Exploration of Diode Valves and Vacuum Tubes: Operating Principles, Theoretical Insights, and Formulas

The advent of the diode valve revolutionized modern electronics. This article explores the vacuum tube diodes' mechanics and applications from their origin to present-day uses. Invented by pioneers like Ambrose Fleming, the diode valve utilizes thermionic emission where electrons from a heated cathode flow toward an anode, forming an electrical circuit. It details the diode’s evolution, from the switch between direct and indirect heating to enhancements in rectification from half-wave to full-wave systems.In addition, the article examines theoretical concepts such as electron emission rates and anode current-voltage relationships, alongside potential distribution between the cathode and anode. These insights demonstrate the diode valve's significance in various applications, from radio communications to power supplies, emphasizing its serious role across historical and contemporary electronic frameworks.

Catalog

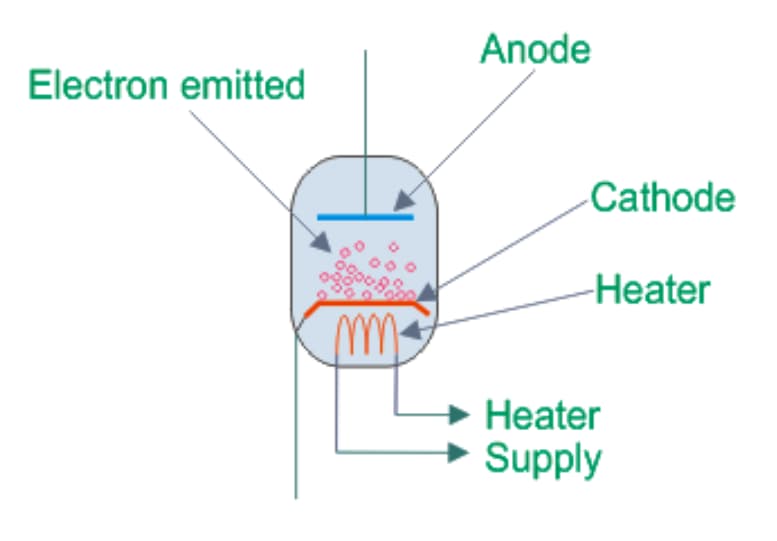

Figure 1: Diode Valve

The Basics of Diode Valves

The diode valve, also known as a vacuum tube, is an ultimate electronic component comprising two main parts: the cathode and the anode. These components are housed within a glass container that is vacuum-sealed. The operation of the diode valve relies on a process called thermionic emission.

When the cathode is heated, it releases electrons due to the thermal energy it receives. These electrons, carrying a negative charge, briefly cause the cathode’s surface to become positively charged, which pulls some of the electrons back toward it. This results in the formation of an electron cloud surrounding the cathode. The density of this cloud decreases as the distance from the cathode increases. The substantial to how the diode valve works lies in the behavior of the electrons in this cloud. Some of the electrons have enough energy to escape the cloud and move toward the anode. Once they reach the anode, they lack the energy to return to the cathode. This movement of electrons from the cathode to the anode completes a circuit through any external load connected between the two electrodes. This flow of electrons is unidirectional, meaning it allows current to pass in only one direction.

This one-way flow of current is settling in applications such as converting alternating current (AC) to direct current (DC), a process known as rectification. In this context, the diode valve serves to change AC into DC. Applying a positive voltage to the anode helps to enhance the flow of electrons, highlighting the diode's dynamic role in rectification and signal detection. The concept of the diode valve was pioneered by Ambrose Fleming at University College London, marking a significant milestone in the development of modern electronics.

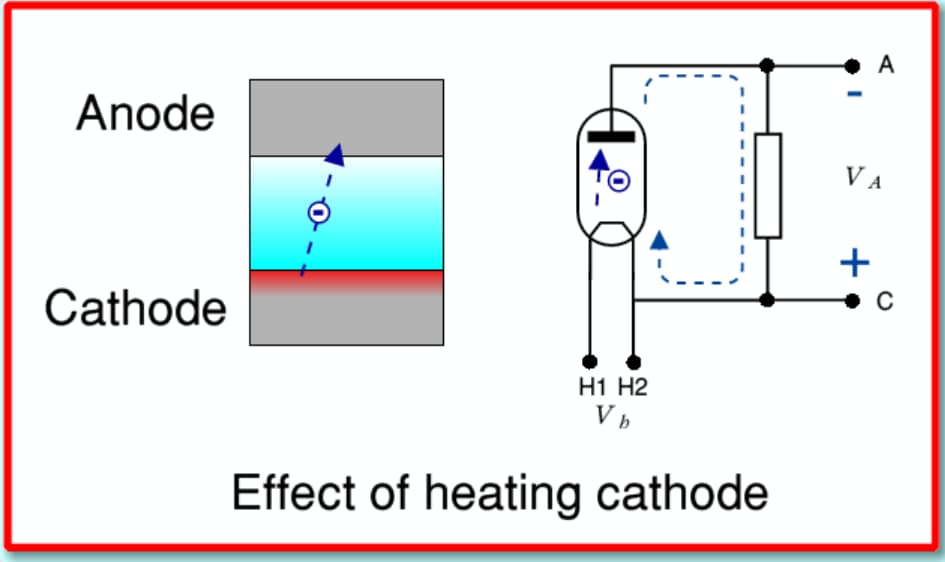

Figure 2: Vacuum Tube Diodes Work

Working Principles of Vacuum Tube Diodes

Analyzing vacuum tube diodes begins with the concept of electron emission from heated materials. When a material is heated, it releases electrons, and this emission rate depends on the temperature and a specific constant known as 'b,' which indicates the energy required for electrons to escape the material.

The rate of electron emission is described by the equation

![]()

where:

![]() is the current in amperes.

is the current in amperes.

![]() is a constant specific to the material.

is a constant specific to the material.

![]() is the absolute temperature.

is the absolute temperature.

![]() is the work function, or the energy desired for an electron to break free from the surface.

is the work function, or the energy desired for an electron to break free from the surface.

This principle is dominant to the development of thermionic valves, a technology advanced by pioneers like Walter H. Schottky and Thomas Edison.

In a diode valve, the anode is maintained at a positive voltage to attract electrons emitted from the cathode. Nevertheless, the effectiveness of this process is closely linked to the level of the anode voltage. If the voltage is too low, a space charge forms—a dense cluster of electrons that pushes back against additional electrons trying to escape the cathode, limiting further emission. Conversely, a sufficiently high anode voltage eliminates this space charge, enabling a steady flow of electrons and a consistent current through the circuit. Controlling the anode voltage is used for optimizing a diode's performance. Proper voltage management ensures efficient electron flow, which in turn enhances the functionality and efficiency of the diode across various applications.

Figure 3: Heated Diode Valve

Indirect Heating in Diode Valves

The move from directly heated to indirectly heated diode valves was a major advancement in vacuum tube technology. Initially, diode valves used a directly heated cathode, which also served as the heater. However, this design had several drawbacks, particularly when the cathode was heated by alternating current (AC). The AC created hum and noise in the output signal, compromising the valve’s performance. In addition, directly heated cathodes required specific voltage settings for each valve, making multi-valve circuit designs more complex and less scalable.

The introduction of indirectly heated cathodes addressed these issues effectively. In this design, the heater and cathode are electrically separate. This separation allows a consistent heater supply across multiple valves without affecting the voltage settings needed for proper operation. This change greatly improved reliability, simplified circuit design, and reduced the overall cost of electronic devices.

Indirect heating has since become the standard in vacuum tube design, from simple diodes to complex triodes and multi-electrode tubes. This standardization has made it easier to incorporate these components into a wide range of electronic systems, enhancing their functionality and performance.

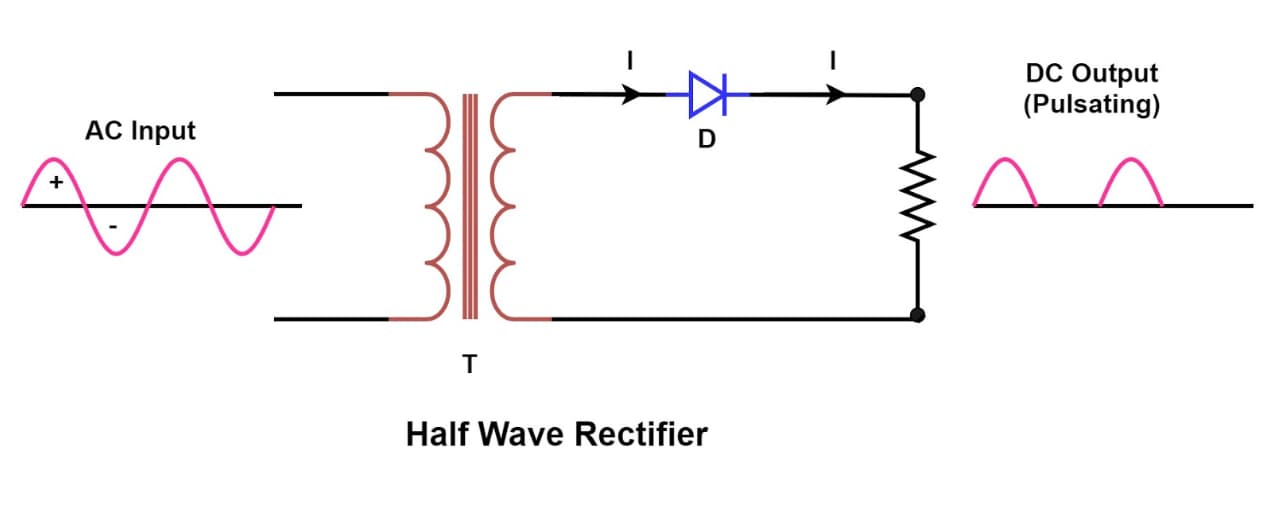

Figure 4: Half-Wave Diode Valve Rectifier

Efficiency of Half Wave Diode Valve Rectifiers

The half-wave rectifier is the most basic way to convert alternating current (AC) into direct current (DC) using a single diode valve. It works by allowing the diode to conduct electricity during one phase of the AC cycle and blocking it during the other. As a result, only one-half of the AC waveform is used, leading to a rectification efficiency of about 50%.

Despite its simplicity and low cost, the half-wave rectifier has a major limitation: it can't provide a stable, continuous DC output. This makes it unsuitable for applications that require a consistent DC power supply.

The half-wave rectifier demonstrates the ultimate concept of rectification, but its performance limitations underscore the need for more advanced designs that can deliver higher efficiency and meet the demands of modern electronic systems.

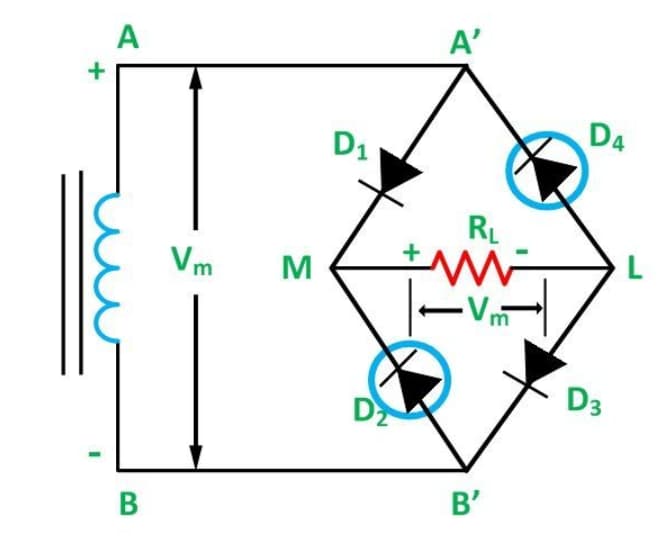

Figure 5: Full-Wave Diode Valve Rectifier

Dynamics of Full Wave Diode Valve Rectifiers

The full-wave rectifier advances the simple half-wave design by using multiple diode valves to capture both halves of the AC waveform. This approach doubles the efficiency of converting AC to DC.

Typically, two diodes are used in this configuration. Each diode handles one half of the AC cycle—one conducts during the positive half-cycle, and the other during the negative half. This setup ensures that the entire AC waveform is converted into DC.

The full-wave rectifier significantly reduces the gaps between the peaks of the output waveform, leading to a much smoother DC output with less ripple compared to a half-wave rectifier. This smoother output is dynamic for applications that require a stable and consistent DC supply. Full-wave rectifier tubes are often designed with dual anodes and a single cathode in one tube, which simplifies the circuitry while ensuring robust rectification.

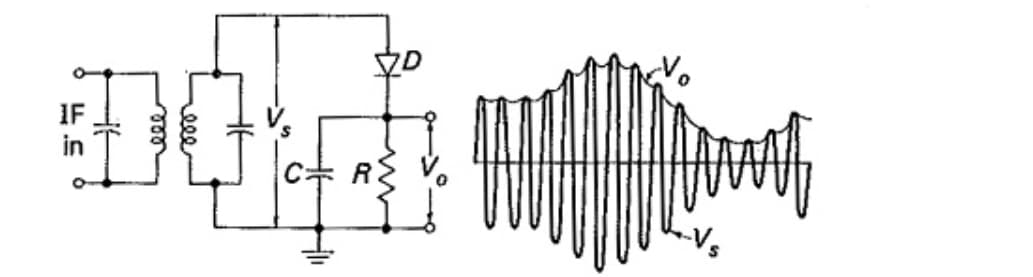

Figure 6: Diode Valve Signal Detector

Signal Detection with Diode Valve Technology

The diode valve is focal in demodulating amplitude-modulated (AM) signals, a method pioneered by Ambrose Fleming. In this role, the diode valve rectifies the incoming AM signal by removing the carrier wave and extracting the underlying audio or data signal.

Although the basic concept is straightforward, the process faces challenges. The diode's non-linear response can cause distortions, and selective fading—common in radio transmissions—can affect the signal quality.

Despite these issues, the diode valve remains useful in detecting and processing radio signals. Its ability to perform reliably, even when signal integrity is compromised, underscores its importance in modern signal processing.

Figure 7: Diode Anode Current and Voltage

Theories Behind Diode Anode Current and Voltage

The current is primarily controlled by how many electrons the cathode can emit, which depends on its temperature. As the anode voltage increases, it captures more electrons, eventually reaching a point where the current saturates because all available electrons are being used.

When the anode voltage is lower, a negative space charge may form between the cathode and anode. This charge acts as a barrier, slowing down the electron flow and reducing the current.

Properly setting the anode voltage ensures that the diode operates efficiently, delivers the desired electrical performance, and avoids conditions that could lead to excessive wear or failure, thereby extending the diode’s lifespan.

Cathode and Anode Potential in Diodes

The potential distribution between the cathode and anode in a diode valve is heavily influenced by the space charge—a collection of electrons that are emitted from the cathode but do not immediately reach the anode. This accumulation of electrons forms a potential barrier that impacts the flow of subsequent electron emissions, controlling the diode's current conduction.

Analyzing the interaction between the space charge and the potential gradient is required for optimizing diode performance. This knowledge allows for accurate predictions of how changes in voltage and temperature will affect the diode's efficiency and reliability.

For engineers and technicians, mastering these concepts is used for fine-tuning diode applications, ensuring they operate within optimal parameters, minimize energy losses, and avoid performance degradation.

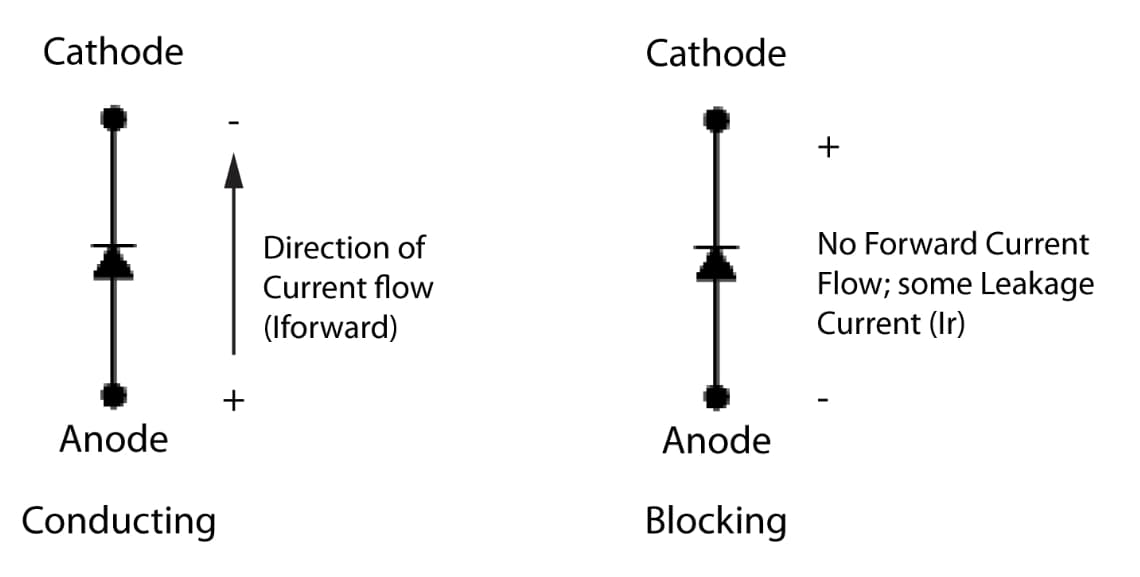

Different Types of Vacuum Tube Diodes

Vacuum tube diodes, ultimate to early electronic design, remain significant in modern technology despite the dominance of semiconductors. These diodes allow current to flow in one direction through a vacuum-sealed tube, a principle that underpins their diverse applications. They are categorized by their construction, materials, and specific uses, each tailored for particular performance needs such as frequency response, power handling, and stability.

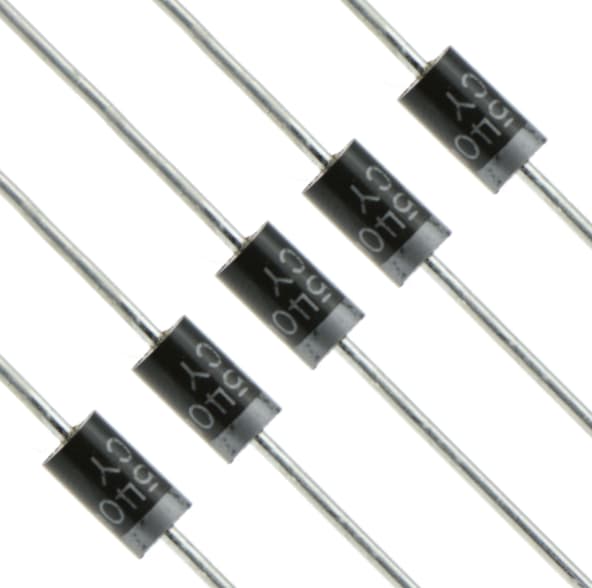

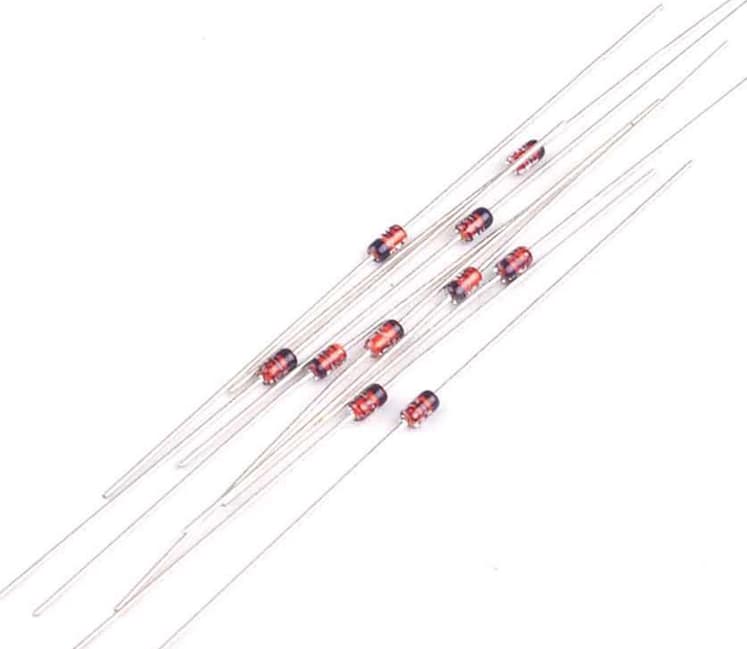

Figure 8: Rectifier Diodes

Rectifier diodes are among the most common types, designed to convert alternating current (AC) into direct current (DC). They are basic in power supplies for radios, TVs, and other electronics. Their robust design allows them to handle high voltages and currents, making them requisite in heavy-duty applications.

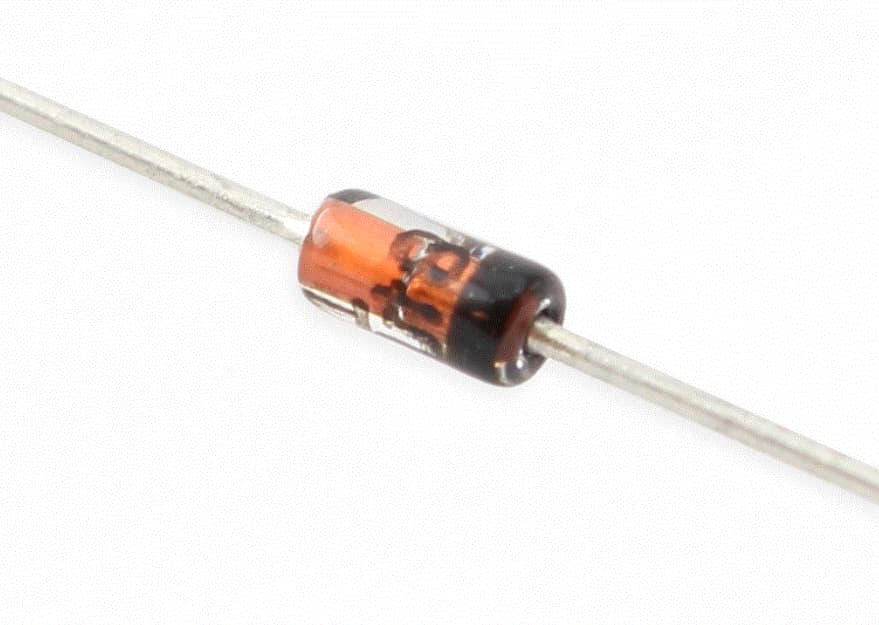

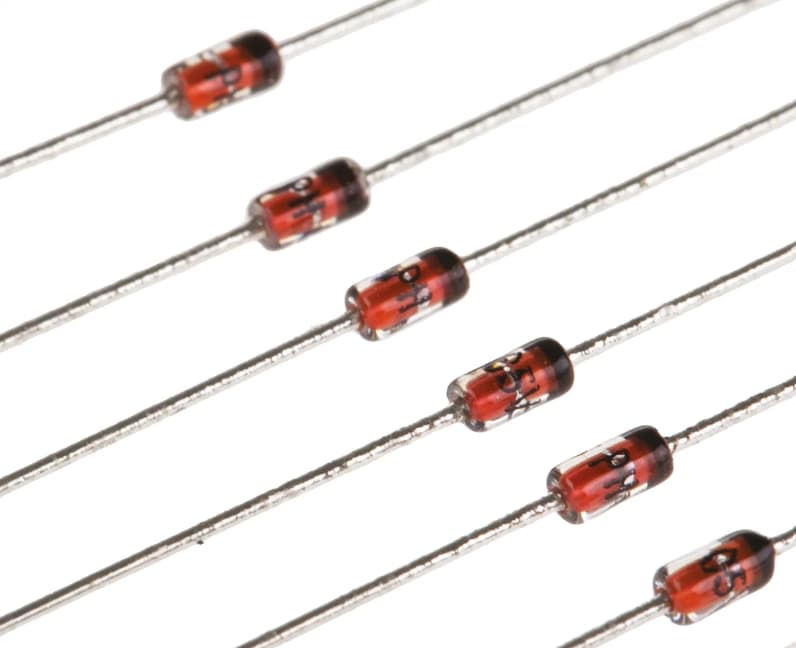

Figure 9: Signal Diodes

Signal diodes are used primarily in signal processing, including mixing, detection, and switching in radio frequency (RF) circuits. These diodes are optimized for low-power and high-frequency use, offering precise control with minimal signal loss, making them ideal for communication equipment.

Figure 10: Switching Diodes

Switching diodes are built for rapidly turning signals on and off, key in digital computing, and pulse circuits. They generate sharp pulse edges, ensuring reliable performance in radar and digital systems where speed and precision are serious.

Figure 11: Zener Diodes

Though rare in vacuum tube form, Zener diodes have historically been used for voltage regulation. They provided stable voltage references and waveform clipping, maintaining a constant voltage across a wide range of currents, which is valuable for power regulation.

Figure 12: Audio Diodes

Audio diodes are tailored for audio applications where low noise and high fidelity are dynamic. Used in audio amplifiers, signal processing, and broadcasting, these diodes minimize distortion and noise, enhancing sound quality in high-fidelity systems.

Applications of Vacuum Tube Diodes in Modern Technology

Vacuum tube diodes are suitable components in many fields, known for their durability and exceptional performance in challenging environments. Their ability to handle high voltages, and high currents, and resist electromagnetic interference makes them requisite in a variety of applications.

|

Applications of Vacuum Tube Diodes |

|

|

Radio and Communication Systems |

Historically, vacuum tube diodes were key

in the development of radio technology, especially in demodulating AM signals

to convert them into audible sounds. Today, they remain relevant in certain

high-frequency radio applications, particularly where solid-state devices

might fail under extreme conditions like high power or temperature. |

|

Power Conversion and Supply |

In power supply units, vacuum tube diodes

help convert AC to DC, a process dynamic for everything from household

electronics to industrial machinery. Their ability to handle high voltages

makes them especially suitable for powering tube-based audio amplifiers,

ensuring smooth and stable performance. |

|

Medical Equipment |

Vacuum tube diodes are risky in the power

supplies of medical devices, such as X-ray machines. Their ability to manage

high voltages is useful for producing medical-grade X-rays, and their

reliability under constant use ensures the safety and effectiveness of

diagnostic imaging. |

|

Microwave and Radar Systems |

In microwave systems and radar

technology, vacuum tube diodes excel due to their ability to handle high

frequencies and power levels, making them ideal for use in aviation, maritime

navigation, and other high-energy environments. |

|

Military and Aerospace Applications |

The resilience of vacuum tube diodes

against electromagnetic pulses (EMP) makes them ideal for military and

aerospace applications. They perform reliably in environments with intense

electromagnetic fields, where solid-state devices might fail, ensuring the

success of serious operations. |

|

Renewable Energy Systems |

Vacuum tube diodes also find applications

in renewable energy systems, particularly in solar power. They are used in

high-voltage DC transmission lines connected to solar collectors,

contributing to efficient and stable power transfer from solar panels to the

grid or storage systems. |

|

Audio Amplification |

In high-end audio amplification, vacuum

tube diodes are valued for their ability to produce superior sound quality

with minimal harmonic distortion. They are a staple in professional audio

studios and home systems that prioritize analog sound characteristics. |

Conclusion

Vacuum tube diodes, as detailed in this exploration, stand out not only for their historical significance but also for their robust performance in modern high-demand applications. The discussion spans various types of diode valves, each tailored for specific roles, such as rectification, signal processing, and high-frequency operations. This versatility underscores the diode’s ability to adapt to evolving technological needs while maintaining reliability in environments where modern semiconductors might falter. As we traced the development from basic rectifiers to sophisticated signal detectors and explored the theoretical models that predict diode behavior, it became evident that understanding these devices is used for optimizing electronic designs.

Eventually, the resilience and adaptability of vacuum tube diodes enhance a wide array of systems, from vintage audio equipment to cutting-edge military technology, demonstrating their requisite role in the advancement of electronic engineering. This article reaffirms that despite the prevalence of semiconductor technology, the foundational principles and applications of vacuum tube diodes remain basic to the ongoing evolution of electronic systems.

Frequently Asked Questions [FAQ]

1. What is the basic concept of a vacuum tube?

A vacuum tube, also known as a thermionic valve, is an electronic device consisting of sealed glass or metal enclosures from which the air has been removed to create a vacuum. Inside, there are electrodes for controlling electron flow. These tubes were used extensively in early electronics, such as radios, televisions, and early computers, to amplify signals and switch currents.

2. How do vacuum tube valves work?

Vacuum tubes operate by controlling the flow of electrons in a low-pressure environment. When a filament within the tube is heated by an electric current, it emits electrons in a process called thermionic emission. These electrons are attracted to a positively charged plate inside the tube. By controlling the voltage on an additional electrode called the grid, which sits between the filament (cathode) and the plate (anode), the flow of electrons can be regulated, allowing the tube to amplify or modify signals.

3. What is the operation of a vacuum valve?

The operation of a vacuum valve involves three main components: the cathode, the anode, and the grid. When the cathode is heated, it emits electrons. The grid controls the number of these electrons that reach the anode, which collects them. By adjusting the grid’s voltage, the current flowing through the tube is controlled, facilitating functions like amplification.

4. What are the two main functions of a vacuum tube?

Amplification: Vacuum tubes can increase the amplitude of electrical signals, making them useful in audio and radio technology.

Switching: They can rapidly switch currents on and off, making them useful in early digital computers.

5. What is the vacuum tube method?

This term might refer to various specific techniques within different contexts, but generally, it relates to using vacuum tubes to achieve amplification or switching. In practical terms, it involves setting up circuits with vacuum tubes, where the specific arrangement of cathodes, anodes, and grids allows for control over electron flow, thereby influencing the electrical output in response to input signals.