Comparing Axial and Centrifugal Fans: Understanding the Key Differences

In the contemporary industrial landscape, the key role of axial and centrifugal fans extends across numerous applications, ranging from electronic cooling to industrial ventilation. These fans are ultimate in managing thermal dynamics and air quality, conclusive for maintaining the efficiency and longevity of various systems. Axial fans, recognized for their ability to move large volumes of air along the axis of rotation, excel in applications requiring broad air dispersion at low pressure. On the other hand, centrifugal fans, or blowers, utilize a different mechanical design to deliver air radially , making them ideal for situations that demand high-pressure airflow with focused direction. This article digs into the operational principles, common applications, and the nuanced distinctions between these two types of fans, further exploring their advantages in specific environmental and industrial contexts.

Catalog

Figure 1: Axial Fans

Basics of Axial Fans

Axial fans are insistent for cooling and ventilation, characterized by dominant motor driving blades that push air parallel to the rotation axis. Resembling propeller fans can be adapted for ducts as tube axial or vane axial fans, depending on the addition of guide vanes or tubes.

These fans are designed to move large volumes of air, making them ideal for cooling electronics or ventilating large spaces. Their adaptable design allows them to range in size from small units for electronics to large models for room-wide air management. Smaller fans use less power, making them energy-efficient for portable and low-energy applications.

Axial fans are available in both AC and DC models. AC models run on standard line currents above 100 volts, while DC models operate on lower voltages from 3 to 48 VDC, suitable for battery or external power supplies. They generate high volumes of air with low pressure, ensuring even air distribution over large areas, which improves cooling efficiency and comfort.

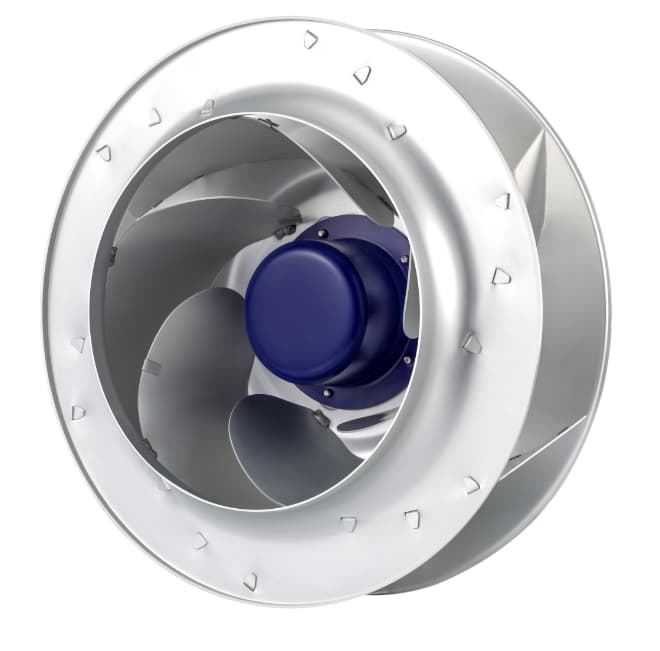

Figure 2: Centrifugal Fans

Insights into Centrifugal Fans

Centrifugal fans, also called radial fans or blowers, operate on a unique principle different from axial fans. They have a motor-driven hub with impellers that push air outward from the center. The air is drawn into the center and then expelled perpendicularly through a surrounding housing, increasing the air pressure significantly.

This design allows centrifugal fans to create a concentrated, high-pressure airflow, ideal for applications needing directed airflow. They move less air volume than axial fans but produce focused, powerful air streams noteworthy for precise air direction, such as in systems with densely packed electronic components.

Centrifugal fans come with impellers that have either forward or backward curves, optimizing either pressure capabilities or energy efficiency. They usually require more power and generate more noise compared to axial fans. However, their robust design, including a protective casing around the moving parts, enhances their durability and operational reliability. This is useful for supporting high-performance components like power Field-Effect Transistors (FETs), Digital Signal Processors (DSPs), and Field-Programmable Gate Arrays (FPGAs). The cowl of the centrifugal fan not only directs airflow efficiently but also acts as a shield, protecting sensitive areas from overheating, thus ensuring safety and extending the lifespan of the components.

Common Uses for Axial and Centrifugal Fans

Axial Fans

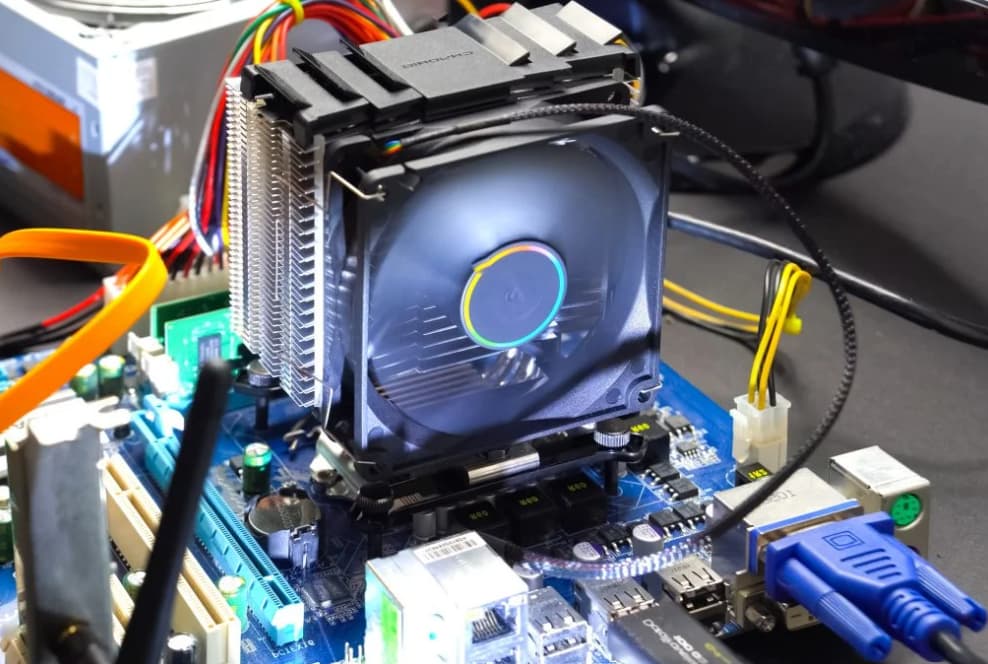

Figure 3: Information Technology and Server Rooms

Cool server rooms and data centers by dissipating heat from high-density computing equipment. Prevent hardware malfunctions and extend equipment life.

Figure 4: HVAC Systems

Enhance the efficiency of air conditioners and heat exchangers by moving cool and warm air. Ensure comfortable temperatures in residential, commercial, and industrial settings.

Figure 5: Industrial Cooling and Exhaust Systems

Aid in air circulation and targeted cooling of machinery in manufacturing and industrial plants. Integral to exhaust systems that regulate air quality and temperature, such as cooling parts and ventilating paint spray booths in automotive manufacturing.

Figure 6: Agricultural Applications

Used in greenhouses and storage facilities to maintain specific temperature and humidity levels. Circulate air to ensure even temperature distribution and prevent mold buildup on plants.

Figure 7: Commercial Ventilation

Improve air quality in restaurants, gyms, and shopping malls by ventilating stale air and odors. Manage odors, moisture, and pollutants effectively.

Figure 8: Transportation

Cool engines and brake systems in automotive and aerospace applications. Ventilate cabins and cargo spaces.

Figure 9: Event Spaces

Manage air quality and comfort in temporary setups like tents and large event halls. Handle high air volumes desirable for large, densely populated spaces.

Centrifugal Fans

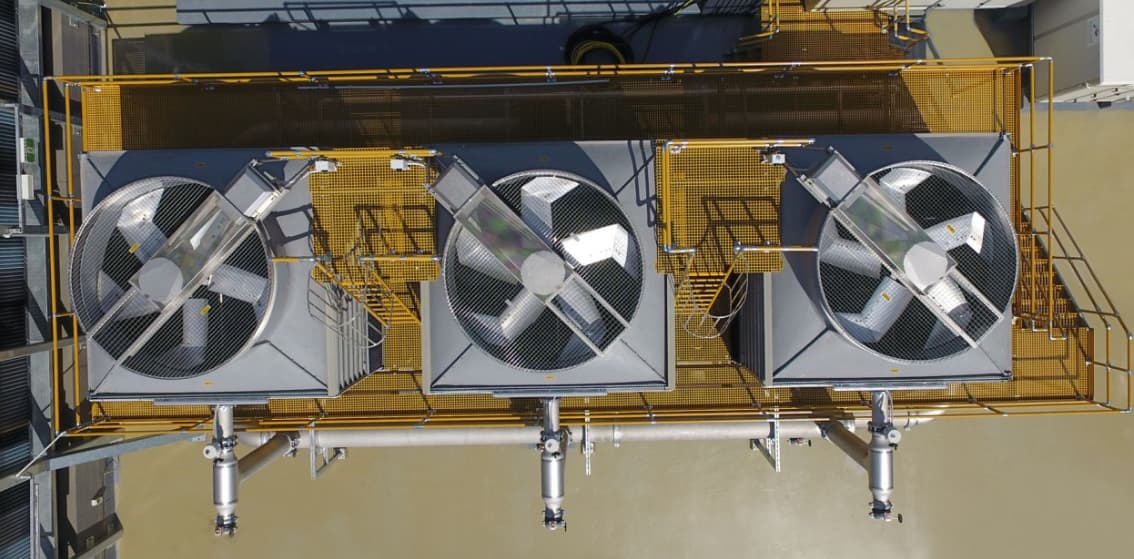

Figure 10: Industrial Ventilation

Provide consistent air supply and exhaust in factories and industrial plants. Effectively remove pollutants like dust and fumes to maintain air quality and safety standards.

Figure 11: HVAC Systems

Circulate air through long ductwork due to high pressure and flow capabilities. Ensure consistent indoor air quality.

Figure 12: Drying Systems

Used in agricultural and industrial drying applications to generate concentrated airflows. Ideal for drying grains, pharmaceuticals, and other materials requiring controlled air conditions.

Figure 13: Cooling of Electronics

Key in cooling systems for electronics manufacturing. Cool devices like servers, laptops, and power supplies with their compact design and precise airflow direction.

Figure 14: Pollution Control Equipment

Integral to systems designed to control environmental pollution, such as scrubbers, cyclone separators, and electrostatic precipitators. Maintain needed airflow for effectively removing pollutants from emissions.

Figure 15: Commercial Kitchens and Laundries

Expel heat and moisture in commercial kitchens and industrial laundries. Help control the climate and remove airborne contaminants like grease and smoke.

How to Reduce Fan Noise and Interference?

Managing electromagnetic interference (EMI) and noise are settling for the effective operation of both axial and centrifugal fans. These fans can produce EMI through radiated emissions from their components and conducted emissions via power leads. Additionally, the magnetic fields generated by the motor's magnets or stator windings can cause interference, making it compulsory to design strategies to minimize these effects. DC-powered fans usually exhibit lower levels of EMI compared to AC-powered ones.

Acoustic noise is another significant factor in fan design. Various parameters influence the noise level emitted by a fan, including its installation location, air density, nearby components, fan size, and type of bearings used. Although axial fans generally produce less noise than centrifugal fans, effective noise reduction can be achieved through careful fan placement, mechanical isolation techniques, and incorporating features like air inlet grills and outlet diffusers.

Addressing these acoustic and electromagnetic factors during the initial design phase can prevent the need for costly modifications later and ensure that the fan's operational noise and EMI levels are suitable for its intended environment.

Axial Fans vs. Centrifugal Fans: The Difference

Choosing the right fan for thermal management in electronic systems requires understanding the distinct attributes and benefits of axial and centrifugal fans.

Axial Fans:

• Optimized for moving large volumes of air at low pressure.

• Ideal for environments needing extensive air dispersion.

• More energy-efficient, quieter, and cost-effective.

• Suitable for general cooling applications where space and noise are concerns.

Centrifugal Fans:

• Provide high-pressure airflow with lower volumes.

• Suited for precise cooling targets.

• Operate at slower speeds but consume more power and generate higher noise levels.

• Robust construction makes them ideal for challenging conditions.

• Offer superior durability and resistance to harsh environments.

Pros and Cons of Using Centrifugal Fans

Centrifugal fans are excellent for applications needing high-pressure air delivery, such as air filtration systems, cooling towers, and demanding industrial processes. Their ability to handle diverse airflow and pressure conditions, along with their sturdy construction, ensures consistent performance in harsh environments. However, their sophisticated design can increase maintenance demands.

Pros: Handle high-pressure air delivery effectively. Suitable for air filtration systems, cooling towers, and industrial processes. Durable construction ensures reliable performance in adverse conditions. Various designs (airfoil, backward-curved, forward-curved, and radial blades) allow for customization to meet specific performance criteria. Generally, operating quietly is beneficial in noise-sensitive environments.

Cons: Sophisticated design can lead to higher maintenance requirements. Complex structures may complicate repairs and maintenance.

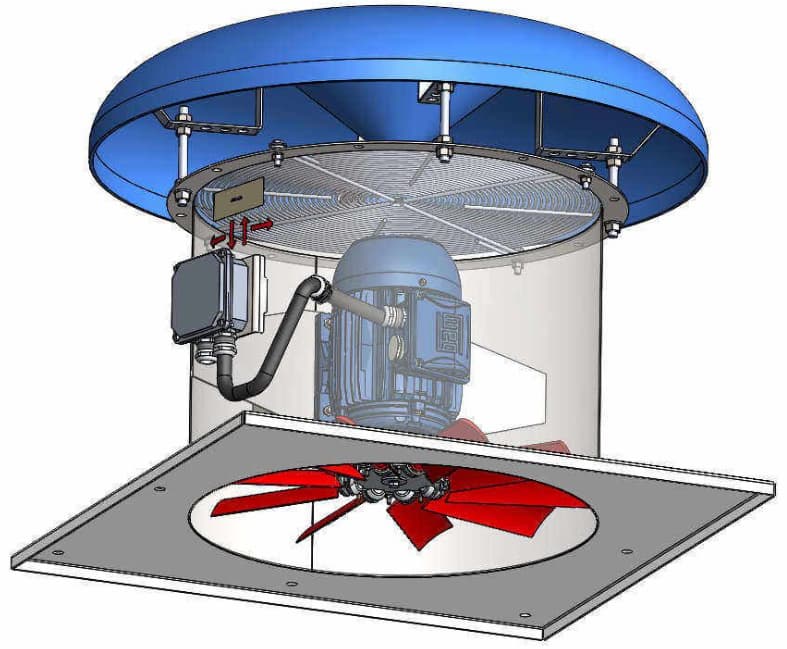

Figure 16: Belt Drive Axial Flow Fan

Exploring Belt Drive Axial Flow Fans

Belt-driven axial flow fans are designed to move large volumes of air at low pressures, making them suitable for various settings. These fans feature an external motor connected to the fan blades through a belt and pulley system. This setup allows for adjustable rotational speeds and greater versatility, though it tends to be more expensive than direct-drive fans.

The external positioning of the motor offers operational safety by keeping it away from extreme temperatures and hazardous gases. This design extends the motor's lifespan and reduces the risk of overheating. Built for durability and efficiency, these fans incorporate advanced features.

• Hot-Dipped Galvanized Casing: Provides corrosion resistance.

• Aerodynamically Optimized Belt Tube: Minimizes energy loss.

• Industrial-Grade Material: Ensures the casing is durable and robust.

Figure 17: Direct Drive Axial Flow Fan

Unveiling Direct Drive Axial Flow Fans

Direct-drive axial flow fans offer several advantages over belt-driven models due to their simpler design. The motor is directly coupled to the fan blades, enhancing energy efficiency by eliminating mechanical losses from belts and pulleys. This streamlined design not only conserves energy but also significantly reduces maintenance needs. With no belts to replace or adjust, these fans ensure higher operational uptime and lower overall ownership costs.

These fans are ideal for environments with hazardous fumes and airborne contaminants such as heat, steam, dust, and industrial pollutants. They are specifically designed to expel and mitigate contaminated air efficiently, playing a key role in maintaining air quality in industrial settings.

Conclusion

The detailed exploration of axial and centrifugal fans underscores their requisite role in modern engineering and environmental management. While axial fans are celebrated for their efficiency and versatility in cooling and ventilation across expansive areas, centrifugal fans are distinguished by their robust construction and precision in directing high-pressure airflows in compact or harsh environments.

In addition, solving challenges such as noise and electromagnetic interference in fan design can optimize its performance and adaptability. Ultimately, the selection between axial and centrifugal fans should be informed by a thorough analysis of their characteristics, application requirements, and environmental constraints, ensuring that the chosen solution enhances system performance while mitigating potential operational issues. This discussion not only illuminates the technical intricacies of fan operations but also encourages advancements in fan technology to better meet the evolving demands of industrial and technological environments.

Frequently Asked Questions [FAQ]

1. Which is better, an axial or centrifugal fan?

The choice between an axial and a centrifugal fan depends on the specific application requirements. Axial fans are typically more efficient at moving large volumes of air under low-pressure conditions. In contrast, centrifugal fans are better suited for applications requiring high pressure and are capable of moving air against considerable resistance.

2. Which type of fan is most efficient?

Axial fans are generally more efficient when it comes to energy consumption versus air movement, particularly in situations where large volumes of air need to be moved across relatively low resistance. They are simpler in design and often more cost-effective to operate under typical conditions.

3. What is an axial fan used for?

Axial fans are commonly used in situations requiring significant ventilation. They are ideal for moving large amounts of air at low pressure, such as in residential cooling systems, computer cooling components, and large-scale ventilation systems like those found in warehouses or commercial buildings.

4. What is a centrifugal fan used for?

Centrifugal fans are primarily used in applications that demand higher pressures, especially where the air needs to be directed through ducts or over longer distances. They are extensively used in HVAC systems, various industrial processes, and air pollution control systems, where moving air against resistance is required.

5. What is the difference between centrifugal and axial flow?

The ultimate difference lies in the direction of airflow and the design. Axial fans draw air parallel to the axis of rotation, allowing the air to move linearly. Centrifugal fans, on the other hand, draw air into the fan and then turn it at a 90-degree angle, pushing it out radially. This design difference makes axial fans better for low-resistance, high-volume flow, while centrifugal fans excel in high-pressure, high-resistance applications.