How to Maximize the Use of a Digital Multimeter in Electrical Testing?

In the rapidly evolving landscape of electrical measurement tools, digital multimeters (DMMs) have established themselves as typical devices, transcending their analog antecedents with remarkable advancements in functionality and precision. This article digs into the significant evolution of DMMs, tracing their journey from simple instruments measuring basic electrical units to sophisticated devices capable of handling complex diagnostics across diverse industries. The integration of state-of-the-art technologies such as analog-to-digital converters (ADCs) and liquid crystal displays (LCDs) has not only refined the basic functionalities but also expanded their applicability, making DMMs requisite in fields ranging from industrial maintenance to educational labs.Catalog

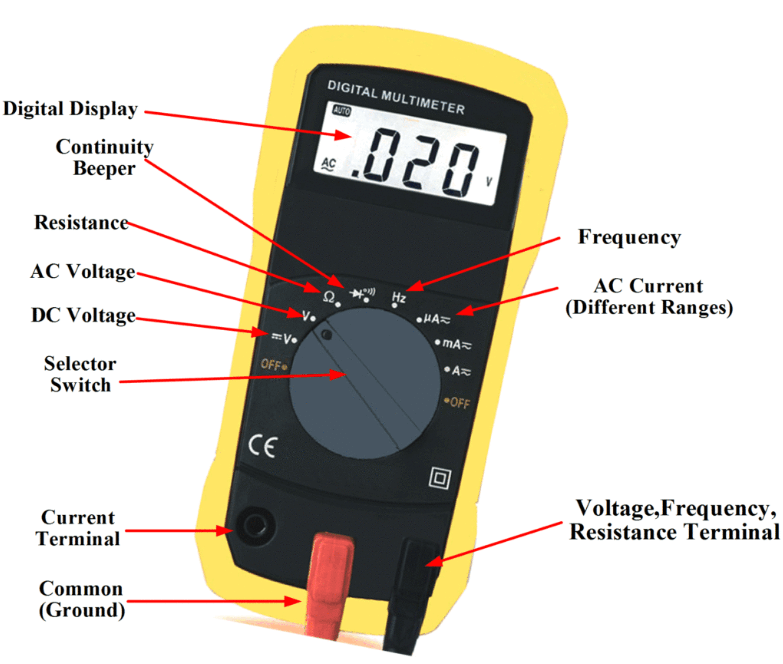

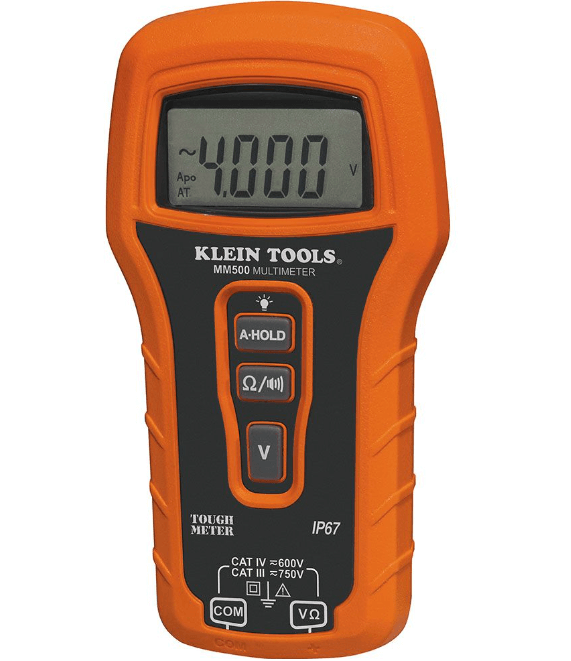

Figure 1: Digital Multimeters

Basics of Digital Multimeters

Digital multimeters (DMMs) represent a major advancement from their analog predecessors. Initially limited to measuring volts, amps, and ohms, DMMs now offer a broader array of functions. This evolution was driven by the integration of advanced technology, particularly the incorporation of integrated circuits. Key developments such as analog-to-digital converters (ADCs) and liquid crystal displays (LCDs) played a significant role in this transition. These technologies not only preserved the basic functionalities of analog multimeters but also enhanced the precision, versatility, and ease of use in DMMs, all while keeping them affordable.

At the core of a DMM's operation is its ADC. Most DMMs use a successive approximation register (SAR) method for ADC, which allows for highly accurate voltage measurement. This process involves converting the analog signal into a digital format through a series of precise steps, each refining the accuracy of the reading. This step-by-step conversion is a key improvement in DMMs, significantly boosting their operational efficiency.

These enhancements have expanded the usefulness of DMMs far beyond basic electrical measurements. The increased precision and broader measurement capabilities have made DMM requisite tools in various industries. They are now used for tasks in electrical engineering, telecommunications, and automotive diagnostics. In these fields, DMMs are basic for detailed troubleshooting and effective problem-solving.

Figure 2: DMM Controls and Connections

Exploring Typical DMM Controls and Connections

Digital multimeters (DMMs) are designed with a focus on user-friendliness, making them easy to use even for those new to electrical measurements. The most significant control on a DMM is the rotary switch, which sits prominently at the center of the device. This switch allows the user to choose between different functions and measurement ranges, providing a straightforward way to navigate the DMM's capabilities. Surrounding the switch is a clear digital display, which typically shows readings with up to four digits, allowing for precise and quick diagnostics.

The connections on a DMM are carefully designed to ensure both simplicity and safety. The standard setup includes ports for connecting the test leads, with a black port for the negative lead and a red port for the positive lead. In addition, there are dedicated ports specifically for current measurements, including those designed to handle high currents. Some DMM models also feature specialized ports for tasks like measuring temperature or testing transistor gain. This well-organized layout of controls and connections reduces the likelihood of errors, making it easier to obtain accurate readings and facilitating an efficient testing process.

How to Operate a Digital Multimeter?

To use a digital multimeter (DMM) effectively, you should follow a sequence of careful steps, starting with preparing the device and setting it up properly. First, install the battery, making sure it’s securely in place, then move on to connecting the test probes. Match the probes to the correct ports—black for the negative terminal and red for the positive terminal. This connection step is useful for accurate measurements and should be done carefully.

Next, use the rotary switch to select the appropriate function and measurement range. It’s noteworthy to choose the correct setting to avoid overloading the multimeter, especially when measuring high values that could potentially damage the device. Always aim to set the range to the smallest value that still accommodates the measurement. This practice will increase the resolution, leading to more precise readings and more reliable data.

Safety is a serious aspect of DMM operation. When you’re not actively using the meter, it's a good idea to set it to the highest voltage range. This precaution reduces the risk of accidentally damaging the multimeter or the circuit you're testing. Also, handle the test probes with care to avoid short circuits or other hazards. Proper management of these probes is noteworthy to ensuring that your measurements are both safe and accurate.

Various Types of Digital Multimeters

Digital multimeters (DMMs) are designed to cater to a variety of needs, ranging from simple tasks to complex engineering analyses. There are several types of DMMs, each suited to specific applications and environments.

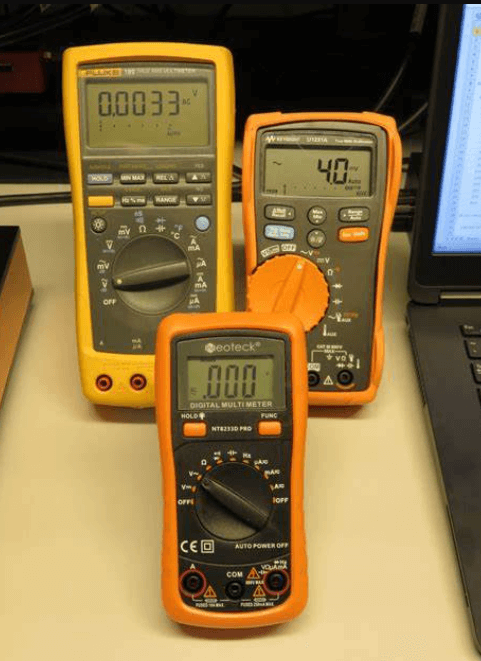

Figure 3: Handheld DMMs

Handheld DMMs are perfect for field work. Their compact design makes them easy to carry, and they offer the needed precision for diagnosing issues on-site.

Figure 4: Benchtop DMMs

Benchtop DMMs, on the other hand, are built for laboratory use. They provide higher accuracy and stability, making them ideal for situations where precision is serious. These models are typically larger and are used in controlled environments where the highest level of measurement reliability is required.

Compact DMMs are beneficial in manufacturing settings where space is limited. Despite their small size, these models deliver high accuracy, balancing the need for space efficiency with the requirement for reliable measurements. They are designed to perform well in environments where space is at a premium, without compromising on performance.

Digital Multimeters Used in Modern Electronics

Digital multimeters (DMMs) are versatile tools with applications across various professional, consumer, educational, and research sectors. Their precision and adaptability make them requisite in a wide range of tasks.

|

Digital Multimeters Used in Modern

Electronics |

|

|

Industrial Maintenance |

In industrial settings, DMMs are insistent

on keeping heavy machinery and electrical systems in good working order.

Technicians use these devices for preventive maintenance, checking that

motors, generators, and switchgear are operating within safe limits. Regular

use of DMMs helps prevent unexpected breakdowns and prolongs the lifespan of

expensive equipment. |

|

Automotive Industry |

Mechanics depend on DMMs to diagnose

electrical issues in vehicles. These tools are used to check batteries, test

alternators, and assess wiring integrity. The accuracy of DMMs allows

mechanics to quickly identify faults that might otherwise require extensive

manual testing. |

|

Telecommunications |

For telecommunications technicians, DMMs

are suitable for setting up and maintaining network equipment. By measuring

signals and other electrical parameters, these tools help ensure that

communication channels remain clear and reliable. |

|

Home Electrical Projects |

Homeowners frequently use DMMs for a

variety of electrical tasks, such as installing, testing, and repairing

household appliances and wiring. Whether checking the output of a socket,

troubleshooting a malfunctioning appliance, or ensuring the safety of electrical

fixtures, DMMs provide the needed accuracy for these tasks. |

|

Educational and Training Uses |

In schools and universities, DMMs are

used to teach the basics of electronics and electrical engineering. Students

use them to experiment with circuits, apply Ohm’s Law in practical scenarios,

and observe the behavior of electrical components in a controlled setting. |

|

Research and Development |

In R&D labs, engineers use DMMs to

test prototypes and new electronic products. They conduct rigorous testing

under various electrical loads and conditions to ensure that new designs are

both innovative and compliant with safety standards. |

|

Environmental Monitoring |

Environmental engineers use DMMs to

assess the efficiency of renewable energy systems, such as solar panels and

wind turbines. Accurate measurements help optimize system performance and

contribute to reducing the carbon footprint of energy production. |

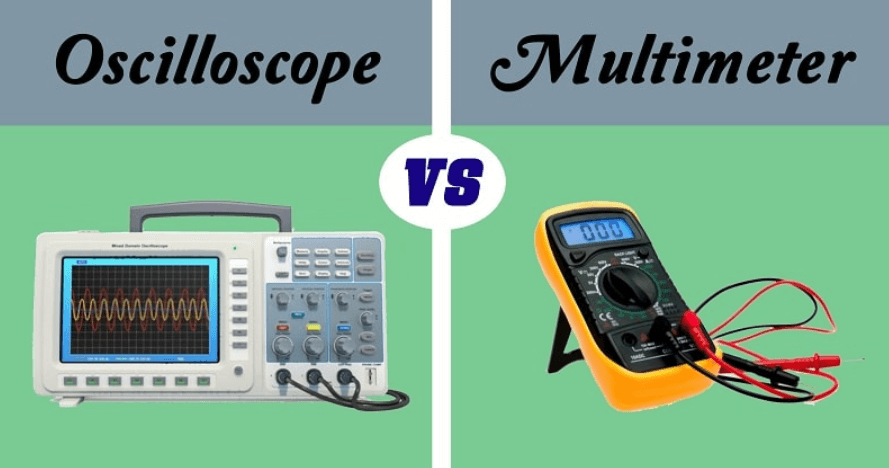

Figure 5: Digital Multimeter vs. Oscilloscope

Comparing Digital Multimeters and Oscilloscope

Digital multimeters (DMMs) and oscilloscopes are both dynamic tools in electrical diagnostics, but they serve different purposes. A DMM is designed to give you a precise, static measurement of electrical parameters like voltage, current, or resistance at a specific point in time. This makes it ideal for quick checks when you need an accurate number to confirm a circuit's status.

In difference, an oscilloscope provides a dynamic, real-time view of how voltage changes over time. Instead of just giving you a single reading, it shows a continuous graphical representation, allowing you to see fluctuations, patterns, and transient events in the signal. This ability to visualize electrical activity as it happens is suitable for deeper analysis, especially when troubleshooting complex electronic systems.

So, while a DMM is your go-to tool for immediate, numerical data, an oscilloscope gives you a visual timeline that helps you understand how electrical properties evolve and interact over time. Each tool complements the other, depending on whether you need a snapshot or a moving picture of what's happening in your circuit.

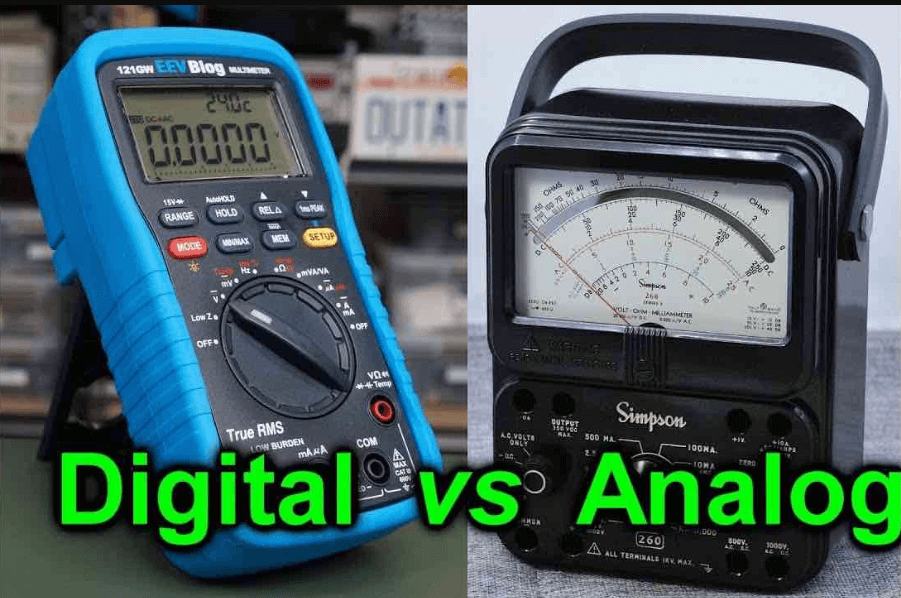

Figure 6: Digital over Analog Multimeters

Benefits of Using Digital Multimeters Over Analog Meters

Digital multimeters (DMMs) offer several significant advantages over analog models, particularly in terms of accuracy, stability, and ease of use.

|

Benefits of Using Digital Multimeters

Over Analog Meters |

|

|

Enhanced Accuracy |

Digital multimeters provide highly

accurate readings by converting analog signals into digital data. This

digital conversion minimizes the risk of errors that often occur when reading

the needle on an analog meter. With a DMM, you get precise numerical values

without the ambiguity of interpreting a needle's position on a scale. |

|

Greater Stability |

DMMs are more stable over time, offering

consistent readings that are less affected by external factors. Unlike analog

meters, which can drift and require frequent recalibration, digital meters

maintain their accuracy longer and are less sensitive to environmental

conditions and aging. |

|

Higher Input Impedance |

Digital multimeters typically feature

higher input impedance, which is influential when testing circuits. High

input impedance means the meter draws minimal current from the circuit,

preventing it from altering the circuit's operation. This results in more

accurate readings, especially in sensitive electronic applications. |

|

Ease of Use |

The digital display on a DMM is easy to

read, eliminating the need to interpret a needle's position. This

user-friendly interface significantly reduces the chances of reading errors,

making DMMs particularly suitable for beginners or situations where quick,

clear readings are beneficial. |

|

Versatility and Features |

DMMs often come equipped with a wide

range of measurement capabilities, including voltage, current, resistance,

capacitance, and frequency. Some models also offer advanced features like

temperature measurement, data logging, computer connectivity, and graphical

displays of signals, which are generally not available in analog meters. |

|

Durability and Reliability |

Digital multimeters are generally more

durable and resistant to damage from drops or impacts. Their electronic

design, which relies less on mechanical parts like the needle and coil in

analog meters, results in a longer operational lifespan and fewer maintenance

issues. |

|

Safety |

The increased accuracy and reliability of

DMMs contribute to safer electrical measurements. Precise readings are suitable

for correctly diagnosing electrical problems and ensuring that systems

operate within safe parameters, reducing the risk of accidents. |

Ensuring Safety When Using Digital Multimeters

When using digital multimeters (DMMs), following safety protocols is a must. Start by thoroughly inspecting the device for any physical damage and confirming that it functions properly before use. Always use fused test leads, as they provide a substantial layer of protection for both you and the equipment, reducing the risk of electrical hazards. It's also settling to select the correct measurement category for your specific task, ensuring that the DMM is used within its safe operating limits. These precautions not only help prevent accidents but also enhance the reliability and longevity of the multimeter, keeping both the instrument and the user safe in various work environments.

Discovering the Best Digital Multimeter

Selecting the right digital multimeter (DMM) depends on your specific needs, including the type of measurements you'll be taking and the environment in which you'll be working.

Figure 7: Auto-Ranging

If you need quick and accurate readings without the hassle of manually selecting the range, look for a DMM with auto-ranging capabilities. This feature automatically adjusts to the appropriate measurement range, simplifying the process and reducing the chance of errors.

Figure 8: True RMS

For situations involving non-linear loads or complex signals, a True RMS (Root Mean Square) multimeter is desperate. This type of DMM provides more accurate readings by correctly measuring the effective value of AC voltage and current, especially when dealing with irregular waveforms.

Figure 9: Clamp Meter Functionality

If your work involves measuring high currents, especially in industrial or high-power environments, consider a multimeter with clamp meter functionality. This allows you to measure high currents safely without needing to break the circuit, adding both convenience and safety to your measurements.

Conclusion

The exploration of digital multimeters reveals a profound transformation in measurement technology, characterized by enhanced accuracy, expanded functionality, and user-centric design. DMMs have become fundamental tools in a plethora of settings, aiding in the maintenance of industrial equipment, automotive diagnostics, telecommunications, and even educational endeavors.

Their evolution from analog devices to sophisticated digital tools underscores a broader trend toward digitalization in measurement technology, driven by the need for precision, reliability, and versatility. The future of DMMs likely holds further integration with digital technologies, such as IoT connectivity and advanced data analysis capabilities, which will continue to redefine the boundaries of what these tools can achieve. As we have seen, digital multimeters are not merely tools but key components in the

Frequently Asked Questions [FAQ]

1. What is the simple definition of a multimeter?

A multimeter is a tool that combines multiple measurement functions in one device, typically used to measure voltage, current, and resistance.

2. What is a multimeter with a description?

A multimeter, also known as a volt-ohm meter, is a handheld device with a digital or analog display that is used by electricians and electronics technicians to diagnose and troubleshoot electrical circuits and components. It can measure voltage (volts), current (amps), and resistance (ohms), and often includes other functions like testing diodes, capacitors, and continuity.

3. What is the working principle of a multimeter?

The core principle of a multimeter is to use electronic circuitry to convert the electrical measurements it takes into a readable form on its display. When measuring voltage, it uses high-resistance circuits to ensure minimal current is drawn from the circuit being tested. For current, it uses low-resistance paths to measure the flow of current directly. Resistance measurement is done by applying a small known voltage and measuring how much current flows, which calculates resistance using Ohm’s Law.

4. How does a DMM measure voltage?

A DMM measures voltage by connecting its probes across a component or section of a circuit. It uses high input impedance to ensure that it does not significantly alter the voltage it is measuring. The voltage causes a small current to flow through the meter's internal circuitry, which is then converted and calibrated to display the voltage value.

5. What are the specifications of a digital multimeter?

The specifications for digital multimeters can vary widely but typically include:

Accuracy: Describes how close the displayed measurement is to the actual value, often expressed as a percentage.

Resolution: The smallest increment of measurement displayed, which can affect how precise a reading you can get.

Input Impedance: Noteworthy for voltage measurements to avoid affecting the circuit.

Range: The maximum and minimum limits it can measure, such as volts, amps, and ohms.

Safety Ratings: Based on the highest voltage and category of equipment it can safely measure, according to industry standards like CAT I, CAT II, etc.