How Do Overcurrent Protection Devices Work?

Managing overcurrent in electrical systems is settling to prevent catastrophic failures and ensure safety. Overcurrent occurs when the current exceeds the circuit's design capacity due to overloads, short circuits, or other abnormalities, requiring robust protective measures. This analysis explores the dynamics of overcurrent, examining causes, consequences, and the devices used for mitigation, such as Overcurrent Protection Devices (OCPDs). It digs into the intricacies of short circuits and overload scenarios, assessing the effectiveness of OCPDs. The discussion also includes criteria for selecting, maintaining, and complying with standards for these devices. Emphasizing the importance of precise OCPD sizing and selection, the review highlights the need for routine evaluations to maintain protection and adhere to electrical standards. This comprehensive overview, catering to professionals and students in electrical engineering, details the use of circuit breakers, fuses, and other protective elements, providing needed insights into overcurrent protection.

Catalog

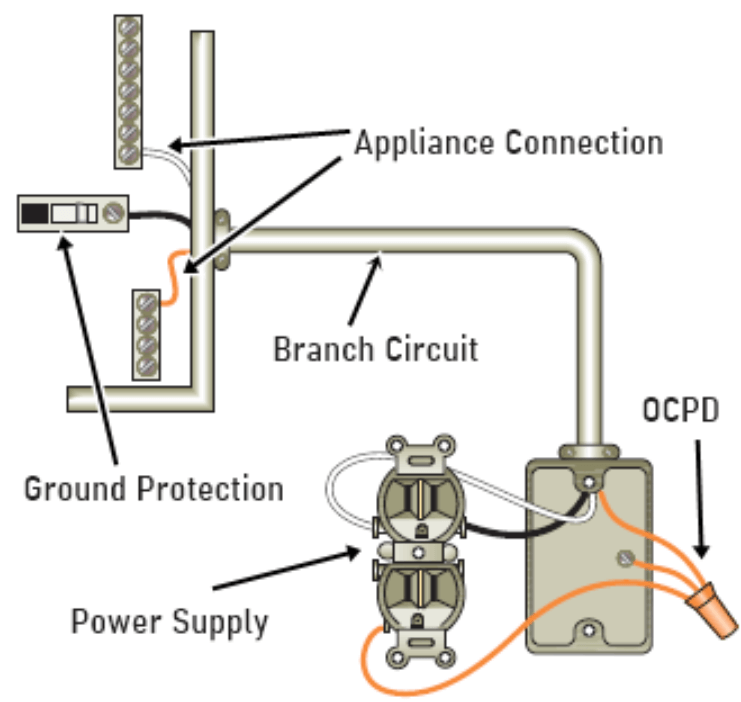

Figure 1: Overcurrent

Understanding Overcurrent: What It Is and Why It Matters?

Overcurrent in electrical systems occurs when the current exceeds the circuit's normal operational limit, often due to overloads or short circuits. This excessive current can cause various issues, from minor component wear to severe damage, including fires, making effective management and preventive measures testing.

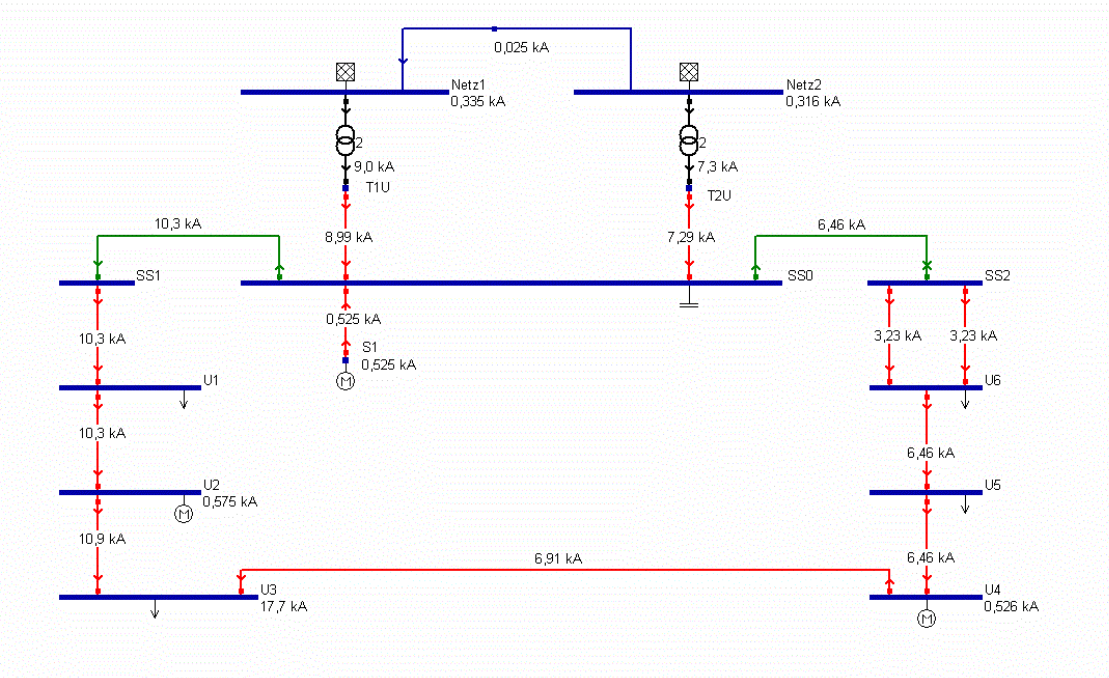

Figure 2: Short Circuits Analysis

Short circuits are significant hazards in electrical systems, creating an unexpected, low-resistance path that bypasses the designed circuitry. This path causes a sharp drop in resistance, leading to a large increase in current flow. Short circuits can range from partial, causing a moderate rise in current that may not immediately damage components, to complete or "dead" shorts, which virtually eliminate resistance in the affected segment. A dead short can result in severe outcomes like melting circuit elements, overheating conductors, and burning insulation. The rapid escalation from a short circuit to a potential fire highlights the need for stringent protective measures in electrical system design to prevent loss of life and property.

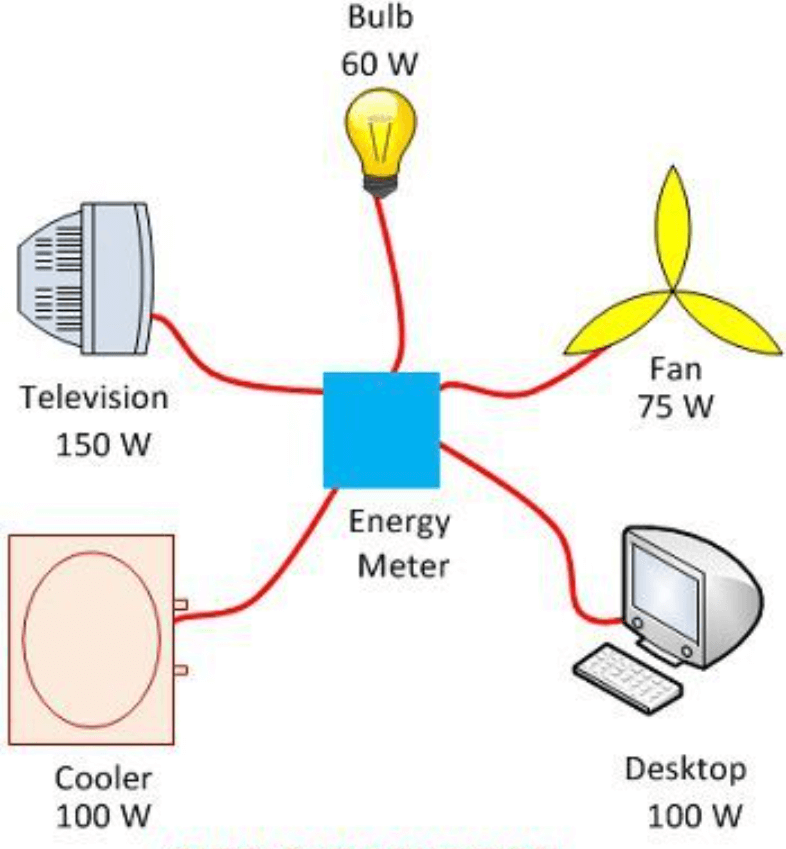

Figure 3: Overload Conditions

Overloads happen when the power demand exceeds a source's capacity to deliver current safely. Unlike short circuits, overloads typically do not cause immediate dramatic effects like arcing or sparking. However, their long-term impact can be just as harmful. Temporary overloads might seem harmless, causing minimal immediate damage. Yet, chronic overloading increases conductor temperatures, gradually degrading insulation and increasing the fire risk. This slow deterioration emphasizes the importance of monitoring circuits and taking corrective actions to prevent persistent overcurrent conditions, which could lead to circuit failure and significant safety hazards

Designing an Effective Overcurrent Protection Circuit

In electrical safety, fuses, and circuit breakers are required for managing overcurrent conditions. These devices are integrated into electrical circuits with minimal resistance and function as conductors under normal conditions. They are strategically placed at key points where power is first distributed within the circuit to ensure quick mitigation of excessive current.

When overcurrent is detected, these devices immediately interrupt the flow of electricity. This rapid disconnection is settling to prevent damage to the circuit and connected equipment. However, fuses and circuit breakers only stop the immediate danger by isolating the affected circuit segment. They do not address the root cause of the overcurrent. After such an interruption, a thorough examination and corrective actions are needed to resolve the underlying issue, ensuring system integrity and preventing future occurrences.

Exploring Popular Overcurrent Protection Devices (OCPDs)

Overcurrent Protection Devices (OCPDs) are dynamic for maintaining the integrity and safety of electrical systems. These devices, including fuses, circuit breakers, and fusible links, are designed to cut off the current flow when it exceeds safe levels. OCPDs come in various forms, some protecting entire systems and others shielding specific components within a circuit.

Choosing an effective OCPD depends on matching it accurately with the circuit’s operational parameters, such as amperage and voltage. Technicians must carefully select the correct size and type of OCPD. This decision involves more than just fitting the circuit’s maximum operational limits; it requires a detailed evaluation of the circuit's typical and peak performance demands. Ensuring robust protection under both normal and exceptional conditions is serious. This careful selection process is needed to prevent routine and extraordinary overcurrent events, thereby safeguarding the electrical system from damage or failure.

Figure 4: Fusible Link

The Role of Fusible Links in Circuit Safety

Fusible links are requisite for safety components in electrical systems, particularly those with heating elements. They are designed to melt and disconnect the circuit when exposed to excessive current or heat, preventing further damage. These links are made from materials chosen for their predictable response to high temperatures or currents, ensuring reliable operation.

When a fusible link activates, it permanently melts and must be replaced to restore circuit protection. Each fusible link is labeled with its specific temperature and amperage limits, making maintenance and replacement straightforward. This clear labeling helps technicians choose the correct replacement, matching the original specifications to ensure the ongoing integrity and safety of the electrical system.

Decoding the Ratings of Overcurrent Protection Devices

Overcurrent protection devices (OCPDs) such as fuses and circuit breakers are basic components in electrical systems, designed to prevent the hazards of excessive current that can lead to overheating, fires, and other dangerous conditions. Here's an expansion on the various aspects related to OCPD ratings:

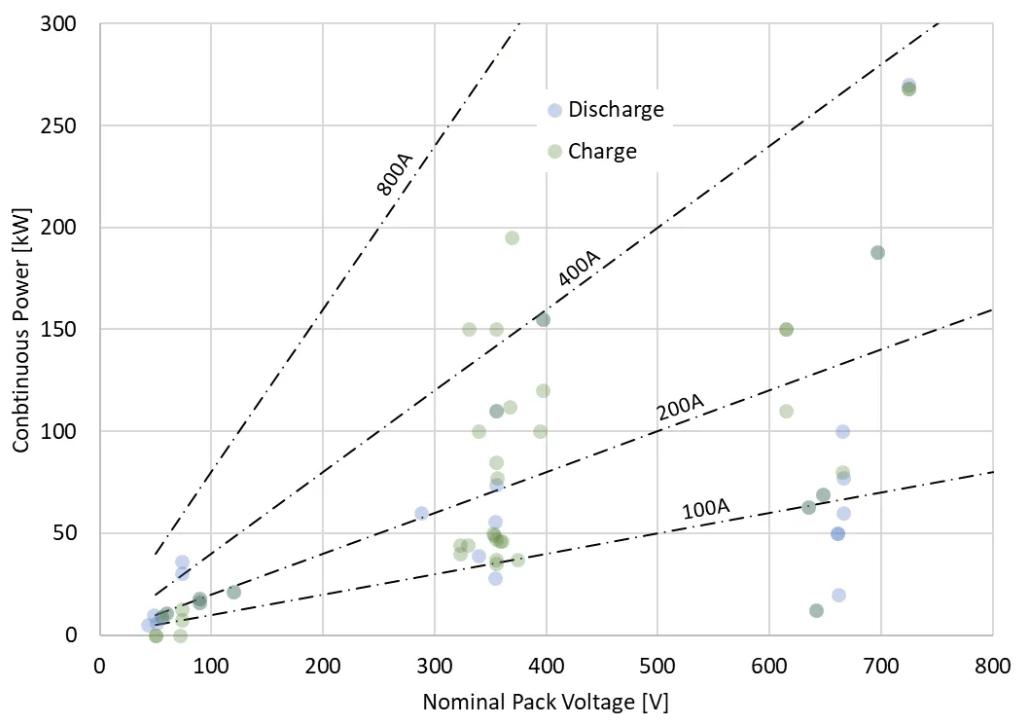

Figure 5: Continuous-Current Rating

Continuous-Current Rating

The continuous-current rating indicates the highest current a device can handle indefinitely without shutting down or failing. It's desperate for this rating to meet or slightly exceed the circuit's full-load current. This match ensures the device protects effectively without overloading and failing prematurely. Choosing a device with the right continuous-current rating improves its lifespan and reliability, preventing electrical hazards caused by inadequate protection.

Voltage Rating

The voltage rating specifies the highest voltage a device can handle while safely stopping the current flow. For an Overcurrent Protection Device (OCPD) to work properly and safely, its voltage rating must meet or exceed the circuit's operating voltage. This ensures the device can control and extinguish internal arcing when interrupting current, maintaining the electrical system's integrity and safety during faults.

Interrupting-Current Rating

The interrupting-current rating specifies the highest current an Overcurrent Protection Device (OCPD) can handle without getting damaged. This rating must be much higher than the maximum current the power source could potentially deliver. This ensures the device can protect against surges and faults, preventing catastrophic failure and maintaining system integrity. By choosing a device with a higher interrupting-current rating, risks are minimized, and reliability is improved.

Current-Limiting Ability

Current-limiting ability measures how well a device can restrict electrical current flow in a circuit, protecting sensitive components from excessive current. This feature reduces the duration of current flow during faults and minimizes thermal and mechanical stress on circuit parts. By quickly lowering peak current values, effective current limitation prevents damage and enhances the safety and longevity of the electrical system.

Time-Current Characteristics

Time-current characteristics indicate how quickly a device responds to overcurrent conditions, insistent on preventing damage or fire hazards. This parameter shows the relationship between the current magnitude and the time it takes for the device to activate its protection. Accurate calibration ensures the device reacts quickly enough to prevent failures and fires but with a slight delay to avoid redundant trips during brief spikes. This balance is dynamic for maintaining both safety and efficiency in electrical systems.

Electrical Terminology for Mastering Overcurrent Protection

Considering these terms not only aids in precise diagnostics but also in designing safer and more efficient electrical systems. Here’s an extended discussion of the key terms and additional concepts:

Ampacity: Ampacity, or current-carrying capacity, is the maximum amount of electrical current a conductor or device can carry before sustaining immediate or gradual damage. Factors influencing ampacity include the conductor's material, insulation type, ambient temperature, and installation conditions. Ampacity is a deciding factor in selecting the appropriate wire size in electrical wiring to prevent overheating and potential fire hazards.

Overload: An overload occurs when equipment or wiring carries current beyond its capacity, leading to excessive heat generation. Overloads can be caused by excessive demand (e.g., plugging too many devices into one circuit) or by a failure in circuit management systems. Protective devices like fuses and circuit breakers are designed to interrupt the circuit when an overload condition is detected to prevent damage to the electrical system.

Short Circuit: A short circuit is a specific type of electrical fault that occurs when a low-resistance pathway forms between two points in an electrical system, allowing a high flow of current that bypasses the normal load. Short circuits are dangerous because they can produce very high temperatures and sparks, leading to fire risks. They are typically caused by exposed or damaged wires, faulty installations, or when insulation breaks down.

Ground Fault: A ground fault happens when an unintended path forms between an electrical current and a grounded element. This can occur if there is a breach in the insulation of devices or wiring, allowing current to flow directly to the earth or to a conductive object that personnel might touch. Ground Fault Circuit Interrupters (GFCIs) are designed to shut off electric power within milliseconds of detecting ground faults to prevent electrocution.

Importance of Circuit Overcurrent Protection in Electrical Systems

Circuit overcurrent protection plays a dominant role in maintaining the safety and functionality of electrical systems across various industries and residential applications. This type of protection is designed to mitigate the risks associated with excessive currents that can arise due to short circuits, overloads, or faulty equipment operations. Here's an expanded view of its importance and implementation:

|

Importance of Circuit Overcurrent Protection

|

|

|

Preventing Equipment Damage |

Excessive current can cause severe damage to electrical components, from simple wiring to complex machinery. Overcurrent protection devices help prevent costly repairs and replacements by interrupting the current flow before damage occurs.

|

|

Enhancing Safety |

By limiting the current in an electrical circuit, these devices prevent overheating and reduce the risk of electrical fires and explosions, which could result in severe injury or death.

|

|

Compliance with Standards |

Many electrical standards and building codes mandate overcurrent protection to ensure that electrical installations are both safe and effective. Compliance helps avoid legal and insurance implications that might arise from electrical accidents.

|

|

Maintaining System Reliability |

Overcurrent protection is required for the reliability of electrical systems. It ensures that systems operate without interruptions and downtimes, which is settling for industrial applications where production depends on continuous electrical supply.

|

|

Proper Sizing and Selection |

The effectiveness of overcurrent protection depends on selecting the correct size and type of protection device based on the circuit's normal operating current and potential fault currents.

|

|

Regular Maintenance and Inspection |

Overcurrent protection devices should be inspected and tested regularly to ensure they function correctly. This includes checking for signs of wear and testing trip mechanisms in circuit breakers.

|

|

Integration with System Design |

Overcurrent protection should be integrated into the electrical system design. This includes considering the locations of devices, the coordination between devices (to ensure the correct device trips under fault conditions), and the overall system’s operational demands.

|

Comparing Fuses and Circuit Breakers

Circuit breakers and fuses play an insistent role in protecting electrical systems, each operating differently and suited to specific applications. They prevent circuit damage by interrupting electricity flow during faults.

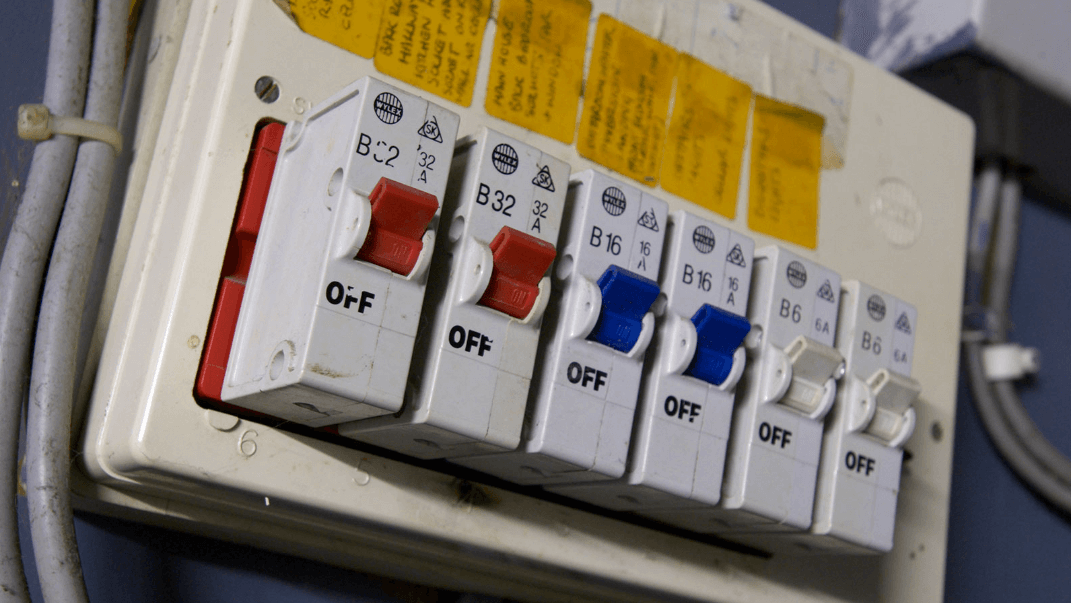

Figure 6: Circuit Breakers

Circuit breakers are electromechanical devices designed to disconnect electrical circuits upon detecting faults. They provide two primary types of protection: thermal protection against overloads and magnetic protection against short circuits. Thermal protection employs a bi-metallic strip that heats and bends as current flows through it, causing the breaker to trip during an overload to prevent damage. Magnetic protection uses a coil to generate a magnetic field proportional to the current; in the event of a short circuit, this magnetic field increases suddenly, activating a lever that trips the breaker instantly. One significant advantage of circuit breakers is their ability to be reset after tripping. After addressing the fault, users can reset the breaker, which avoids the need for replacement and reduces downtime and maintenance costs. Circuit breakers typically make an audible click when they trip, signaling the operator. The breaker lever remains in the middle position to indicate a fault. To reset, the lever must be moved to the "off" position and then back to "on" to ensure the internal mechanism is properly reset. Regular maintenance includes manually tripping the breaker using a test button to check its response time and confirm it trips correctly, which helps in identifying potential issues early on.

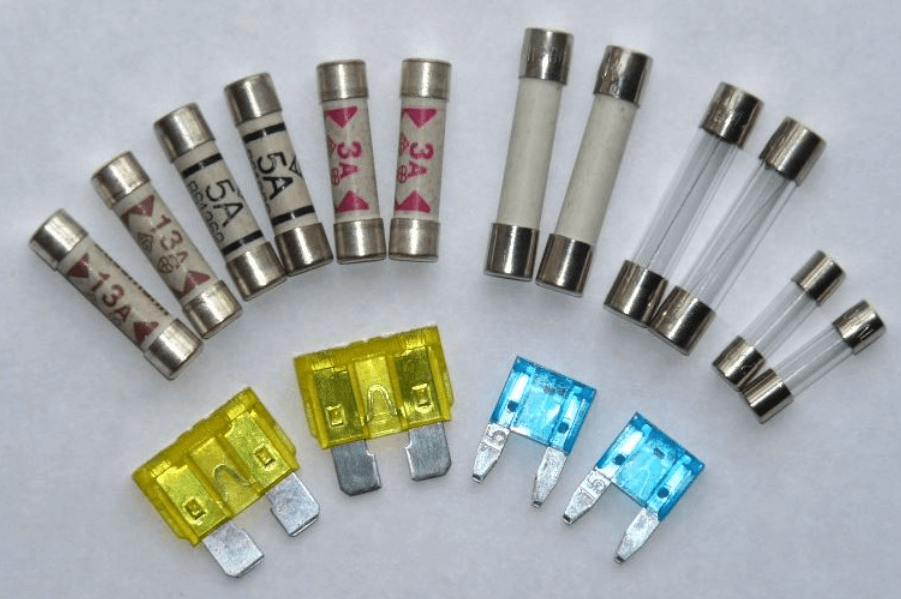

Figure 7: Fuses

Fuses are simple protective devices designed to be the weakest link in an electrical circuit, featuring a metal strip (fuse-link) within an insulated tube that melts under fault conditions to break the circuit and prevent damage. They come in two main types: fast-acting, ideal for circuits without high inrush currents like lighting, and time-delay, which tolerates initial surges in motor circuits. When a fuse blows, it may show a visible gap or blackened glass, and it is replaced with care to avoid injuries from the often-spring-loaded holders. Selecting the correct fuse (matching current rating and type) can protect circuits and prevent unnecessary power interruptions. Regular inspections help ensure fuses are in good condition and properly rated, protecting against potential circuit issues indicated by signs of wear or overheating.

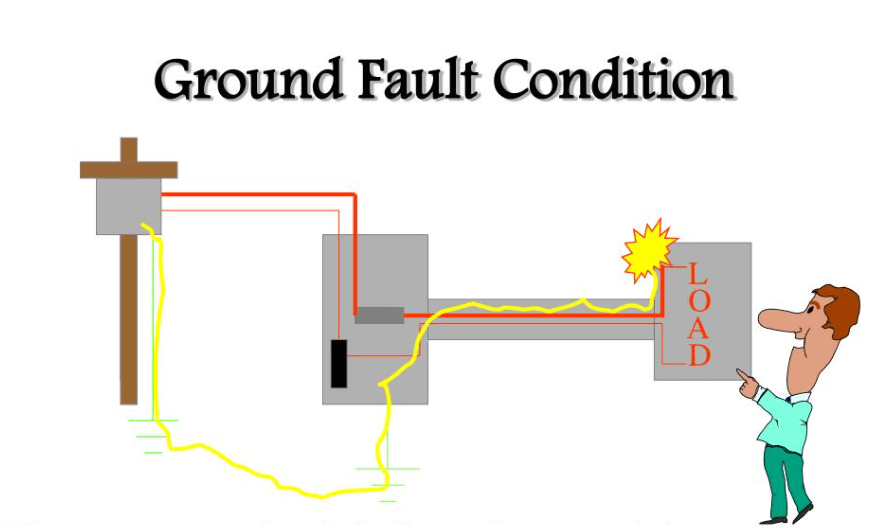

Figure 8: Ground-Fault Overcurrent

The Basics of Ground-Fault Overcurrent Protection

Ground-fault overcurrent is a specific type of short-circuit overcurrent that occurs when a circuit conductor makes contact with the earth's ground. This type of fault is common in power systems with Star transformer configurations. In these setups, one terminal of the transformer's single-phase AC windings is connected to a grounding electrode system, creating a mix of grounded and ungrounded paths in the circuit.

Characteristics and Magnitude

The current in a ground-fault overcurrent is typically lower than in other short-circuit overcurrents. This happens because a ground fault usually affects only one phase of the transformer winding, unlike short circuits that often involve multiple windings.

Designing Protective Mechanisms

Recognizing the unique nature of ground-fault overcurrent allows for the development of tailored protection strategies. These strategies are specifically tuned to address the particular risks and operational characteristics of ground faults. This precise approach enhances safety and helps prevent significant damage to electrical infrastructure.

Characteristics Between Overcurrent Protection and Overload Protection

Overcurrent protection devices (OCPDs) are designed to handle different types of overcurrent situations, including overloads and faults. Overload protection specifically targets excessive current flow that, if sustained, can overheat and damage wires and related equipment. This is significant because short, occasional overloads, like the initial surge of current when starting heavy tools such as miter saws, power drills, or air compressors, are generally harmless and expected.

Consider using a power tool. When you pull the trigger, the motor draws a large initial burst of current, known as inrush current. This surge quickly levels off as the motor reaches its normal running state. Without proper protection, everyday devices like refrigerators and air conditioners would trip circuit breakers at start-up, causing significant inconvenience. Circuit breakers are designed to differentiate between these normal surges and more serious faults, providing a nuanced response based on the severity of the current spike.

Handling Short Circuits and Ground Faults: Short circuits and ground faults create much more severe conditions, with current levels spiking to thousands of amps almost instantly. In these situations, overcurrent protection must act quickly to cut off the circuit, preventing extensive damage, reducing fire risks, and ensuring overall safety.

Calculation of Overcurrent Protection

Calculating overcurrent protection is required in designing electrical systems to ensure safety and adherence to electrical codes. This involves a comprehensive analysis of multiple factors, handled predominantly by licensed electricians due to its technical complexity. The process starts with determining the total expected load on the circuit by summing the power requirements of all connected devices and equipment. It is imperative to ascertain whether the load will persist for three hours or more; for continuous loads, overcurrent protection devices (OCPDs) should be rated at 125% of the load to prevent overheating and nuisance tripping, while for non-continuous loads, a rating of 100% suffices.

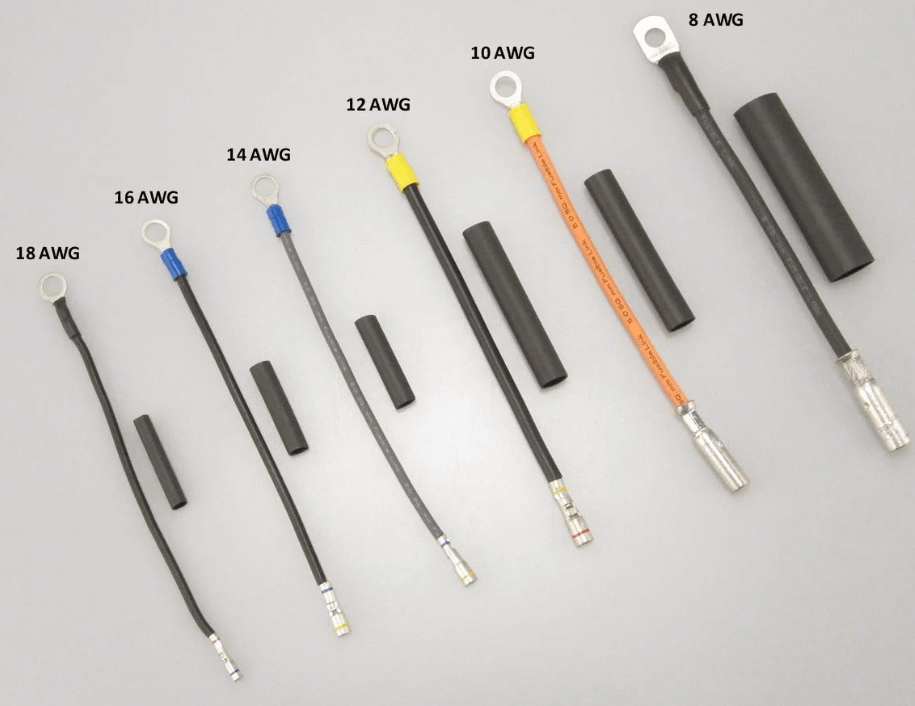

The next step is to ensure the conductors’ ampacity, or current-carrying capacity, meets the expected load requirements. This depends on the conductor material (copper or aluminum), insulation type, and installation conditions, which influence the temperature rating of the conductors. Higher ambient temperatures can reduce ampacity, necessitating adjustments in both conductor sizing and the OCPD rating. The OCPD size must not surpass the ampacity of the conductors it protects. For instance, a #12 AWG copper conductor typically supports an ampacity of 20 amps, thus the OCPD should also not exceed this value. Ensuring that OCPDs are coordinated with other protective devices in the system can provide selective tripping and minimize the effects of faults.

Lastly, after selecting the appropriate conductor and OCPD based on the adjusted current and ampacity, the installation involves placing the OCPD in the correct panel or enclosure, securing all connections, and adhering to electrical codes. Post-installation, load testing is useful to confirm that the OCPD functions correctly under both normal and fault conditions. This includes using clamp meters to measure the actual current draw and comparing it with the calculated values. Regular inspections and maintenance are also required to ensure ongoing compliance and to address any potential issues that may arise during routine checks.

Conclusion

The control of overcurrent is a complex issue that necessitates the use of exact protective measures as well as a thorough understanding of electrical system dynamics. The selection and maintenance of OCPDs can protect circuits from the dangers of excessive current. Through careful analysis, we have explored various types of OCPDs, including fuses, circuit breakers, and fusible links, each integral to preventing equipment damage, enhancing safety, and ensuring compliance with regulatory standards. The technical consideration of continuous-current ratings, voltage ratings, interrupting-current ratings, and other characteristics of these devices underscores the complexity involved in providing effective overcurrent protection. In addition, the integration of protective devices within the system design and their regular inspection and maintenance are dynamic for sustaining system reliability and safety. As electrical technologies advance and demands on systems grow, ongoing research and development in overcurrent protection will continue to be requisite. Eventually, the effective management of overcurrent not only prevents physical and economic losses but also supports the overall stability and efficiency of electrical infrastructures across various sectors.

Frequently Asked Questions [FAQ]

1. What are overload protection devices?

These are safety mechanisms designed to protect electrical circuits and equipment from excessive current, which can cause overheating and damage. They work by detecting when the electrical current exceeds a predetermined level and then interrupting the flow of electricity to prevent harm

2. What are two types of overcurrent?

Overload: Occurs when too many devices or appliances draw more current than the circuit can handle, typically over a prolonged period.

Short Circuit: A more severe form of overcurrent, this happens when there is a direct path between two conductors at different voltages, leading to a massive surge in current flow in a very short time.

3. What is an overcurrent protection device NEC?

This refers to a device that meets the standards set by the NEC to protect electrical circuits by interrupting the circuit if excessive current flows through it. These devices include circuit breakers and fuses.

4. What device provides overcurrent protection in a circuit?

Commonly, circuit breakers and fuses are used to provide overcurrent protection. Circuit breakers can be reset and reused, whereas fuses need to be replaced after they blow. Both act to interrupt the electrical flow when the current exceeds safe levels.

5. Is a disconnect an overcurrent device?

No, a disconnect is not an overcurrent device. Its primary function is to allow equipment to be disconnected from the power source for maintenance or safety purposes. It does not protect against overcurrent by itself.