Discovering the role of thermistors in modern electronics

Thermistors with 'thermal' and 'resistance' portanto are specialized resistances with significant changing resistance values with temperature changes. Unlike traditional resistance designed to maintain a dark resistance, thermistors are designed to have a significant temperature coefficient and this response to the temperature fluctuations in a precise way to the temperature fluctuations.This unique feature requires thermistors in a wide range of applications, from control to temperature detection and circuit protection.This article investigates its operational mechanisms, structural features and multi -faceted roles that define their important role in modern technology in various industries.In addition to special variants such as, we investigate the technological turmoil that defines the thermistor functionality and application.

Catalog

Demiistization of thermists

A thermistor is a type of resistance that significantly changes resistance with temperature changes, which is extremely useful in many applications. The word "thermistor" combines "thermal" and "resistance".It is designed to have a temperature coefficient, which allows them to quickly react to temperature changes.

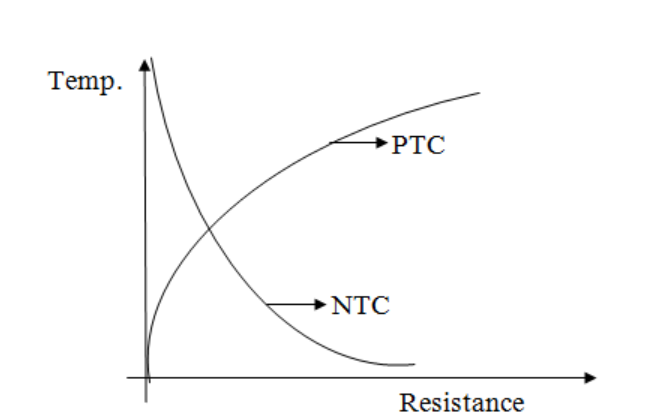

Thermistors are mainly classified according to the temperature coefficient. As the temperature increases, these thermistors decrease in resistance. They are widely used in temperature monitoring and control systems, because resistance change can be foreseen with temperature changes.It makes it, where the temperatures rise too much, they help to prevent overheating by reducing current flow.

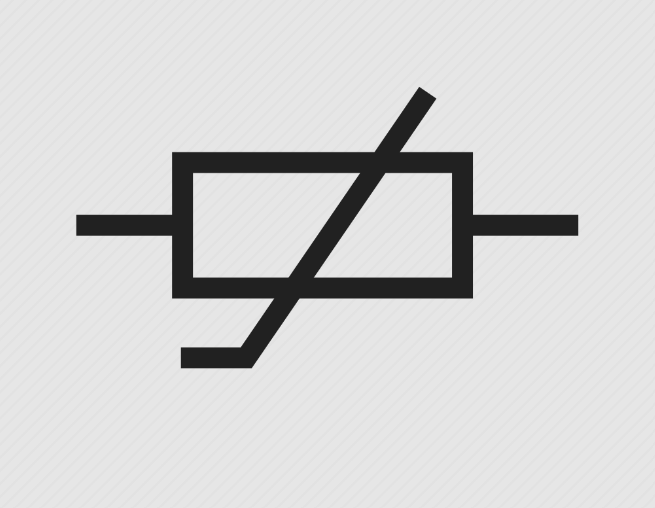

Figure 2 Thermistor Circuit Symbol

The circuit symbol of the thermistors

The circuit symbol of a thermistor is a modified version of the standard resistance symbol represented by a rectangle. A short diagonal line with a vertical segment clearly distinguishes this rectangle and clearly distinguishes in electronic schemes.This standardized symbol is the most common and widely recognized symbol. This ensures that thermistors are easily identified and encourages the consistency and clarity in electronic design documents.

Different Types of Thermistor

Thermistors are resistant devices that are significantly changing resistance to temperature, making them useful for precise temperature detection and control.

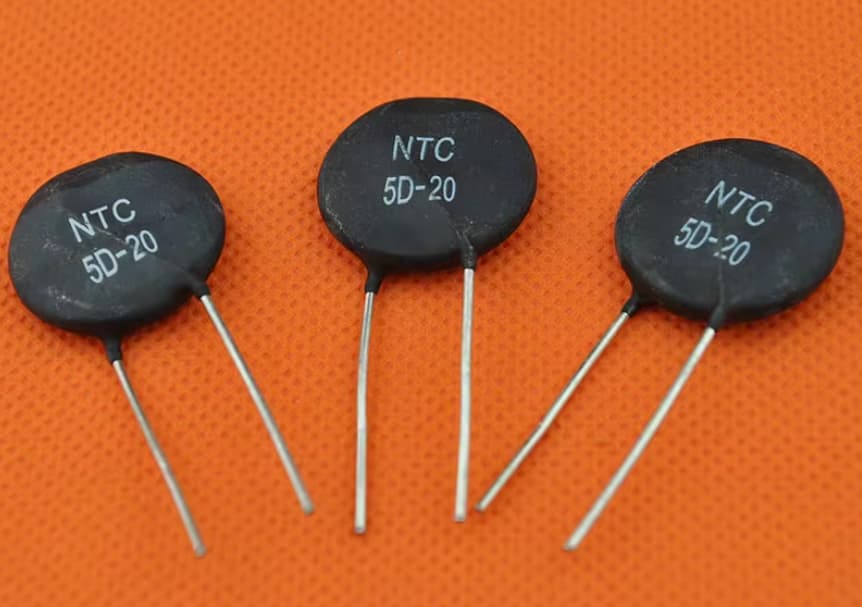

Figure 3 Negative temperature coefficient (NTC) Thermistors

As the temperature increases, NTC thermistors decrease in resistance. This reverse relationship follows the Steinhart-Hart equation that accurately defines the resistance temperature relationship.NTC thermistors are made of materials such as manganese, nickel, cobalt oxides and copper that contribute to temperature sensitive properties.For, to prevent overheating, it is widely used in consumer electronics and medical devices in which sensitivity is insistent. Protecting the resistance from gradual increasing the resistance as it heats up, thus limiting the current flow during the device starting.

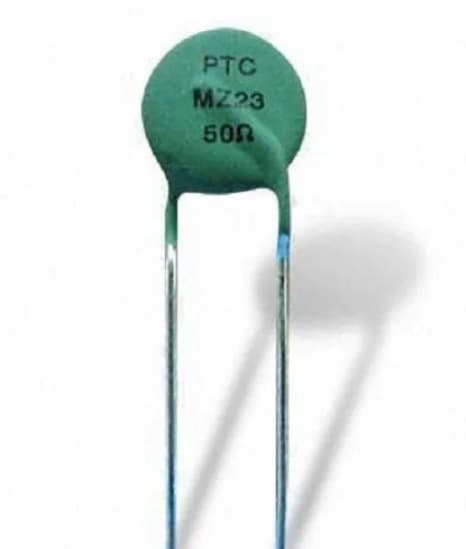

Figure 4 Positive temperature coefficient (PTC) Thermistors

PTC thermistors increase their resistances with temperature increase. This feature is useful for existing limitation and overflow protection. PTC thermistors typically are typically made of barium titanate and other polycrystalline ceramics. When the flow flow increases the temperature, the resistance of the thermistor increases and the thermistor increases and the thermistor's resistance increases.Reduces current flow to prevent damage. Serve as self -regulating heating elements that maintain a fixed temperature without the need for separate control systems.

Figure 5 Silistor

A PTC thermistor made of silicone provides a linear response to temperature changes that are suitable for sensitive temperature measurements in a narrower range than the thermistors, silistors, metallic oxide thermistors.

Evolution of thermistors

The idea that resistance has changed with temperature has been known since the nineteenth century. Michael Faraday first observed the negative temperature coefficient (NTC) in the silver sulfur in 1833.However, metallic oxide thermistors were not commercially produced until the 1940s.After World War II, the developments in semiconductor technologies led to the development of crystalline Germanium and silicone thermistors.

These innovations have greatly expanded the use of thermistors from simple temperature sensors to complex control mechanisms in industrial environments.

Figure 6 Anatomy of thermistors

Anatomy of thermistors

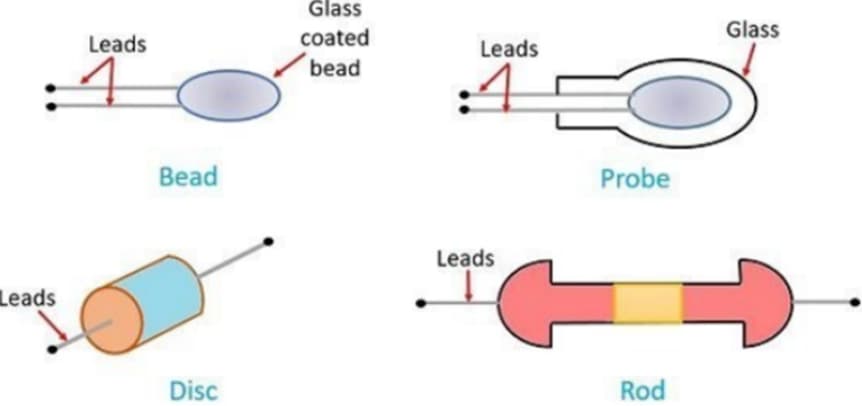

Thermistors come in various ways, including flat discs, beads and bars to meet different application and temperature requirements. Each shapes are designed to optimize the thermal theme with surfaces or to fit into certain devices without any problems.

Metallic oxide thermistors, manganese, nickel, cobalt, copper and ferric oxides, which work effectively between 200 and 700 k, are made from a mixture of the materials.

Germanium -based semiconductor thermistors are preferred for low temperature applications below 100 K.

Figure 7 Thermistor specification

Basic features of thermistors

When evaluating the thermistors, several basic specifications are desperate. These parameters include base resistance, temperature coefficient, thermal distribution factor, maximum power distribution and operational temperature range. These parameters are detailed in the data pages required to select the appropriate thermistor for certain applications.

Thermistors are particularly valuable in devices that require quick response to temperature changes such as fire detectors. In addition, they play an important role in circuits designed for precision temperature control and protection that provide optimal performance and safety in various electronic systems.

Various applications of the thermistor

Thermistors are dynamic components in various industries due to their sensitivities and accuracy in temperature measurement and control.

Industrial Applications: Thermistors in industrial environments provide optimal working conditions. Termistors protect the desperate temperature and humidity levels that are desperate for processes requiring strict climate control.Readings are used.

Automotive Industry: Thermistors increase safety and efficiency in automotive systems by measuring engine oil and cooling temperatures, prevent potential overheating and engine damage.marks.

Consumer electronics and home devices: Thermistors are integrated into many houses and electronic devices, follow CPU temperatures, activate cooling mechanisms when necessary to prevent damage and efficient operation.

Medical Equipment: In medical equipment, thermistors are effective in cases where sensitivity is serious, protecting the stable temperatures required for newborn and microbiological incubators. Termisors provide sensitive temperature control in devices that storing blood, vaccine and other biological materials and protect their aliveness.

Energy Management: Termistors play an important role in energy management. They monitor and manage the temperature of various components that contribute to the distribution of energy and minimizing waste. In Sun panels and wind turbines, thermistors follow the temperature to optimize performance and prevent damage from thermal ends.

Research and Development: Thermistors in laboratories are suitable for correct temperature control in experiments and test environments and provide consistent test conditions.

Aviation and Defense: Thermistors are serious in aviation and defense applications, monitor and control the cabin, equipment and motor temperatures to increase performance and safety under challenging conditions. Termisers protect their equipment temperatures within the safe working limits in vacuum vacuum.

Figure 8 Ceramic Switching PTC Thermistor

Discovering ceramic switching PTC thermistors

Ceramic switching PTC thermistors have a unique non-linear resistance-temperature relationship. Under the point ofurie, their resistance slightly decreases with temperature. As the temperature reaches the curie point, their resistance increases to a significant extent due to a positive temperature coefficient.

This sharp resistance change at the curie point is dynamic for applications that require precise control over temperature resistance variations. These thermistors are especially effective for thermal management and protective functions in electronic circuits.

Solution

In general, since they respond to a dynamic response to a wide range of temperatures and changes in temperature, thermistors stand out as stable parts in the pantheon of electronic devices.At the same time, they play an important role in the advancement of research and development in various scientific fields. The ongoing development and improvement of thermistor technology, which underlines history developments and material innovations, continues to expand its benefits and ensures that thermistors remain at the front of the temperature -sensitive practices.

The thermistors' ability to adapt to a series of operational demands through fast temperature detection or effective current limitation makes them very valuable in both daily and highly specialized technological applications.It promises more integration and functionality in a world.

Frequently Asked Questions [FAQ]

1. What is the thermistor used for?

A thermistor is mainly used to measure the temperature. The resistance with temperature changes is an important and predictable type of resistance. This feature is ideal for temperature detection and control of devices such as thermostats, automotive sensors and appliances.

2. What is the working principle of the thermistor?

A thermistor works on the principle that the electrical resistance changes with temperature. This change is due to the properties of the semiconductor material in which the thermistor is made. When the temperature increases, the resistance of the negative temperature coefficient (NTC) thermistin decreases and resistance to a positive temperature coefficient (PTC) increases.

3. Does the thermistor increase with temperature?

For a NTC thermistor, the resistance decreases as the temperature increases. For a PTC thermistor, resistance increases as the temperature increases as the temperature increases.

4. How does the thermistor measure resistance?

To measure the resistance using a thermistor, you can connect to a simple circuit, including a power supply and measure the voltage in the thermistor. OHM Law (V = IR), where V voltage, current and R resistance, you can calculate the resistance of the thermistor's voltage and current values.

5. How to use a thermistor to measure temperature?

To use a thermistor for temperature measurement, include in a voltage divider circuit connected to a power supply. The voltage is later measured along themistor. This voltage is associated with the resistance of the changing thermistor with temperature.You can create a profile that allows you to convert.