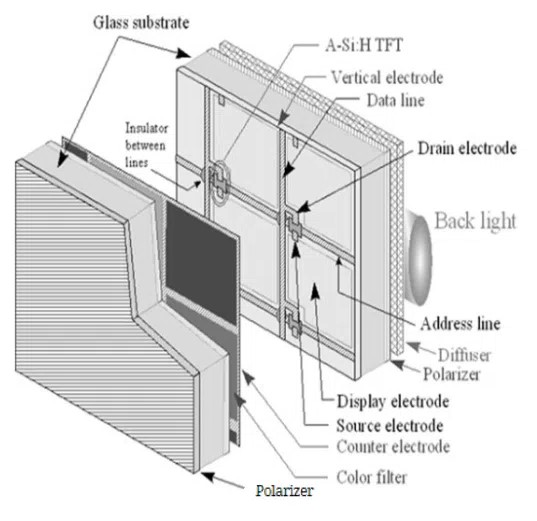

Figure 4: Active Matrix LCD with Thin-Film Transistor (TFT) Structure

In an Active Matrix LCD, also known as a Thin-Film Transistor (TFT) display, each pixel in the screen has its own transistor and capacitor. These components are built into the glass substrate and act as tiny switches that precisely control the alignment of the liquid crystals at each pixel.

The transistors are connected to vertical and horizontal electrodes, which are known as data lines and address lines. When electricity flows through these lines, it activates the transistors, which in turn control the liquid crystals at specific pixels. The drain electrode and source electrode in the diagram show where the electrical current enters and exits the transistor.

This setup allows each pixel to be controlled individually, rather than scanning row by row as in Passive Matrix LCDs. As a result, the screen can change images more quickly and with better accuracy, leading to sharper, clearer images even when displaying fast-moving content.

Polarizers and a diffuser are used to manage the light coming from the backlight. The polarizers control the direction of the light, while the diffuser spreads the light evenly across the screen. The color filter then adjusts the light to produce the right colors.

Because of this individual pixel control, Active Matrix LCDs are much faster and produce higher quality images than Passive Matrix LCDs. This makes them well-suited for high-definition displays and devices where clear, sharp image quality is needed.

Different Types of LCDs

Liquid Crystal Displays (LCDs) come in various forms, each with unique features that make them better suited for specific tasks. The main types include Twisted Nematic (TN), In-Plane Switching (IPS), Vertical Alignment (VA), and Advanced Fringe Field Switching (AFFS). Understanding the differences between these types can help you choose the right display for your needs.

Twisted Nematic (TN) LCDs

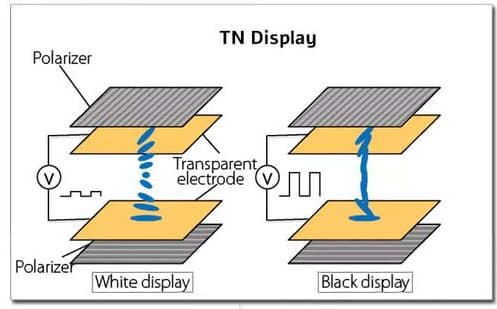

Figure 5: Twisted Nematic (TN) LCD Display Structure

Twisted Nematic (TN) displays are a widely used type of LCD, especially in more affordable devices. These displays work by twisting liquid crystal molecules between layers to control the light that passes through the screen.

In a TN display, when electricity is applied to the transparent electrodes, it causes the liquid crystals to twist, either allowing light to pass through or blocking it. When the liquid crystals are twisted, light passes through both polarizers, resulting in a bright or white display. When the crystals are not twisted, they block the light, leading to a darker or black display. This twisting and untwisting process happens quickly, which is why TN panels are known for their fast response times. This makes them suitable for fast-moving content like video games, where reducing motion blur is needed.

TN displays are also less expensive to produce, making them common in budget-friendly devices. However, they do have some drawbacks. TN panels often struggle with color accuracy, contrast, and viewing angles. If you view the screen from the side or at an angle, the image might look faded or washed out. Despite these downsides, TN panels remain popular because of their quick response times and affordability.

In-Plane Switching (IPS) LCDs

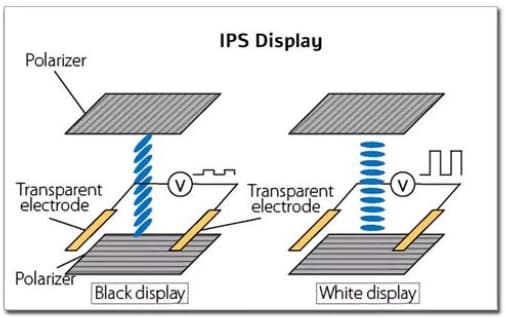

Figure 6: In-Plane Switching (IPS) LCD Display Structure

In an In-Plane Switching (IPS) LCD, the liquid crystals are lined up side by side, parallel to the screen. They are placed between two transparent electrodes. When there is no voltage, the liquid crystals block the light, creating a black display. When voltage is applied, the crystals move to let light pass through, resulting in a white display. The polarizers at the top and bottom help direct the light through the liquid crystals to form the image.

In-Plane Switching (IPS) technology was created to solve some of the issues with TN panels. In IPS displays, the liquid crystals move side-to-side instead of twisting as they do in TN displays. This side-to-side movement helps the screen show colors more accurately and keeps the image clear, even when viewed from different angles. Because of this, IPS panels are commonly used in devices where good image quality is needed, such as monitors for graphic design, photography, and video editing.

However, IPS displays generally have a slower response time than TN panels, which means the image might take longer to update. They are also more expensive to produce. Additionally, IPS panels can sometimes show a slight glow at the edges when viewed from certain angles, especially in dark settings. Despite these downsides, IPS technology is widely used because it provides better color accuracy and consistent image clarity from different viewing angles.

Vertical Alignment (VA) LCDs

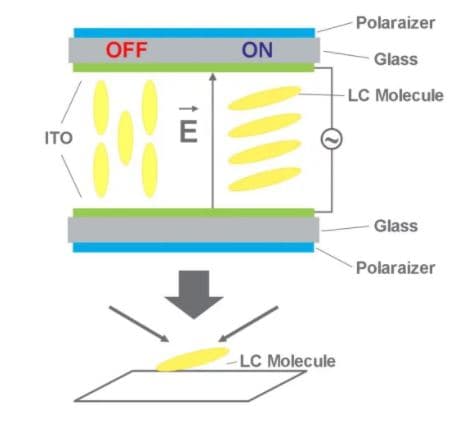

Figure 7: Vertical Alignment (VA) LCD Display Structure

In a Vertical Alignment (VA) LCD, the liquid crystal molecules stand upright when the screen is off, which blocks the light. When the screen is on, these molecules tilt to allow light to pass through. This change in the alignment of the molecules between the off and on states creates the images on the screen. The polarizers placed above and below the liquid crystal layers guide the light in the right direction to form the image when the molecules tilt.

Vertical Alignment (VA) LCDs offer a middle ground between TN and IPS technologies. In VA panels, the liquid crystal molecules align vertically when the screen is off and tilt when it is on, allowing light to pass through. VA displays offer better contrast, meaning they produce deeper blacks and more vibrant colors compared to both TN and IPS panels. This makes them a good choice for watching movies or playing games in dark rooms.

However, while VA panels provide better color accuracy and wider viewing angles than TN panels, they don’t quite match the performance of IPS displays in these areas. VA panels also tend to have slower response times than TN panels, but they are usually faster than IPS panels. This balance of features makes VA panels a versatile option for many users.

Advanced Fringe Field Switching (AFFS) LCDs

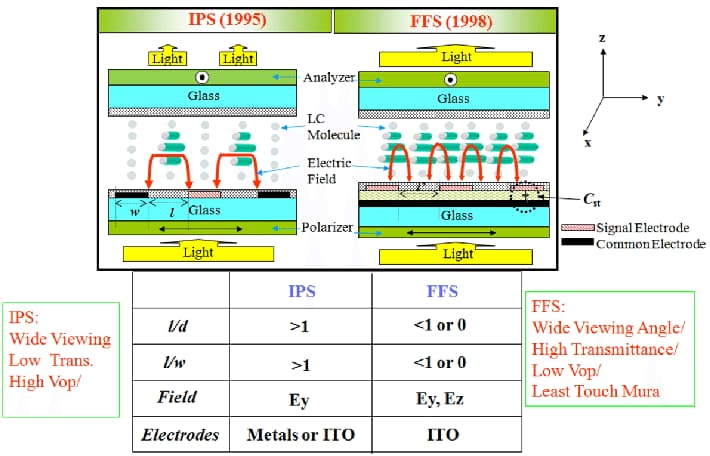

Figure 8: Advanced Fringe Field Switching (AFFS) LCDs Compared with IPS (In-Plane Switching)

In Advanced Fringe Field Switching (AFFS) technology, the electric field interacts with liquid crystals differently compared to older IPS displays. In IPS displays, the liquid crystals are lined up parallel to the screen, and when an electric field is applied, these crystals turn to control how light passes through the screen. The light goes through layers like polarizers and glass, and the way the liquid crystals are arranged determines how much light gets through, affecting the brightness and color of the display.

AFFS makes this process better by changing how the electric field is applied. Instead of using the traditional method, AFFS applies the electric field more evenly and precisely across the liquid crystals. This method reduces light leakage and gives better control over the liquid crystals, leading to more accurate colors and consistent brightness across the screen. This results in a display that shows more vivid colors and clearer images, with a stronger difference between light and dark areas.

The use of glass layers, polarizers, and analyzers in AFFS technology further improves the light passing through the screen, making sure the final image is not only brighter but also more accurate in color. This precise control of light and color makes AFFS displays a good choice for high-end uses, where image quality is a main focus.

LCD vs. OLED vs. QLED

When we talk about display technology, LCD (Liquid Crystal Display) has been around for a long time. However, newer options like OLED (Organic Light-Emitting Diode) and QLED (Quantum Dot LED) are becoming more common because they offer better performance in some areas. To understand what each of these technologies does well and where they might fall short, it's helpful to look at how they work and what they bring to the table.

LCD (Liquid Crystal Display)

Figure 9: Structure of an LCD (Liquid Crystal Display) with Key Components

LCD screens are made up of several layers that work together to create the images you see. It starts with a backlight that shines white light through the different layers. Polarized filters are placed at the front and back to control how the light moves. The liquid crystal layer in the middle doesn’t produce light on its own; instead, it acts like tiny shutters that can either block or let light pass through. The liquid crystals are controlled by a TFT (Thin-Film Transistor) layer, which decides which parts of the screen should be bright or dark. The color filter layer then adds red, green, and blue colors to the light, creating the full range of colors you see on the screen. Lastly, the screen is covered by a glass layer that protects the inside parts.

LCDs have been the most used technology for screens for many years. They work by using a backlight that shines through a layer of liquid crystals. These crystals don’t create their own light but act like tiny shutters, either blocking or allowing light to pass through. One of the advantages of LCDs is that they are less expensive and widely available. They also use power efficiently. However, compared to newer screen technologies, LCDs have some downsides. For example, they don’t have as much contrast, meaning the difference between the darkest and lightest parts of the image isn't as clear. Since LCDs rely on a backlight, they can’t show true blacks—black areas on the screen might look more like dark gray because some light always gets through.

OLED (Organic Light-Emitting Diode)

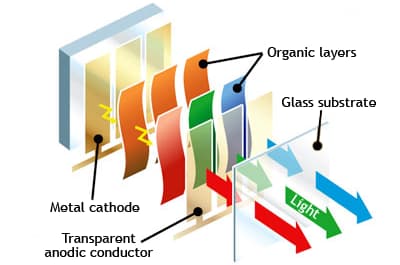

Figure 10: Structure of an OLED (Organic Light-Emitting Diode) Display

In OLED technology, each pixel is made up of organic layers placed between a transparent conductor and a metal cathode. When an electric current flows through these layers, they light up on their own. This means that each pixel can be controlled individually, including the ability to turn off completely, which creates deep blacks. The glass substrate provides support and structure to the layers.

OLED is a step up from LCD technology. In an OLED display, each pixel can light up by itself when electricity runs through it. This lets OLED screens turn off specific pixels entirely when displaying black, leading to much darker blacks and better contrast. This is why OLED screens are known for their sharp and vibrant images.

OLED screens are also thinner and more flexible than LCDs, which has allowed for new designs like curved or foldable screens. But, OLED screens have some downsides. They are usually more expensive to produce, which means devices that use them cost more too. Additionally, OLED screens can suffer from burn-in, where a static image left on the screen for too long can leave a lasting, ghost-like image. Despite these issues, the ability to show deep blacks and bright colors makes OLED a popular choice for high-end screens.

QLED (Quantum Dot LED)

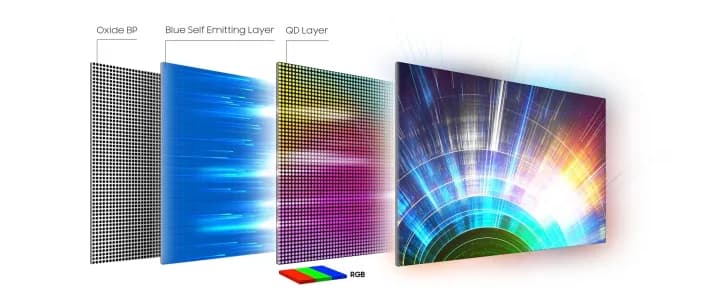

Figure 11: Structure of a QLED Display

In QLED technology, a special layer of tiny particles called quantum dots is placed between the LED backlight and the screen. These quantum dots help improve color and brightness, making the display more vibrant and accurate. The oxide layer supports the structure, while the blue self-emitting layer and QD (Quantum Dot) layer work together to enhance the light that passes through the screen, creating the final image with rich colors, especially noticeable in well-lit environments.

QLED is a technology mainly developed by Samsung and is an upgrade of LCD rather than a completely new technology like OLED. QLED screens use a special layer of tiny particles called quantum dots that sits between the LED backlight and the screen. These quantum dots improve color and brightness, making QLED screens better at showing brighter and more accurate colors, especially in well-lit rooms.

Another advantage of QLED screens is that they’re less likely to suffer from burn-in compared to OLEDs, which means they might last longer without showing marks from static images. However, since QLED screens still need a backlight, they can’t achieve the deep blacks and high contrast of OLED screens.

The Future of Liquid Crystal Displays

Even as newer technologies like OLED and QLED become more common, Liquid Crystal Displays (LCDs) are still widely used because they cost less to make and use energy more efficiently. LCDs have improved a lot over time, giving us the sharp, bright, and colorful screens we see in many devices today. They work by using liquid crystals to control light from a backlight, which creates the images we see. While OLEDs offer deeper blacks and better contrast, LCDs use less power for bright images, making them a good choice for devices like laptops that need to save battery life.

Looking ahead, LCD technology is expected to keep getting better with new ideas like mini-LED and micro-LED backlights, which make screens brighter with better colors and contrast. Also, flexible and see-through LCDs could lead to new uses in things like wearable devices and smart windows. Beyond just screens, liquid crystals might also be used in other types of electronics, which means they will likely continue to play a role in future technology.

Conclusion

The growth of liquid crystal technology is an amazing story of discovery, creativity, and continuous improvement. From the surprising discovery by Friedrich Reinitzer of crystals that melted in two stages to the widespread use of LCDs in many devices, liquid crystals have changed how we see and use technology. While newer display technologies like OLED and QLED bring exciting new features, LCDs continue to be used because they are still getting better and are a good choice for many types of screens. As we look to the future, there is a lot of potential for liquid crystals to be used in new ways, ensuring they will keep playing a big role in our visual experience. Whether in the screens we use every day or in new technologies that are yet to come, the story of liquid crystals is far from over, and they will continue to reflect the creativity and curiosity that drive human progress.

Frequently Asked Questions [FAQ]

1. How are liquid crystals made?

Liquid crystals are created by designing and making special organic molecules with specific features. These molecules usually have a stiff, rod-like shape with flexible parts. When combined under the right conditions, like the right temperature and concentration, the molecules line up in a way that allows them to act both like a liquid and a solid, forming a liquid crystal state.

2. What are the functions of liquid crystals?

Liquid crystals mainly control how light passes through them. In displays, they help create images by changing their alignment when an electric current is applied. Liquid crystals are also used in sensors, thermometers, and optical devices because they can change their properties when exposed to things like temperature or electric fields.

3. What is the short definition of liquid crystal?

A liquid crystal is a material that behaves both like a liquid and a solid, where the molecules are more ordered than in a liquid but less ordered than in a solid.

4. What are the characteristics of a liquid crystal?

Liquid crystals can flow like a liquid while still keeping some order, similar to a solid. They can change their alignment when exposed to electric currents or temperature changes, which changes how they interact with light. They also have the ability to split light into two beams that move at different speeds.

5. What are the applications of liquid crystals?

Liquid crystals are mainly used in display screens, such as those found in TVs, computers, and smartphones. They are also used in medical imaging devices, thermometers, adjustable lenses, and optical switches. Liquid crystals can also be found in some sensors and advanced materials that change their properties based on different conditions.