Circular Connectors and Cables

Circular connectors and cables are important parts used in many electronic devices and industrial machines. They are designed to connect different systems by transferring power, signals, or data. These connectors are known for being strong and reliable, making them suitable for tough environments like factories, airplanes, and medical equipment. In this article, we will walk you through the basics of circular connectors, explaining their features, how they are built, the different types available, and the standards they follow. Whether you’re an experienced engineer or just starting out, this guide will help you understand these connectors better so you can pick the right one for your needs.Catalog

Figure 1: Various Types of Circular Connectors

Understanding Circular Connectors

Circular connectors are round electrical parts that help connect different devices by transferring power, signals, or data. Their round shape makes them strong and dependable, especially in tough conditions where they need to handle vibrations, impacts, and extreme temperatures.

These connectors have three main parts: the outer shell, the contacts inside, and the insulating material. The outer shell is usually made of metal or strong plastic, giving the connector its shape and protecting it. Inside, there are pins or contacts made of materials like gold or copper, which help carry electricity or data. The insulating material around the contacts keeps the connection safe by preventing electrical problems.

Circular connectors are used in many areas, like airplanes, military equipment, factory machines, and medical devices. They can carry different kinds of signals, whether it's power, data, or communication, making them a good choice for systems that need reliable connections. These connectors often have features that lock them in place, so they stay securely connected and don’t accidentally come apart.

Key Features of Circular Connectors

Circular connectors are known for being strong, dependable, and easy to use. Their round shape helps protect them from things like dust, water, and vibrations, which makes them work well in tough conditions where other connectors might not last.

One reason circular connectors are popular is that they can be used many times without wearing out. Their design allows them to be connected and disconnected often without getting damaged, which is handy in places where machines or equipment need regular maintenance.

These connectors usually stay in place with a threaded shell, which screws together tightly to hold the connection firm, even if the equipment is moving or shaking. Other ways to lock these connectors in place include bayonet locks, which are quick to connect and disconnect, push/pull mechanisms that don’t need any tools to secure or release the connector, and snap locks that make it easy to quickly switch connectors when needed.

Structural Components of Circular Connectors

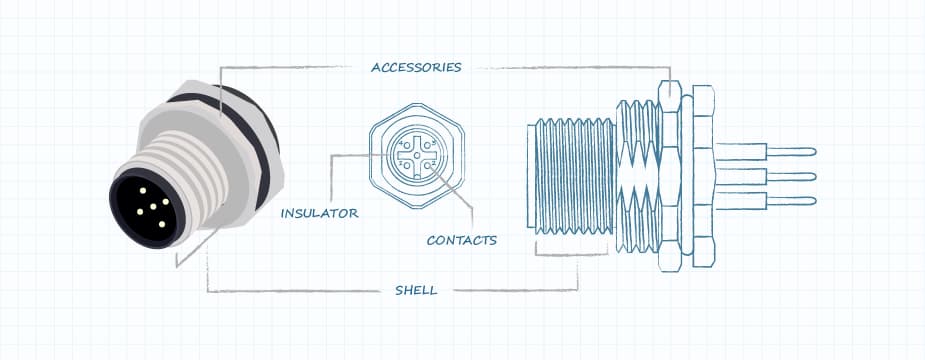

Figure 2: Structural Components of Circular Connectors

Circular connectors are widely used in various electrical systems to connect devices and ensure that they communicate effectively. These connectors consist of several parts that work together to make sure the connection is strong and reliable.

Contacts are the small metal pins and sockets inside the connector. When the connector is plugged in, these contacts touch each other, allowing electricity or signals to flow between devices. The contacts need to be well-designed and made from the right materials so that they can keep a steady connection without losing power, even in different environments.

The Insulator is the part of the connector that surrounds the contacts. Its job is to keep the contacts separate from each other and from the connector’s outer casing. The insulator is usually made from a material that does not conduct electricity, like plastic or rubber. By keeping the contacts apart, the insulator helps prevent electrical short circuits, which could disrupt the flow of electricity or signals.

The Shell is the outer casing of the connector. It protects the internal parts from damage, dirt, moisture, and other environmental factors. The shell is usually made of metal, which makes it strong and durable. It also helps align the connector properly so that it can be plugged in and unplugged easily without damaging the internal parts.

Accessories are extra parts that improve the connector’s performance and reliability. These can include items like pins, rings, keys, clamps, and gaskets. Each accessory has a specific job, such as making sure the connector fits together correctly, locking it in place to prevent it from coming loose, or sealing it to keep out water and dust. These additional parts are especially helpful when the connector is used in harsh conditions or when precise alignment is needed.

Types of Circular Connectors

Circular connectors come in different types, each designed for specific tasks and uses. Knowing about these types helps you pick the right connector for the job. Below, we explain the various types of circular connectors in simple terms, highlighting what makes each one unique and where it’s often used.

DIN Connectors

Figure 3: DIN Connector

DIN connectors follow standards set by the German institute, which ensures they work well with a wide range of devices, especially in audio, video, and computer networking equipment. These connectors have multiple pins arranged in a circle, which makes them reliable for steady connections. DIN connectors are strong and can handle moderate amounts of data and power, making them a good choice for many electronic devices.

Metric Connectors

Figure 4: Metric Connector

Metric connectors are named for their use of metric measurements in their size and thread dimensions. They are often used in industrial settings where precise measurements are important. These connectors are built to last and are designed to resist dust, moisture, and other harsh environmental factors, making them suitable for tough working conditions.

Hermetic Connectors

Figure 5: Hermetic Connectors

Hermetic connectors are made to be completely sealed, so no air, moisture, or other contaminants can get in. These connectors are used in situations where it’s very important to keep the inside environment controlled, such as in aerospace, military, and medical devices. Hermetic connectors usually have a glass or ceramic seal with metal, ensuring the connection stays airtight and stable even under extreme conditions.

Push-Pull Connectors

Figure 6: Push-Pull Connector

Push-pull connectors are designed for easy and quick connections. You can connect or disconnect them with a simple push or pull motion. These connectors are often used in medical equipment, instruments, and audio systems where fast connections are needed. They lock securely when connected, so you don’t have to worry about them accidentally disconnecting during use.

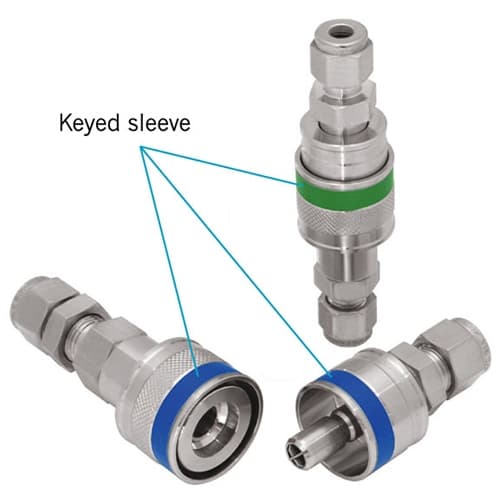

Keyed Connectors

Figure 7: Keyed Connectors

Keyed connectors have special alignment features, like keys or grooves, that make sure the connector can only be plugged in the correct way. This prevents damage to the pins and ensures the connection is made correctly. Keyed connectors are useful when multiple connectors are used close together, as they help avoid plugging the wrong connectors into the wrong ports. You often see them in industrial and automotive settings.

Mixed Signal Connectors

Figure 8: Mixed Signal Connectors

Mixed signal connectors can handle different types of signals—like power, data, and analog signals—through a single connector. These connectors are useful in complex systems where you need to send various types of signals without them interfering with each other. Mixed signal connectors are often used in telecommunications, industrial automation, and multimedia systems, where they offer a compact and efficient way to manage different signal needs.

Micro or Nano Versions

Figure 9: Micro and Nano Circular Connectors

Micro and nano circular connectors are tiny versions of standard circular connectors, made for places where space is tight. Even though they are small, these connectors can still provide high-quality connections for both power and data. They are often used in aerospace, medical devices, and other industries where precision and space-saving designs are important. These connectors usually have many pins packed into a small space to make the most of the limited area available.

Hybrid Options

Figure 10: Hybrid Circular Connectors

Hybrid circular connectors combine the ability to transmit power, signals, and data all in one connector. This reduces the number of connectors needed in a system, which simplifies the design and reduces potential issues. Hybrid connectors are useful in places where space is limited, such as in advanced robotics, automotive systems, and industrial machinery. By merging several functions into one connector, hybrid connectors offer a simple and flexible solution for complex systems.

Understanding M5, M8, and M12 Connectors

Figure 11: M5, M8, and M12 Connectors

M5, M8, and M12 connectors get their names from the size of their threads, which are measured in millimeters. These connectors are popular because they are dependable and can be used in many different ways.

M5 connectors have a thread size of 5 millimeters. They are small and fit well in places where space is limited. You often find them in devices like sensors and electronics where a compact connection is needed.

M8 connectors have an 8-millimeter thread size. They are commonly used in industrial settings to connect devices such as sensors and actuators. These connectors are built to handle tough conditions like vibrations, dust, and moisture, making sure the connection stays strong.

M12 connectors have a thread size of 12 millimeters. They are tough and reliable, especially in the automotive industry. These connectors are designed to work well in harsh conditions like exposure to water, dust, and constant movement. They are also commonly used in industrial automation systems.

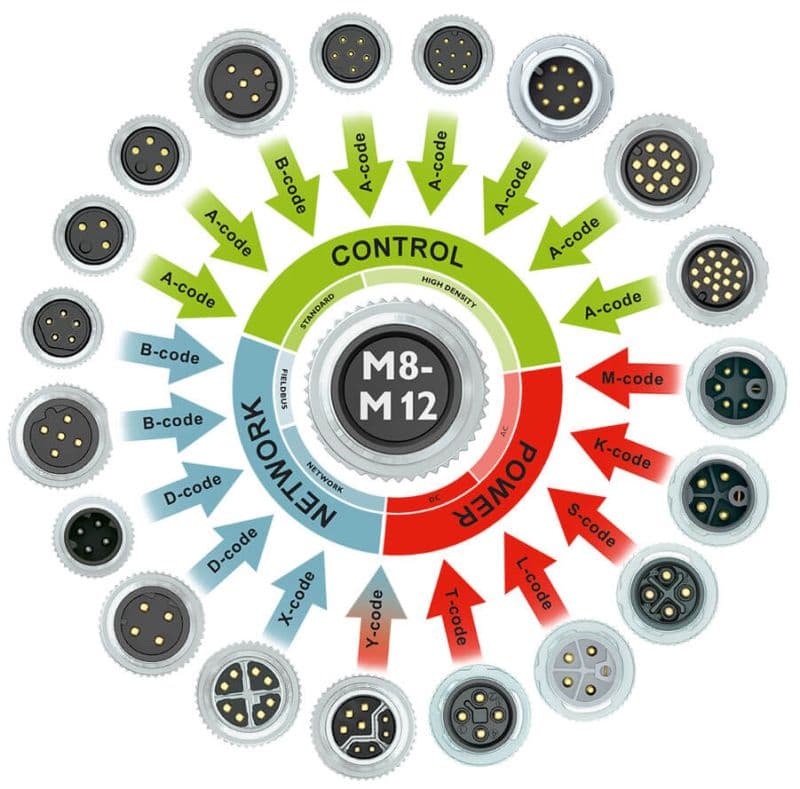

M12 connectors are classified by coding, which defines their specific applications and prevents mismatching.

Figure 12: M8 and M12 Connector Coding Types

Here's a breakdown of the coding types:

• A-Coded: Used for sensors, DC power, and 1 Gbit Ethernet.

• B-Coded: Designed for Fieldbus and Profibus systems.

• C-Coded: Utilized for AC power, featuring dual keyways. Less common now, replaced by S-coded connectors.

• D-Coded: Supports 100 Mbit Ethernet and Profinet systems.

• X-Coded: Handles high-speed 10 Gbit Ethernet and Power over Ethernet (PoE).

• S-Coded: Replaces C-coded connectors for AC power applications.

• T-Coded: Replaces A-coded connectors for DC power applications.

Broad Uses of Circular Connectors

Circular connectors are strong and reliable, making them great for tough industrial settings where equipment needs to work well even in harsh conditions. Circular connectors are often used in Electric Power Transmission systems where they need to handle high levels of electricity. Their strong design makes sure that the connection remains safe and stable, even in demanding environments. In Signal Transmission, circular connectors help ensure that signals, whether analog or digital, are sent accurately. Their construction reduces interference, helping to keep the signals clear and precise. Circular connectors are also used in Data Transfer, especially where secure and fast connections are needed. These connectors are designed to support high-speed data transfer while protecting against data loss or errors.Circular connectors are perfect for Mixed Signal Transmission, where both power and data are sent through the same connector. They are designed to handle both types of signals without any loss in quality or reliability.

Real-World Uses of Circular Connectors

Circular connectors are used in many different industries because they offer dependable connections even in tough conditions. In process control and industrial automation, they link sensors, switches, and control systems, helping machines and systems communicate clearly. They are very useful in factory wiring, keeping machines connected and working smoothly, even in places where there is a lot of movement or vibrations. In transportation, circular connectors are found in vehicles, trains, and other transport systems, where they keep connections stable despite constant motion and exposure to the elements. They are also widely used in aerospace and defense, where they ensure reliable connections in aircraft systems, communication devices, and military equipment. In medical equipment, these connectors make sure that medical devices are safe and work well, especially when it’s important for them to function properly. Circular connectors play a big role in robotics, connecting parts like sensors and motors, even in complex and challenging environments. They are used in audio and video communications for clear and continuous connections, which is very useful in broadcasting and live events. In the energy sector, these connectors handle large amounts of electricity and protect against things like water and dust in power plants and other energy systems. Circular connectors are also found in UAVs (drones), where their lightweight and strong design allows drones to operate effectively in various weather conditions. Finally, in test and measurement equipment, circular connectors connect sensors and probes, helping collect accurate data even in challenging environments.

Conclusion

Circular connectors are widely used because they provide strong and dependable connections in a variety of industries, from transportation and robotics to healthcare and power generation. By learning about the different types of connectors, their main features, and the rules they follow, you can choose the best one for your specific needs. Whether you need a connector that can handle extreme conditions, or one that fits into a small space, making the right choice can help your system work better and last longer. As technology keeps advancing, these connectors will continue to be a trusted choice for keeping all kinds of equipment running smoothly.

Frequently Asked Questions [FAQ]

1. What is a circular connection?

A circular connection is a round-shaped plug or socket used to join different parts of a device or system so that electricity or signals can flow between them.

2. What are the 3 types of cable connectors?

The three common types of cable connectors are coaxial connectors, twisted pair connectors, and fiber optic connectors. Each one is made for specific tasks, depending on what kind of data or signal they need to carry.

3. What is the round connector called?

The round connector is usually called a circular connector. This is a general term for any plug or socket that has a circular shape, often used in many electronic and industrial devices.

4. How to choose a circular connector?

When choosing a circular connector, think about how many connections (pins) you need, the size of the connector, where it will be used (like whether it needs to handle water or extreme temperatures), and whether it’s for carrying power or data.

5. What is the most commonly used type of connector?

The most commonly used type of connector is the USB connector. It's widely found in computers, phones, and other electronic gadgets to help transfer power and data.