Introduction to Superconducting Magnetic Energy Storage (SMES): Principles and Applications

The article discuss how energy is stored in magnetic fields through electromagnetic induction and the related equations. It also examines the advanced designs and materials used in creating SMES systems, focusing on toroidal and solenoidal coils. These systems are used in different settings, from medical facilities to industrial sites. The article provides a detailed overview of components, such as superconducting materials like Niobium-titanium and Yttrium Barium Copper Oxide, and important design considerations for coil configurations in SMES systems.

Catalog

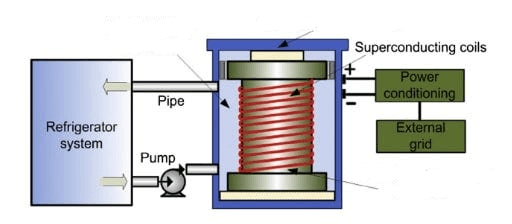

Figure 1: Superconducting Magnetic Energy Storage

What Is Superconductivity?

Superconductivity is a quantum mechanical phenomenon where certain materials conduct electricity without resistance when cooled below a required temperature. It include:

Zero Electrical Resistance

Superconductors allow perpetual current flow without energy loss under ideal conditions, which is their defining characteristic.

Meissner Effect

Superconductors expel magnetic fields from their interior when in the superconducting state. This is known as the Meissner effect and good for maintaining stable and efficient magnetic fields in SMES applications.

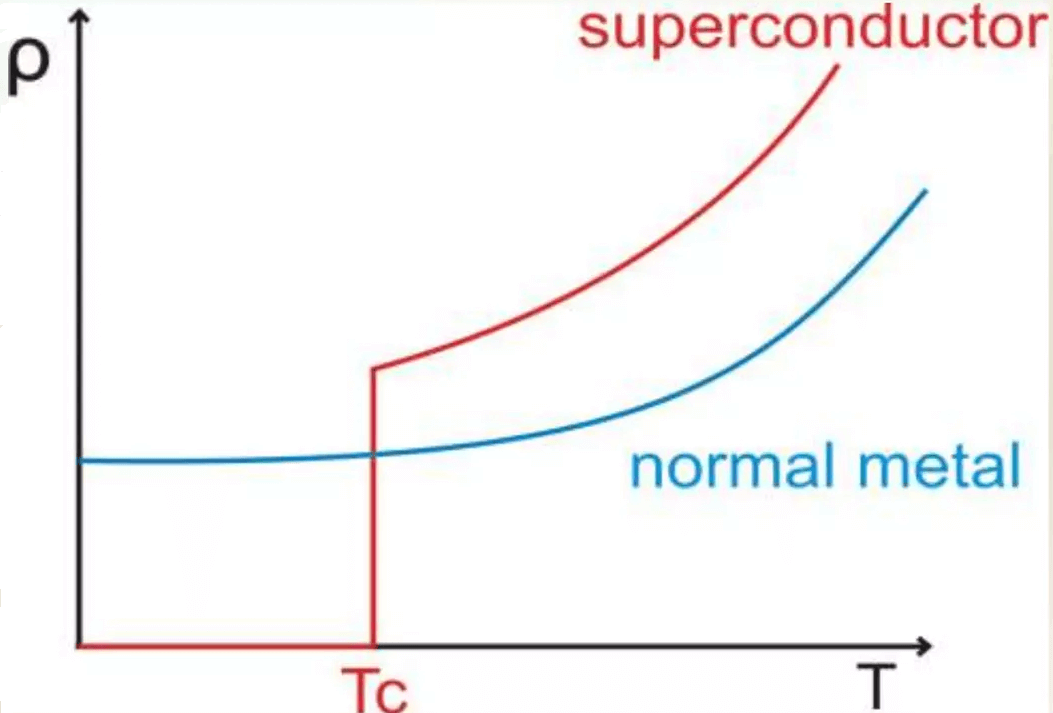

Phase Transition

Superconductivity occurs at a specific temperature called the critical temperature. This temperature is material-specific and can range from near absolute zero to higher temperatures for high-temperature superconductors.

Figure 2:

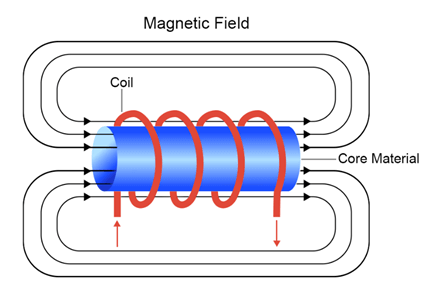

Figure 3: Electromagnetic Force

Mechanism of Energy Storage in a Magnetic Field

In SMES systems, energy is stored in the magnetic field generated by direct current in a superconducting coil. The process involves:

When current flows through the superconducting coil, a magnetic field is created. According to electromagnetic theory, the energy stored in the magnetic field is proportional to the square of the current and the coil's inductance.

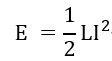

The energy (E) stored can be quantified by the equation:

where L is the inductance of the coil, and I is the current. The coil design focuses on maximizing inductance and current capacity to increase energy storage.

To store and utilize energy effectively, the magnetic field must be contained and controlled. This involves complex geometries and materials engineering to optimize magnetic pathways and minimize losses.

Components of a Superconducting Magnetic Energy Storage (SMES)

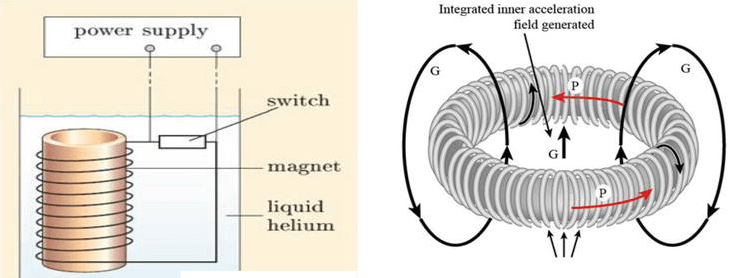

Superconducting coils are engineered to optimize superconductivity, which allows electric current to flow without resistance. These coils are created by winding superconducting wire around a core or shaping it into a solenoid.

• Coil Configuration

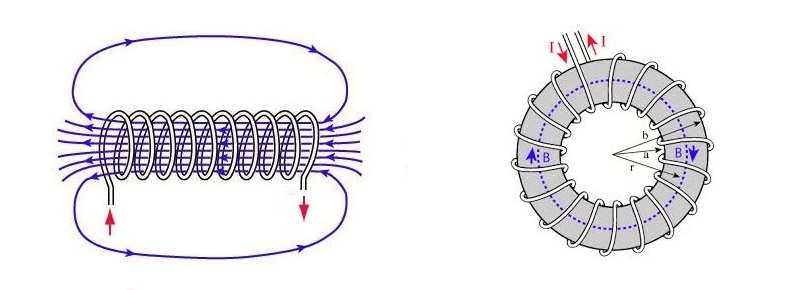

Solenoid Coils - These cylindrical coils generate a uniform magnetic field inside and are used in MRI machines.

Toroidal Coils - Shaped like a doughnut, these coils are used in applications like tokamak reactors for plasma containment in fusion research.

Figure 4: Solenoid Coils and Toroidal Coils

• Cooling Systems

Advanced cooling systems are useful to maintain superconductivity. These systems use liquid helium, liquid nitrogen, or cryocoolers to keep the coils at temperatures well below their threshold.

Materials Used in Superconducting Coils

The performance of superconducting coils heavily depends on the materials used. The two primary types of superconducting materials are:

• Low-Temperature Superconductors (LTS)

Niobium-titanium (NbTi): Commonly used in MRI systems and research facilities, NbTi is valued for its durability and relatively simple cryogenic requirements.

Niobium-tin (Nb3Sn): With a higher temperature and magnetic field threshold than NbTi, Nb3Sn is ideal for applications needing stronger magnetic fields.

• High-Temperature Superconductors (HTS)

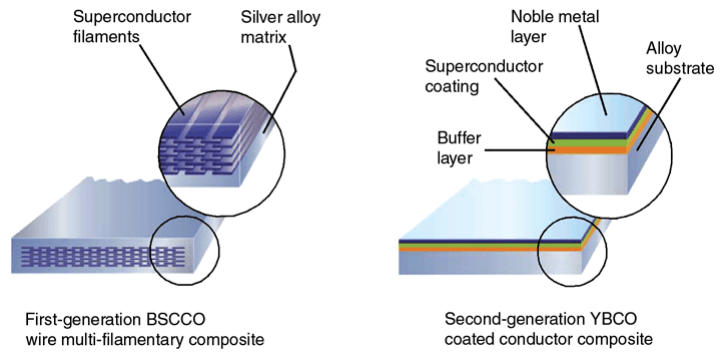

Yttrium Barium Copper Oxide (YBCO): This material operates at higher temperatures than LTS materials, simplifying and reducing the cost of cooling systems.

Bismuth Strontium Calcium Copper Oxide (BSCCO): Known for its tape-like form, BSCCO is flexible and suitable for coils with complex shapes.

Figure 5: Yttrium Barium Copper Oxide (YBCO) and Bismuth Strontium Calcium Copper Oxide (BSCCO)

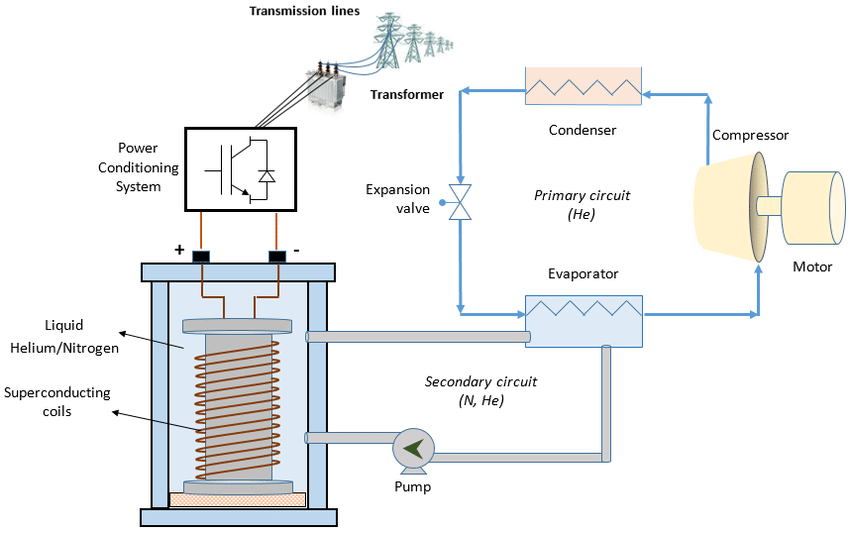

Energy Conversion Process in a Superconducting Magnetic Energy Storage System

The first step in a SMES system is changing alternating current (AC) to direct current (DC) because the superconducting coil runs on DC.

The AC, which comes from the grid or a power plant, goes into a rectifier. The rectifier’s job is to turn the AC, which changes direction, into DC, which flows in one direction. It uses devices like diodes or thyristors to do this.

After this conversion, the DC might still have some AC-like ripples. To smooth these out, we use filters with capacitors and inductors. This makes the DC steady, for the SMES system’s efficiency and safety.

With smooth DC ready, the DC flows into a superconducting coil, which has no electrical resistance. This allows the current to flow without losing energy.

The DC in the coil creates a strong magnetic field around it, converting electrical energy into magnetic energy stored in this field.

To keep the coil superconductive, the coil is kept at very low temperatures using cryogenic coolants like liquid helium or nitrogen. This is important because any temperature rise can cause the coil to lose its superconductivity, leading to energy loss.

When we need the stored energy, the energy stored in the magnetic field drives the DC current in the coil. This DC needs to be turned back into AC to be useful for most power systems. An inverter does this by changing the current's direction at a frequency matching the AC grid.

The AC output is synchronized with the grid’s voltage, frequency, and phase before being sent out, ensuring it works well with the grid and other electrical loads.

Figure 6: Schematic Diagram of Superconducting Magnetic Energy Storage System

Design of Superconducting Magnetic Energy Storage Systems

The coil design in SMES systems required for efficiency, cost, and energy storage capacity. The two main coil designs are toroidal and solenoidal.

|

Coil Type |

Geometry and Function |

Advantages |

Disadvantages |

|

Toroidal Coils |

Donut-shaped, designed to keep almost all

the magnetic field inside the coil, minimizing leakage. This shape helps

reduce electromagnetic forces acting on the coil structure. |

Magnetic Field Containment: The magnetic

field stays within the coil, leading to lower stray magnetic fields. |

Manufacturing Complexity: Constructing

toroidal shapes is complex and costly. |

|

Safety: This design is safer and reduces interference

with nearby electronic devices and other sensitive equipment. |

Maintenance Challenges: Accessing the

inner parts of these coils is difficult, complicating maintenance and

inspection. |

||

|

Solenoidal Coils |

Cylindrical, with current running along

the length of the cylinder. This design is simpler and more straightforward

than the toroidal configuration. |

Ease of Manufacture: Solenoidal coils are

easier and less expensive to produce due to their simple geometry. Maintenance Accessibility: The open-ended design makes them easier to maintain and inspect. |

Magnetic Field Leakage: The magnetic

field leaks at both ends of the cylinder, which can affect nearby electronic

devices and require additional shielding. |

Factors Influencing the Choice of Coil Design

Figure 7: Solenoidal Coil and Toroidal Coil

Intended Application: The application dictates the coil choice. For example, toroidal coils are preferred where electromagnetic interference must be minimized, such as in medical facilities or near sensitive scientific equipment.

Energy Storage Requirements: The amount of energy to be stored affects coil design. Solenoidal coils may suit smaller-scale applications due to their cost-effectiveness, while toroidal coils might be used for larger, industrial-scale storage due to efficiency and minimal magnetic leakage.

Space and Environmental Constraints: Available physical space and environmental conditions are primary considerations. Toroidal coils, with their compact and enclosed magnetic field, are better suited for confined spaces or populated areas.

Budget Constraints: Budget limitations impact coil design choice. Solenoidal coils are less expensive and may be preferred in cost-sensitive projects.

Maintenance and Operational Considerations: Ease of maintenance and operational reliability are important. Solenoidal coils, offering easier access for maintenance and inspection, can be a decisive factor in their selection.

Advantages of Superconducting Magnetic Energy Storage Systems

|

Advantage |

Description |

|

High Efficiency and Fast Response Times |

SMES systems achieve over 95% efficiency

by storing energy in a superconducting coil with almost zero resistance. They

can respond to power demand changes in milliseconds. |

|

Environmental Impact and Stability |

These systems are eco-friendly, emitting

no greenhouse gases or using toxic materials. They maintain stable

performance regardless of external conditions like temperature or weather. |

|

Reliability and Longevity |

SMES systems have no moving parts and use

durable superconducting materials, resulting in less wear and tear and lower

maintenance costs over their long lifespan. |

|

Scalability and Versatility |

Capable of storing energy from a few

kilowatt-hours to several megawatt-hours, SMES units are flexible for various

applications and can be installed in diverse environments with minimal

modifications. |

|

Supporting the Grid and Renewable Energy |

They help regulate voltage, stabilize

frequency, and smooth output from renewable sources, enhancing grid

reliability and supporting greater integration of renewable energy. |

|

Long-Term Cost-Effectiveness |

In spite of high initial costs, SMES

systems have low operational and maintenance expenses, making them

cost-effective in the long run, especially in specific applications. |

|

Safety and Security |

SMES systems avoid the risks of

explosions or toxic leaks associated with chemical storage solutions, making

them safer for different settings, including urban areas. |

Applications of Superconducting Magnetic Energy Storage

Figure 8: Flexible AC Transmission System, One of the Major Applications of Superconducting Magnetic Energy Storage

Hospitals

Hospitals rely on an uninterrupted power supply (UPS) to keep life-saving equipment and care systems operational. SMES systems provide a reliable UPS solution by instantly releasing stored energy during power failures, minimizing operational disruptions. They also maintain high-quality power regulation, which protects sensitive medical equipment from minor power fluctuations.

Data Centers

Data centers, which manage vast amounts of digital information, are highly sensitive to power quality issues. SMES systems are ideal for protecting against short-duration power disturbances like voltage sags and surges. By integrating SMES, data centers can ensure continuous operation of servers and networking equipment, maintaining data service availability and integrity.

Renewable Energy Integration

Renewable energy sources like wind and solar introduce variability in power generation due to weather conditions. SMES systems stabilize the grid by quickly absorbing excess electricity during high production periods and releasing energy during low production, smoothing out fluctuations and enhancing grid stability.

Electric Vehicle Charging Stations

With the increasing adoption of electric vehicles (EVs), the demand for efficient and fast charging solutions rises. SMES systems at EV charging stations manage load demands by storing energy during off-peak times and releasing it during peak demand. This reduces strain on the electrical grid and enables faster charging times.

Industrial Applications

Industries that require sudden bursts of power benefit from SMES systems. These systems provide the right energy without heavily drawing on the grid, need in manufacturing for precise control of machinery and maintaining product quality.

Military and Aerospace

Military bases and aerospace operations require reliable and high-quality energy. SMES systems offer a quick-response power supply that ensures uninterrupted operations and supports the high energy demands of advanced technology and equipment in these sectors.

Mass Transit Systems

Rail networks and urban transit systems improve power efficiency and reliability with SMES. These units manage energy produced during braking and redistribute it efficiently, enhancing the overall energy efficiency of the transit system.

Conclusion

The article explores Superconducting Magnetic Energy Storage (SMES) systems, highlighting their potential as a revolutionary energy storage technology. SMES systems offer high efficiency, quick response times, and low environmental impact, making them solution for current energy challenges. The article covers their use in various fields, including healthcare, renewable energy, and transportation, showing their versatility and scalability. As the world moves towards sustainable energy solutions, SMES technology stands out in enhancing global energy resilience. Ongoing developments in SMES for integrating renewable energy sources, improving the stability and efficiency of the global power infrastructure.

Frequently Asked Questions [FAQ]

1. How Does a Magnetic Field Store Energy?

A magnetic field stores energy through the alignment and movement of magnetic dipoles or charged particles. When an electric current passes through a coil of wire, it creates a magnetic field around the coil. This magnetic field is capable of storing energy due to the work done to establish the field. Specifically, energy is required to align the magnetic moments of atoms in a material, which in turn creates a field that can exert forces and do work on other objects. The energy stored in a magnetic field is directly proportional to the square of the field's intensity.

2. What Device Stores Energy in a Magnetic Field?

The device that stores energy in a magnetic field is an inductor or a magnetic coil. Inductors consist of coils of wire, often wrapped around a magnetic core, which enhances the magnetic field's strength. When current flows through the coil, a magnetic field builds up, and energy is stored in this field. The ability of an inductor to store magnetic energy is used in many electronic circuits, in power supply and conversion technologies.

3. How Efficient Is Superconducting Magnetic Energy Storage?

Superconducting Magnetic Energy Storage (SMES) systems are highly efficient, achieving round-trip energy efficiency of 90% to 95%. These systems use superconducting coils that can conduct electricity without resistance at very low temperatures. The lack of electrical resistance means almost no energy is lost as heat, which enhances the efficiency of energy storage. SMES systems are valued for their ability to release stored energy almost instantaneously, which is good for applications requiring rapid discharges, like stabilizing power grids during peak demand.

4. Is Magnetic Energy a Store or Transfer?

Magnetic energy is a form of energy storage. The energy is stored in the magnetic field created by the movement of electrical charges, in a coil. When need, this stored energy can be converted back into electrical energy or used to perform mechanical work, thus transferring energy from the magnetic field to another form. However, the primary role of magnetic energy in devices like inductors or SMES systems is to store energy.

5. What Is an Example of a Magnetic Energy Store?

An example of a magnetic energy store is the flywheel energy storage system, which, though primarily mechanical, often incorporates magnetic components for energy storage and stabilization. These systems use a rotating mechanical flywheel whose movement generates a magnetic field, in versions that use magnetic bearings to reduce friction and energy loss. This interaction between mechanical and magnetic energies allows the flywheel system to store energy efficiently and release it rapidly when required, making it a practical application of magnetic energy storage in both mechanical and electrical forms.